Figure 1.

Figure 2.

Figure 3.

Figure 4.

Figure 5.

Figure 6.

Figure 7.

Figure 8.

Figure 9.

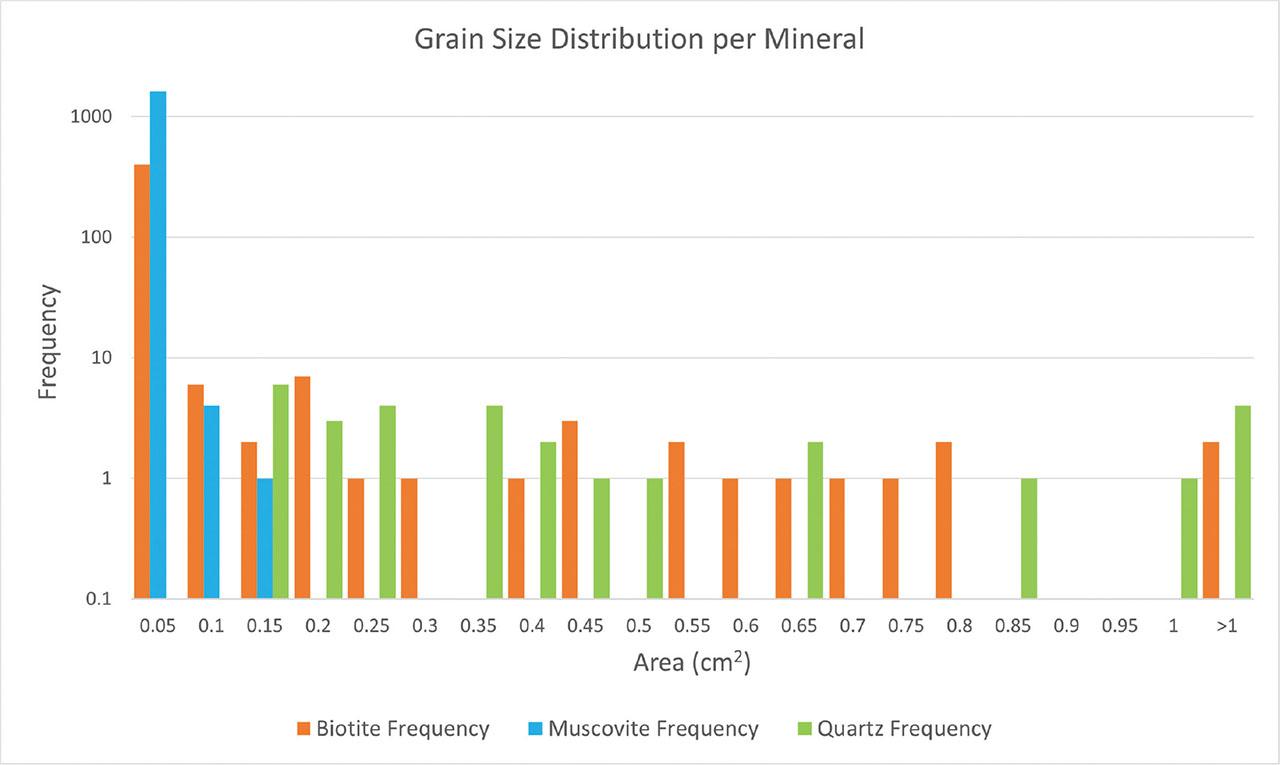

Figure 10.

Figure 11.

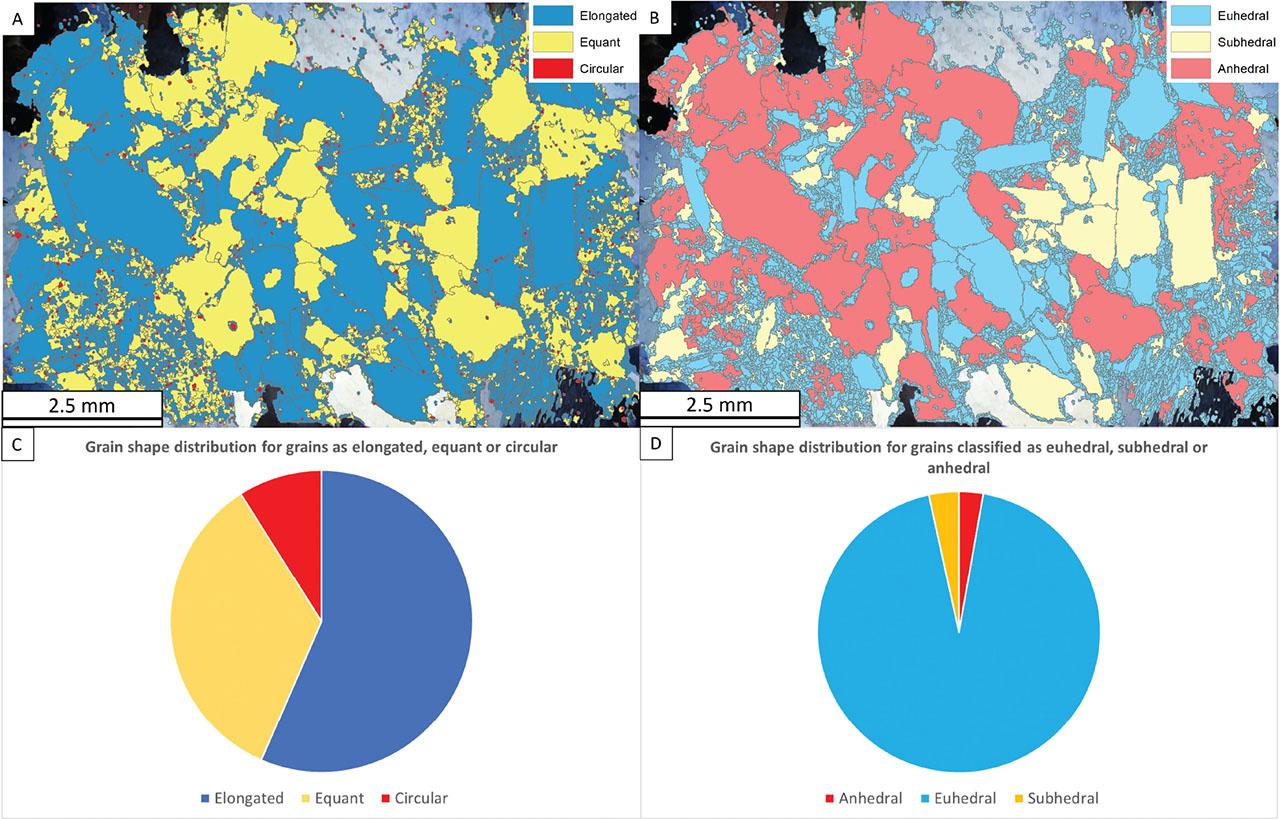

Ranges used for classifying grains based on general proportions_

| Shape | AsR | Circularity |

|---|---|---|

| Elongated | >1.6 | n/a |

| Equant | <1.6 | <0.8 |

| Circular | <1.6 | >0.8 |

Ranges for classifying grains based on crystal shape_

| Shape | Convexity |

|---|---|

| Euhedral | >1.8 |

| Subhedral | <1.8 |

| >1.7 | |

| Anhedral | <1.7 |

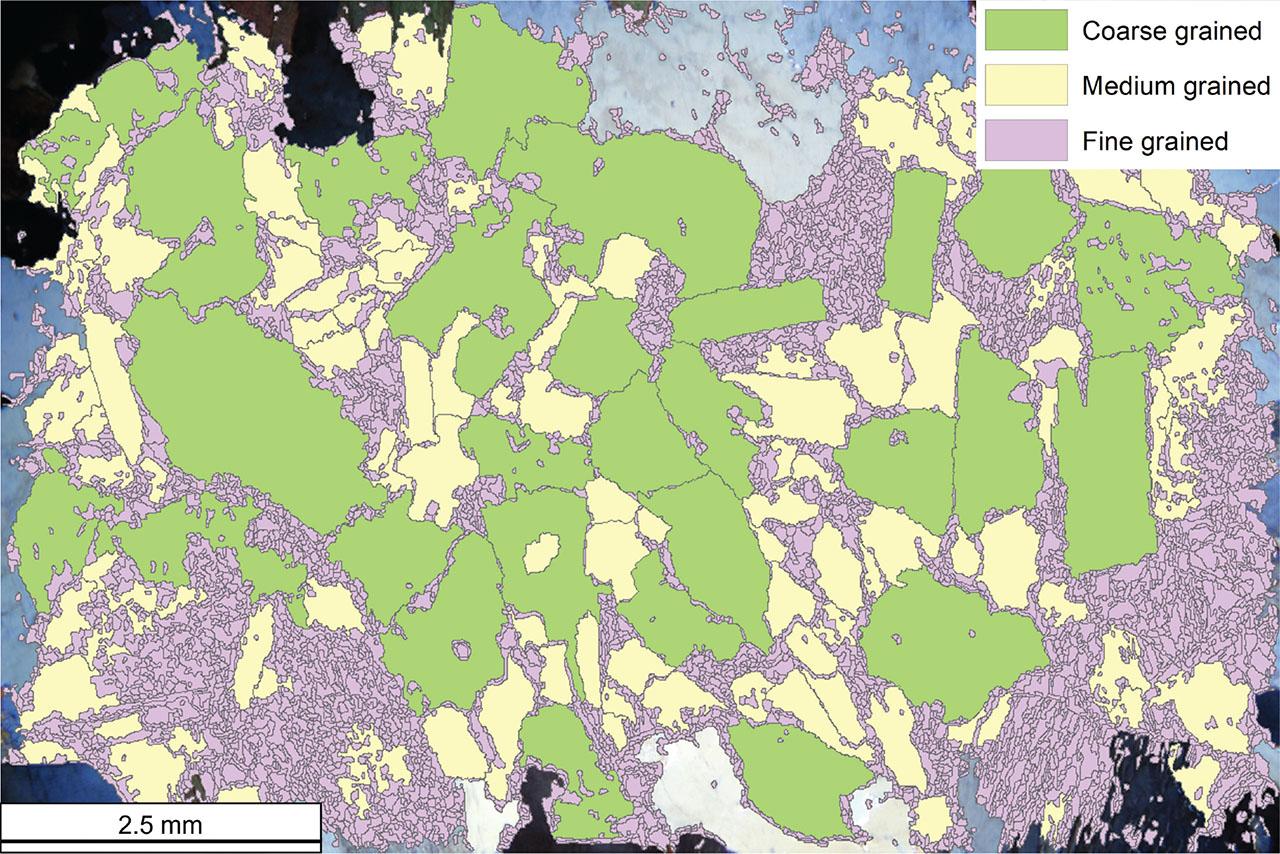

Ranges for grouping grains based on size_

| Size | Pixels | cm2 |

|---|---|---|

| Coarse | >100,000 | >0.37 |

| Medium | <100,000, >10,000 | <0.37, >0.037 |

| Fine | <10,000 | <0.037 |

Microscope specifications_

| Application | Plan UW |

|---|---|

| Magnification | 2× |

| Numerical aperture | 0.06 |

| Lens image distance/coverslip thickness (mm) | ∞/− |

| Working distance | WD 7.5 |

Calculated extinction angles for biotite grains from sample A14_

| Grain ID | Calculated extinction angle |

|---|---|

| 5242 | 5.5 |

| 5498 | 7.8 |

| 6320 | 4.6 |

| 4302 | 0.7 |

| 6123 | 8.7 |

| 6119 | 6.7 |

| 2414 | 5 |

| 2142 | 1.8 |

| 7255 | 2.3 |

| 1983 | 4.5 |