Petrographic thin section analysis is a process routinely used during geological and mineralogical studies (Yu et al., 2023). This process is used to obtain information regarding the mineralogical makeup of a particular rock, grain size, grain shape, and the types of pores (if present) (Zhang et al., 2020). Traditionally this is done manually using an optical light microscope to observe the rock samples. This workflow is simple and easy to implement however the results produced rely on the researcher’s expertise and is often time-consuming (Zhang et al., 2020). A number of other methods have also been developed to characterize these features. These include but are not limited to Helium psychometry, scanning electron microscopy, energy dispersive spectroscopy, electron back scattering diffraction, laser diffraction, X-ray computed tomography, and X-ray diffraction. However, these methods are expensive, time consuming and produce large amounts of data that require computational time for post-processing (Perera et al., 2021).

Optical analysis of petrographic thin sections is a common research methodology for the first characterisation of rock samples and is relatively cheap and quick to perform. With the development of computer technology and digital image processing, more research has been done regarding the implementation of these techniques to the field of geology (Zhang et al., 2020). The majority of this research is based on the supervised classification of petrographic thin sections using training data sets to train machine learning models (Yu et al., 2023), where machine learning is used as an alternative to manual identification (Latif et al., 2022). Other approaches focus more on the segmentation of thin section images based on grain boundaries in order to identify properties such as grain size and shape (Zhang et al., 2024). Regardless of method, these imaging techniques seek to address the issue of linking petrographic data to a specific frame of reference (Asmussen et al., 2015). One of these approaches includes the development of Geographic Information System (GIS) techniques for the analysis of petrographic thin sections (Asmussen et al., 2015). This is due to its ability to manage large datasets in a database as well as its ability to overlay and integrate these datasets. It is also able to analyse data in both raster and vector format (Visalli et al., 2021), with the added benefit of editing polygons produced unlike other similar programs (Asmussen et al., 2015). This makes GIS well suited for extracting, manipulating and analysing of fabric data from thin section images (Visalli et al., 2021). These GIS-based techniques focus on the segmentation of thin section images into objects based on grain boundaries in order to quantify properties such as shape, orientation and distribution of mineral grains.

Since the observed minerals within a petrographic thin section generally have different mineral orientations, common practice during manual petrographic thin section interpretation is to observe the full range of properties for each grain upon rotation of the sample under plane polarised and cross polarised light. Then ranges of properties observed for different grains of what is believed to be the same mineral are attributed together in the observers report in order to increase the accuracy of diagnostic interpretations of mineral species.

The purpose of this study is to integrate these aspects of rotation to the process of image acquisition thereby allowing the range of properties observed for each mineral grain to be recorded and then to use this data to develop techniques that can attribute mineral properties, such as extinction angle or interference colours on rotation to individual mineral grains. The purpose being to assist with mineral identification and to provide aggregated fabric data such as the modal abundance of minerals, crystal size distribution and grain orientation. The focus will be the use of colour values, extracted from image pixel values, in both plane polarised light (PPL) and crossed polarised light (XPL) of a full 90° rotation image stack to identify the minerals present and to calculate extinction angles of minerals. An image stack is used due to the variation of interference colours and other properties with respect to the orientation of the grain in relation to orientation of the polarisation of light.

Colours within an image can be represented by three components, namely: red, green, blue (RGB) (Naseri & Rezaei Nasab, 2023) or hue, saturation and value (HSV) (Naseri & Rezaei Nasab, 2023). Hue (H) represents a true colour, e.g., red, yellow, green, blue, etc. Saturation (S) is a measurement of how much the true colour is diluted by white. With low S values producing more faded colours and high values producing deeper colours. Value (V) is a measurement of the brightness, with decreasing V value corresponding to increasing blackness (Chernov et al., 2015). During this study both colour models were investigated.

Grain segmentation is used to extract and attribute optical properties observed for individual pixels within grains. This is done using Micro Fabric Analyser (MFA), a GIS-based tool designed for the quantitative extrapolation of rock microstructural features (Visalli et al., 2021). It was developed to take advantage of the characteristics of both X-ray images and optical image features. The toolbox consists of two tools, namely grain size detector (GSD) and mineral grain size detector (Min-GSD) (Visalli et al., 2021). GSD allows the user to quantify fabric parameters that identify the edges of the individual grains present in the thin section, with the results being maps of polygon objects representing the grains, with all the associated fabric parameters such as grain area, perimeter, long and short axis, aspect ratio (AsR) and grain orientation. This is normally performed on a crossed-polarizers high-resolution RGB image. Using the second tool, Min-GSD, the results from GSD are integrated with a set of micro-X-ray maps. The tool assigns each polygon to a given mineral and produces a map of the grain boundaries categorized according to the pairs of minerals that are in contact (Visalli et al., 2021). However, because this study did not use any micro-X-ray images, only the GSD tool was used.

A number of petrographic thin sections of igneous rocks were used in this study: samples A14 (Granite), D15 (Gabbro), C20 (Granite) and DRT 34 (Gabbro). Using these thin sections, several of images were taken of a representative cluster of minerals, with each image being a 5° rotation of the bottom and top polarizers in a clockwise direction. This gives the same results as rotating the stage and removes the need to rotate images. The images are acquired using a Nikon eclipse 50i POL petrographic microscope at times two magnification, specifications according to Table 1, in both XPL and PPL with a Canon camera using EOS utility software. The white balance was set to auto. These images were imported to ArcMap for image analysis as the tool selected for grain boundary determination MFA is hosted through ArcMap. This software was developed specifically for ArcGIS®.

Microscope specifications.

| Application | Plan UW |

|---|---|

| Magnification | 2× |

| Numerical aperture | 0.06 |

| Lens image distance/coverslip thickness (mm) | ∞/− |

| Working distance | WD 7.5 |

In ArcMap, the Colour Model Conversion tool was used to produce HSV images from the original RGB thin section images. For both image sets, additional raster datasets were produced that represent their individual colour components. This was done using the Composite Bands tool, a data management tool from the ArcGIS image analysis menu, that creates a single raster dataset from multiple bands. Part of its function is to create a raster dataset containing a subset of the original raster dataset bands, which means it breaks each input raster into its individual components. The resulting raster datasets are sorted based on their representing component. These raster groups are then used to produce a single raster dataset where the pixel values represent the minimum, average or maximum pixel values across the full rotation. This is done using the Cell Statistics tool. Using the Composite Bands tool, the three separate components are combined to produce a single raster data set with pixel values of all three components. These “summarised” images are used for grain segmentation.

MFA was used for grain segmentation, specifically the GSD tool. The tool possesses three main parameters that determine the sensitivity of the segmentation: spectral detail, spatial detail and minimum segment size (Visalli et al., 2021). These parameters were optimised based on visual inspection of the segmentation. Individual polygons produced can be edited if needed using the editor function which can edit vertices, perform polygon splits and mergers. However, some parameters will need to be recalculated if the polygons are edited. The MFA polygon vector file was then used for extracting pixel values for each individual mineral grain. This was done using the “Zonal Statistic as Table” tool. This tool summarizes the values of a raster within the designated zones of another data set and reports them as a table. The MFA polygons were used to designate the zones and the values summarized to be the average per zone. These tables are then joined to the MFA polygons.

Using the HSV pixel values, the polygons can be classified based on interference colour. Using the field calculator within the attribute table it is possible to create a formula that classifies the polygons based on set ranges for each mineral present. The same is done with PPL images to extract pixel values representing pleochroism. These values are then used to determine which grains are pleochroic and can be used along with the interference colour values to classify the polygons based on the minerals present. The formula therefore incorporates both interference colour values and pleochroic colour values. The handling of colour values in HSV format is preferred here as a single value for Hue (H) produces a smaller more manageable dataset.

Using the above-mentioned methods, it is possible to attribute the average V value of each rotation to each grain for the full range. The V value measures the departure of the true colour (red, blue, etc.) from black. This means the V values can be used to determine at what point in the rotation the grain is fully extinct. This is done in two steps. The first is calculating the minimum V value of the entire image stack. The second step is using an IF function to attribute which specific rotation contains the minimum V value. One of the attributes that MFA produces is the orientation of its polygons, in other words the orientation of the grains. Using the grain orientation produced from MFA with the point of maximum extinction calculated using the V value, it is possible to calculate the extinction angle for each individual grain.

Twinning is a key identifying feature for a number of minerals, e.g., plagioclase. Because of the difference in interference colour for twin sets, MFA treats twins as different grains. This results in MFA producing separate polygons for each twin present within a grain. However, it is possible to determine which of these polygons are in fact twins sets. This is done using the Polygon Neighbours tool, which creates a statistical table based on polygon contiguity (overlaps, coincident edges, or nodes), and this allows the system to find the neighbours of each individual polygon within the selected input. This produces one of three factors that determine whether a polygon is part of a twin set. These factors are as follows: the polygons need to be adjacent to each other, their orientation needs to be similar in the case of lamellar twins (up to 3° difference in orientation to account for variation as a result of polygon shape) and they need to be classified as the same mineral. The interference colour values can be used to classify the minerals and the orientation is acquired from MFA. With these three factors, a formula can be created to determine whether the polygon is part of a twin set.

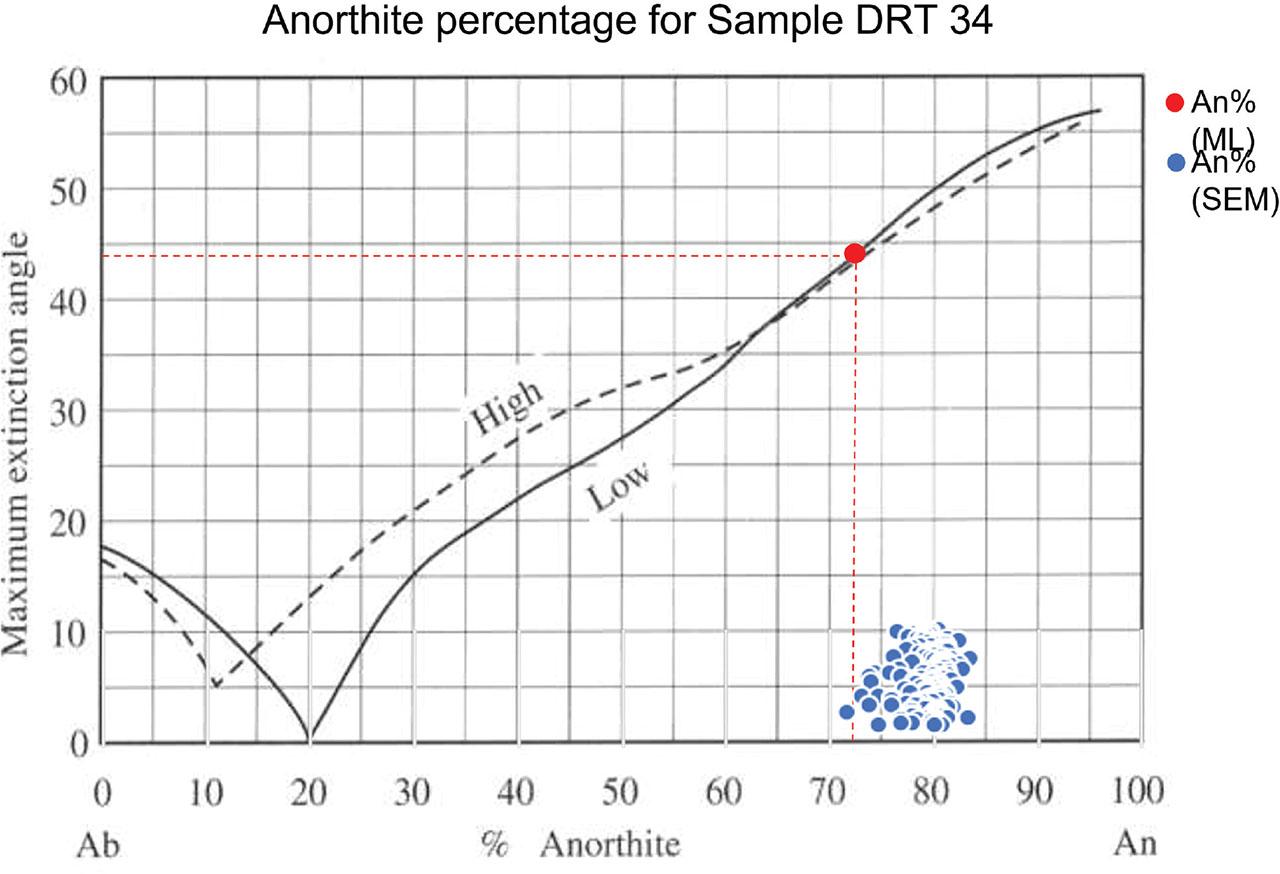

In some cases, twinning can also be used to differentiate between different end-members for certain minerals. For example, the extinction angles of paired lamellar twins in plagioclase feldspar crystals can be used to estimate the anorthite percentage (An%) using the Michel-Levy method (Ermanovics, 1967). In a manual workflow this is done by measuring the extinction angles of plagioclase twins. Only using the angles of grains with no more than 5° difference between twins, the maximum angle of all the grains is taken. This value is then plotted using the Michel-Levy graph, and the An% is acquired. This same procedure could be integrated to an automated workflow using the methods developed in this study. By integrating rotational components, the extinction angles for each plagioclase grain and their twins can be calculated. These angles are then filtered to those where the difference between twin sets are no more than 5° (to filter out crystals whose c axis is at a significant angle to the field of view). The maximum of the measured values is then calculated and plotted against the experimental curve to estimate the An%.

It is possible to attribute shape descriptors to the grains. This is done using the shape factors that are produced from MFA, as well as calculating additional factors such as convexity. Convexity is calculated using the Minimum bounding Geometry tool, with the MFA shapefile as input and the type set to convex hull. Using the resulting shapefile with the formula as seen in Figure 1, it is possible to calculate the convexity of the polygon. Using these factors, it is possible to classify the polygons based on basic shape e.g., elongated, rounded, irregular, etc.

Equation for calculating convexity. Convexity = (perimeter of A + B)/(perimeter of A).

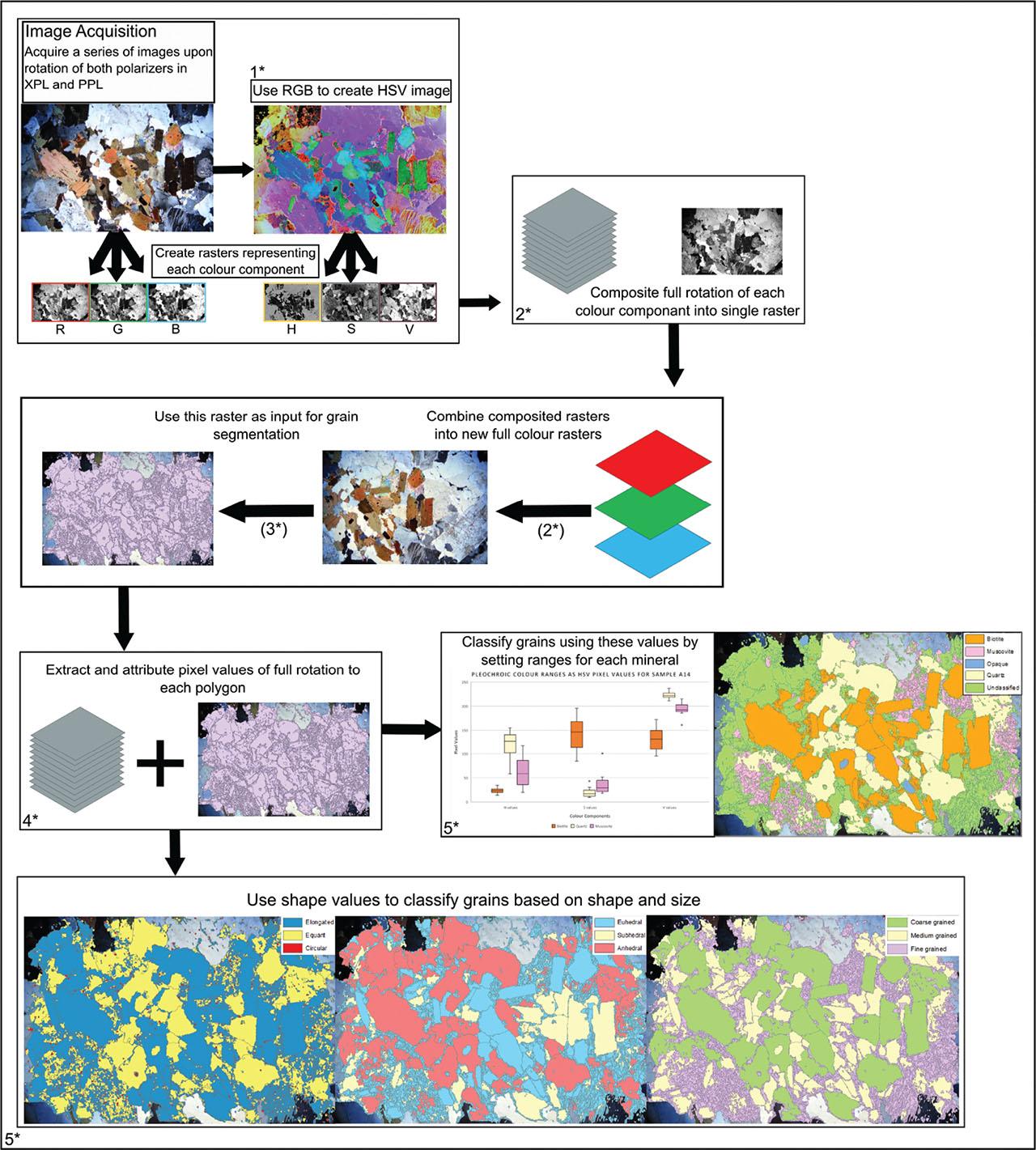

By compositing the full image stack a single raster is produced with the pixel values representing the average, maximum or minimum pixel value across the entire rotation. The workflow can be seen in Figure 2.

Workflow devised for this study. The ArcMap tools used are numbered and are as follow: (1) Colour Model Conversion function, (2) Composite Bands tool, (3) MFA, specifically the GSD tool, (4) Zonal Statistics tool, (5) Inbuilt raster calculator. GSD, grain size detector; MFA, micro fabric analyser; PPL, plane polarised light; RGB, red, green, blue; XPL, crossed polarised light.

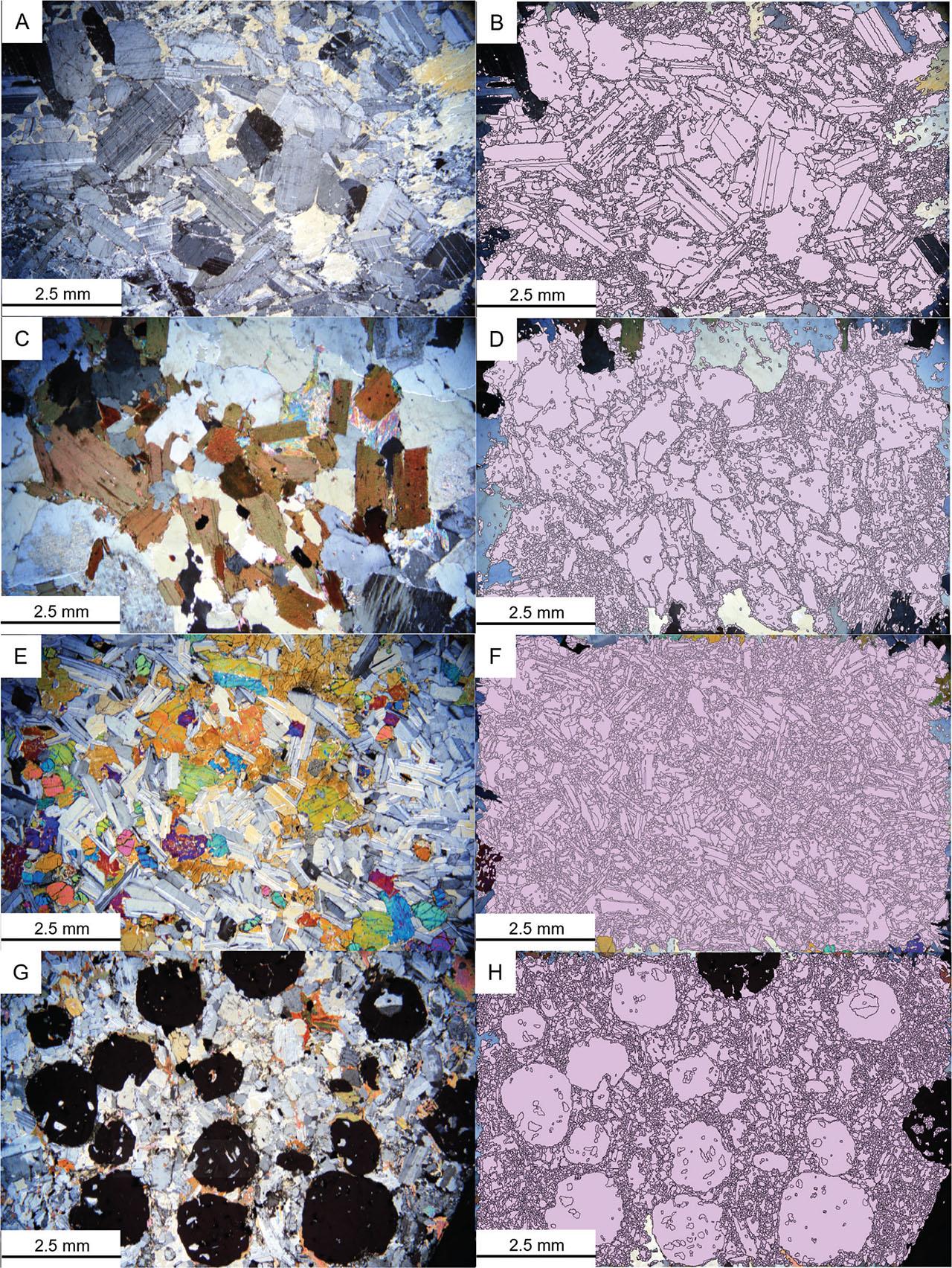

The maximum and average interference colour images (Figs. 3A and 3C) appear similar, with the maximum interference colour image appearing brighter. The minimum interference colour image (Fig. 3E) shows an approximation of all grains being extinct. The average interference colour image results in more homogeneous interference colours throughout the grains, with only isotropic minerals, opaque minerals and pore spaces appearing extinct.

Average interference colour images and MFA polygons for sample DRT 34 (A, B), sample A14 (C, D), sample D15 (E, F) and sample C20 (G, H). MFA, micro fabric analyser.

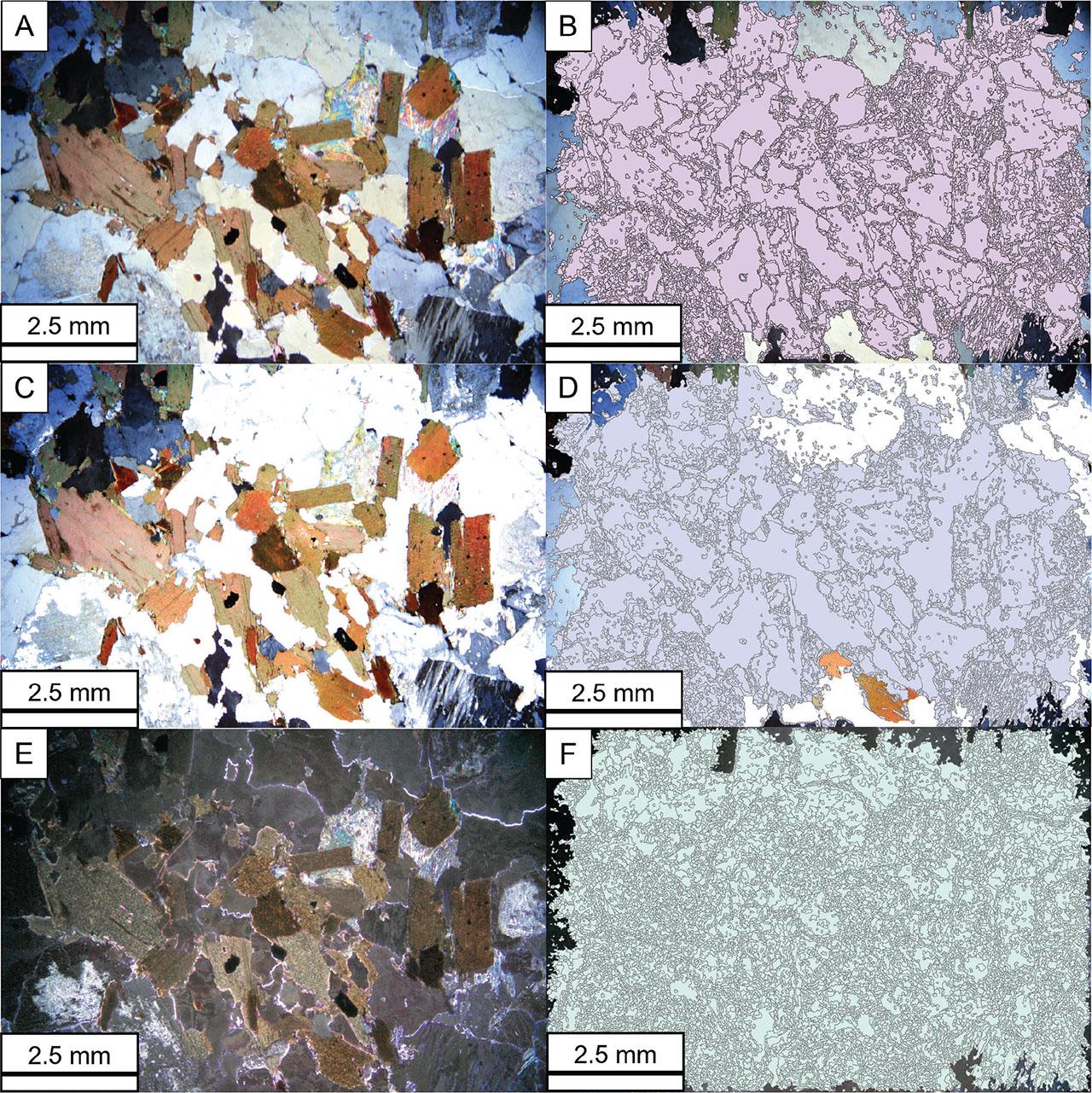

The composited interference images (average, maximum or minimum) are then used as the input for grain segmentation, resulting in a polygon data set with each polygon representing a different grain (Figs. 3 and 4). The maximum interference colour image (Fig. 3D) produces less polygons that are also larger than those produced by the average interference colour image (Fig. 3B). The minimum interference colour image (Fig. 3F) produces the opposite, resulting in more polygons that are also smaller than those produced from the average interference colour image.

Average Interference colour image for sample A14 along with polygons produced from grain segmentation (A, B). Maximum Interference colour image for sample A14 along with polygons produced from grain segmentation (C, D). Minimum interference colour image for sample A14 along with polygons produced from grain segmentation (E, F).

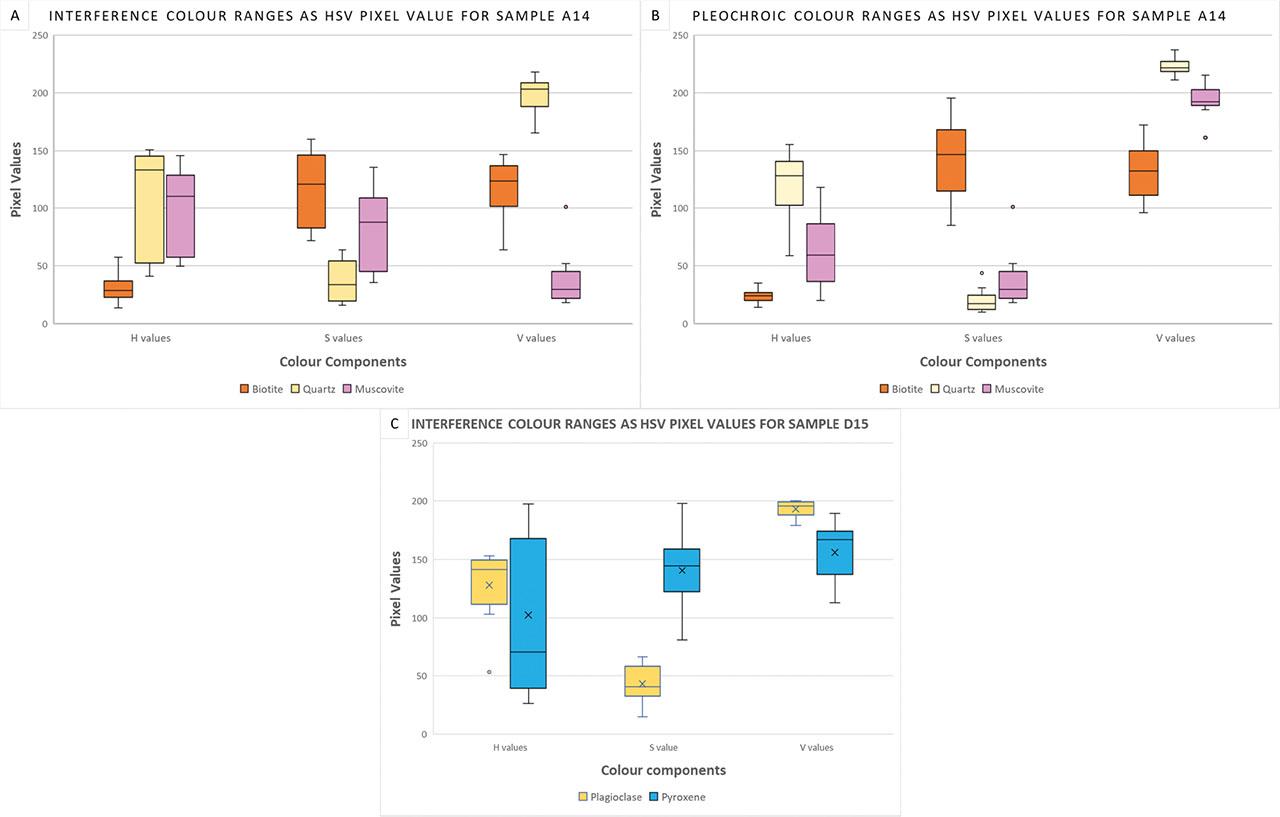

Using the MFA polygons to designate the zones, the interference colours (and pleochroic colours if necessary) are extracted as pixel values and attributed to their representing grain. Ranges are set for these values (Fig. 5), with each range representing the interference colours for specific minerals. If the polygon values fall within these ranges they are labelled accordingly (Figs. 6A and 6C). Once all polygons are classified, the overall modal proportion can be calculated (Figs. 6B and 6D).

Graphs showing the interference colour ranges (A) and the pleochroic colour ranges (B) for sample A14. (C) Graph showing the interference colour ranges for sample D15. HSV, hue, saturation and value.

Interference based classification for sample A14 (A, B) and sample D15 (C, D) along with mineral proportions.

It is possible to determine at which point in the rotation a grain is fully extinct by attributing the V colour values of the full rotation to their associated grains. This, along with the grain orientation, can be used to calculate the extinction angle for each individual. Table 2 shows the extinction angles calculated in this way for a number of biotite grains from sample A14.

Calculated extinction angles for biotite grains from sample A14.

| Grain ID | Calculated extinction angle |

|---|---|

| 5242 | 5.5 |

| 5498 | 7.8 |

| 6320 | 4.6 |

| 4302 | 0.7 |

| 6123 | 8.7 |

| 6119 | 6.7 |

| 2414 | 5 |

| 2142 | 1.8 |

| 7255 | 2.3 |

| 1983 | 4.5 |

By plotting the calculated extinction angles of plagioclase grains on the graph as seen in Figure 7, it is possible to determine the An% for the grains present. For Sample DRT 34, separate images stacks were used for three different areas within the thin section. This can then be compared to the An% acquired from SEM analysis (Fig. 7).

The anorthite percentage for plagioclase grains in sample DRT 34 using both the Michel-Levy method and SEM analysis.

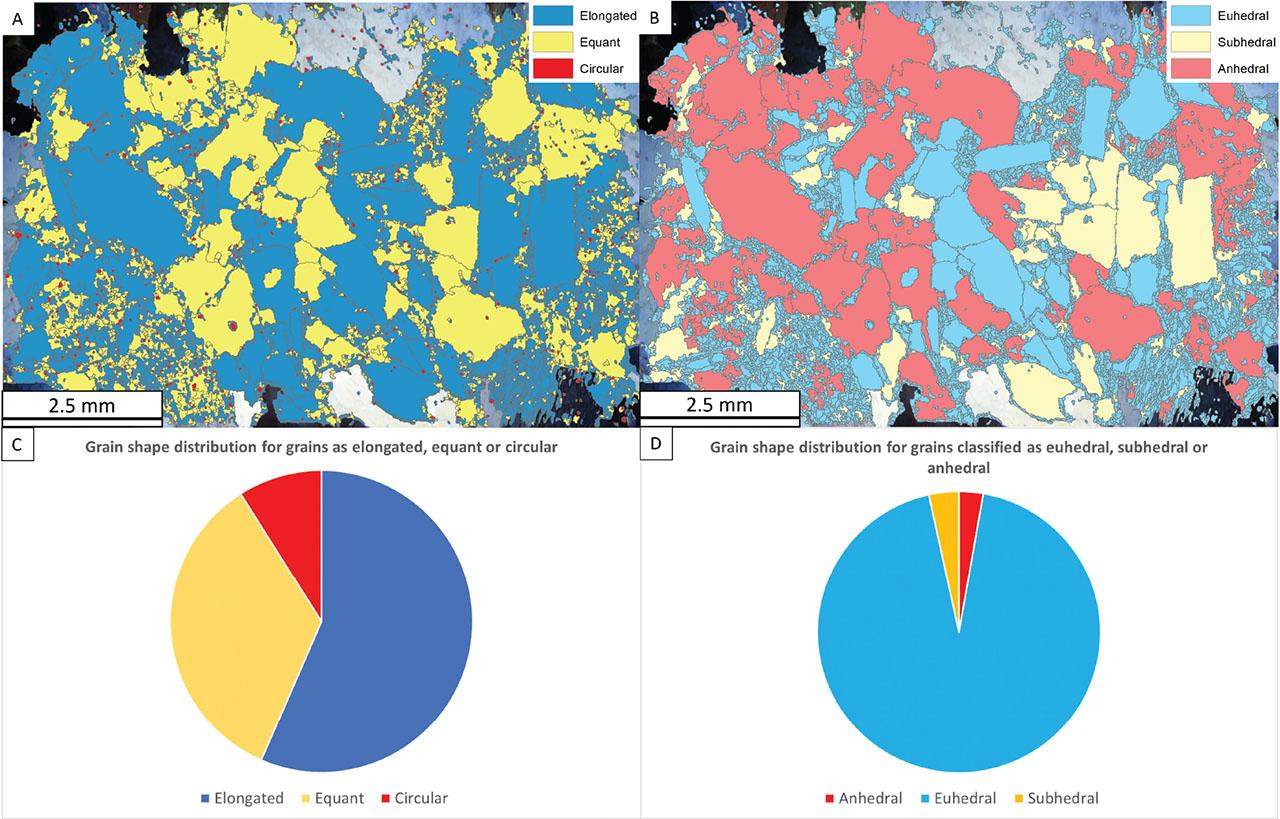

By using a number of attributes, such as AsR, circularity and convexity, it is possible to classify the mineral grains based on shape and size. For shape, the grains can be classified based on general proportions, in this case elongated, equant or circular (Fig. 8A). This was done using the ranges as seen in Table 3. The grains can also be classified based on crystal shape, e.g., euhedral, anhedral or subhedral (Fig. 8B), using the ranges as seen in Table 4. Once all polygons are classified as one shape or another the overall modal proportions and thereby the texture of the sample can be determined (Figs. 8C and 8D).

Grain shape classification for sample A14. (A) Grains classified as either elongated, equant or circular. (B) Grains classified as either euhedral, subhedral or anhedral. (C) The distribution of grains classified as elongated, equant or circular. (D) The distribution of grains classified as euhedral, subhedral or anhedral.

Ranges used for classifying grains based on general proportions.

| Shape | AsR | Circularity |

|---|---|---|

| Elongated | >1.6 | n/a |

| Equant | <1.6 | <0.8 |

| Circular | <1.6 | >0.8 |

AsR, aspect ratio.

Ranges for classifying grains based on crystal shape.

| Shape | Convexity |

|---|---|

| Euhedral | >1.8 |

| Subhedral | <1.8 |

| >1.7 | |

| Anhedral | <1.7 |

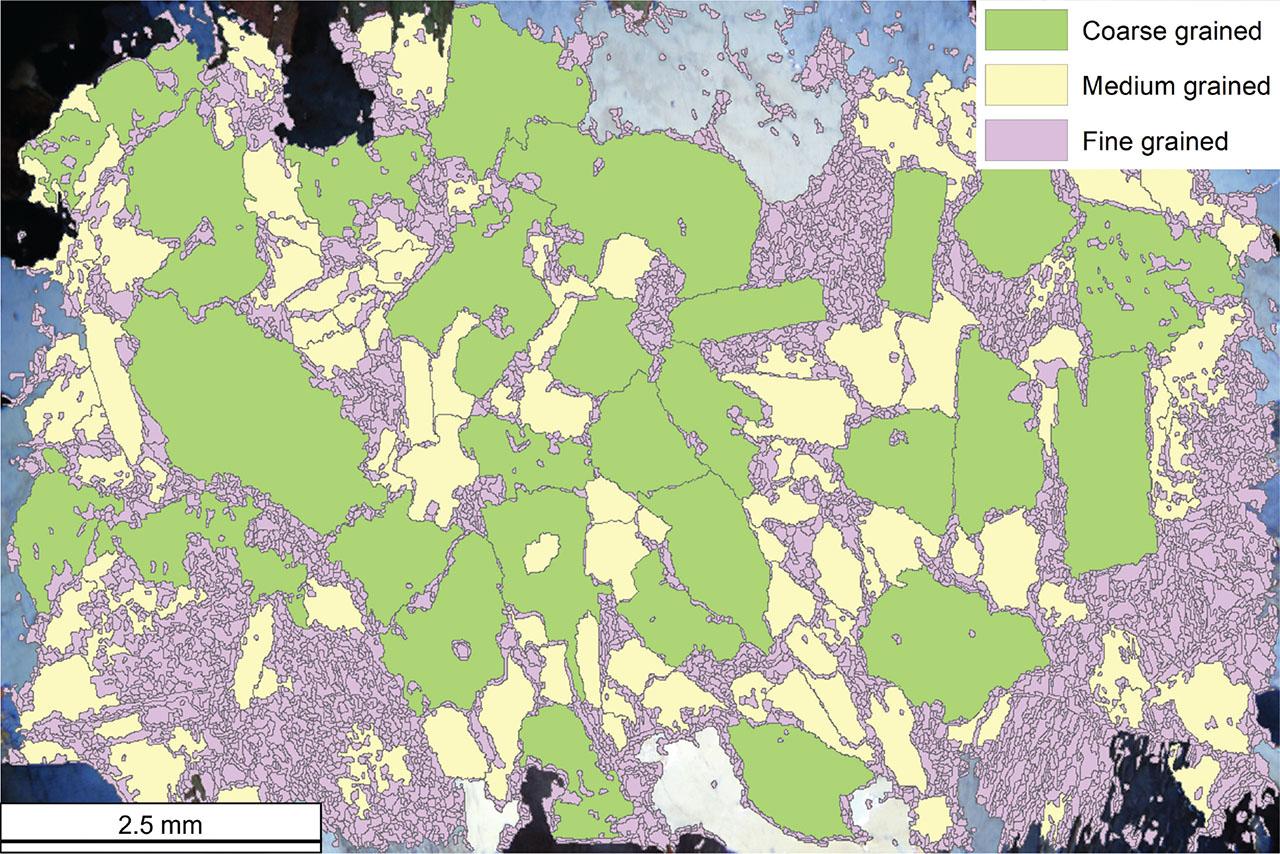

Using either the grain perimeter or area, it is possible to acquire the size distribution of all grains present within the thin section. The size distribution for each mineral can be acquired once classification is done (Fig. 9). It is also possible to classify the grains based on size e.g., coarse-, medium- or fine-grained, as seen in Figure 10. This is done by setting ranges as either pixel count or in cm2, as seen in Table 5. Note that a scale will have to be calculated depending on the magnification of the thin section.

Grain size distribution per mineral.

Grains classified based on size as either coarse-, medium- or fine-grained.

Ranges for grouping grains based on size.

| Size | Pixels | cm2 |

|---|---|---|

| Coarse | >100,000 | >0.37 |

| Medium | <100,000, >10,000 | <0.37, >0.037 |

| Fine | <10,000 | <0.037 |

Scale: 2687.38 pixels/cm2.

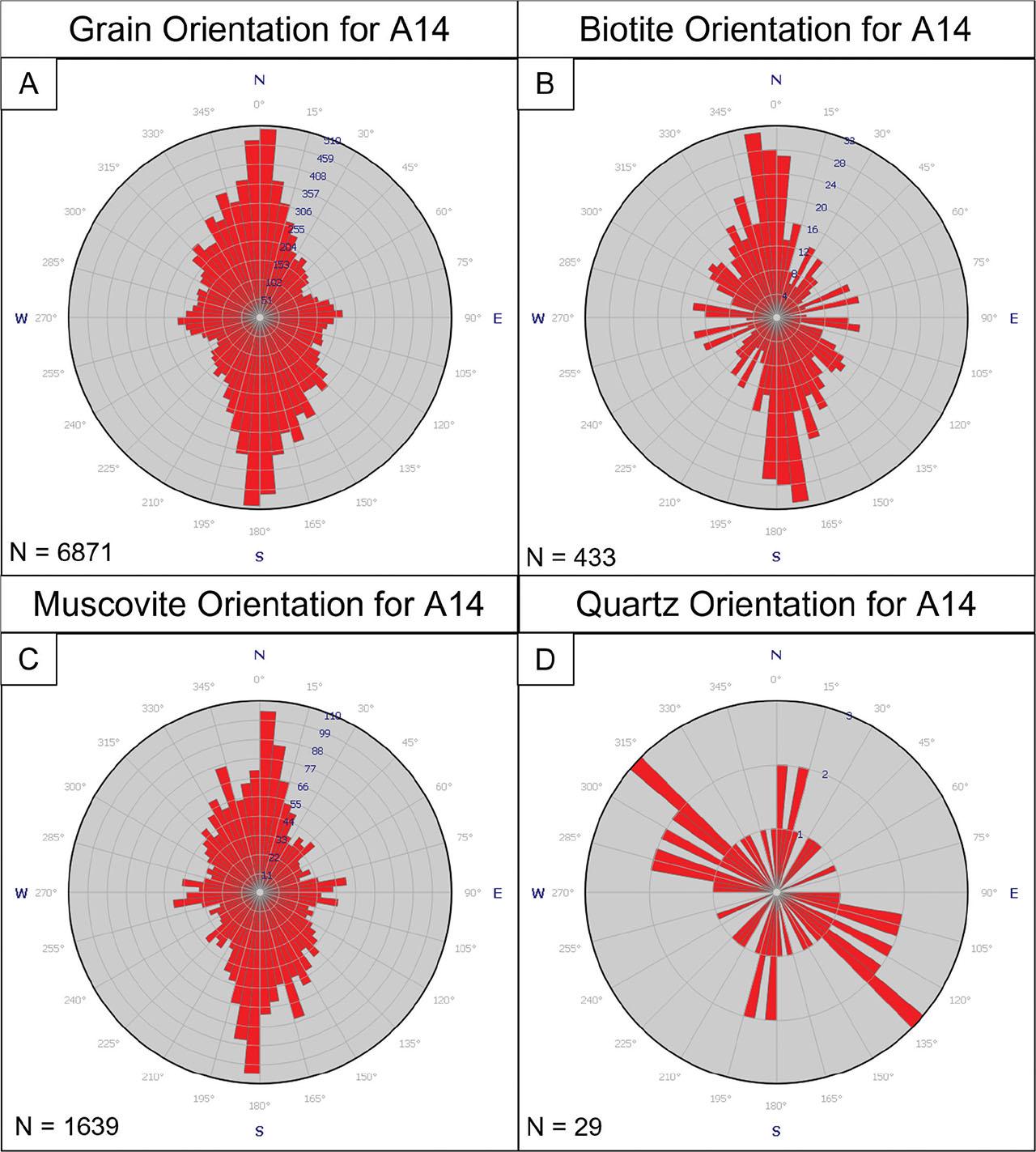

MFA calculates a number of attributes, grain orientations being one of them. These values can be plotted on a rose diagram to visually represent the overall grain orientation. After mineral classification, it is possible to plot the orientation of each mineral as well. This can be seen in Figure 11.

Grain orientation with respect to the long axis for sample A14 plotted as rose diagrams. (A) Orientation of all grains within thin section. (B–D) Represent the orientation of the biotite, muscovite and quartz grains present.

The main issue in image analysis of petrographic thin sections is the identification of individual mineral grains. In polarized light, different grains exhibit different properties as a result of their mineralogy and optical orientation (Li et al., 2008). If there is significant contrast in interference colour between adjacent grains, the boundaries between them can be easily identified. However, if they have similar interference colours, it is more difficult to recognize their boundaries (Li et al., 2008). In order to increase the contrast between grains, the thin section needs to be rotated relative to the polarizer and analyser to view the full range of properties exhibited by grains upon rotation. In this study a composite image was produced by compiling multiple images at different degrees of polariser rotation relative to the sample. Using the methods developed in this study, it is possible to produce a single image where the pixel values represent the average values of the full rotation, as seen in Figure 3. Because the pixel values represent the average interference colour for the grains, all grains appear non-extinct except for opaque and isotropic minerals as well as pore spaces. This is a useful tool for separating isotropic and opaque minerals from anisotropic mineral. The average interference image also results in more homogeneous interference colours within each grain, which improves the quality of grain segmentation.

It is also possible to produce a maximum and minimum interference colour image using these methods (Fig. 4). The maximum image appears similar to the average image, except that all interference colours appear much brighter. Theoretically, the maximum interference image will show a greater contrast between different grains than the average image. However, an error occurs where some pixels exhibit no data. Upon investigation it was found that this only occurs to pixels with values representing pure white. It is unclear whether this is as a result of a boundary parameter set by the tool used or if it is an error that occurs when pixel values are too high. If this error could be corrected, the maximum image could serve as a better representative image and a better input for grain segmentation.

Although a single representative image can be used for grain segmentation, it can still be difficult to distinguish between different grains of the same mineral or different minerals with similar inference colours that are adjacent to each other. Depending on the specifications of the tool used, there is a possibility of under segmentation occurring. This is where multiple grains are grouped into one polygon. In regards to MFA, it has three main parameters that groups adjacent pixels with similar colours. By changing these parameters, it is possible to increase the accuracy of segmentation. However, it is still difficult to find the perfect fit. In the case of under segmentation, it is possible to edit the polygons and divide them into their separate grains. Another option is to use values that produce an over-segmented dataset, where multiple polygons are produced representing a single grain as a result of minor variations in interference colour within the grain. These over-segmented polygons can be merged where necessary to produce a usable dataset. To minimize under- or over-segmentation, it is important to use the correct composited interference colour image. The maximum interference colour image produces more under-segmentation while the minimum interference colour image results in more over-segmentation. The average interference colour image has a balance between the two and is the better option out of the three.

Because MFA produces grain boundaries based on pixel values, it will always result in over segmentation for mineral grains that possess twinning. This is due to twinning causing the grain to have different sections with different interference colours. However, this does not occur when using the average interference image, which results in twins disappearing. If the focus of the analysis is texture, it would be better to use the average interference image. This is because the polygons produced during segmentation will represent the entire grain. However, if the focus is twinning, it is better to use a representative image from the image stack. This will result in different polygons representing the twins present within the grain.

By attributing colour pixel values to the polygons produced by MFA it is possible to classify the grains based on interference colour. Both the RGB and HSV values can be used for the identification of the minerals present based on interference colour. However, of the two models the HSV model is better. The reason being that when the RGB model is used, three different values are used to represent a single colour. This means that to utilize the full range of interference colours, the values of all three components for every rotation will be needed. However, this will result in a large dataset. By using the HSV model, it is possible to use only one value to differentiate between minerals. The H value represents the true colour of the associated grain. By extracting the H value for each grain at each rotation, it is possible to attribute the full range of interference colours to each individual grain.

An issue that can occur is that some minerals exhibit a wide range of interference colours, which may result in an overlap between colour ranges (Fig. 5). These are minerals such as muscovite, pyroxenes and amphiboles. This means the H value alone won’t suffice to differentiate between different minerals. In these cases, it is possible to use the S and/or V values as well to distinguish between different minerals. By using all three components it is possible to increase the accuracy of classification.

It is possible to use multiple ranges to classify the minerals. For example, in sample D15 multiple ranges can be used to classify the pyroxenes based on their different colour (e.g.; yellow pyroxene, blue pyroxene) or they can all be simply classified as pyroxene. However, it is not so simple for minerals such as muscovite. Because of the wide range of interference colours of muscovite, it will require too many different ranges to classify muscovite based on each individual colour (e.g.; purple, blue, green). In cases like this, classifying minerals based on interference colour alone will not suffice. It is also possible to extract the HSV value from PPL images in order to extract the colour values of any pleochroic minerals. However, there is still the possibility of different minerals having similar pleochroic colours. If minerals can’t be differentiated using interference colours or pleochroic colour, then additional properties, such as shape and size, can be used in addition.

Another complication is chemically altered minerals. As a result of this alteration, it is possible for minerals to exhibit interference colours outside the norm. Depending on the extend of the alteration, it is possible to classify these grains as the altered versions of the original mineral by using a separate range of pixel values. It is also possible that the alteration only causes a slight variation in interference colour and the pixel values can be included in the formula for classification.

Image quality can also affect the accuracy of classification. As was the case in this study, there was a noticeable halo effect on certain images. This led to certain grains along the boundary having pixel values that fall outside the set ranges and were left as unclassified. Another reason why polygons cannot be classified is if they are at the boundary of two different grains. These polygons can be merged with the bordering grain it is closest to, but this can affect the overall values.

Extinction angle is one of a number of properties that can be used to identify minerals through petrographic microscopy. It can also be used to calculate the An% of plagioclase grains, if the grain is orientated correctly.

By attributing the interference colour values to the MFA generated polygons, it is possible to determine at what point throughout the rotation each grain was fully extinct. This can be done using RGB values, but it is easier to simply use the V value. The V value is a measurement of how far the colour is from black. By using the V values of the full rotation, it is possible to find the point of maximum extinction by determining the minimum V value within the range and using an IF function to determine in which image it occurs. This is one of two components needed to calculate the extinction angle.

The second component is the orientation of the grain. The orientation is given by MFA and is calculated by using the angle between the vertical direction and the long axis of the grain (Visalli et al., 2021). The long and short axis of the grain is represented by the length and width respectively. This means that the grain orientation is affected by the grain shape. Therefore, if the representing polygon is incorrect, it is possible to produce an incorrect orientation. This means that the segmentation needs to be as accurate as possible, and will likely require editing the polygons.

When calculating the extinction angle manually, the chosen grain is orientated with either their cleavage plane, twins or elongation direction parallel to the north-south direction. Then the stage is rotated both clockwise and anti-clockwise and the extinction angle is calculated when the grain reaches maximum extinction. In this study it was not possible to determine the orientation of the cleavage plane of any of the minerals. However, some minerals have cleavage planes that are parallel to their elongation direction, such as biotite. For these minerals it is possible to use the elongation direction (grain orientation) as a proxy for the cleavage direction.

Using the grain orientation, the degrees needed to rotate the grain with its long axis parallel to north-south from its orientation in the image is calculated. The orientation is given as the angle between the long axis and the vertical (0°) in a clockwise direction. Therefore, the difference between the grain orientation and 0°, or 180° in some cases, can be used to “reorient” the grain. This value is then used to correct the interference colour ranges to be in a similar sequence to that of a grain oriented north-south from the start. This was tested using biotite grains from sample A14. Ensuring that some of the grains in the image were orientated north-south, the point of maximum extinction was determined for all the grains present. For the correctly orientated grains, the point of maximum extinction was first used as a proxy for the extinction angle and thus an indicator as to whether the method is correct. For these grains the point of maximum extinction was either 0° or 5°. This falls within the known extinction angle range that biotite exhibits, which is straight to near straight up to a maximum of 9° (Reinhardt, 2004; Reinhardt & Raith, 0000).

For the grains orientated at different angles, the orientation values were “re-orientated” and the corrected point of maximum extinction also agreed with the extinction angle for biotite, as can be seen in Table 2. However, because each image is only 5°, the extinction angle has an error margin of up to 3°. This is because the true point of maximum extinction is between two images. Therefore, in order to improve the accuracy of the calculated extinction angle, images will have to be taken with a larger rotation resolution (e.g., 1° increments). This could be automated by a stage rotation tool or thin section scanning technologies such as the Axioscan from ZEISS.

This method was used on plagioclase grains to determine the An%. Treating the polygons representing the twins of the grain as separate grains their extinction angle was calculated. Using the polygon neighbours tool, it is possible to determine which polygons are adjacent to each other. Using the criteria mentioned before, it is possible to determine which polygons represent twins. The dataset is then filtered to only contain the values for the plagioclase twins. The polygon neighbours tool produces a table with the data of the source polygon and its adjacent polygons. This means that the dataset contains the extinction angle for each twin in a twin set. This is then further filtered to only contain the values for grains where the difference between the extinction angles are no more than 4°. After filtering these values, the maximum extinction angle is the used to calculate the An% of the thin section using the Michel-Lévy method (Ermanovics, 1967). However the Michel-Lévy method does have limitations, namely it uses the symmetrical extinction angles of albite twins in sections normal to (010) (Ermanovics, 1967). This means that plagioclase grains without twins or with twins that are not well developed are excluded from the calculation.

Using Sample DRT 34, image stacks were taken of three separate areas within the thin section and the An% calculated for each area. The same sample was analysed using SEM and the An% calculated using the different methods were compared. As can be seen in Figure 7, the An% calculated using the extinction angles falls on the lower edge of the cloud of points defined by range of values acquired via SEM analysis.

Calculating the An% using the data produced by SEM analysis is still more accurate and can be considered as more representative. Using SEM analysis, it is possible to acquire a wider range of values and therefore improve the accuracy compared to calculating the An% using extinction angles. However, the accuracy of the calculated An% could be improved if the thin section images were captured with higher rotational resolution (e.g., 1° rotations rather than 5°). It should be noted that this process is not meant to replace SEM analysis, but to provide an alternative, low cost and fast microtextural tool to enhance the analysis of petrographic thin sections.

Grain shape is another property that can be used to identify minerals. The overall grain shape and size within a thin section is also important textural and structural descriptors, depending on the rock type. In petrographic microscopy, grains are often described based on shape.

Using the attributes produced from MFA and other calculated attributes, it is possible to classify the grains based on shape. From MFA the attributes Shape Factor 2 (SF2), AsR and Roundness can be used. SF2 is a measurement of how deviated the shape is from the reference shape, in this case a circle (Visalli et al., 2021). The higher the SF2 value, the closer the shape is to that of a circle. The AsR is calculated dividing the long axis (length) by the short axis (width). The higher the AsR value the more elongated the grain is. The roundness is the reciprocal of the AsR and the higher the value the more equant the shape. Along with these attributes, the convexity was calculated. The convexity is calculated using the Minimum bounding Geometry tool and the equation from Figure 1. Using these values, it is possible to classify the grains based on shape.

It is important to note that in order to get an accurate classification, the polygons need to be as close as possible to their representative grains. Therefore, in the case of either over or under segmentation, the polygons will need to be edited to produce accurate data. In the case where some polygons have been edited, some shape factors can no longer be used. These are the attributes calculated by MFA, such as the shape factor, AsR and roundness. This is because they do not update automatically after editing. However, these factors can be recalculated using the new area, perimeter, length and width of the edited polygons. These calculations were done using the formulas as seen in the Supplementary data.

Once all factors have been calculated or recalculated, the grains can be classified in a number of ways by setting specific ranges for specific shapes. Using high AsR values or low roundness values it is possible to classify grains as elongated, while the inverse is used to determine more equant shapes. Because roundness is the reciprocal of the AsR, only one factor is needed. By using the circularity, the recalculated shape factor, it is possible to distinguish between more rounded and more angular shapes. The closer the value is to one, the more rounded or circular the shape, while the closer to zero, the more angular or irregular the shape. Using the convexity values, it was possible to distinguish between more euhedral shapes and more irregular shapes. The higher the convexity value, the more euhedral the grain.

Using these shape attributes, it is possible to distinguish between minerals with the same interference colours. For example, plagioclase and quartz have very similar interference colour ranges, which means it is difficult to distinguish between them. Grain shape can assist with this. In general, plagioclase has a more elongate and euhedral shape while quartz is more equant and anhedral, which means that by adding shape values to colour classification will improve the results. However, this is dependent on the quality of the sample.

By using either the grain perimeter or area it is possible to sort the different grains into size categories, namely coarse-, medium- and fine-grained. This adds another attribute that can be used during classification to assist with distinguishing between minerals with similar optical properties. For example, muscovite can have some overlap with biotite in regards to interference colour. However, in this sample muscovite has a smaller grain size than biotite.

Nature is a complex system and the identification of minerals are not always straightforward, even when using standard microscopy techniques and the quality of the results produced are greatly dependent on the skills of the petrographer (Tarquini & Favalli, 2010). There are several factors that can affect the image analysis on thin sections. These include the orientation of the indicatrix of non-isotropic minerals with respect to the direction of polarization, which in turn affects the birefringence value of the mineral (Tarquini & Favalli, 2010). Alteration can also affect the optical properties of minerals present, as it was seen in this study, and this can then affect the quality of grain segmentation. Complicated patterns, such as twinning, zoning and cleavage, caused by intra-crystalline structures can result in uneven responses to light transmission and add noise to the image (Tarquini & Favalli, 2010). The quality of the thin section itself can affect the observed properties. Perhaps one of the more important factors affecting image analysis is the quality of the images. Higher quality images allow for minerals to be more easily distinguishable. It is also important to consider that the petrographic microscope is well suited to human vision, but not necessarily an accurate system for the quantification of light (Tarquini & Favalli, 2010).

During this study, a number of limitations were encountered and had to be managed, the first being the quality of the grain segmentation. The two main components affecting this is the complexity of the sample and the quality of the images. Less complex samples that are more coarse grain result in better segmentation. For this reason, more granitic samples were used during this study, as they are more coarse grained with a relatively simple mineral assemblage. The accuracy of the grain segmentation affects the quality of data that can be produced. By improving the accuracy of segmentation, less time has to be spent on manually editing the polygons. Segmentation via MFA is relatively quick, taking between 30 min and 45 min to complete. Manually fixing any errors in the resulting data set can take between 5 min and 30 min, depending on the quality of the segmentation.

Extracting and attributing the interference colours as pixel value to the grains is a relatively quick and simple process. Once the ranges have been determined, classification of every grain within the image can quickly be achieved. However, the accuracy is dependent on a number of factors, including alteration, thin section thickness and image resolution. All these factors influence the minerals and can result in interference colour values outside the norm as reported in textbooks dealing with mineral identification via petrographic observation such as Deer, Howie and Zuzzman.

The calculation of the extinction angles is limited to minerals where the elongation direction of the grain can be used. The direction of the cleavage planes cannot be determined using the method used in this study. Therefore, the extinction angle cannot be calculated for minerals where the cleavage plane is used. The accuracy of the calculated extinction angle is also affected by the resolution of the image stack used. In this study a resolution of 5° were used, but a resolution of 1° will likely improve the results produced. However, this will result in more images that need to be processed and this will increase the processing time. The accuracy on the calculated An% is affected by the extinction angle, but also by the Michel-Lêvy method itself. The Michel-Levy method only uses the extinction angles of albite twins in sections normal to (010) (Ermanovics, 1967). This results in grains without twins or with twins that are not well developed being excluded during the calculation of the An%.

At this time the methods used in this study may be complex to some users and require more work than doing regular petrographic observation. However, the limitations and possible errors of each step has to be investigated to produce the best results possible. With these limitations identified, this research can serve as the bases for creating a more automated process. Further research on more complex rocks needs to be done in order to improve these techniques.

The purpose of this study was to generate methods for integrating rotational data to thin section image analysis. This was done in a number of ways. Firstly, it was possible to create a single image where every grain displays the average interference colour using multiple images, where each image is a different rotation of the polarizer and analyser. This average interference image was then used in grain segmentation, which produced a dataset containing a number of polygons representing the grains present within the image. This polygon layer was used to extract the interference colour values of the different minerals present, as well as colour values of pleochroic minerals. By attributing these values to their associated grains, specific ranges were set to classify minerals based on interference colour. Pleochroic colour values were used to assist with classification for minerals with similar interference colours.

By using the brightness values, it was also possible to determine the point of maximum extinction for the mineral grains. This, along with the lengthwise orientation of the grains, was used to calculate the extinction angle for certain mineral grains, namely minerals with their cleavage plane or twinning direction parallel to their elongation direction. Calculated extinction angles had an error margin of up to 3°. This was largely a factor of the low rotational resolution of images acquired at 5° increments. By using the extinction angles for feldspar twins, it was possible to determine which plagioclase end-member is present by calculating the An%. This was done by using the Michel-Levy method, with the resulting An% calculated falling within the range of values acquired from SEM analysis, with an uncertainty of 3%.

Texturally, methods were also developed for classifying grains based on shape and categorizing grains based on size. This was done using a number of attributes produced during grain segmentation and calculated from the resulting polygon dataset. Using these values, it was possible to classify mineral grains as either elongate, equant or rounded. It was also possible to distinguish between grains with a more irregular shape and grains with a more euhedral shape. This, along with the size categories, provides descriptive textural data as well as provides additional attributes for mineral classification.

The methods developed during this study offers several ways for adding quantifiable data during petrographic studies. Also, by using a range of images, more representative data is produced than preforming analysis on an image representing a single rotation.