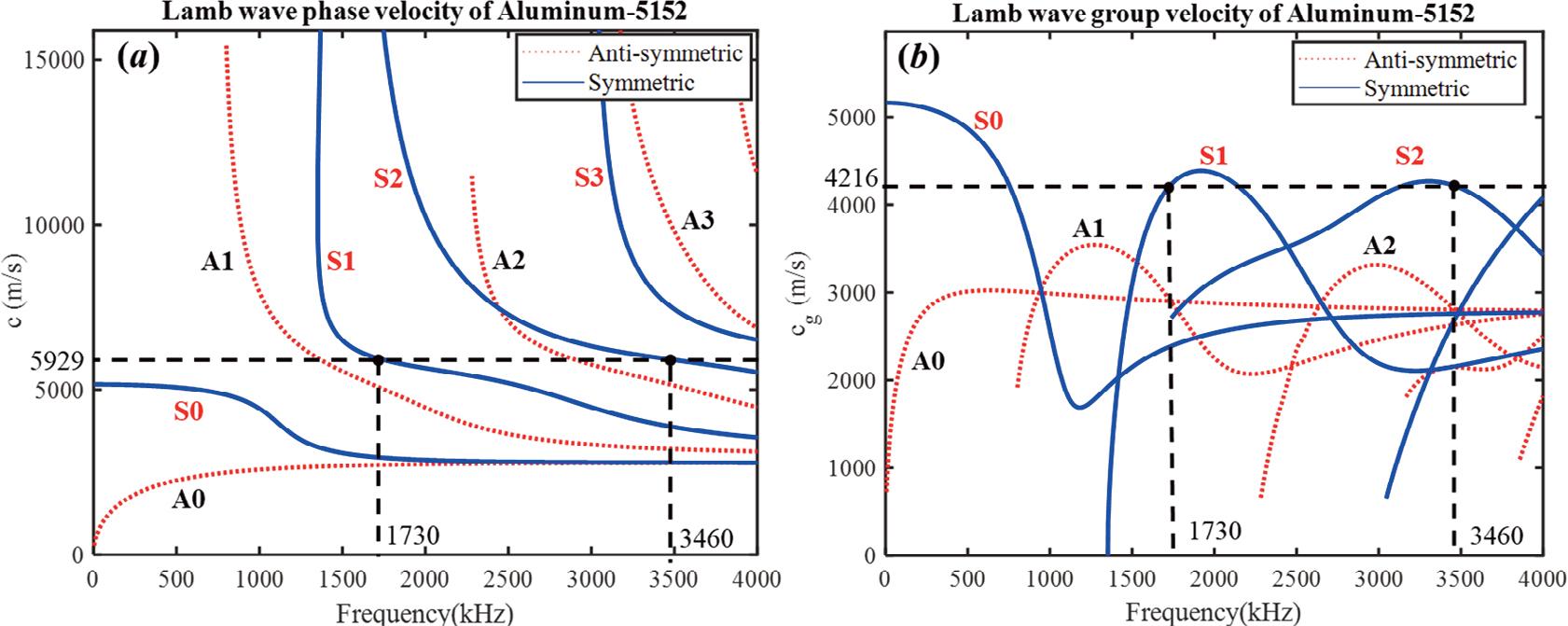

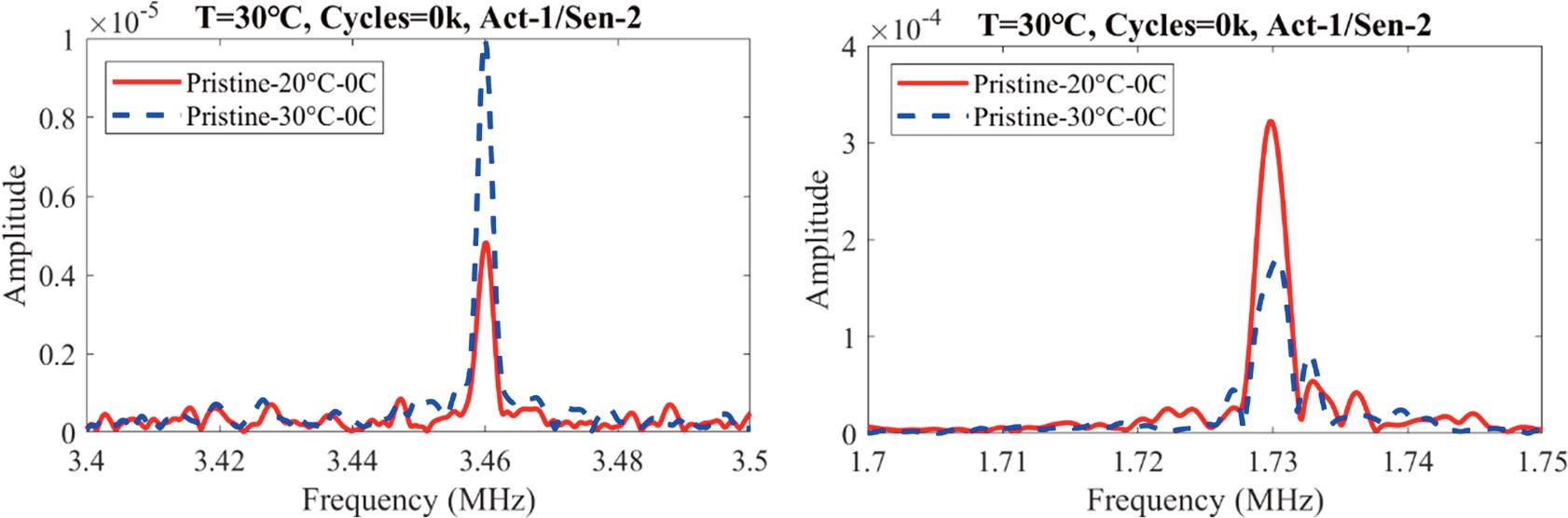

Figure 1.

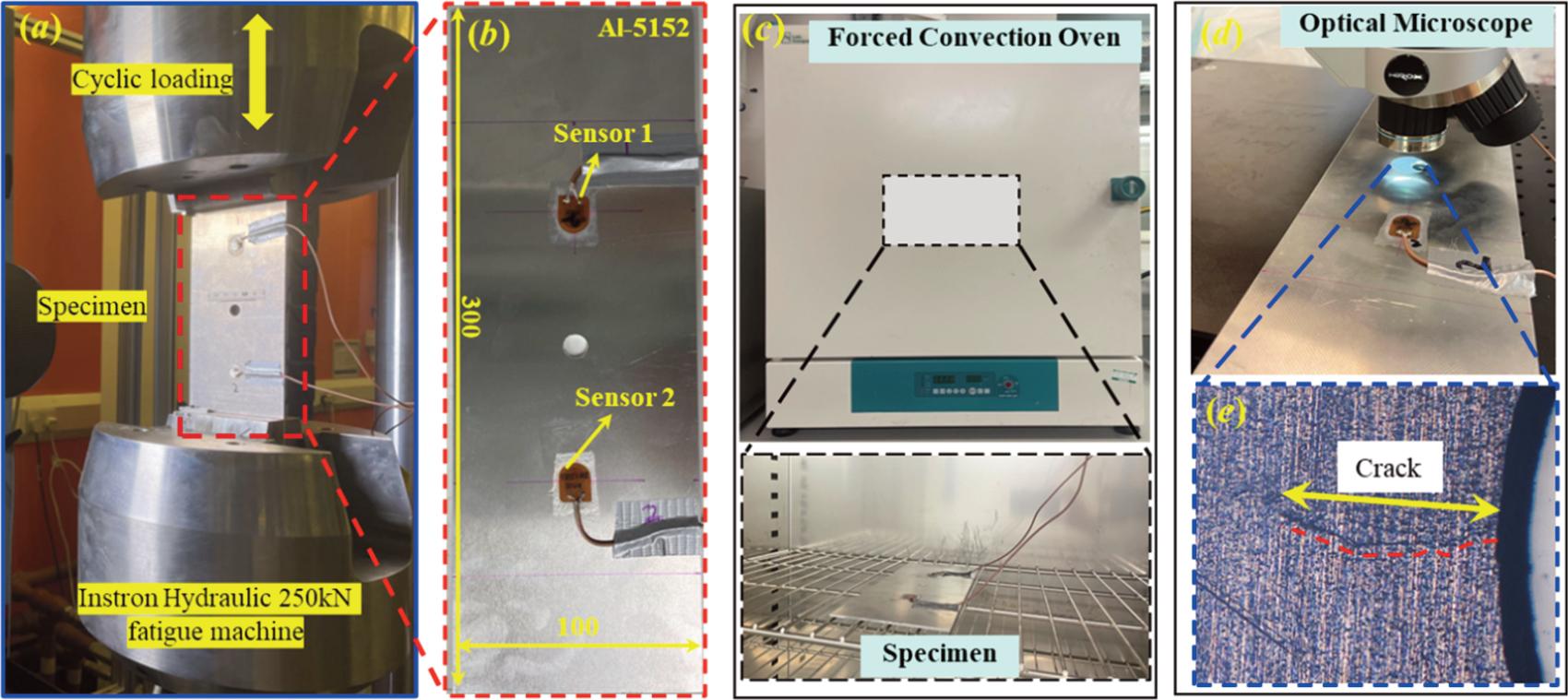

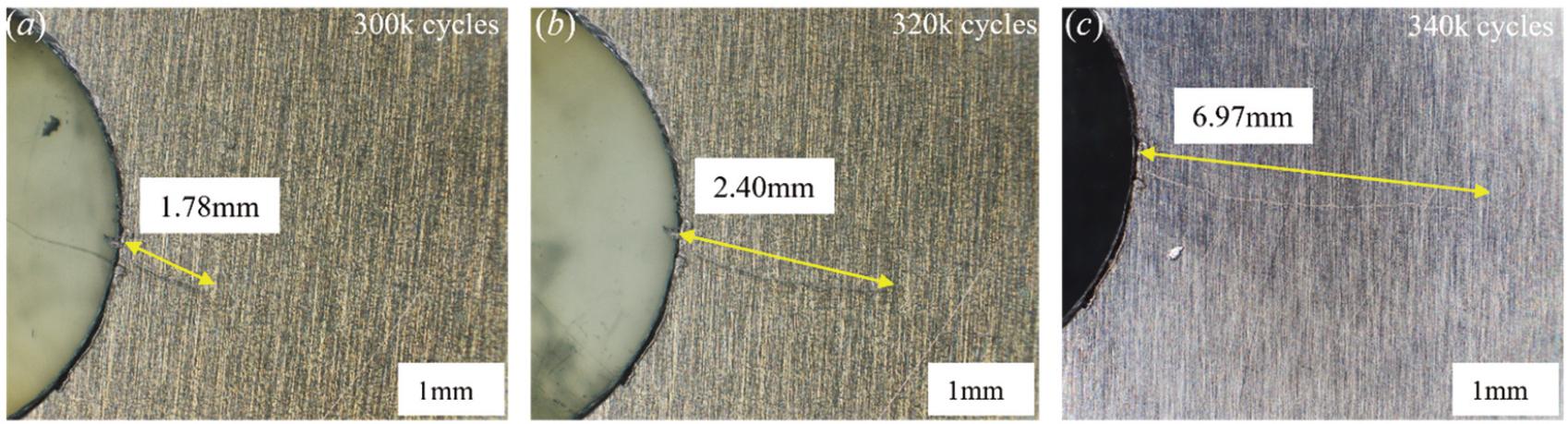

Figure 2.

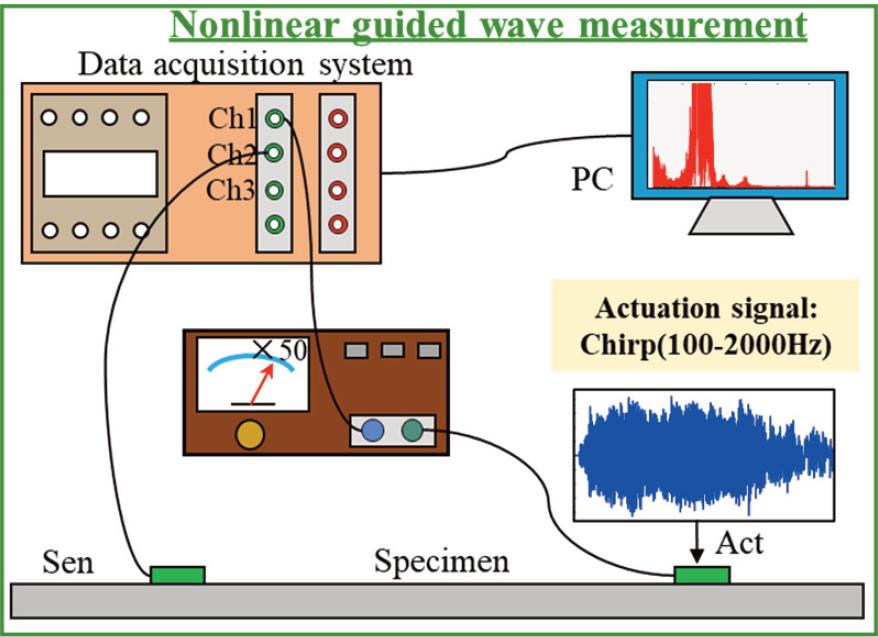

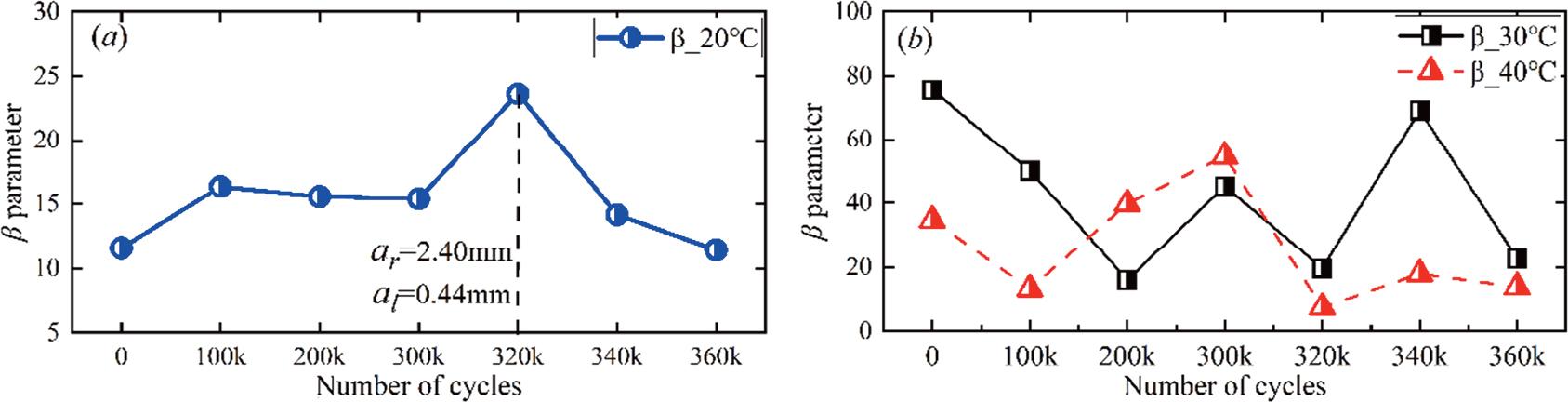

Figure 3.

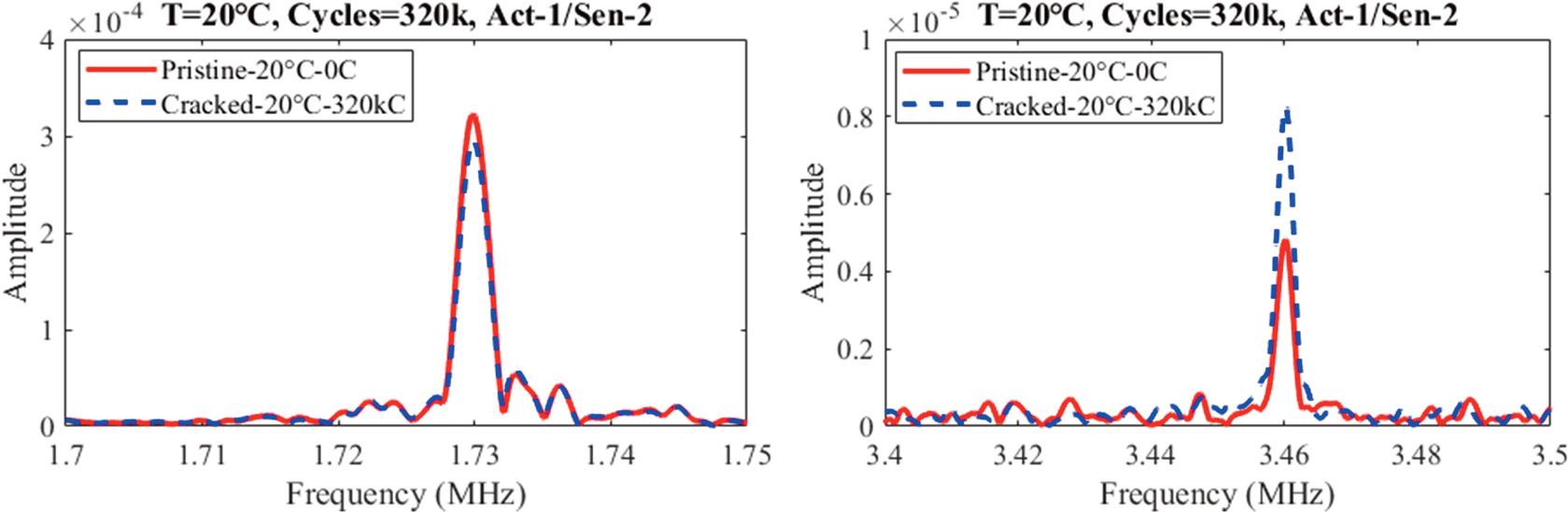

Figure 4.

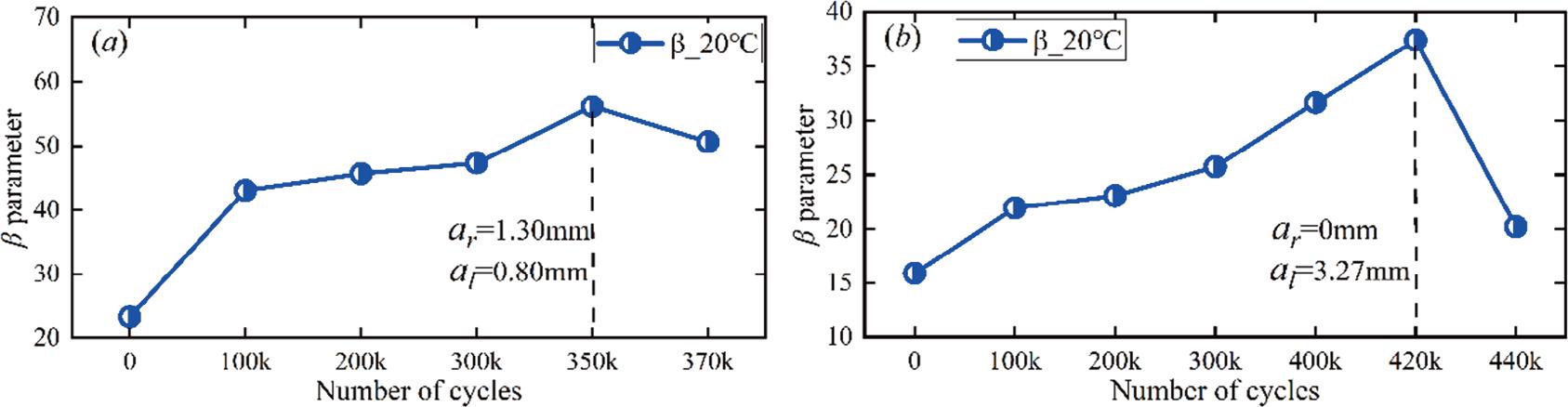

Figure 5.

Figure 6.

Figure 7.

Figure 8.

Fatigue test details on different specimens under different temperatures_

| Stage of fatigue test | T1 | T2 | T3 | Working temperature |

|---|---|---|---|---|

| 1 | 0k | 0k | 0k | 20-40° |

| 2 | 100k | 100k | 100k | |

| 3 | 200k | 200k | 200k | |

| 4 | 300k | 300k | 300k | |

| 5 | 320k | 350k | 400k | |

| 6 | 340k | 370k | 420k | |

| 7 | 360k | 440k |

Crack length of different fatigue stage on specimens T1, T2, and T3_

| Specimens | T1(mm) | T2(mm) | T3(mm) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Num of stage | cycles | al | ar | cycles | al | ar | cycles | al | ar |

| 1 | 0k | 0 | 0 | 0k | 0 | 0 | 0k | 0 | 0 |

| 2 | 100k | 0 | 0 | 100k | 0 | 0 | 100k | 0 | 0 |

| 3 | 200k | 0 | 0 | 200k | 0 | 0 | 200k | 0 | 0 |

| 4 | 300k | 0.42 | 1.78 | 300k | 0 | 0 | 300k | 0 | 0 |

| 5 | 320k | 0.44 | 2.4 | 350k | 0.8 | 1.3 | 400k | 0.6 | 0 |

| 6 | 340k | 2.11 | 6.97 | 370k | 1.93 | 3.90 | 420k | 3.27 | 0 |

| 7 | 360k | 4.05 | 11.4 | 440k | 6.71 | 1.4 | |||