Figure 1

Figure 2

The conditions for the Abyssinian oil modification process with scCO2 (Oil 2) or without scCO2 (Oil 1) and their analytical properties

| Oil 1 | Oil 2 | |

|---|---|---|

| Temperature, °C | 120 | 120 |

| Pressure O2/Σ, MPa | 0.4 | 10 |

| Catalyst, % (w/w) | 0.05 | 0.05 |

| Kinematic viscosity at 40°C, mm2/s | 156.9 | 143.4 |

| Peroxide number, meq O2/kg | 15.16 | 13.10 |

| Iodine number, g I2/100 g | 54.10 | 63.70 |

| Saponification number, mg KOH/g | 214.23 | 248.70 |

| Acid number, mg KOH/g | 25.70 | 28.05 |

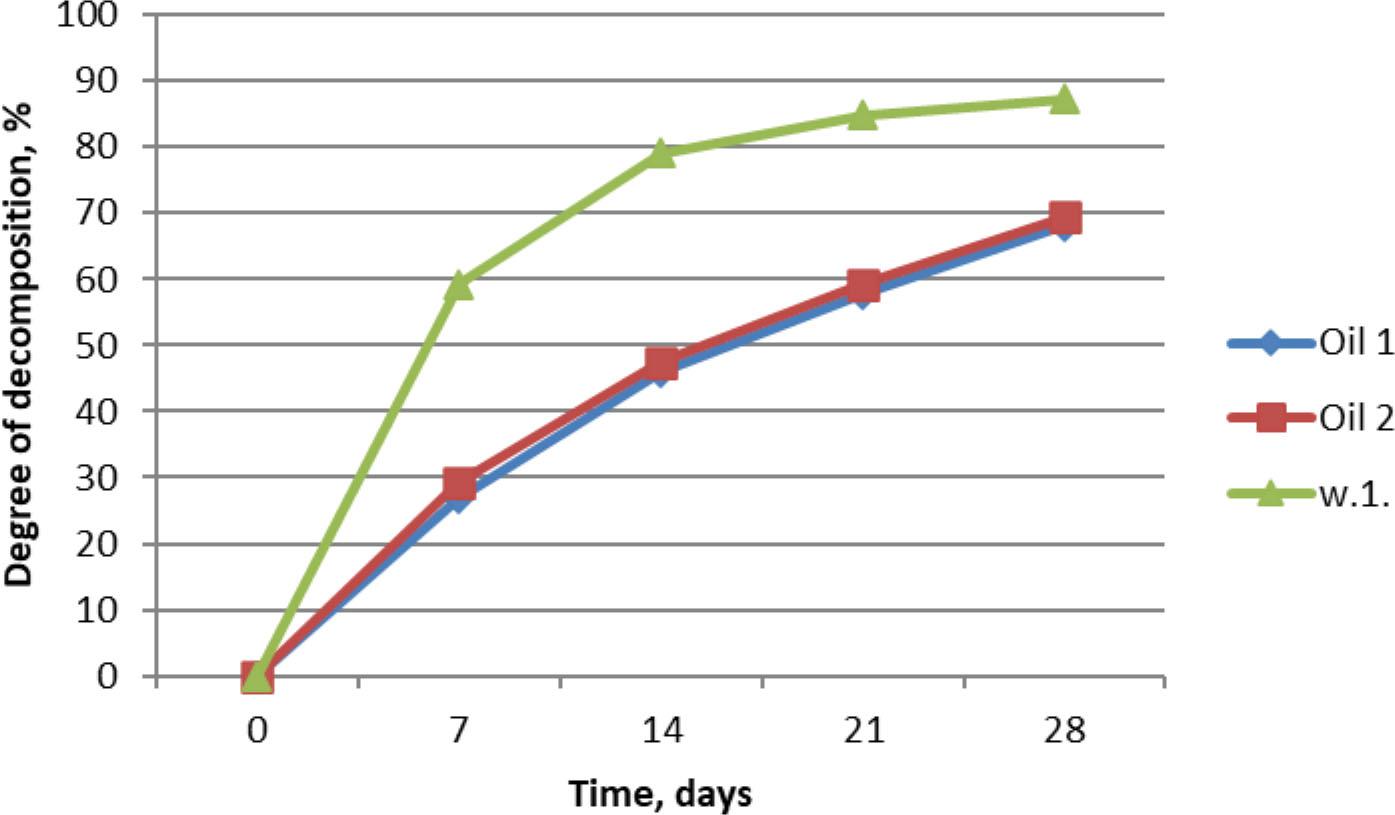

Oxygen uptake and the biodegradation degree of modified vegetable oils during 28 days

| Time, days | ||||||

|---|---|---|---|---|---|---|

| 0 | 7 | 14 | 21 | 28 | ||

| Average O2uptake by test sample, mg/l | Oil 1 | 0.0 ± 0.0 | 83.9 ± 0.0 | 138.8 ± 0.0 | 174.0 ± 0.0 | 202.5 ± 2.0 |

| Oil 2 | 0.0 ± 0.0 | 91.4 ± 2.0 | 144.0 ± 2.0 | 180.0 ± 2.0 | 208.5 ± 6.0 | |

| Average O2 uptake in the blank test, mg/l | Blank test (b.1.) | 0.0 ± 0.0 | 9.0 ± 2.1 | 10.5 ± 2.1 | 13.5 ± 2.1 | 13.5 ± 2.1 |

| Average O2 intake in the reference material, mg/l | Reference material (w.1.) | 0.0 ± 0.0 | 85.4 ± 2.1 | 112.5 ± 2.1 | 123.0 ± 0.0 | 126.0 ± 4.2 |

| Degree of decomposition, % (BOD/ThOD*C)*100 | Oil 1 | - | 26.9 ± 0.0 | 45.9 ± 0.0 | 57.7 ± 0.0 | 68.0 ± 0.8 |

| Oil 2 | - | 29.3 ± 0.8 | 47.5 ± 1.5 | 59.3 ± 0.8 | 69.4 ± 2.3 | |

| Reference material (w.1.) | - | 59.2 ± 1.6 | 79.1 ± 1.6 | 84.9 ± 0.0 | 87.2 ± 3.3 | |

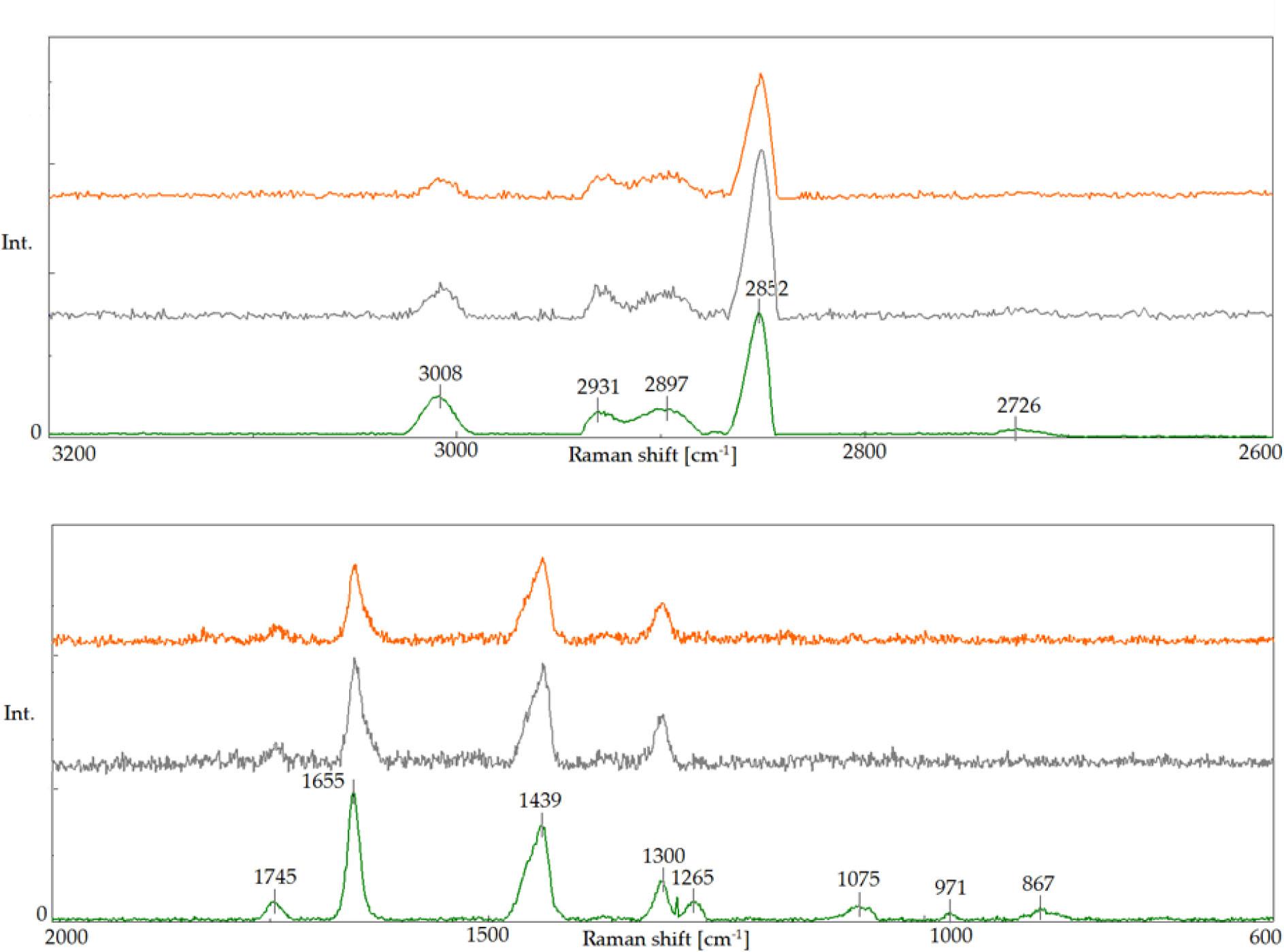

Chemical shifts and vibrational modes present in the Raman spectra of oils

| Raman Shift, cm−1 | Bond | Group | Vibrational Mode |

|---|---|---|---|

| 3100–2800 | =C−H, C−H | −CH3, −CH2 | stretching |

| 1656 | C=C | cis RCH=CHR | stretching |

| 1444 | C−H | −CH2 | stretching |

| 1300 | −C−H | −CH2 | scissoring |

| 1266 | =C−H | −CH2 | twisting |

| 1087 | C−C | −(CH2)n | stretching |

Characterization of activated sludge

| Parameter | Value |

|---|---|

| Activated sludge suspension, g/l | 9.229 |

| pH | 6.93 |

| Dissolved oxygen content, mg/l | 3.02 |

| Sedimentation after 0.5 h, ml/100 ml | 89 |