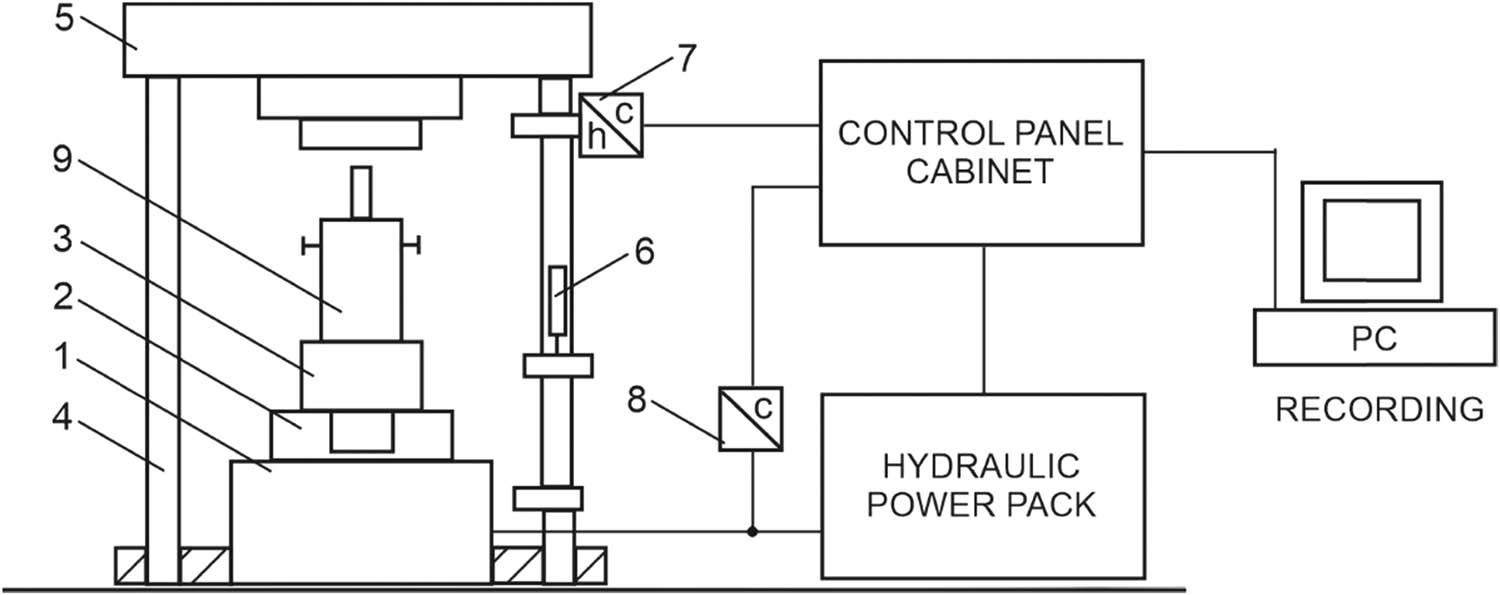

Figure 1

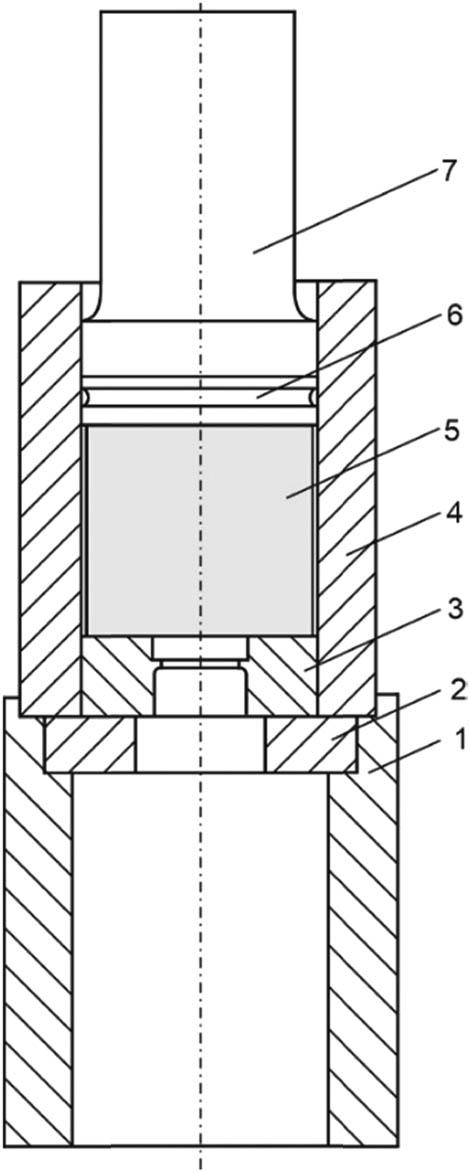

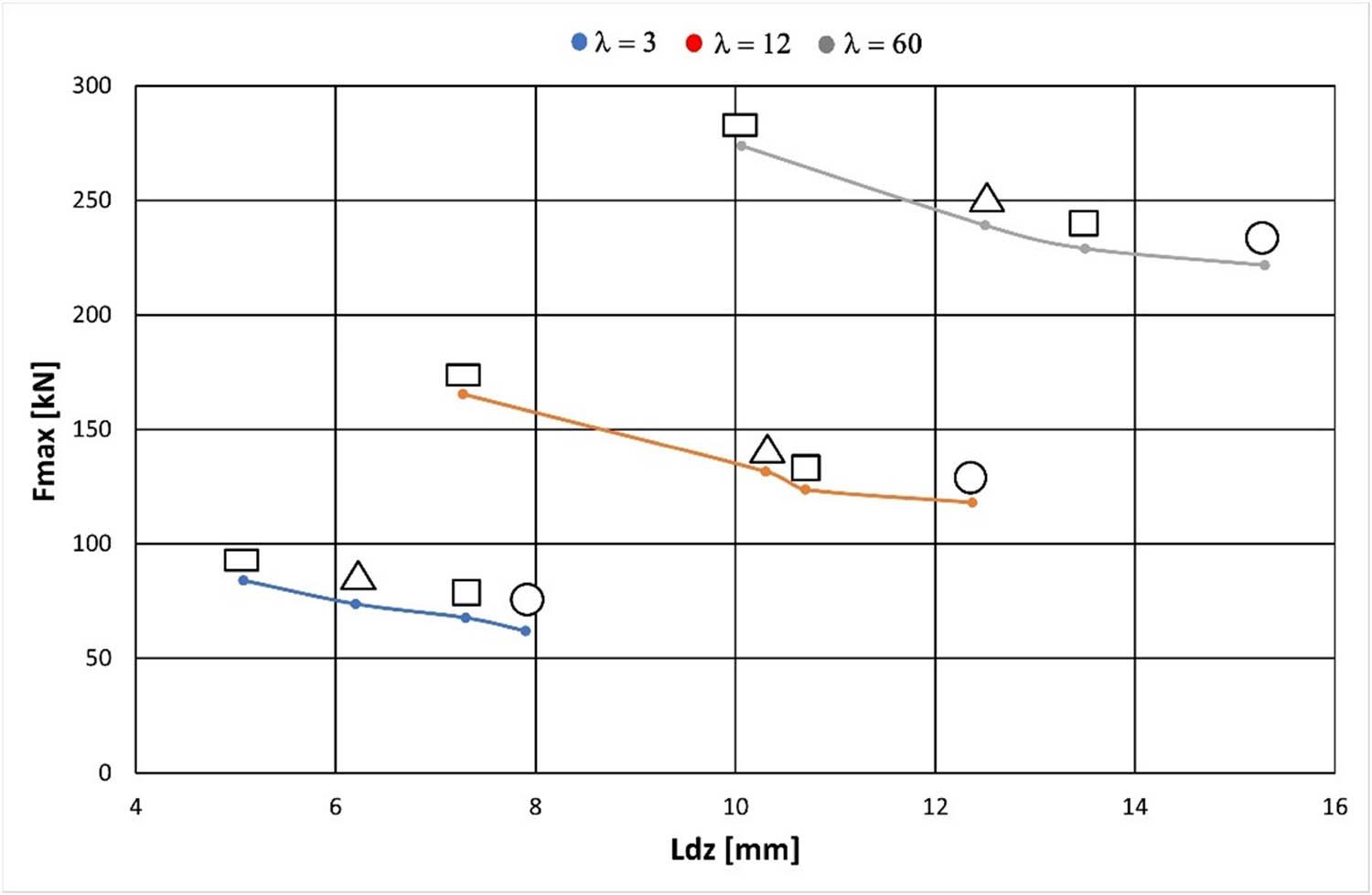

Figure 2

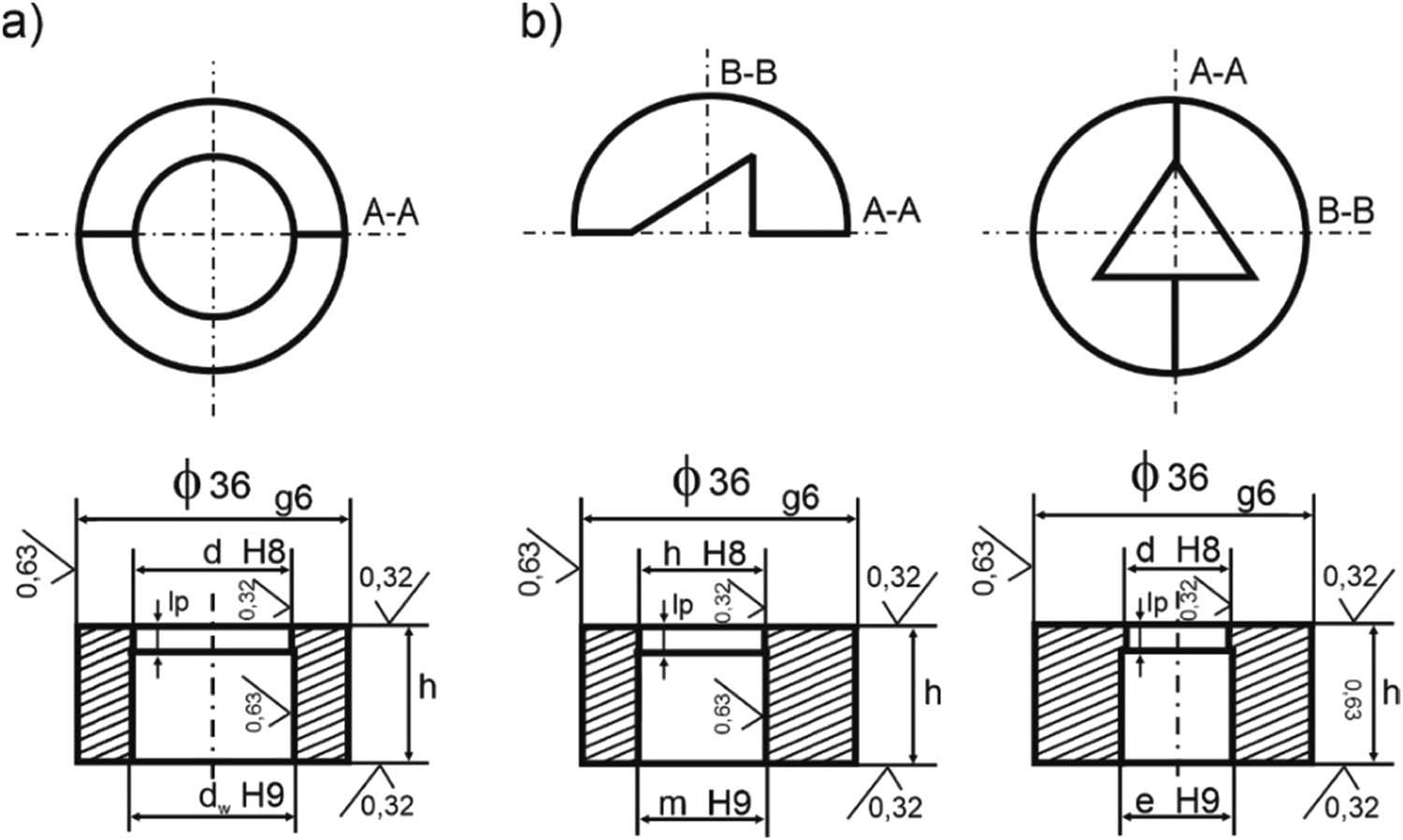

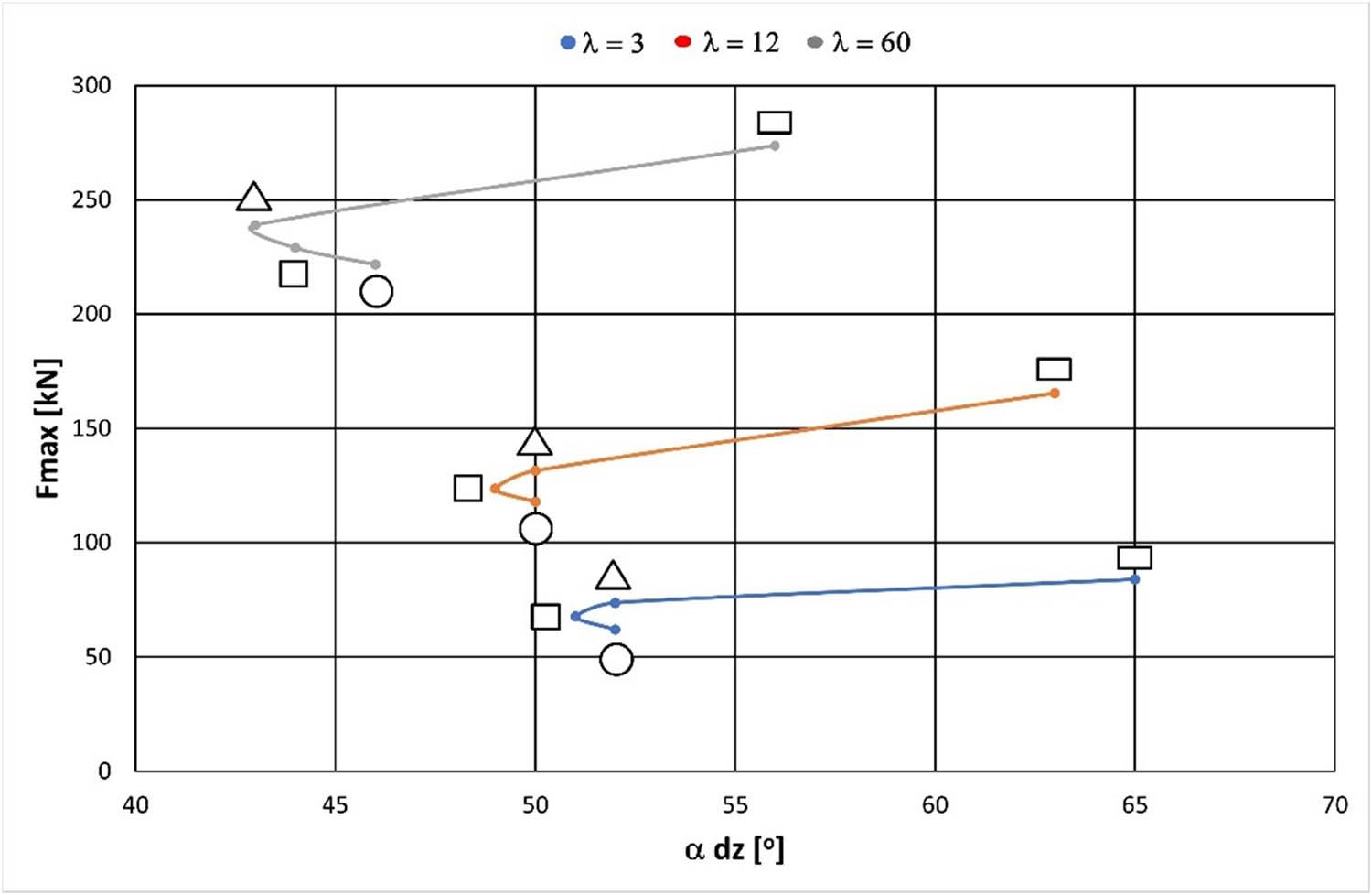

Figure 3

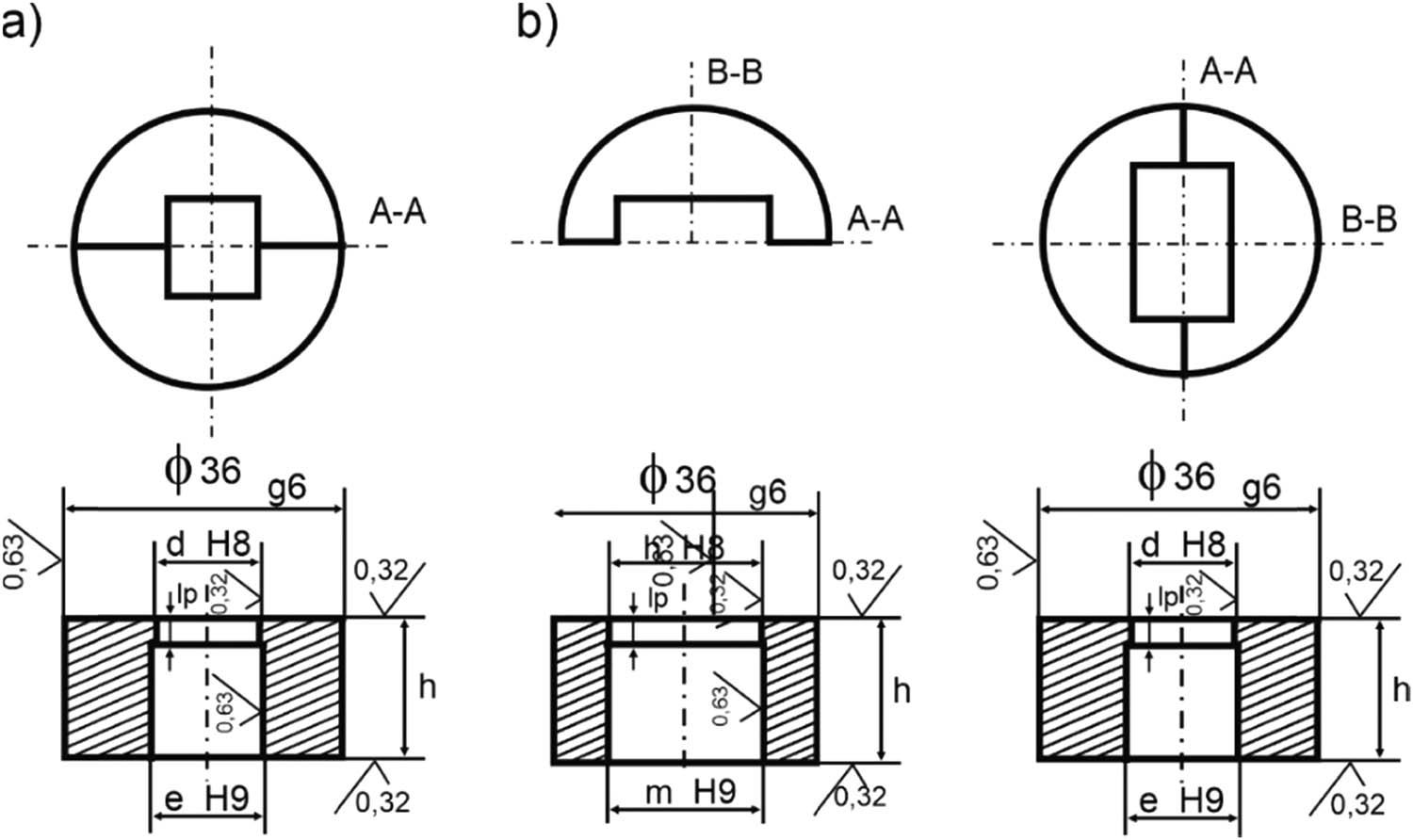

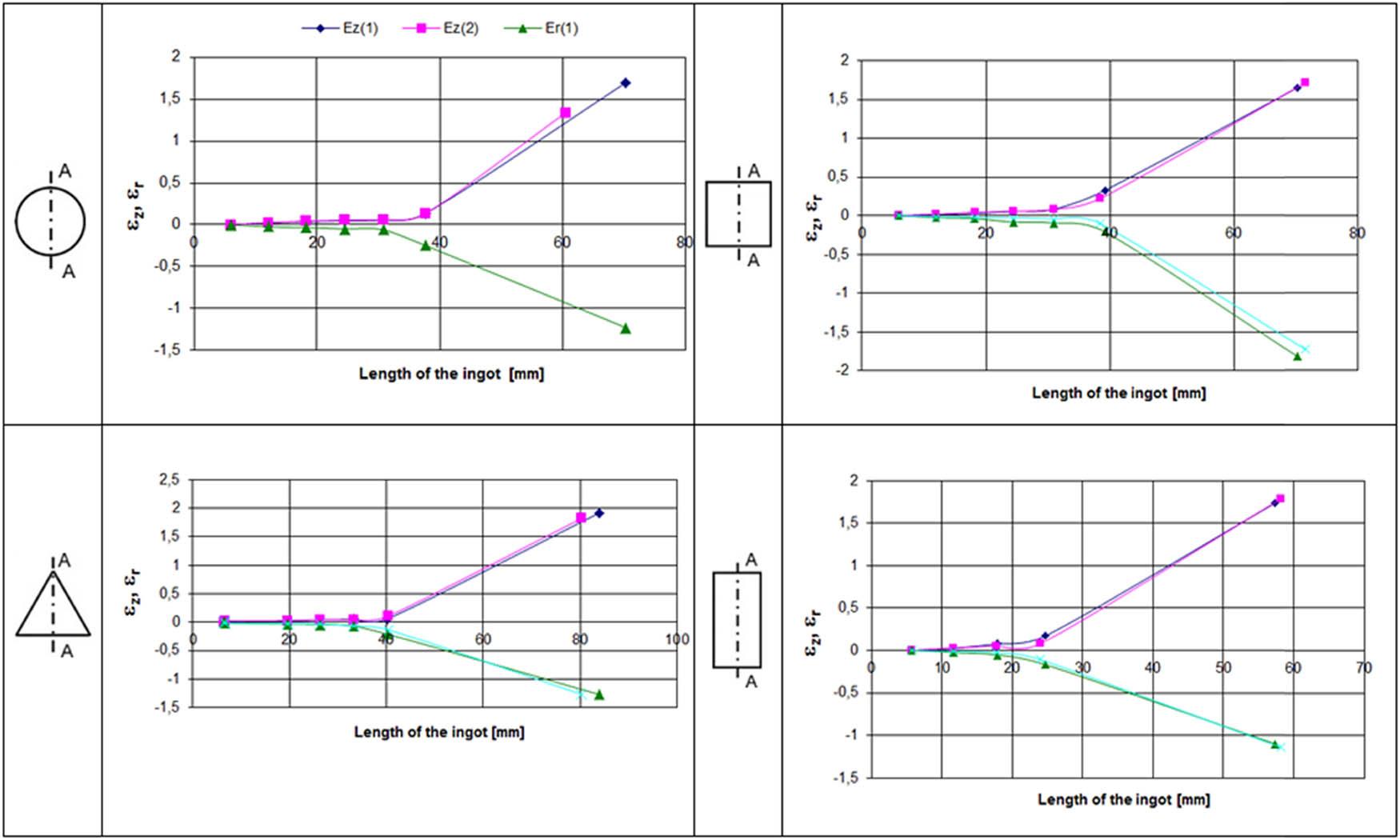

Figure 4

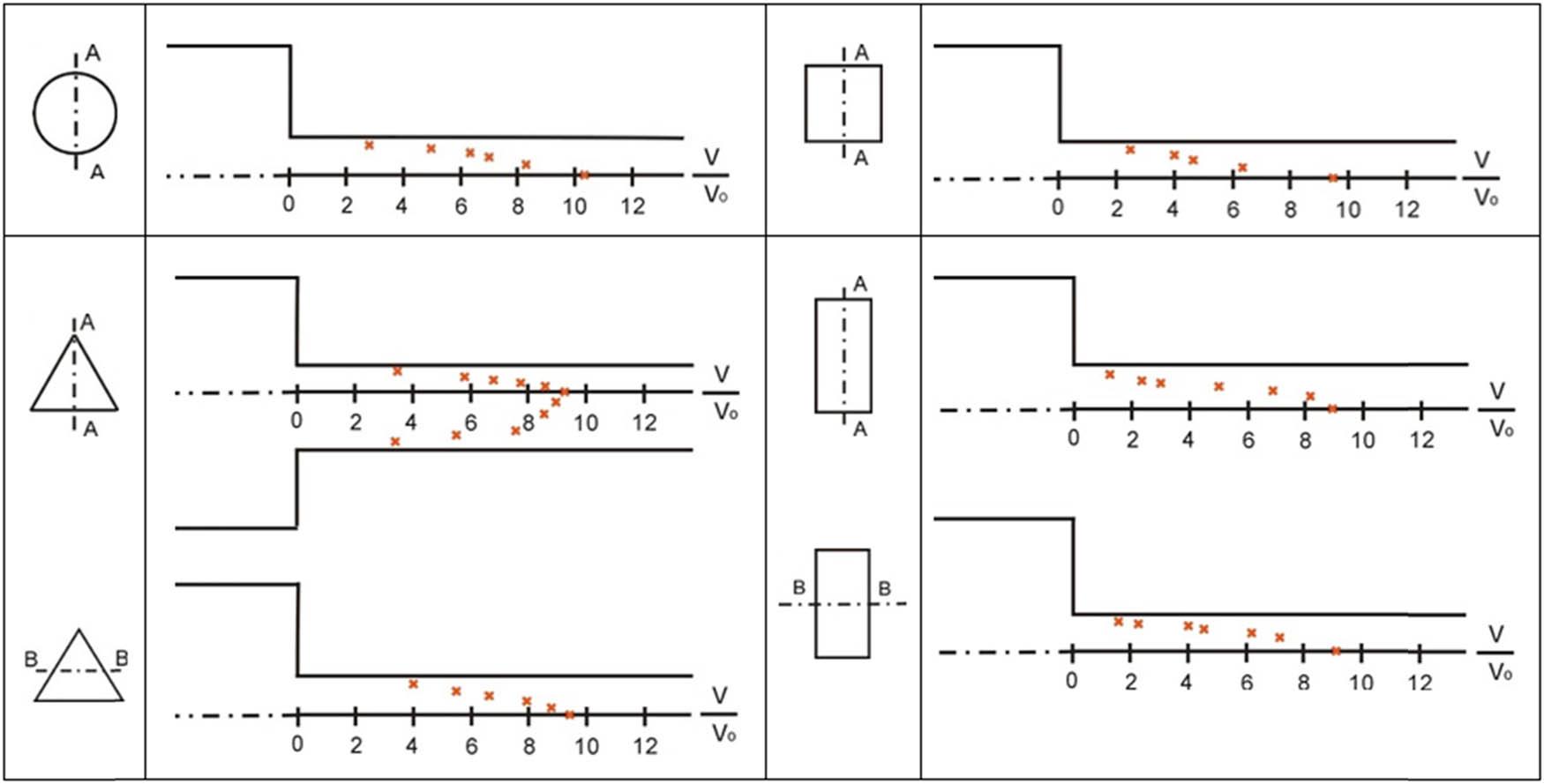

Figure 5

Figure 6

Figure 7

Figure 8

Figure 9

Figure 10

Figure 11

Figure 12

Figure 13

Figure 14

Figure 15

Figure 16

Figure 17

Figure 18

Figure 19

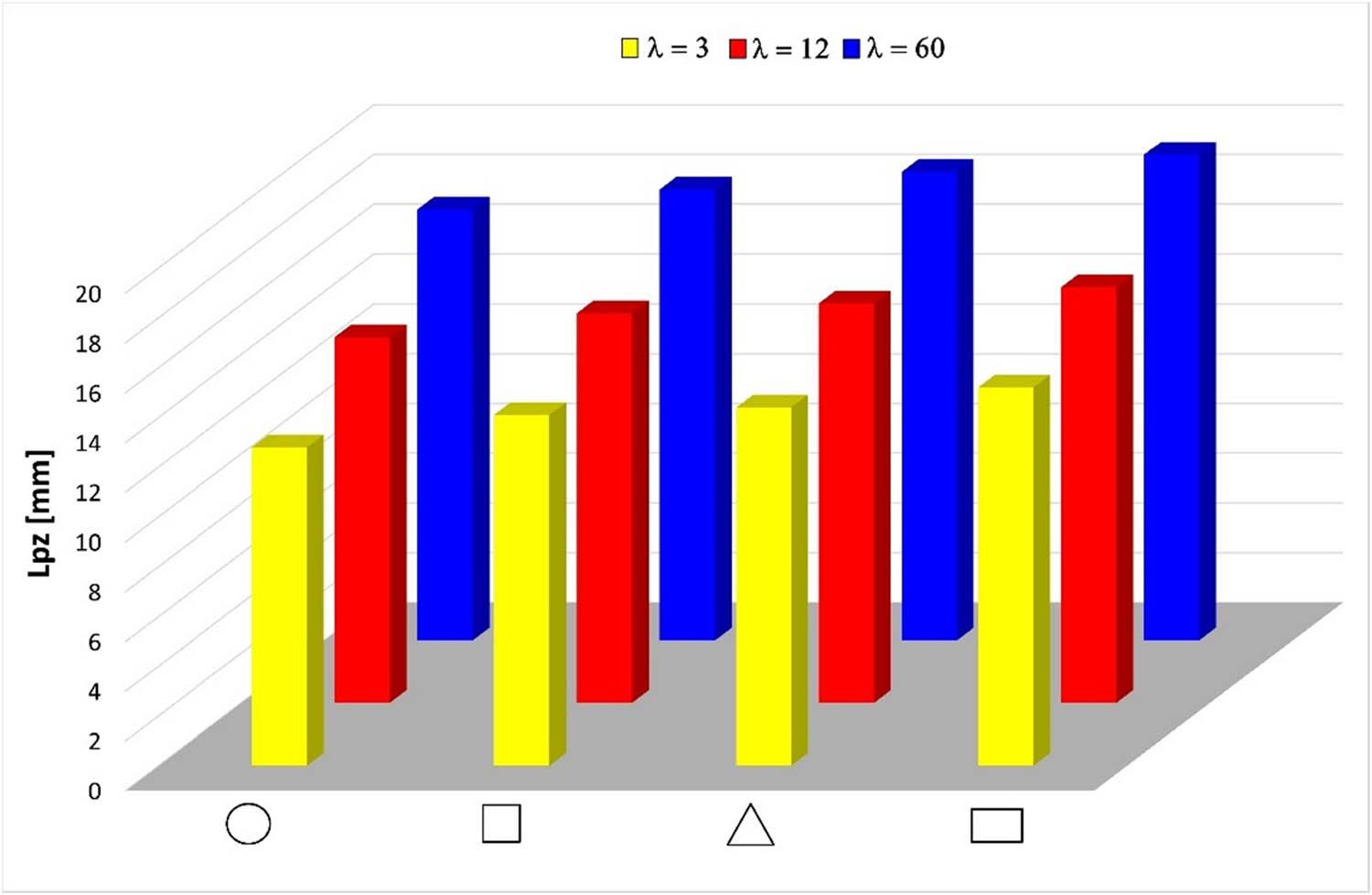

Figure 20

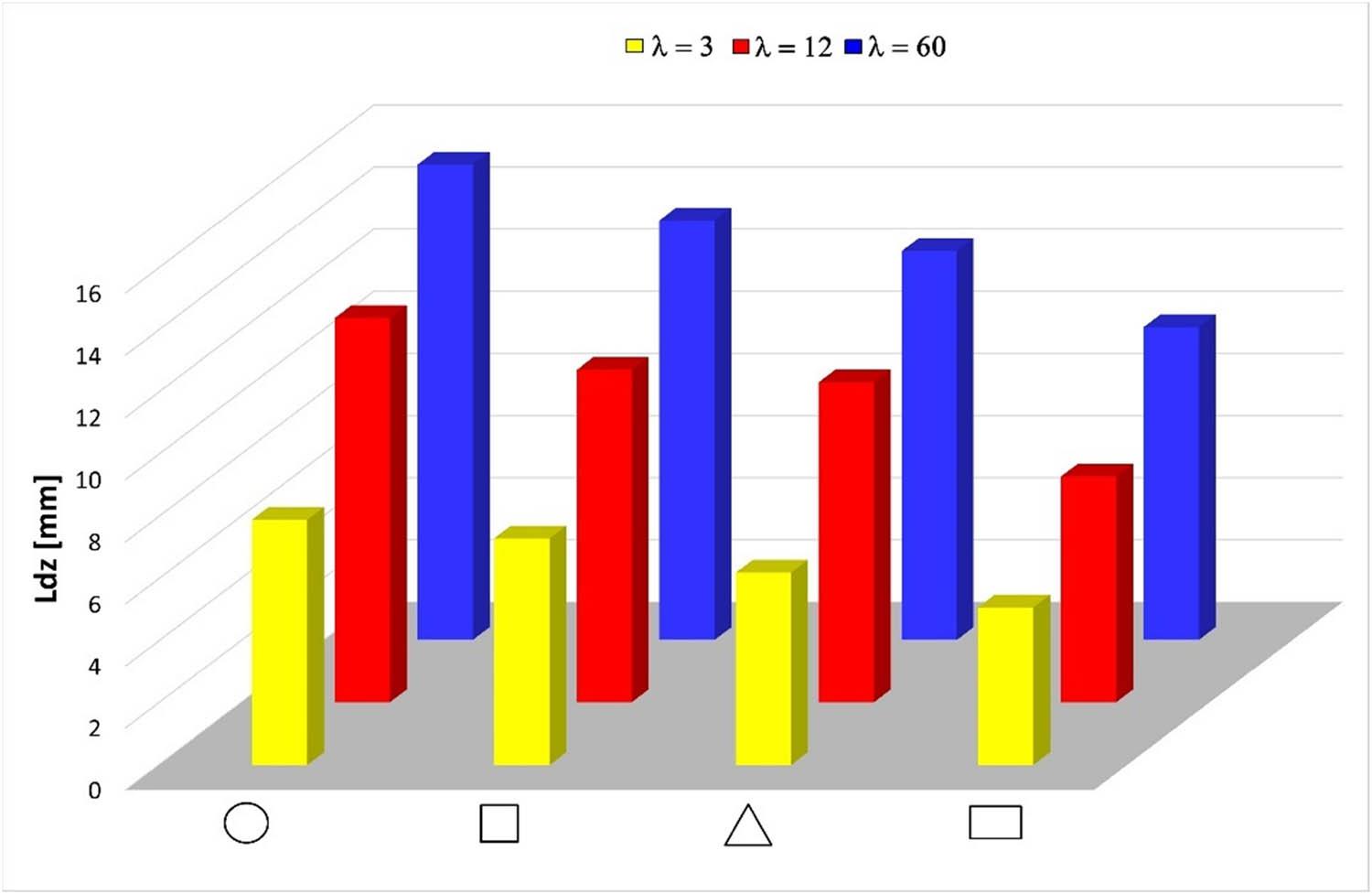

Figure 21

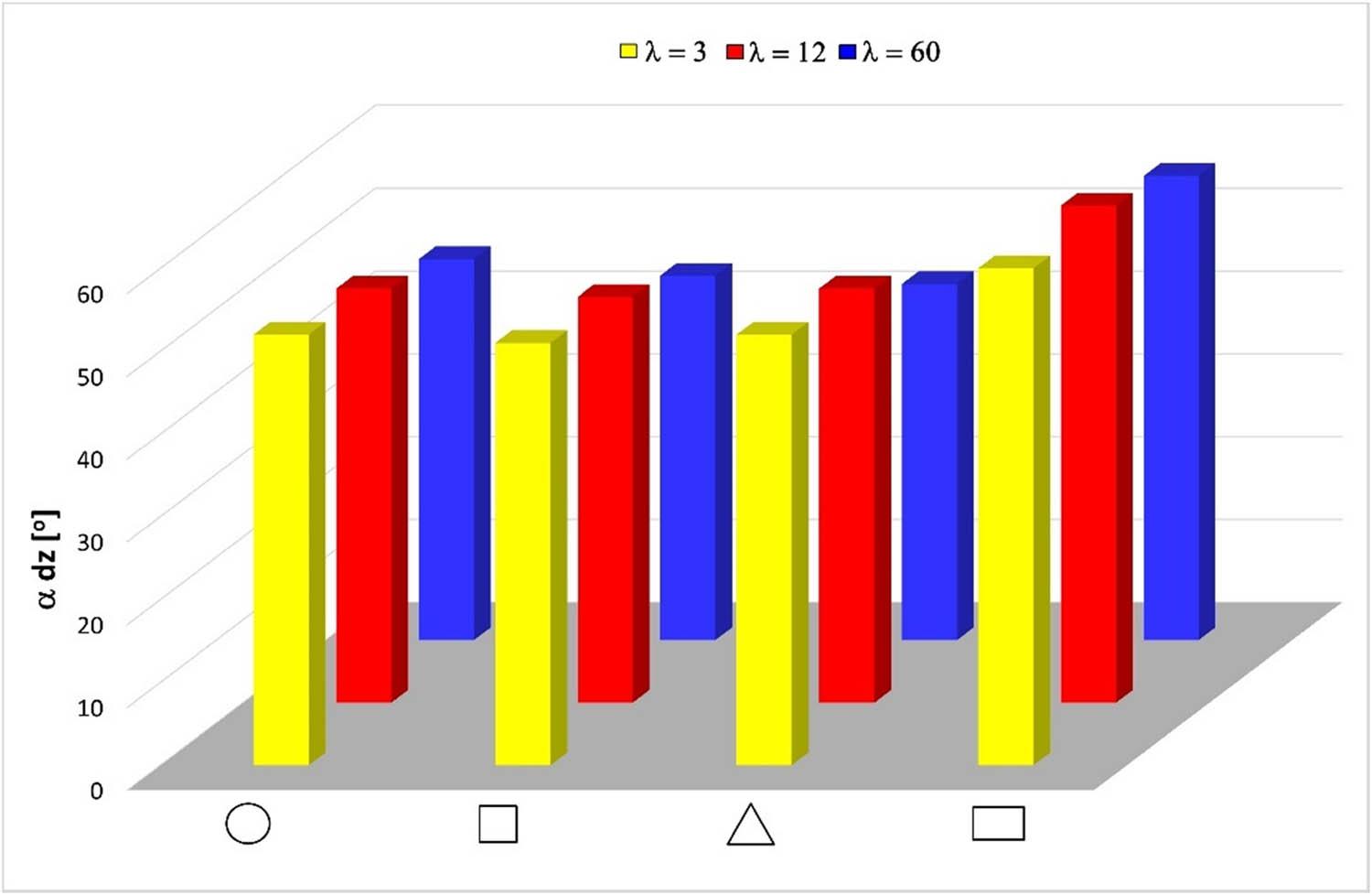

Figure 22

Chemical composition of the material used in the study (Pb1) – weight%_

| Pb | Ag | As | Bi | Fe | Cu | Zn | Sb | Sn |

|---|---|---|---|---|---|---|---|---|

| 99,98 | 0.0005 | 0.0005 | 0.0100 | 0.0006 | 0.0005 | 0.0005 | 0.0005 | 0.0005 |

Extrusion parameters_

| Extrusion speed (mm/s) | 1 |

| Extrusion ratio λ | 3; 12; 60 |

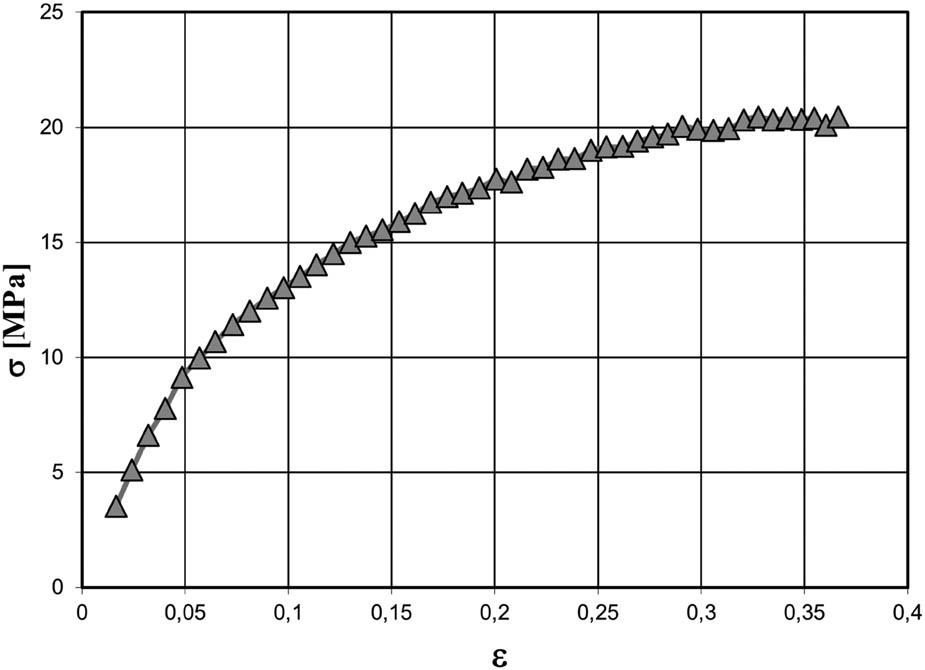

Basic mechanical properties of the material used in the study (Pb1)_

| Unit | ||

|---|---|---|

| Tensile strength R m | MPa | 17 |

| Yield strength R e | MPa | 5 |

| Elongation A | % | 45 |