High-performance concrete (HPC) has emerged as an essential material in modern construction due to its superior mechanical properties, enhanced durability, and excellent workability compared to conventional concrete systems [1]. The continuous pursuit of innovations to further enhance its performance has driven extensive research into new materials and additives, particularly as the construction industry faces unprecedented challenges in balancing infrastructure development demands with sustainable building practices [2,3]. Globally, concrete is classified as HPC when its compressive strength exceeds 50 MPa, achieved through optimized mix proportions, reduced water-to-binder ratios, and the incorporation of supplementary cementitious materials (SCMs) and chemical admixtures [4].

The evolution of HPC technology has been significantly influenced by advancements in superplasticizer technology, which allows for low water-to-cement ratios while maintaining adequate workability [5]. In addition, the incorporation of mineral additives has improved particle packing, enhanced compactness, and densified the porous structure of concrete [6,7]. The use of ultrafine particles, such as silica fume (SF), further enhances HPC’s performance by filling intergranular voids, densifying the cement paste–aggregate interface, and improving fresh-state rheology [8,9]. These pozzolanic materials react with free lime to form additional calcium silicate hydrates (C–S–H), which significantly increase mechanical strength and reduce permeability [10].

However, the construction industry’s environmental footprint has become increasingly scrutinized, with cement production alone accounting for approximately 8% of global carbon dioxide emissions [11]. This substantial environmental impact stems from the calcination process required to produce Portland cement, which releases CO2 from both chemical decomposition of limestone and fossil fuel combustion. Research has consistently demonstrated that SF incorporation can increase compressive strength by 20–40% and significantly improve the interfacial transition zone (ITZ) between cement paste and aggregates [12,13]. Nevertheless, exceeding certain threshold limits can negatively impact mechanical strength development, with studies identifying that SF content of 25% represents an optimal threshold, providing the best (Ca/Si) ratio [14]. Zhang et al. [6] noted that exceeding this SF content leads to reduced compressive strength, while several studies have reported low flowability issues at SF amounts higher than 25% [15,16].

Despite the proven benefits of SF, its industrial production process results in relatively high energy consumption (approximately 0.48 MJ/kg) and significant CO2 emissions compared to alternative materials [17]. This environmental concern, coupled with cost considerations and availability issues in certain regions, has motivated researchers to explore locally available materials that could provide similar or complementary benefits. In the pursuit of sustainable development, focus has shifted toward utilizing cost-effective materials such as metakaolin, fly ash, and ground granulated blast furnace slag, which have shown to enhance the ITZ and improve concrete performance [18,19]. Nanomaterials such as nano-silica have also gained attention for their ability to enhance hydration, reduce calcium hydroxide content, and promote C–S–H gel formation [20,21].

Desert sand, characterized by its high silica content (typically 80–95% SiO2), fine particle size distribution, and minimal extraction costs, presents a compelling opportunity for sustainable concrete production [22]. The vast reserves of dune sand in many regions represent an untapped opportunity for sustainable construction, being rich in quartz and silica, and known for its cleanliness and fineness [14]. Research has demonstrated the feasibility of incorporating dune sand into HPC, ultra-high-performance concrete, and self-compacting concrete, offering significant economic and ecological benefits [23].

The environmental advantages of utilizing desert sand are remarkable, with CO2 emissions recorded as only 0.0013 kg and energy consumption measured at 0.017 MJ/kg [24]. In comparison, while SF offers significant advantages for improving mechanical properties, it generates higher CO2 emissions and energy consumption due to its industrial production process [25]. These differences highlight the importance of selecting materials based on their environmental impacts and specific performance requirements in concrete formulations. Recent research has demonstrated that mechanical treatment of desert sand through crushing and grinding processes can significantly improve its suitability for concrete applications [26]. The crushing process creates angular particles with increased surface roughness, improving particle interlocking and bond strength within the concrete matrix. Studies have shown that crushed dune sand (CDS) exhibits pozzolanic activity when finely ground to particle sizes below 45 µm, contributing to long-term strength development through pozzolanic reactions [27]. The resulting CDS exhibits improved specific surface area and enhanced reactivity compared to uncrushed desert sand, making it suitable for use as both a fine aggregate and an SCM [28].

Research has demonstrated that optimal CDS replacement levels of 8–12% by weight of cement provide significant improvements in both fresh and hardened concrete properties [29]. CDS incorporation enhances workability through improved particle packing and reduced water demand, while also contributing to long-term strength development through pozzolanic reactions. Comparative studies have shown that CDS incorporation can achieve compressive strength improvements of 15–20% compared to control mixtures, while maintaining cost reductions of 15–25% compared to conventional HPC formulations [30,31].

Recent advances in sustainable concrete technology have emphasized the importance of binary and ternary binder systems that combine multiple SCMs to achieve synergistic effects [32]. The combination of CDS with SF represents a particularly promising approach, as the materials can complement each other’s characteristics while optimizing both performance and sustainability metrics [26]. Research has shown that binary systems incorporating both CDS and SF can achieve superior performance compared to single-material replacement strategies, with optimal combinations typically involving 8–12% CDS and 6–10% SF by weight of cement [33,34,35].

Although substantial progress has been made in HPC technology in recent years, a critical research gap remains in the efficient utilization of local mineral admixtures, especially in regions like Algeria, where local mineral resources are abundant but not fully harnessed for industrial applications. The lack of advanced research in this area limits the potential to optimize these materials, which could offer significant economic and environmental benefits. Bridging this gap is essential to enhance sustainable development in such regions.

The present study aims to examine the impact of incorporating CDS and SF on the physico-mechanical behavior of HPCs. The purpose is first to better understand how these alternative materials can influence concrete properties to provide guidelines for optimizing HPC formulations and second to maximize performance while reducing environmental impact.

The novelty of this study lies in four main aspects: (i) the systematic characterization of mechanically processed desert sand from the Algerian Sahara as a SCM, (ii) a direct comparative evaluation of CDS and SF across fresh, mechanical, durability, and microstructural properties, (iii) demonstration of the superior cost-effectiveness and environmental advantages of CDS relative to conventional additives, and (iv) the development of optimized HPC mixtures that integrate locally available resources to achieve both structural efficiency and sustainability. These contributions address a critical research gap and provide new insights into the use of desert sand for sustainable construction in arid regions.

The materials used in this experimental investigation were carefully selected to ensure consistent quality and reliable results. All materials were characterized according to the relevant international standards to establish their physical, chemical, and mechanical properties. This section provides detailed information about each constituent material used in the HPC formulations.

The binding agent used throughout this study was Portland cement Type CEM I 42.5R, conforming to the European Standard EN 197-1. This cement type was selected due to its high early strength development and consistent performance characteristics. The cement exhibited excellent hydraulic properties with a specific surface area of 3,850 cm2/g determined by the Blaine permeability test according to ASTM C204. The chemical composition analysis revealed typical Portland cement characteristics with C3S content of 58.2%, C2S of 18.7%, C3A of 8.4%, and C4AF of 9.8%. The physical properties included a normal consistency of 28.5% and an initial setting time of 165 min, meeting the requirements for HPC applications. The cement’s fineness and consistent particle size distribution contributed to improved workability and enhanced pozzolanic reactions when combined with supplementary materials.

Natural river sand was used as the primary fine aggregate, obtained from quarries oued m’zi en Algeria and characterized according to ASTM C33 specifications. The sand exhibited a fineness modulus of 2.68, indicating well-graded particle distribution suitable for concrete production. Specific gravity was determined to be 2.64 g/cm3 with an absorption capacity of 1.2%. The sand showed excellent soundness properties with minimal deleterious substances, ensuring durability of the final concrete product. Particle size analysis revealed 95% passing through 4.75 mm sieve and less than 3% passing 0.075 mm sieve, confirming appropriate grading for high-performance applications.

Limestone gravel was employed as coarse aggregate in two distinct size fractions: 3/8 and 8/16 mm. The limestone aggregate demonstrated excellent mechanical properties with a crushing value of 18.2% and an impact value of 14.5%, indicating superior strength characteristics. Specific gravity values were 2.68 g/cm3 for the 3/8 mm fraction and 2.69 g/cm3 for the 8/16 mm fraction. Water absorption rates were measured at 0.8 and 0.6%, respectively, demonstrating low porosity and high durability potential. The angular particle shape and rough surface texture provided excellent bonding characteristics with the cement matrix, contributing to enhanced mechanical properties.

Commercially available SF was incorporated as a highly reactive pozzolanic material. The SF was supplied in a micro-pellet form, consisting of agglomerated individual particles forming larger clusters with a bulk density ranging from 200 to 600 kg/m3. This form facilitates handling and reduces dusting during mixing operations. Chemical analysis revealed SiO2 content of 94.3%, with minimal impurities including 0.8% Al2O3, 0.4% Fe2O3, and 0.9% alkalis. The material exhibited extremely fine particle size with an average diameter of 0.15 μm and a specific surface area of 205,000 cm2/g measured by the Brunauer–Emmett–Teller (BET) method. This ultrafine characteristic enables efficient filling of voids and significant pozzolanic activity. The amorphous nature of the silica was confirmed through X-ray diffraction (XRD) analysis, ensuring high reactivity with calcium hydroxide produced during cement hydration.

Desert sand obtained from the Taghit region of southwestern Algeria was mechanically processed to produce CDS for use as an SCM. The raw dune sand underwent controlled crushing and grinding operations using ball mill equipment to achieve the desired particle size distribution. Following mechanical processing, the material was oven dried at 105°C for 24 h to remove residual moisture and then sieved to pass through an 80 µm mesh to ensure appropriate fineness for pozzolanic applications.

Chemical composition analysis of the processed CDS revealed a high silica content of 89.7% SiO2, with secondary components including 4.2% Al2O3, 2.1% Fe2O3, 1.3% CaO, 0.3% MgO, 0.4% Na2O, 0.8% K2O, and a total loss on ignition (L.O.I) of less than 1.2%. Mechanical processing substantially improved the material’s specific surface area from 18,000 cm2/g in its natural state to 2,850 m2/kg after grinding, thereby enhancing its potential pozzolanic reactivity. Particle size distribution analysis indicated a median particle diameter (d 50) of 12.5 µm, with 90% of particles finer than 45 µm, meeting the requirements for SCMs. The crushing process transformed the originally spherical particles into angular morphologies with increased surface roughness, which is expected to improve mechanical interlocking within the concrete matrix.

To ensure reliability and standardization of the reported properties, the characterization tests were carried out in accordance with recognized ASTM standards. Density was measured following ASTM C188 (Standard Test Method for Density of Hydraulic Cement), while the specific surface area was determined using the BET method in accordance with ASTM C204. Particle size distribution was analyzed using a laser diffraction technique according to ASTM C430, with measurements conducted on a Malvern Mastersizer 3000. The specific surface area was additionally confirmed by nitrogen adsorption analysis to provide an accurate assessment of particle fineness. These standardized methods provide a robust and reliable basis for characterizing CDS and affirm its suitability for pozzolanic applications in concrete.

A high-performance superplasticizer based on polycarboxylate ether technology was employed to maintain workability while reducing water content. This third-generation admixture complies with European Standard EN 934-2 and demonstrates excellent dispersion characteristics. The admixture exhibits a specific gravity of 1.08 g/cm3 and pH value of 6.2, ensuring compatibility with cement systems. Its polycarboxylate structure provides superior water reduction capabilities of up to 25% while maintaining extended workability retention. The admixture’s molecular structure allows for controlled hydration and improved particle dispersion, contributing to enhanced mechanical properties and durability.

Potable water conforming to ASTM C1602 specifications was used for all mixing operations. The water exhibited pH value of 7.2 with total dissolved solids content of 180 ppm, well within acceptable limits for concrete production. Chemical analysis confirmed the absence of harmful substances including sulfates (<150 ppm), chlorides (<100 ppm), and organic compounds that could adversely affect cement hydration or steel reinforcement durability.

All materials were stored under controlled conditions to maintain consistent properties throughout the experimental program. Cement was stored in sealed containers to prevent moisture absorption and carbonation. Aggregates were maintained in saturated surface-dry condition before mixing to ensure accurate water–cement ratio calculations. Supplementary materials were kept in dry storage with regular monitoring of moisture content. Chemical admixtures were stored at room temperature and thoroughly mixed before each use to ensure homogeneous distribution. Quality control measures included regular testing of material properties and batch-to-batch consistency verification to ensure reliable experimental results.

The experimental program was designed to examine the individual effects of CDS and SF on the properties of HPC, with the sand, gravel, superplasticizer, and water kept constant across all mixtures. This was done to isolate the effects of CDS and SF, ensuring that no other factors influenced the study. The mix design followed the absolute volume method to ensure consistent concrete density while optimizing performance characteristics. A water-to-binder ratio of 0.35 was maintained across all mixtures to classify the concrete as high-performance. The superplasticizer dosage was kept fixed to ensure the target slump flow of 180 ± 20 mm for optimal workability was achieved.

All tests were carried out in accordance with international standards to ensure consistency and reproducibility. The reference procedures followed included ASTM C39 and EN 12390-3 for compressive strength, ASTM C78 for flexural strength, and ASTM C597 for ultrasonic pulse velocity (UPV). Cylindrical and prismatic specimens were prepared with standardized dimensions: 100 × 200 mm cylinders for compressive strength and ultrasonic testing, and 100 × 100 × 400 mm prisms for flexural strength. Curing was performed in lime-saturated water at 20 ± 2°C until the designated test age. Mechanical and durability tests were conducted at 7, 28, 90, 190, and 365 days to evaluate both early and long-term performance. For each property, a minimum of three replicate specimens were tested to ensure statistical reliability, and the average values are reported. These procedures provide a comprehensive basis for evaluating the performance of HPC mixtures containing SF and CDS.

Seven distinct HPC formulations were systematically developed with cement replacement levels ranging from 5 to 15% by weight, incorporating SF and CDS both individually. The control mixture (HPC0%) contained 500 kg/m3 ordinary Portland cement, establishing the baseline composition for comparative analysis. Cement replacement strategies included individual SF incorporation at 5 and 10% levels, CDS at 5, 10, and 15% levels, and combined SF-CDS formulations maintaining equivalent total replacement percentages. The formulation methodology employed systematic binder modification while preserving aggregate grading and chemical admixture proportions to enable the direct assessment of pozzolanic material effectiveness. Table 1 presents the detailed mix proportions together with the fresh bulk density of concrete mixtures, measured immediately after mixing according to ASTM C138, thus reflecting unit weight values at the fresh state prior to casting and curing. The comprehensive results of all concrete formulations are presented in Table 1, with abbreviations for different concrete mixtures listed in Table 2.

Formulation of the different HPC (kg/m3).

| Element (kg/m3) | HPC | ||||||

|---|---|---|---|---|---|---|---|

| HPC0% | HPC5% SF | HPC5% CDS | HPC10% SF | HPC10% CDS | HPC15% SF | HPC15% CDS | |

| Cement | 500 | 475 | 475 | 450 | 450 | 425 | 425 |

| Crushed dune sand (CDS) | — | — | 25 | 00 | 50 | — | 75 |

| Silica fume (SF) | — | 25 | — | 50 | — | 75 | — |

| Sand (S) | 720.26 | 720.26 | 720.26 | 720.26 | 720.26 | 720.26 | 720.26 |

| Gravel (G) | 1050.22 | 1050.22 | 1050.22 | 1050.22 | 1050.22 | 1050.22 | 1050.22 |

| Superplasticizer | 2% | 2% | 2% | 2% | 2% | 2% | 2% |

| Water (W) | 150 | 150 | 150 | 150 | 150 | 150 | 150 |

| G/S | 1.46 | 1.46 | 1.46 | 1.46 | 1.46 | 1.46 | 1.46 |

| W/C | 0.300 | 0.316 | 0.316 | 0.333 | 0.333 | 0.353 | 0.353 |

| Density | 2417.00 | 2409.29 | 2412.96 | 2402.63 | 2408.94 | 2395.51 | 2404.93 |

Abbreviations for different concrete mixtures.

| Abbreviation | Concrete type |

|---|---|

| HPC0% | Reference concrete without mineral additions |

| HPC5% SF | Formulated with 5% of silica fume (SF) |

| HPC10% SF | Formulated with 10% of silica fume (SF) |

| HPC15% SF | Formulated with 15% of silica fume (SF) |

| HPC5% CDS | Formulated with 5% of crushed dune sand (CDS) |

| HPC10% CDS | Formulated with 10% of crushed dune sand (CDS) |

| HPC15% CDS | Formulated with 15% of crushed dune sand (CDS) |

Fresh concrete specimens were prepared at the Cosider laboratory (Djelfa) following the standard curing procedures. The concrete samples were cast and stored in their molds within a controlled humid environment at 20°C temperature and 95% relative humidity for 24 h. After demolding, specimens were immersed in potable water maintained at 20°C until testing age. The physical and mechanical properties of control concrete and modified mixtures were subsequently evaluated and compared. The SCMs, CDS, and SF were incorporated at replacement levels of 5, 10, and 15% by mass of cement.

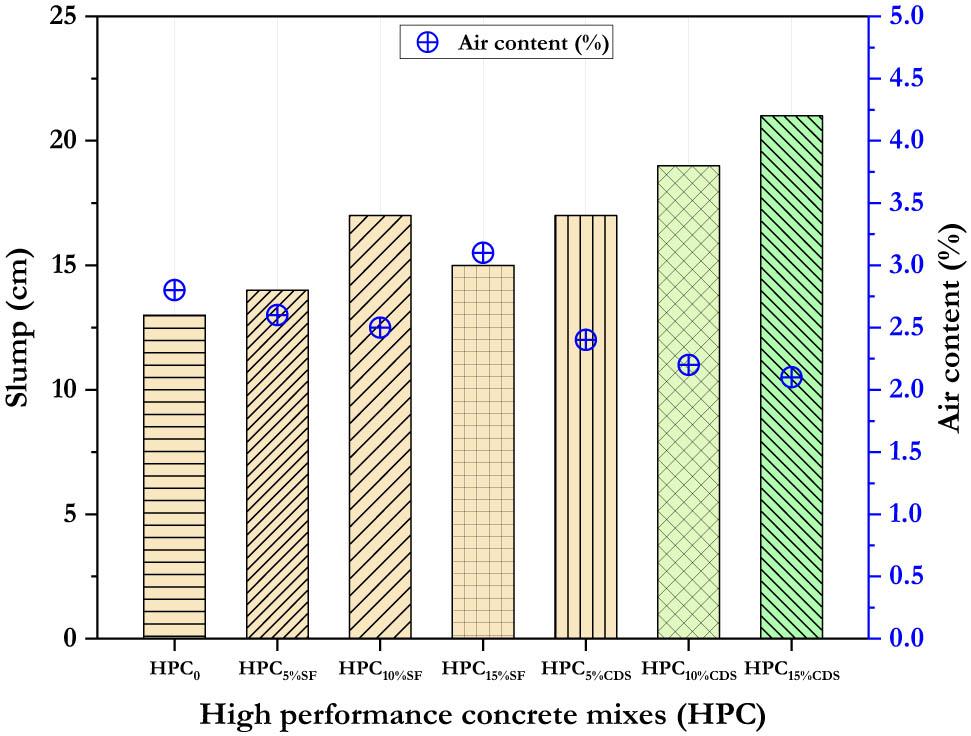

The effect of SF and CDS dosage on HPC workability was assessed using the Abrams cone slump test immediately after mixing. The experimental results, presented in Figure 1, indicate that incorporating these mineral materials significantly improves concrete workability. Both SF and CDS impart highly plastic rheological behavior to the concrete. Consequently, all HPC mixes exhibit plastic concrete characteristics with slump values ranging between 130 and 210 mm.

Experimental results of HPC in the fresh state.

Notably, HPCs containing SF demonstrate slight superiority in workability compared to those incorporating CDS. This difference can be primarily attributed to the spherical particle morphology of SF, which provides HPCs with increased viscosity and enhanced flow characteristics compared to HPCs containing CDS with its more angular particle geometry. Furthermore, all HPC formulations with mineral additions exhibit superior workability compared to the control concrete, which achieved a slump of 130 mm. These observations align with the findings reported in previous studies, confirming improved fluidity of fresh concrete following the incorporation of SCMs.

The air content test was conducted on the prepared HPCs in accordance with Standard NF EN 12350-7. This test operates on the principle of compressibility, assuming that air trapped within the concrete is the only compressible element. It is widely recognized that low entrained air content in concrete correlates with superior mechanical performance and enhanced durability. The air content was measured experimentally using a pressure meter and a concrete air meter apparatus.

The results regarding entrained air content are presented in Figure 1. The data clearly demonstrate that as the cement replacement rate with CDS increases, the entrained air content correspondingly increases. This phenomenon can be attributed to the lower density and specific surface area of CDS compared to cement. However, this trend does not apply to SF incorporation, where different behavior is observed due to its ultrafine particle characteristics and high specific surface area.

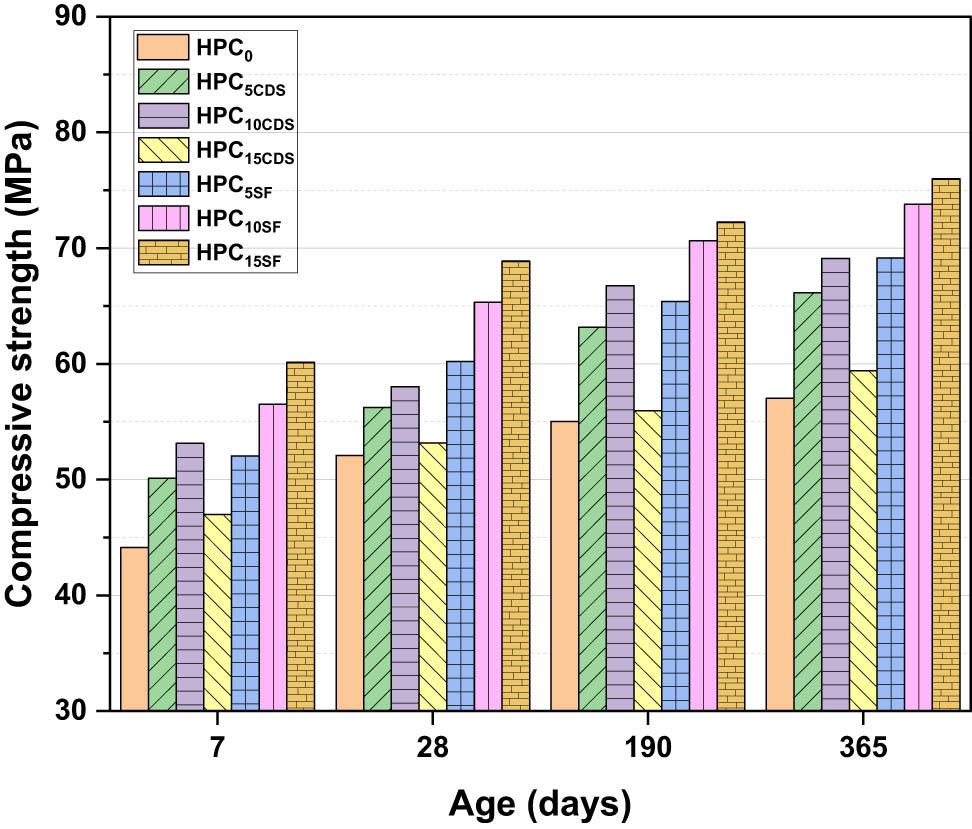

To investigate the effect of these parameters, the concrete specimens under study were subjected to compression tests to determine their compressive strength values at 7, 28, 190, and 365 days. The compressive strength results obtained for the seven concrete formulations represent the average of six tests conducted on specimens prepared from three prismatic samples that were previously subjected to flexural testing.

The resulting data are presented in Figure 2, which illustrates the mechanical behavior of the seven concrete series as a function of time at curing periods of 7, 28, 190, and 365 days in potable water storage. Generally, it is observed that the compressive strength of concretes containing 5, 10, and 15% SF exceeds that of the reference concrete after several days of curing. This compressive strength improvement is even more pronounced for concretes containing 5, 10, and 15% CDS.

Results of compressive strength from HPCs.

Figure 2 also demonstrates that the compressive strength of concretes containing 5 and 10% CDS surpasses that of the reference concrete across all testing periods (7, 28, 190, and 365 days). The results indicate that finely ground dune sand exhibits a beneficial effect on compressive strength up to approximately 10% replacement, with optimal performance observed between 5 and 10% replacement levels. Beyond 10% replacement, the dilution effect becomes predominant, resulting in reduced compressive strength values.

Previous studies have demonstrated that incorporating siliceous mineral additions, such as SF and crushed siliceous dune sand, enhances mechanical strengths in the medium and long term.

Similarly, the introduction of processed siliceous dune sand through controlled grinding procedures yields mechanical strength values superior to reference concretes and comparable to those containing SF. The mineral addition in the form of SiO2 promotes the formation of additional calcium silicate hydrate (C–S–H) gel, which contributes to improved compressive strength in mixtures containing SCMs.

After 28 days, pozzolanic reactions become more pronounced, resulting in secondary C–S–H gel formation that fills voids within the cement matrix, consequently reducing porosity and improving compressive strength. According to studies conducted by Arroudj et al. [36], the addition of crushed siliceous dune sand as cement replacement enables the production of modified cement with superior physicomechanical characteristics compared to conventional cement. This improvement is attributed to the pozzolanic reactivity of CDS and the micro-filling effect of its fine particles. Furthermore, the research by Allout et al. [37] demonstrated that the addition of CDS to cement enhances the compressive strength of concrete specimens at 28 days of age.

The enhancement in compressive strength observed in mixtures incorporating CDS can be explained by the combined physical and chemical contributions of this finely ground siliceous material. The ultrafine CDS particles act as microfillers, occupying voids within the cement matrix and improving particle packing, which reduces internal porosity. Moreover, the high silica content of CDS participates in secondary pozzolanic reactions with calcium hydroxide released during cement hydration, forming additional calcium silicate hydrate (C–S–H) gel that strengthens the matrix. The angular morphology of the crushed particles also promotes better mechanical interlocking and bond development at the ITZs, resulting in a denser and more cohesive microstructure.

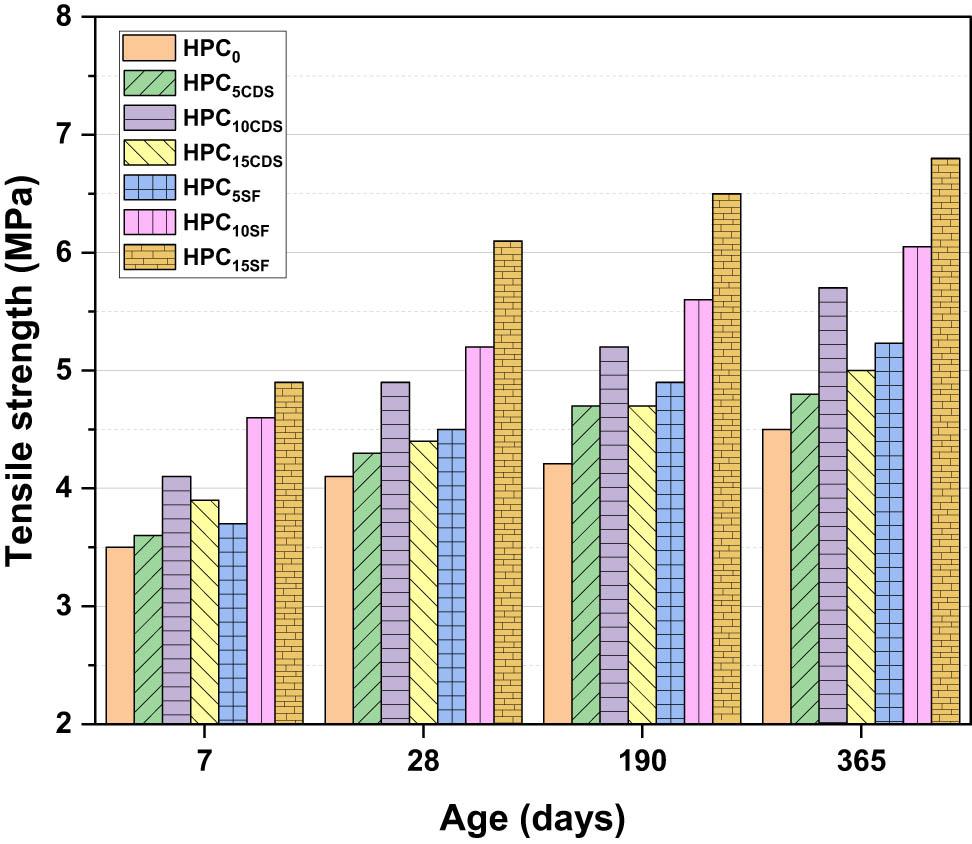

Three-point flexural tests were conducted on prismatic specimens to evaluate the bending performance of the concrete mixtures. The results of the flexural testing program carried out on the different concrete formulations under investigation are presented in Figure 3. Analysis of the average flexural tensile strength values reveals that HPCs incorporating SF exhibit slightly superior performance compared to those containing CDS. This observation can be attributed to the enhanced ITZ between aggregates and the cement matrix, which is promoted by the pozzolanic reactions induced by SF.

Results of tensile strength from HPCs.

Similar to the compressive strength behavior, a significant increase in flexural tensile strength was observed for the composition containing 10% CDS replacement. This improvement can be attributed to improved stress distribution and stronger bond development between aggregates and the cement matrix following CDS incorporation. The enhanced particle packing and micro-filling effect of CDS contributes to a denser ITZ, resulting in improved flexural performance.

However, beyond this optimal replacement level, specifically at higher substitution rates (15% CDS), the flexural tensile strength decreased. This reduction can be attributed to the dilution effect, where excess CDS particles may not participate effectively in pozzolanic reactions, leading to weakened bonding within the concrete matrix and consequently reduced flexural capacity.

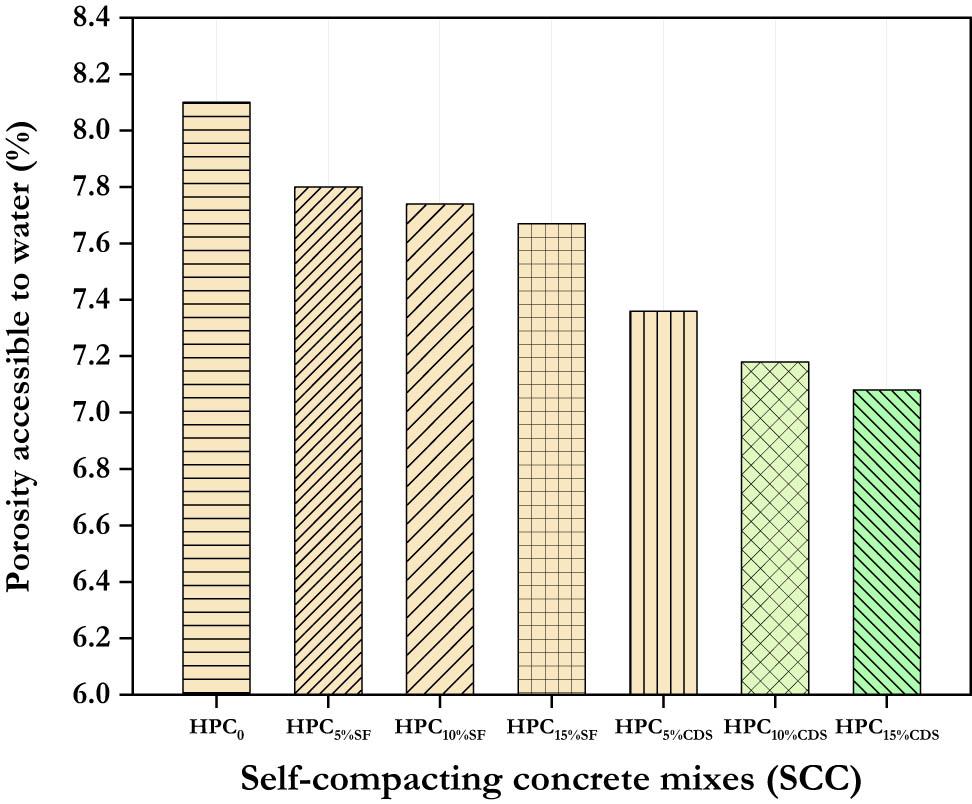

Porosity significantly influences multiple concrete characteristics including permeability, compressive strength, durability, and rheological behavior. Concretes with reduced porosity typically exhibit enhanced durability due to their lower permeability, which delays the ingress of water and other potentially aggressive agents such as sulfates, carbon dioxide, and chlorides.

Figure 4 illustrates the evolution of water-accessible porosity as a function of replacement levels for both CDS and SF. The experimental results demonstrate that HPCs containing SF exhibit significantly reduced porosity compared to the reference mixture. This reduction is attributed to two primary mechanisms: the physical filling effect of ultrafine SF particles, which reduces total porosity by occupying void spaces, and the chemical pozzolanic effect, which enhances the density and compactness of the cement matrix through additional C–S–H gel formation.

Porosity accessible to water of concretes as a function of the FS rate and CDS.

Similarly, the results presented in Figure 4 indicate that water-accessible porosity of CDS-modified formulations decreases progressively as the CDS content increases, contrasting with the behavior of the reference HPC. This porosity reduction can be attributed to the densification effect of CDS, which is rich in siliceous particles that contribute to improved particle packing efficiency. The combination of physical void filling and pozzolanic activity results in reduced overall porosity and increased matrix compactness in these concrete formulations.

The optimal porosity reduction was observed at 10% CDS replacement, aligning with the mechanical strength results and confirming the synergistic effects of proper particle size distribution and pozzolanic reactivity at this replacement level.

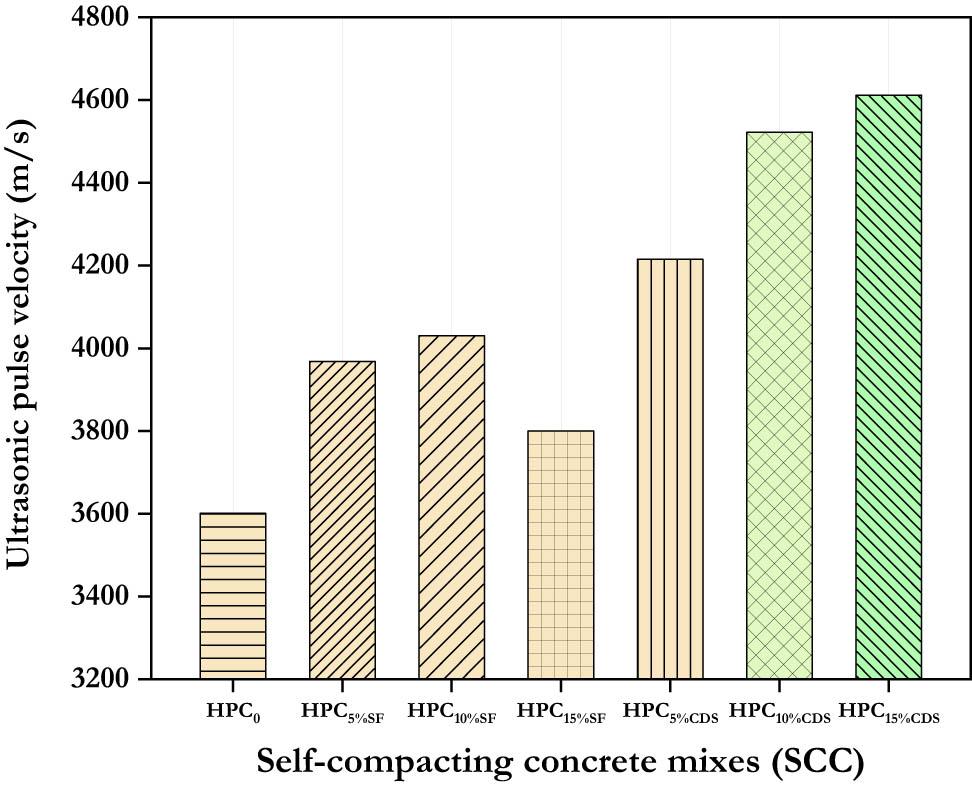

In this investigation, comprehensive nondestructive testing methodologies were implemented to evaluate the mechanical properties and structural integrity of HPC specimens without compromising their physical condition. A systematic approach utilizing both sclerometer testing (EN 12504-2) and UPV measurements was conducted on standardized specimens measuring 16 × 16 × 32 cm3 to assess surface hardness and internal quality characteristics. The sclerometer testing protocol involved systematic rebound measurements across a predetermined 3 × 3 cm2 grid pattern, enabling accurate compressive strength estimation through established correlations between rebound indices and mechanical properties, with comprehensive results presented in Table 3. Simultaneously, UPV measurements were performed to determine the propagation velocity of ultrasonic waves through the concrete matrix, providing valuable insights into material density, homogeneity, and microstructural characteristics that directly correlate with mechanical performance, as detailed in Table 4 and Figure 5.

Sclerometric index of the concretes tested.

| Type of concrete | HPC0% | HPC5% CDS | HPC10% CDS | HPC15% CDS | HPC5% SF | HPC10% SF | HPC15% SF |

|---|---|---|---|---|---|---|---|

| Rcavge | 49.9 | 54.23 | 55.75 | 50.78 | 59.45 | 63.15 | 66.01 |

| Rc28 (MPA) | 52.1 | 56.24 | 58.03 | 53.16 | 60.2 | 65.33 | 68.89 |

| Standard deviation | 2.2 | 2.01 | 2.28 | 2.38 | 0.75 | 2.18 | 2.88 |

Quality of concrete according to the speed of sound.

| Type of concrete | HPC0% | HPC5% CDS | HPC10% CDS | HPC15% CDS | HPC5% SF | HPC10% SF | HPC15% SF |

|---|---|---|---|---|---|---|---|

| Rc28 (MPA) | 52.1 | 56.24 | 58.03 | 53.16 | 60.2 | 65.33 | 68.89 |

| V (m/s) | 3,601 | 3,968 | 4,030 | 3,800 | 4,215 | 4,522 | 4,612 |

| Porosity accessible to water | 8.1 | 7.8 | 7.74 | 7.67 | 7.36 | 7.18 | 7.08 |

| Strength | Good | Good | Excellent | Good | Excellent | Excellent | Excellent |

UPV of concretes mixes.

The experimental results demonstrated that HPC mixtures incorporating SCMs, including CDS and SF, exhibited significantly enhanced UPV values compared to control specimens, indicating improved material density and reduced porosity within the concrete matrix. Among the tested formulations, HPC₁₅₊CDS achieved the highest UPV at approximately 4,600 m/s, representing a 28% improvement over the reference mixture HPC0 (3,580 m/s). This superior performance can be attributed to the combined effects of CDS acting as both a physical filler and a pozzolanic material, which refines the pore structure and enhances the ITZ. The progressive increase in UPV with higher CDS replacement levels confirms that the finely ground dune sand particles effectively fill the microvoids between cement grains while contributing to secondary C–S–H formation through pozzolanic reactions. Notably, all CDS-based mixtures consistently outperformed their SF counterparts in UPV measurements, suggesting that the particle size distribution and the morphology of CDS provide superior packing efficiency in the concrete matrix. These findings are consistent with the established principles that correlate higher pulse velocities with enhanced mechanical strength and reduced void content in cementitious composites [38]. The strong correlation observed between sclerometer rebound values and UPV measurements confirms the reliability of these nondestructive techniques for quality assessment and strength prediction in HPC applications, supporting their practical implementation in both laboratory evaluation and field assessment protocols for structural concrete containing alternative materials.

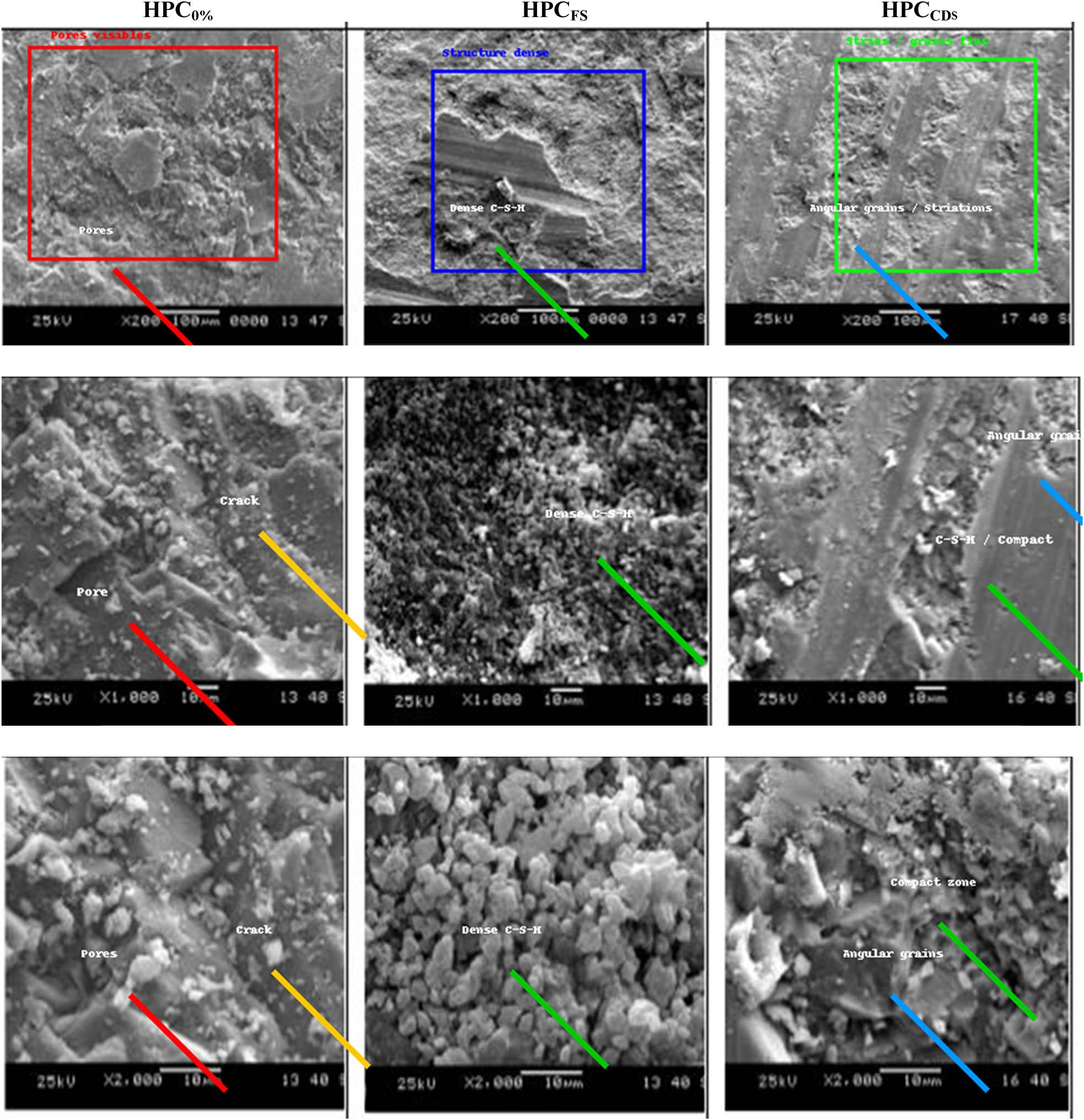

Figure 6 illustrates that the microstructural analysis carried out at different magnifications (×200, ×1,000, and ×2,000) highlights significant differences between the reference (HPCs), the BHP incorporating silica fume (FS), and the BHP incorporating CDS.

Microstructural analysis of the reference HPC as well as those of HPCs including additions (SF and CDS).

The micrographs reveal the ITZ between the cement matrix and aggregates, demonstrating variations in compactness and microporosity. These scanning electron microscopy images provide insights into two distinct aspects of the concrete microstructure.

Regarding mineral additions, the analysis reveals that HPC containing CDS exhibits higher porosity compared to HPC with SF. This observation can be attributed to the spherical morphology of SF particles, which promotes better packing density and reduces void space within the cement matrix. The incorporation of CDS leads to a more compact microstructure compared to the reference, mainly due to a physical filler effect. The angular particles of dune sand effectively occupy voids within the matrix, enhancing compactness.

The microstructural examination also highlights significant differences in the degree of interfacial bonding at the mortar–aggregate interface. Notably, the reference concrete without mineral additions demonstrates consistently weaker interfacial bonding compared to concretes incorporating SF or CDS. This enhanced interfacial integrity contributes to the superior mechanical properties observed in the modified concrete mixtures.

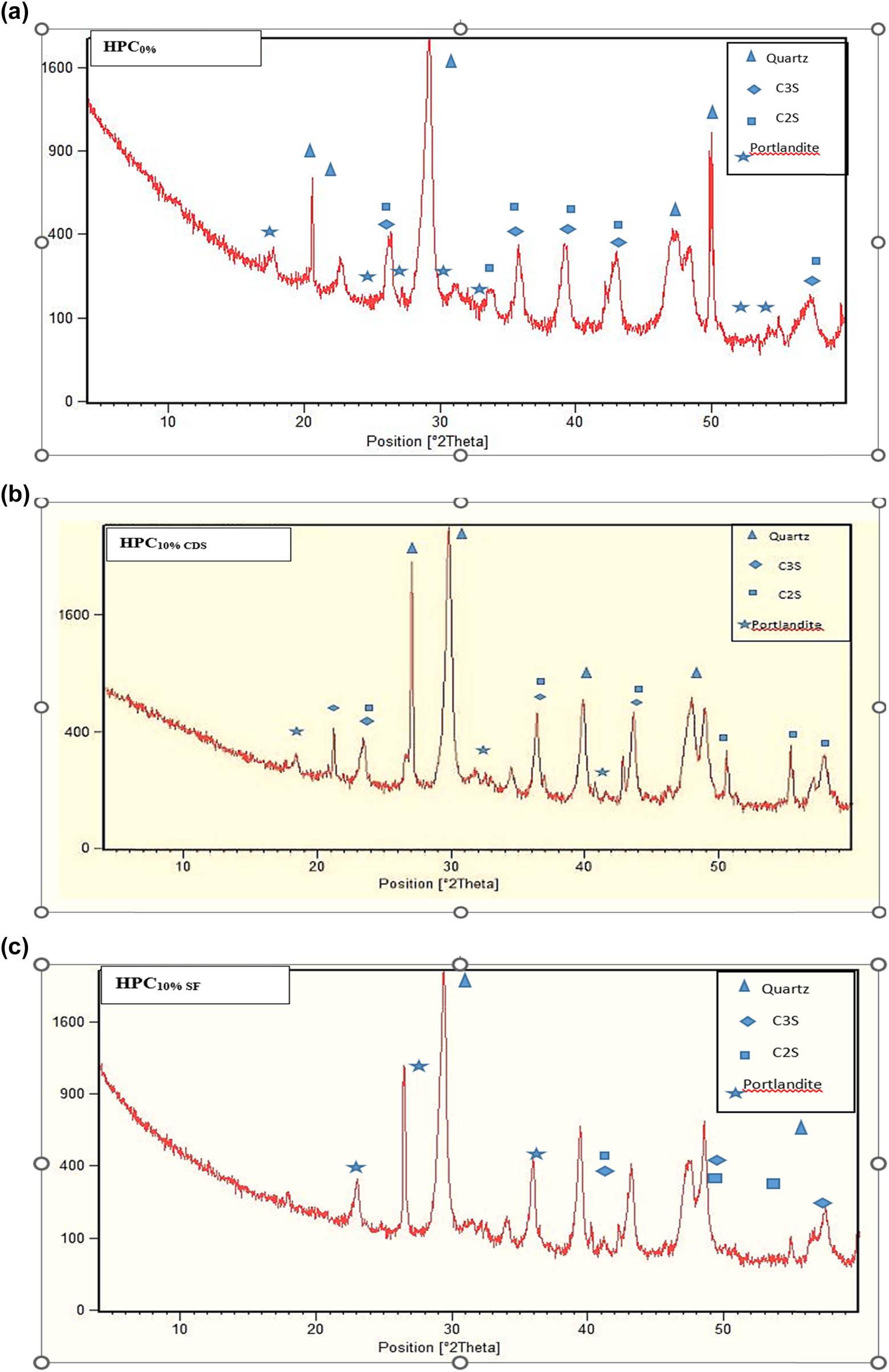

The X-ray diffractograms presented in Figure 7a–d provide a comparative analysis of the crystalline phases in reference HPC and those containing SF and CDS. The main crystalline constituents identified are quartz (SiO2), detected as the predominant peak at ∼26.5° (2θ), and calcite (CaCO3), both originating from the aggregate phase. Unhydrated cement phases such as tricalcium silicate (C3S) and dicalcium silicate (C2S) are also observed, confirming the partial hydration of clinker minerals. The most significant observation concerns the reduced intensity of the portlandite peak at ∼18° (2θ) in mixtures containing SF and CDS compared with the reference paste. In the case of SF, this marked decrease in Ca(OH)2 reflects its consumption through pozzolanic reactions, leading to the formation of additional calcium silicate hydrates (C–S–H), which contribute to the improved performance of the material. For CDS, a moderate reduction in portlandite is observed, indicating a limited but measurable pozzolanic contribution, with its primary effect attributed to the filler action of fine particles, enhancing particle packing. The persistence of quartz and calcite peaks, though less pronounced, further supports the densification of the microstructure. These findings confirm that mineral additions refine the ITZs by increasing C–S–H formation and reducing portlandite, thereby improving compactness and mechanical performance. This interpretation is consistent with previous work by Guettala and Mezghiche [39], who reported that XRD effectively reveals the partial pozzolanic reactivity of CDS, as evidenced by minimal portlandite detection in cement pastes. Overall, the combined pozzolanic activity of SF and the physical filling effect of finely ground dune sand produce blended cements with enhanced physico-mechanical properties, validating the high-performance character of the studied concretes.

(a) XRD pattern of the reference HPC (HPC0%), showing the main crystalline phases (Quartz, C3S, C2S, Portlandite). (b) XRD pattern of HPC containing crushed dune sand (HPC + CDS), with partial portlandite reduction and an intensified quartz peak at ∼26.5° (2θ). (c) X-diffraction patterns of the reference HPC as well as those of HPCs including additions (SF and CDS). (d) Superimposed XRD patterns: Comparison between the reference HPC and the HPCs including additions (SF and CSD).

This investigation demonstrates that CDS serves as an effective SCM for HPC. The optimal 10% cement replacement with CDS achieved 58.03 MPa compressive strength at 28 days, representing an 11.4% improvement over reference concrete while reducing porosity from 8.1 to 7.2%.

CDS enhances concrete performance through combined physical filler effects and pozzolanic reactions that generate additional calcium silicate hydrate gel. Microstructural analysis confirms improved interfacial bonding and reduced portlandite content, validating the dual improvement mechanisms.

The environmental advantages are substantial: CDS exhibits minimal CO2 emissions (0.0013 kg/kg) and energy consumption (0.017 MJ/kg) compared to conventional additives. Combined with local availability, this positions CDS as a sustainable and economical alternative for arid regions.

This research establishes CDS as a viable replacement for traditional SCMs, offering both superior performance and environmental benefits. The findings support broader adoption of locally sourced materials in sustainable concrete technology, particularly in desert regions where conventional additives are costly or unavailable.

Princess Nourah bint Abdulrahman University Researchers Supporting Project number (PNURSP2025R308), Princess Nourah bint Abdulrahman University, Riyadh, Saudi Arabia.

Authors state no funding involved.

All authors contributed to the work equally.

Authors state no conflict of interest.