Figure 1

![Analysis of a doubly reinforced rectangular beam [9]. (a) Cross-section, (b) Strain distribution, (c) Stress and forces, (d) Forces from Part 1, and (e) Forces from Part 2.](https://sciendo-parsed.s3.eu-central-1.amazonaws.com/68b873faafc50a4de096ddc8/j_msp-2025-0034_fig_001.jpg?X-Amz-Algorithm=AWS4-HMAC-SHA256&X-Amz-Content-Sha256=UNSIGNED-PAYLOAD&X-Amz-Credential=AKIA6AP2G7AKOUXAVR44%2F20251204%2Feu-central-1%2Fs3%2Faws4_request&X-Amz-Date=20251204T142044Z&X-Amz-Expires=3600&X-Amz-Signature=604923ab58e2e1601a92d84e8b5db6345cd64c5cc74381faa72358673a89826e&X-Amz-SignedHeaders=host&x-amz-checksum-mode=ENABLED&x-id=GetObject)

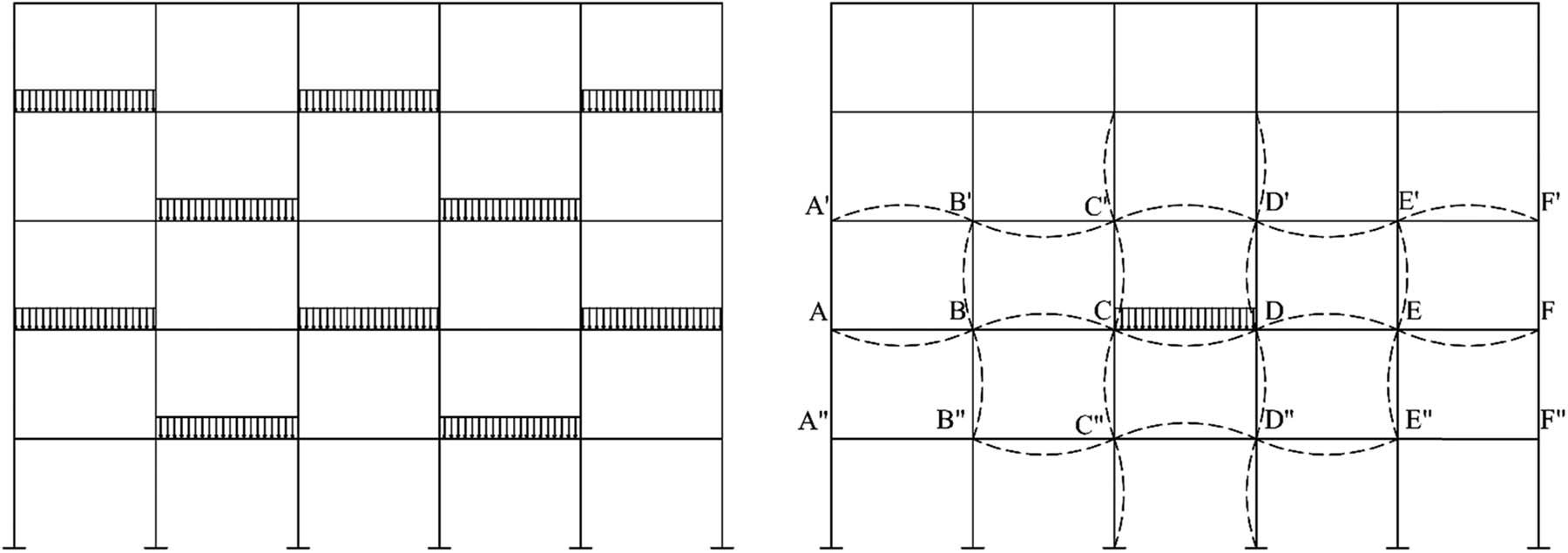

Figure 2

Figure 3

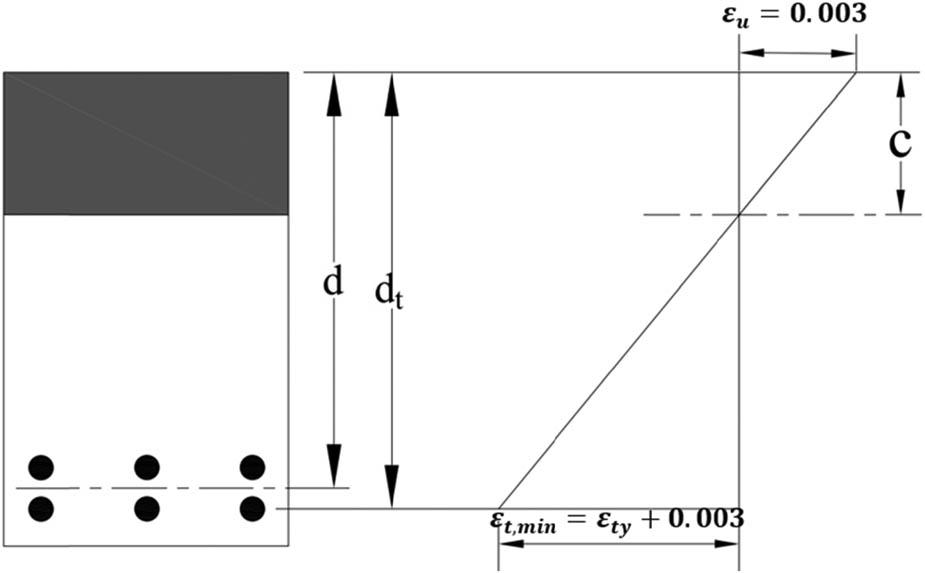

Figure 4

Figure 5

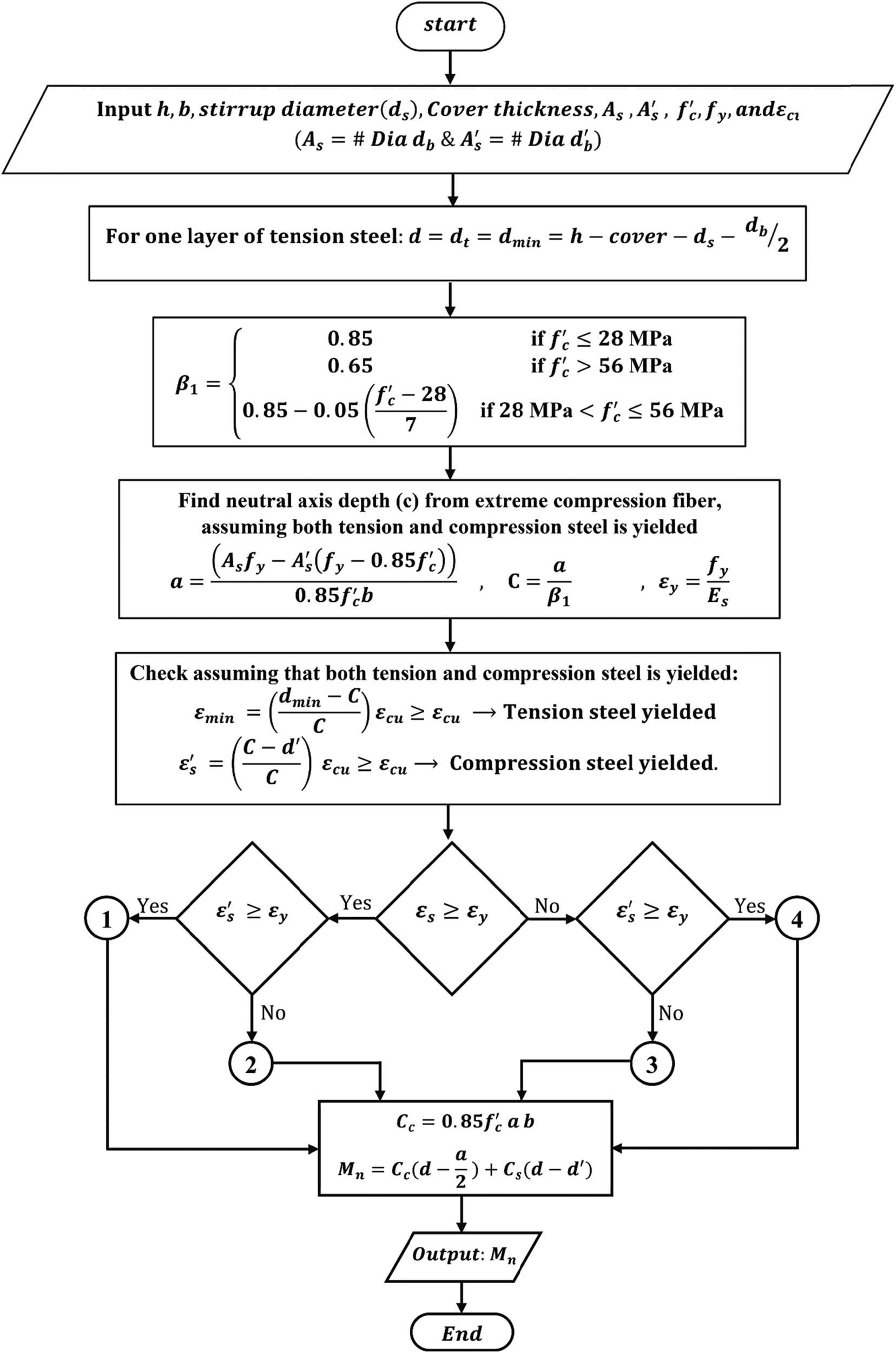

Figure 6

Figure 7

Figure 8

Figure 9

Figure 10

Figure 11

Figure 12

Figure 13

Figure 14

Figure 15

Figure 16

Figure 17

![Initial, tangent, and secant moduli of elasticity of concrete [9].](https://sciendo-parsed.s3.eu-central-1.amazonaws.com/68b873faafc50a4de096ddc8/j_msp-2025-0034_fig_017.jpg?X-Amz-Algorithm=AWS4-HMAC-SHA256&X-Amz-Content-Sha256=UNSIGNED-PAYLOAD&X-Amz-Credential=AKIA6AP2G7AKOUXAVR44%2F20251204%2Feu-central-1%2Fs3%2Faws4_request&X-Amz-Date=20251204T142044Z&X-Amz-Expires=3600&X-Amz-Signature=0e6d1d3a95e8f43527f41dd6bea8415e04e6e625b344f84c5aa31fd45295ebaf&X-Amz-SignedHeaders=host&x-amz-checksum-mode=ENABLED&x-id=GetObject)

Figure 18

![Typical concrete stress–strain curves in compression [9].](https://sciendo-parsed.s3.eu-central-1.amazonaws.com/68b873faafc50a4de096ddc8/j_msp-2025-0034_fig_018.jpg?X-Amz-Algorithm=AWS4-HMAC-SHA256&X-Amz-Content-Sha256=UNSIGNED-PAYLOAD&X-Amz-Credential=AKIA6AP2G7AKOUXAVR44%2F20251204%2Feu-central-1%2Fs3%2Faws4_request&X-Amz-Date=20251204T142044Z&X-Amz-Expires=3600&X-Amz-Signature=e6b54b4ba248a7f5e09439ff938b792cf9c17cb01a1b6a65aff08f13b03c155f&X-Amz-SignedHeaders=host&x-amz-checksum-mode=ENABLED&x-id=GetObject)

Figure 19

![Analytical approximation to the compressive stress–strain curve for concrete [9].](https://sciendo-parsed.s3.eu-central-1.amazonaws.com/68b873faafc50a4de096ddc8/j_msp-2025-0034_fig_019.jpg?X-Amz-Algorithm=AWS4-HMAC-SHA256&X-Amz-Content-Sha256=UNSIGNED-PAYLOAD&X-Amz-Credential=AKIA6AP2G7AKOUXAVR44%2F20251204%2Feu-central-1%2Fs3%2Faws4_request&X-Amz-Date=20251204T142044Z&X-Amz-Expires=3600&X-Amz-Signature=b7d12fbe3d17fe0404a46bf9927b60171e87e1b1f3c33e2b1ffc8d4df3302cfa&X-Amz-SignedHeaders=host&x-amz-checksum-mode=ENABLED&x-id=GetObject)

Figure 20

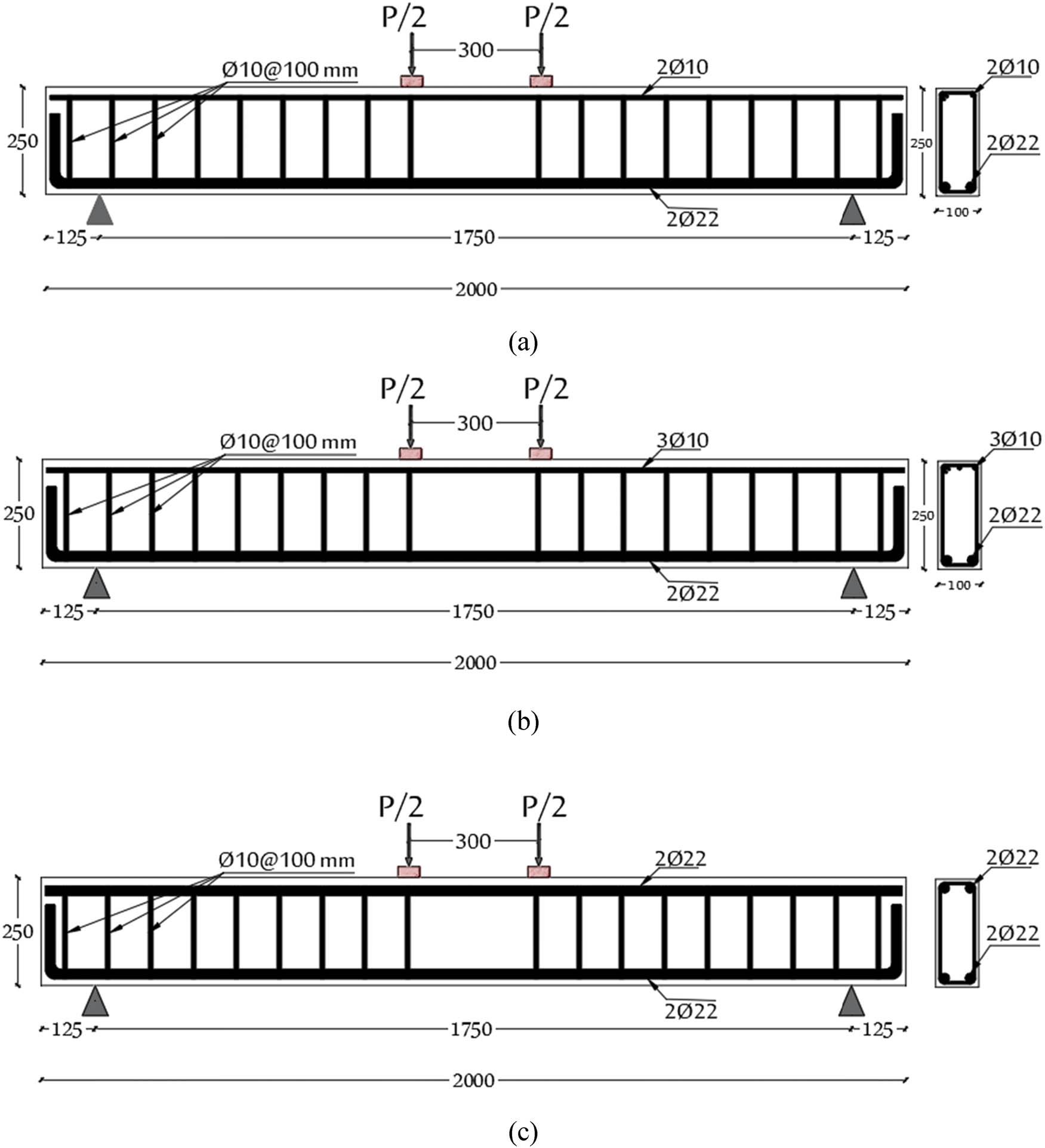

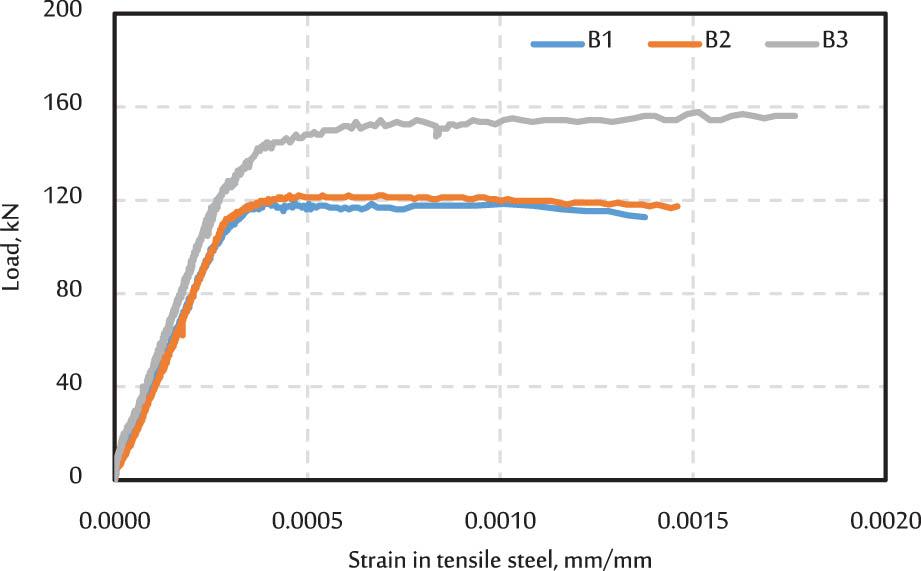

Compression steel in the tested beams_

| Beam ID |

|

|

| Details |

|---|---|---|---|---|

| B1 | 2Ø22 | 2Ø10 | 0.2 | Figure 6(a) |

| B2 | 2Ø22 | 3Ø10 | 0.3 | Figure 6(b) |

| B3 | 2Ø22 | 2Ø22 | 1.0 | Figure 6(c) |

Concrete mix proportion (m3)_

| Cement | Dolomite | Sand | Water | Admixture |

|---|---|---|---|---|

| 350 kg | 1,292 kg | 646 kg | 175 L | 5.4 kg |

Comparison of experimental and proposed method results_

| Point of comparison | B1 beam | B2 beam | B3 beam | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Experimental | Analytical | % | Experimental | Analytical | % | Experimental | Analytical | % | |

| Failure load (kN) | 118.4 | 105.9 | +11.8% | 122.0 | 111.1 | +9.8% | 166.0 | 150.2 | +10.5% |

| Nominal moment strength* (kN m) | 42.92 | 38.39 | +11.8% | 44.23 | 40.27 | +9.8% | 60.18 | 54.45 | +10.5% |

| Concrete compressive strain at failure | 0.001526 | 0.001507 | +1.3% | 0.001413 | 0.001507 | −6.2% | 0.001518 | 0.001507 | +0.7% |

| Strain in tension steel at failure | 0.001376 | 0.001365 | +0.8% | 0.001460 | 0.001446 | +1.0% | 0.001765 | 0.001729 | +2.1% |

| Strain in compressive steel at failure | 0.001344 | 0.001330 | +1.1% | 0.001211 | 0.001194 | +1.4% | 0.000979 | 0.001054 | −7.1% |