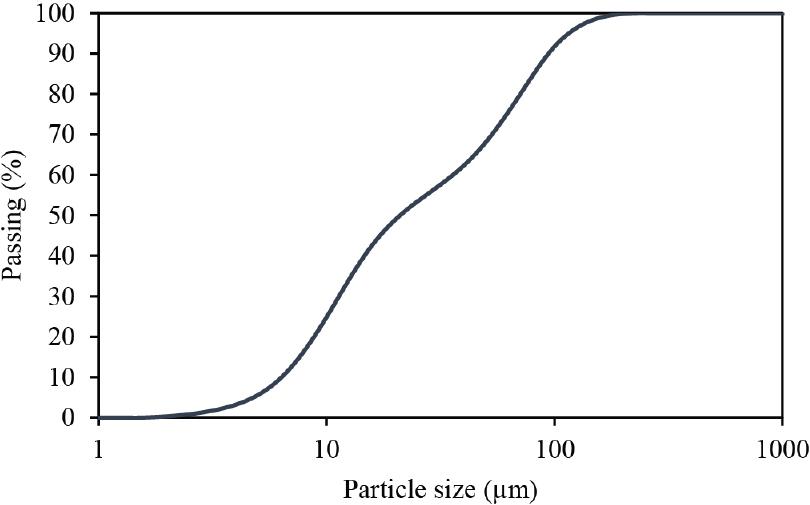

Fig. 1.

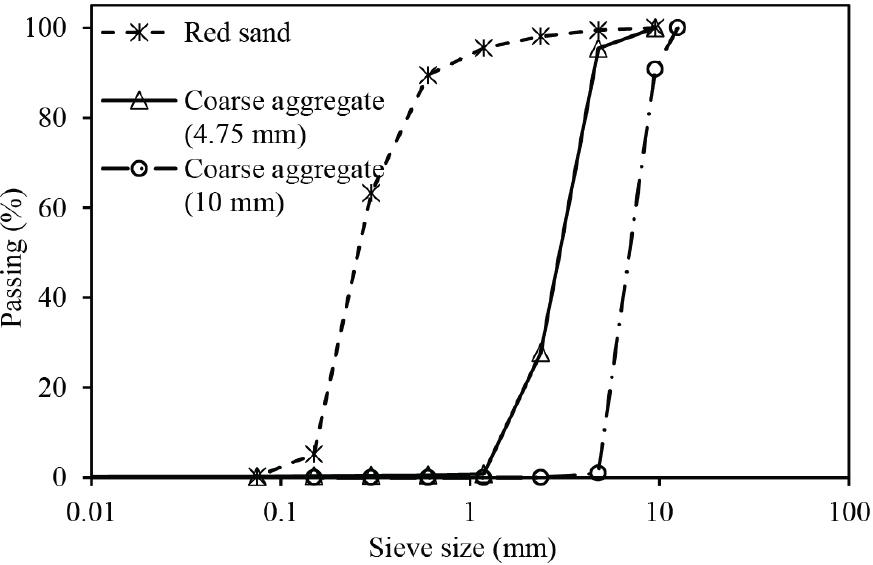

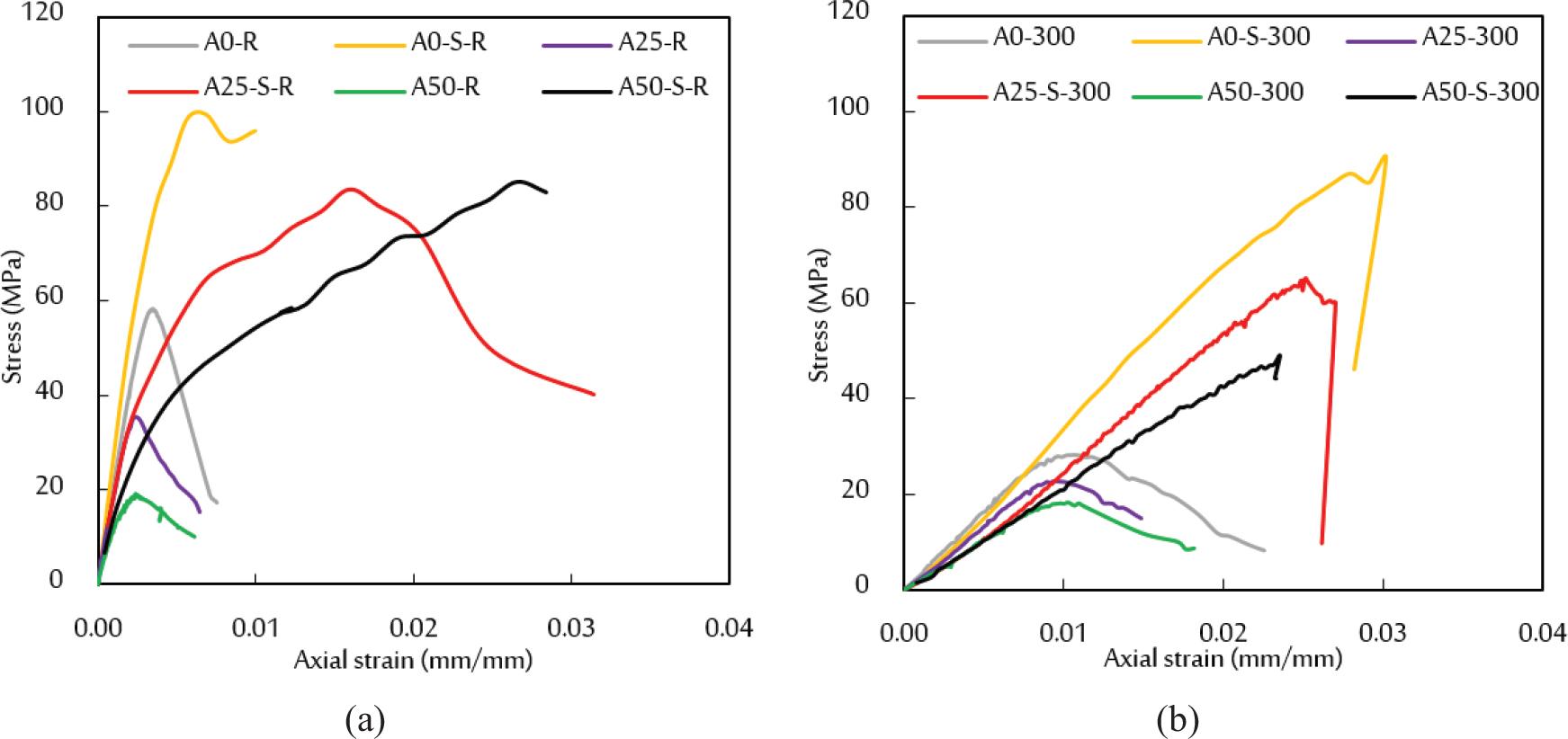

Fig. 2.

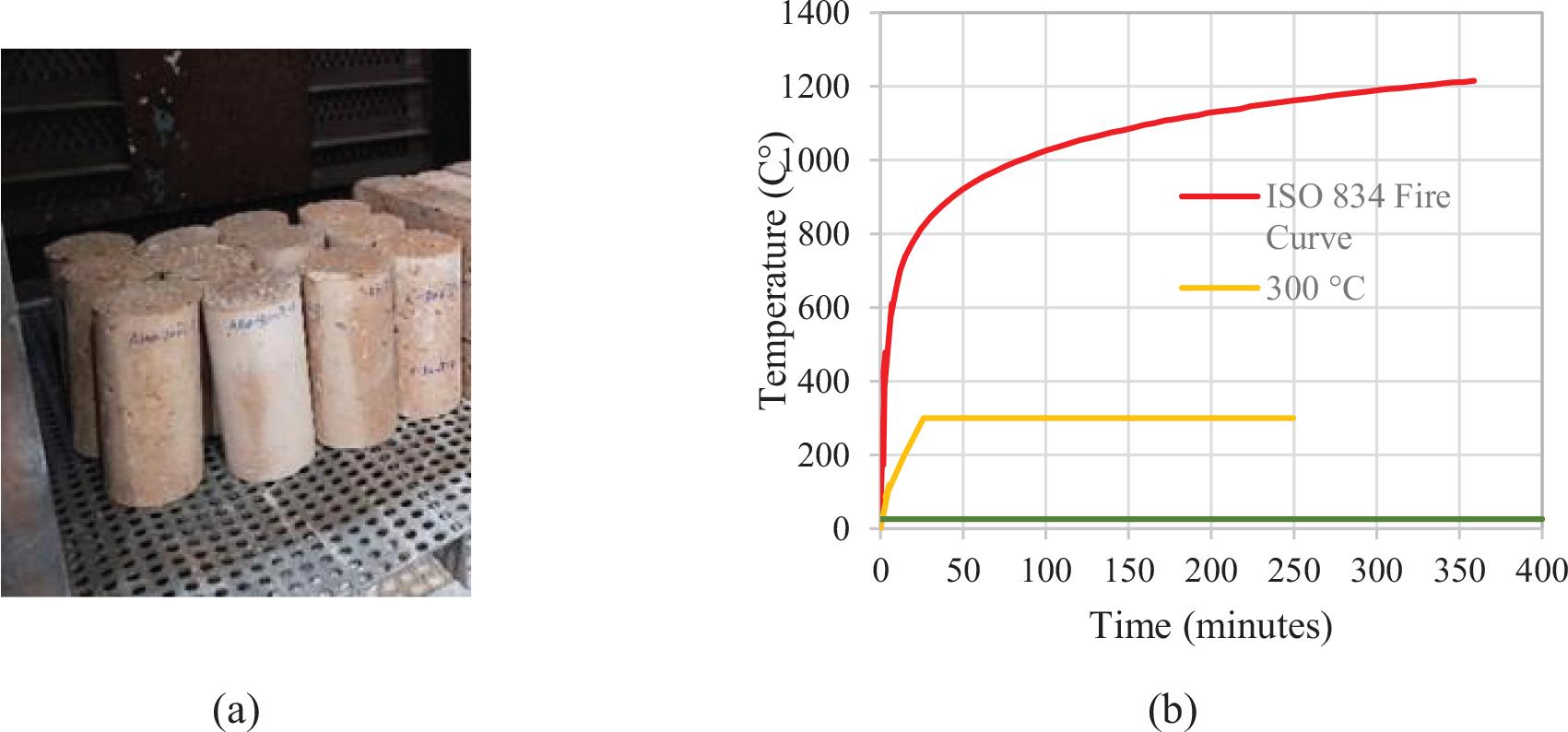

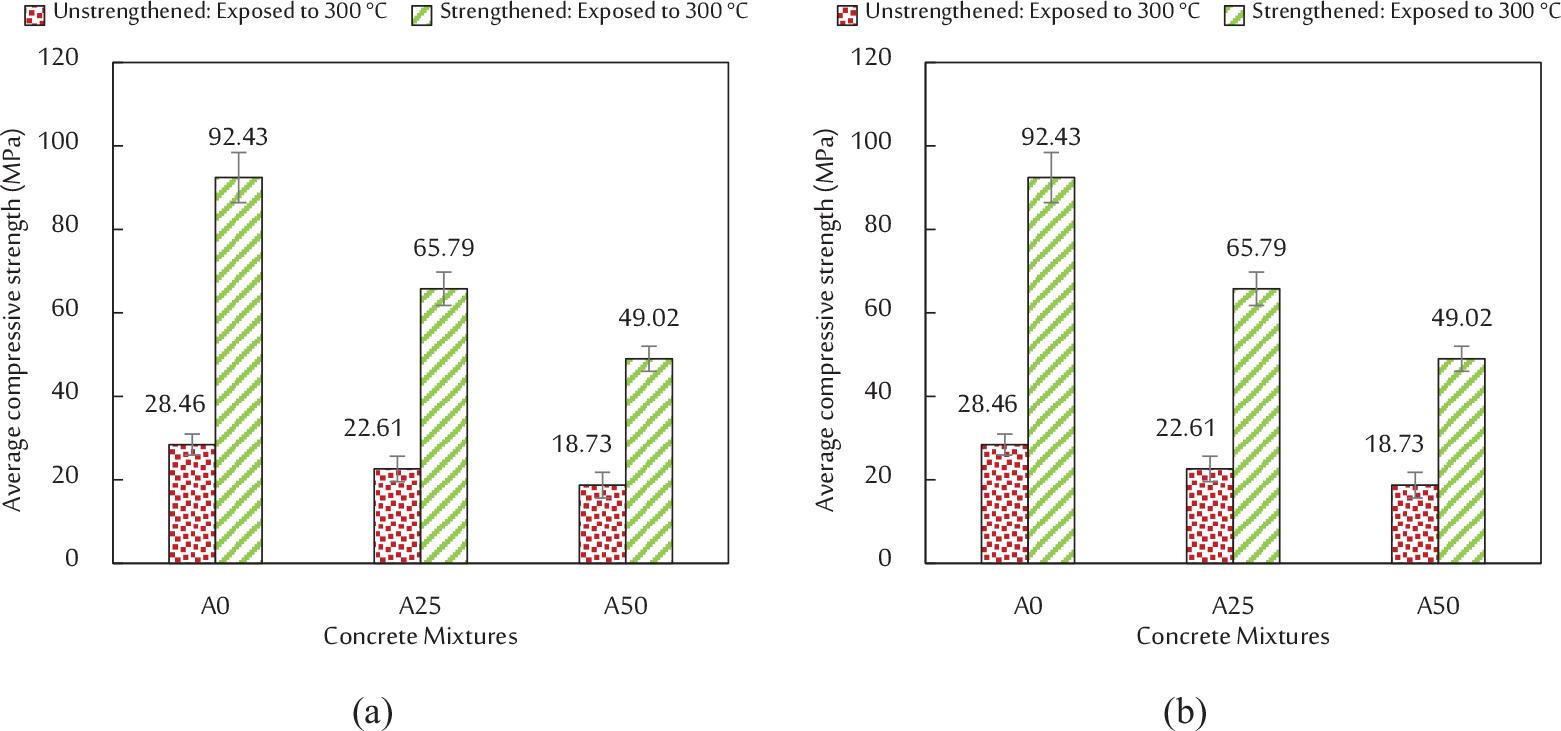

Fig. 3.

Fig. 4.

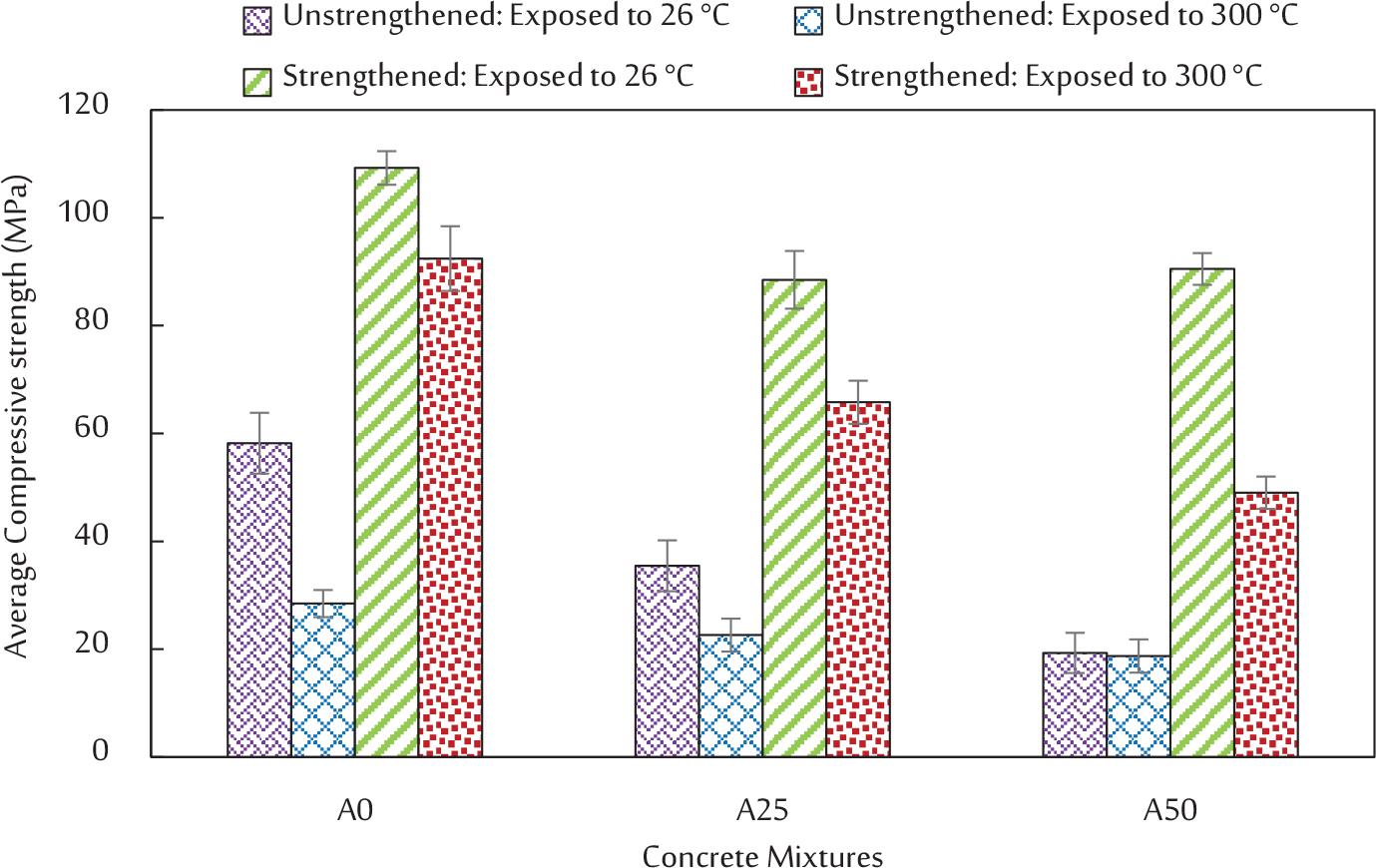

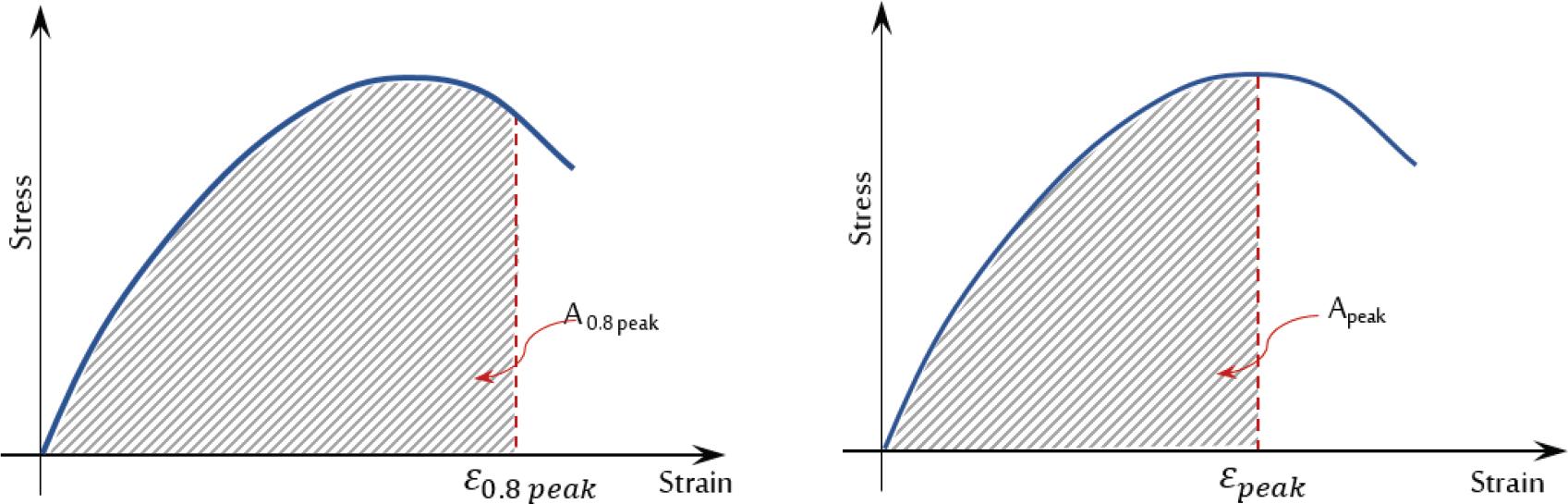

Fig. 5.

Fig. 6.

Fig. 7.

Fig. 8.

Fig. 9.

Fig. 10.

Fig. 11.

Fig. 12.

Test matrix

| Group | Concrete mixture | Specimens ID | RAP aggregate | Exposure to temperature | Strengthening | No. of specimens |

|---|---|---|---|---|---|---|

| Group “1” | A0 | A0-R | 0% | 26°C | – | 3 |

| A0-300 | 300° C | 3 | ||||

| A0-S-R | 26°C | CFRP | 3 | |||

| A0-S-300 | 300°C | 3 | ||||

| Group “2” | A25 | A25-R | 25% | 26°C | – | 3 |

| A25-300 | 300°C | 3 | ||||

| A25-S-R | 26°C | CFRP | 3 | |||

| A25-S-300 | 300°C | 3 | ||||

| Group “3” | A50 | A50-R | 50% | 26°C | – | 3 |

| A50-300 | 300°C | 3 | ||||

| A50-S-R | 26°C | CFRP | 3 | |||

| A50-S-300 | 300°C | 3 | ||||

| Total no. of specimens | 36 | |||||

Properties of the CFRP sheet and epoxy adhesive

| Material | A0 mixture | A25 mixture | A50 mixture | |

|---|---|---|---|---|

| MK | 350 | 350 | 350 | |

| Alkaline solutions | NaOH | 110.04 | 110.04 | 110.04 |

| Na2SiO3 | 196.98 | 196.98 | 196.98 | |

| Water | 5.74 | 5.74 | 5.74 | |

| Fine aggregate | White sand | 419 | 419 | 419 |

| Crushed limestone | 180 | 180 | 180 | |

| Coarse aggregate | Limestone | 1,272 | 954 | 636 |

| RAP | 0 | 334.9 | 669.7 | |

Summary of the test results

| Specimen ID | Average compressive strength | COV | Initial stiffness | Toughness index | |||

|---|---|---|---|---|---|---|---|

| (MPa) | Relative variation * | (N/mm) | Relative variation * | % | Relative variation * | ||

| A0-R | 58.20 | – | 9.69 | 19562.6 | – | 1.55 | – |

| A0-300 | 28.46 | -51.1% | 12.98 | 3265.6 | -83.3% | 1.51 | -2.5% |

| A0-S-R | 109.24 | +87.7% | 4.29 | 26563.4 | +35.8% | 1.06 | -31.9% |

| A0-S-300 | 92.43 | +58.8% | 1.65 | 3409.2 | -82.6% | 1.01 | -34.8% |

| A25-R | 35.46 | – | 7.16 | 17900.7 | – | 1.73 | – |

| A25-300 | 22.61 | -36.2% | 13.62 | 2540.9 | -85.8% | 1.52 | -11.7% |

| A25-S-R | 88.50 | +149.6% | 3.43 | 16389.2 | -8.4% | 1.04 | -39.9% |

| A25-S-300 | 65.79 | +85.5% | 2.66 | 2501.5 | -86.0% | 1.01 | -41.3% |

| A50-R | 19.31 | – | 15.39 | 13431.9 | – | 2.00 | – |

| A50-300 | 18.73 | -3.0% | 15.27 | 2019.7 | -85.0% | 1.86 | -7.1% |

| A50-S-R | 90.51 | +368.8% | 5.90 | 9028.6 | -32.8% | 1.03 | -48.2% |

| A50-S-300 | 49.02 | +153.9% | 3.06 | 2152.2 | -84.0% | 1.02 | -49.0% |

Chemical analysis of MK (% weight)

| Composition | SiO2 | Fe2O3 | Al2O3 | Na2O | CaO | SO3 | TiO2 | K2O | MgO | P2O5 | Others |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Value (%) | 50.995 | 2.114 | 42.631 | 0.284 | 1.287 | 0.439 | 1.713 | 0.337 | 0.127 | 0.051 | 0.022 |