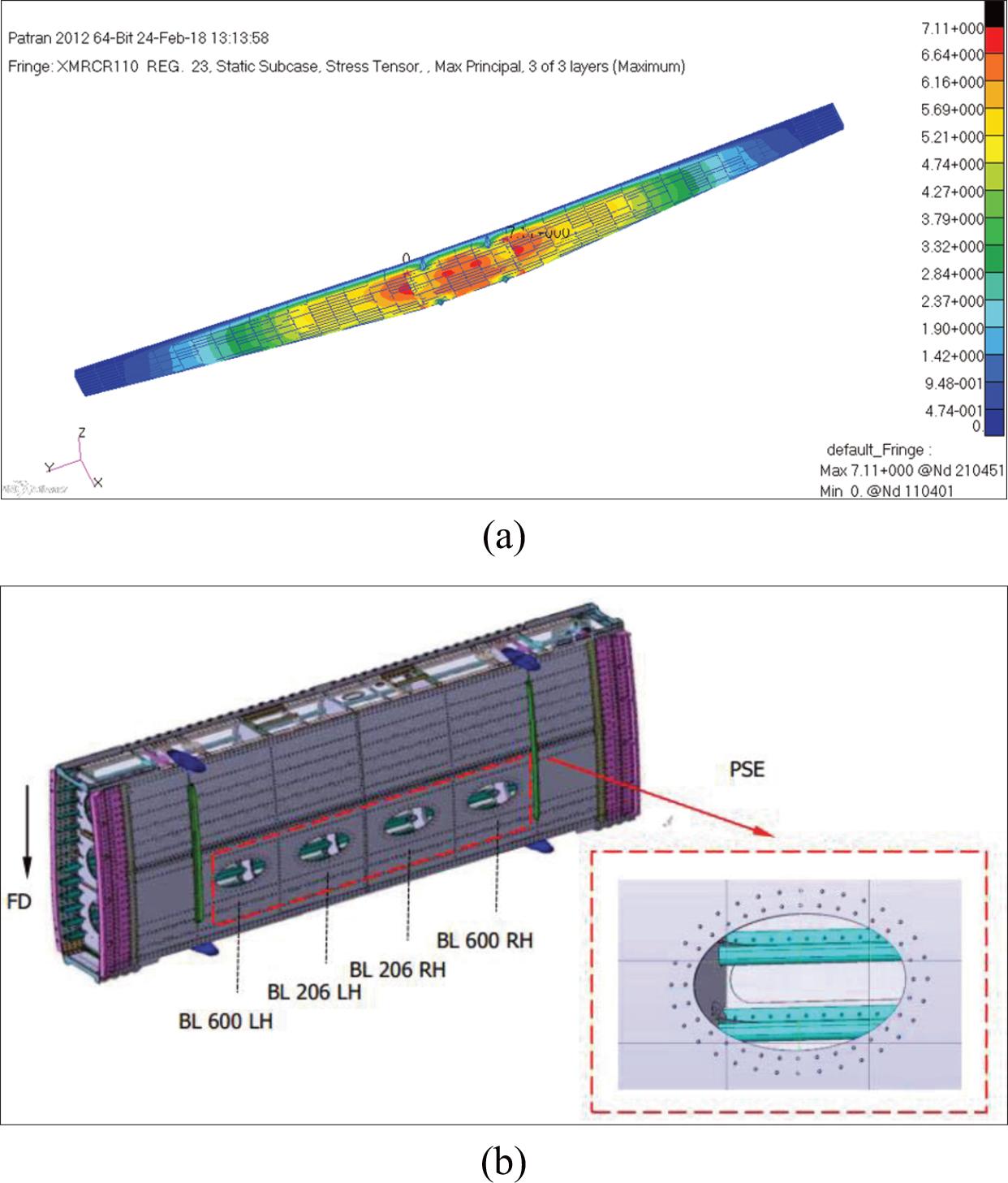

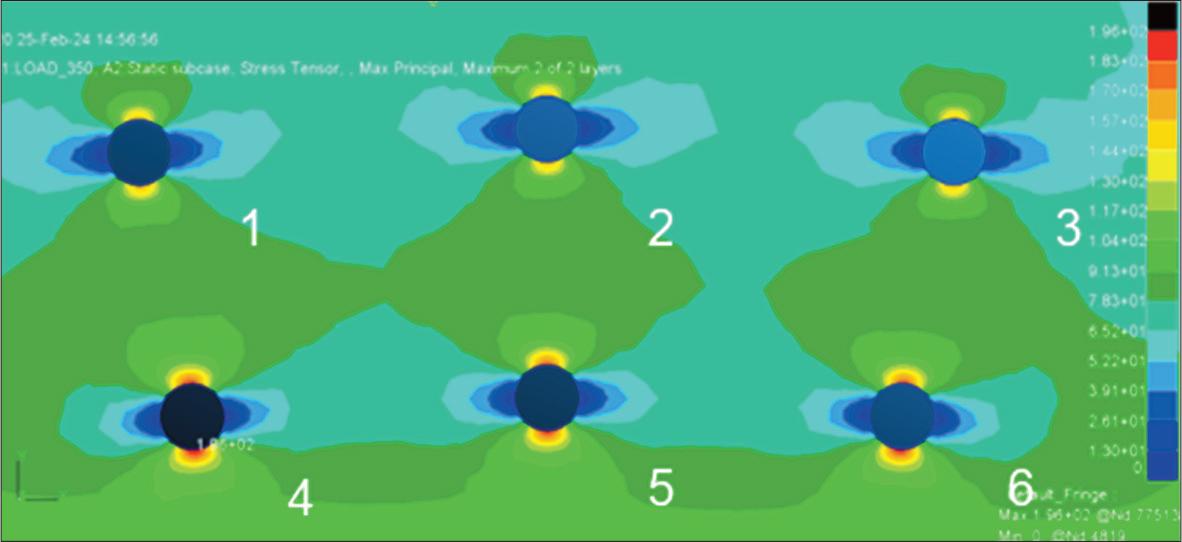

Figure 1.

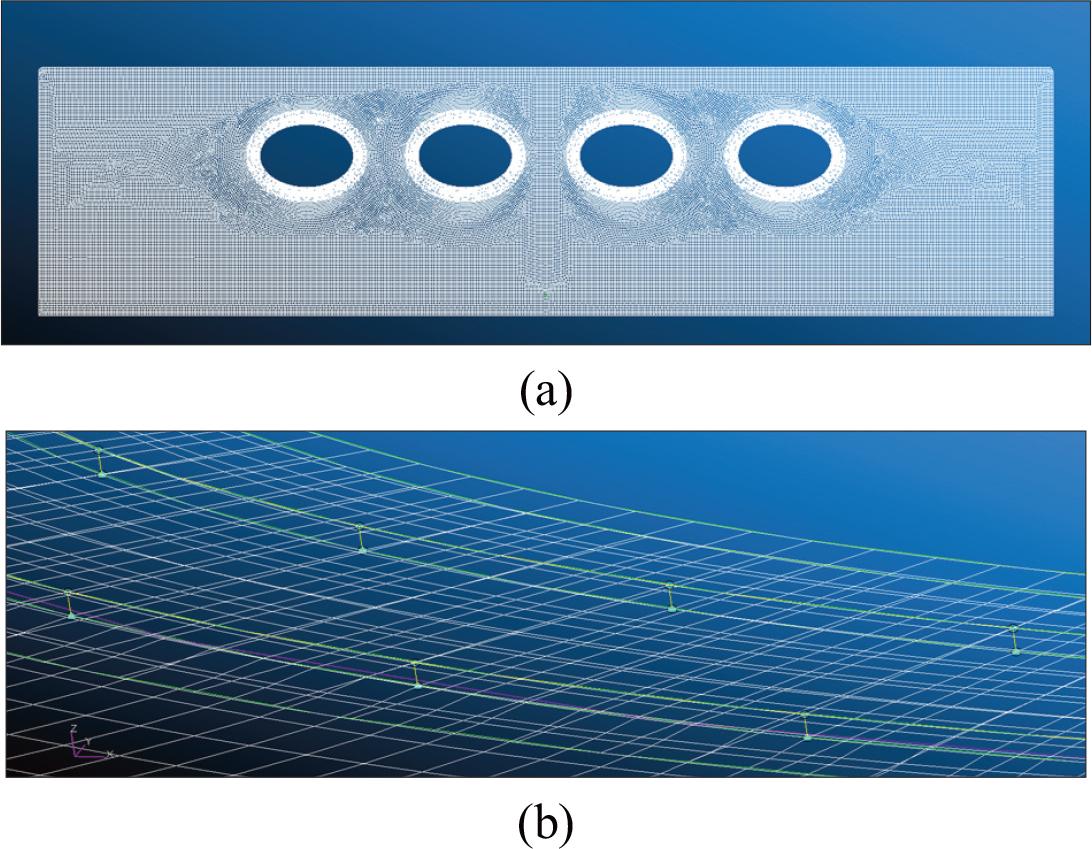

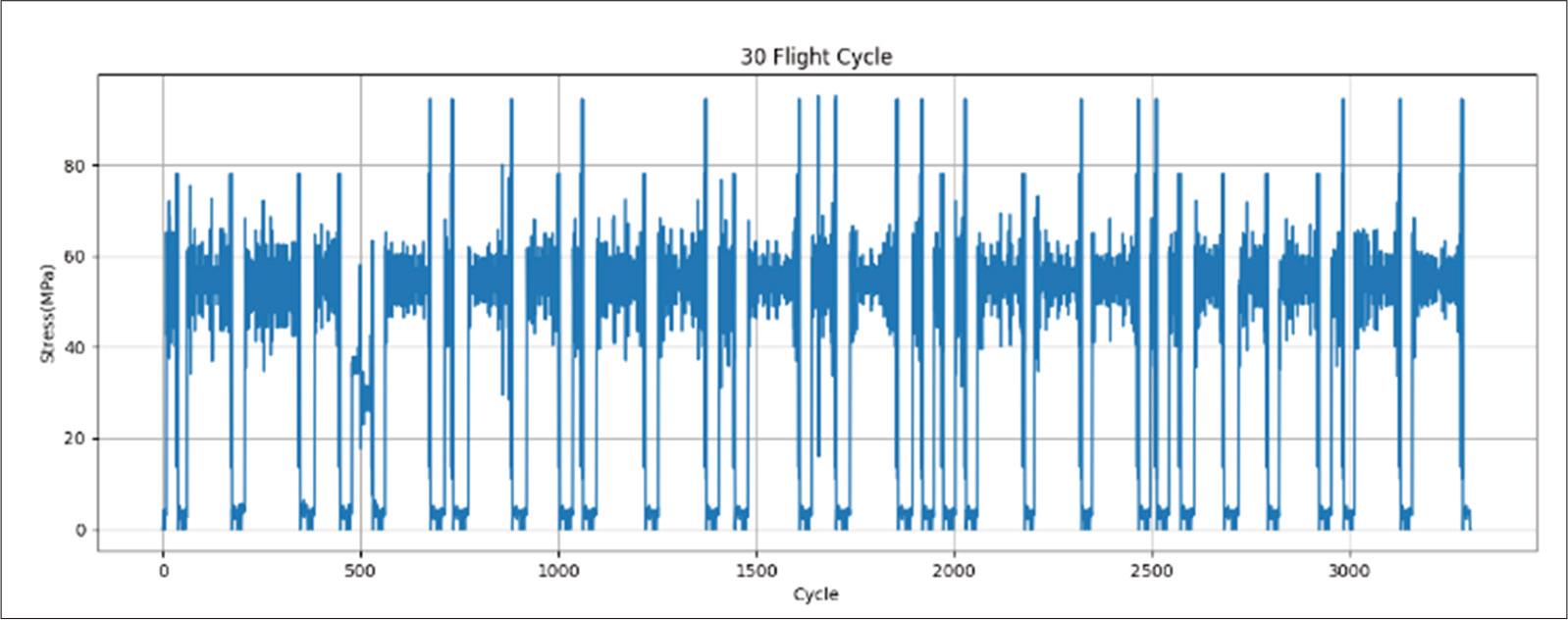

Figure 2.

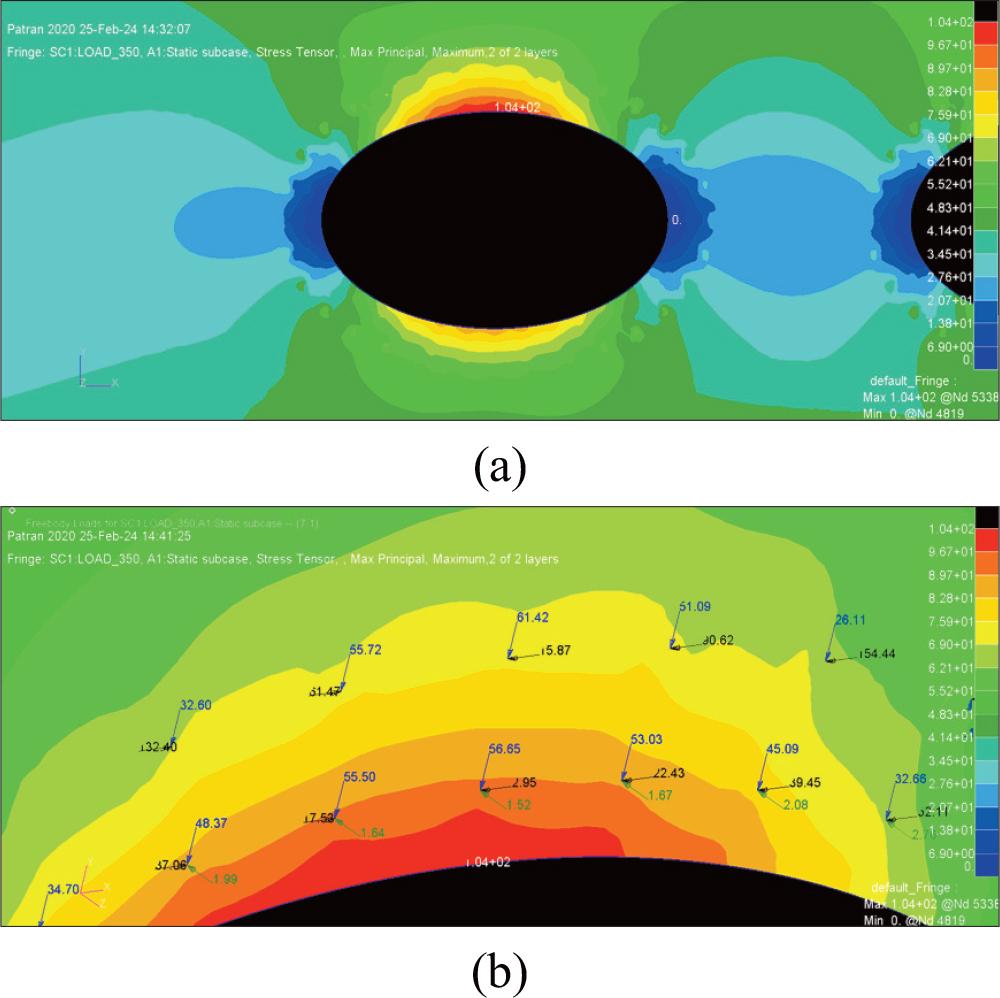

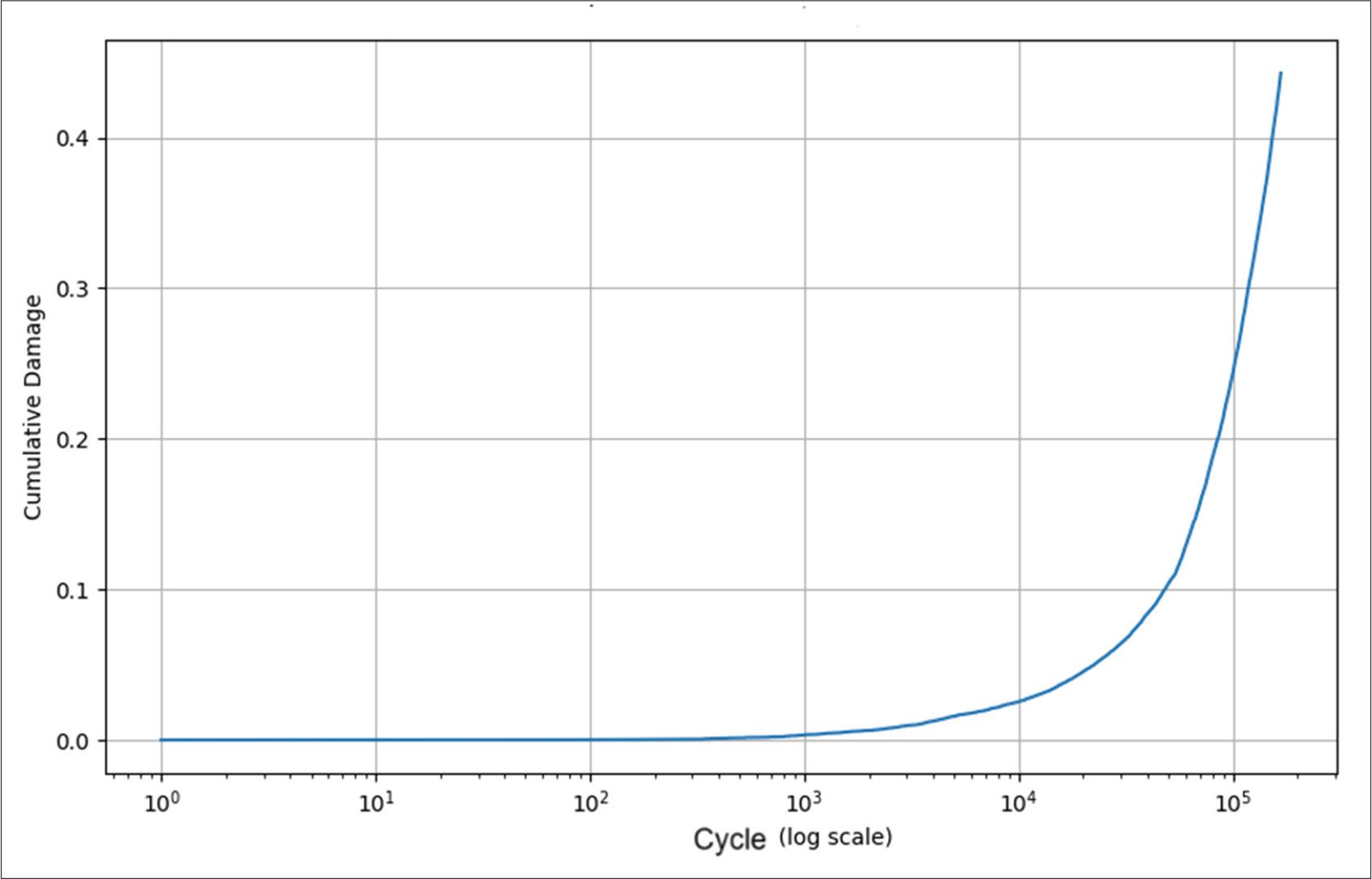

Figure 3.

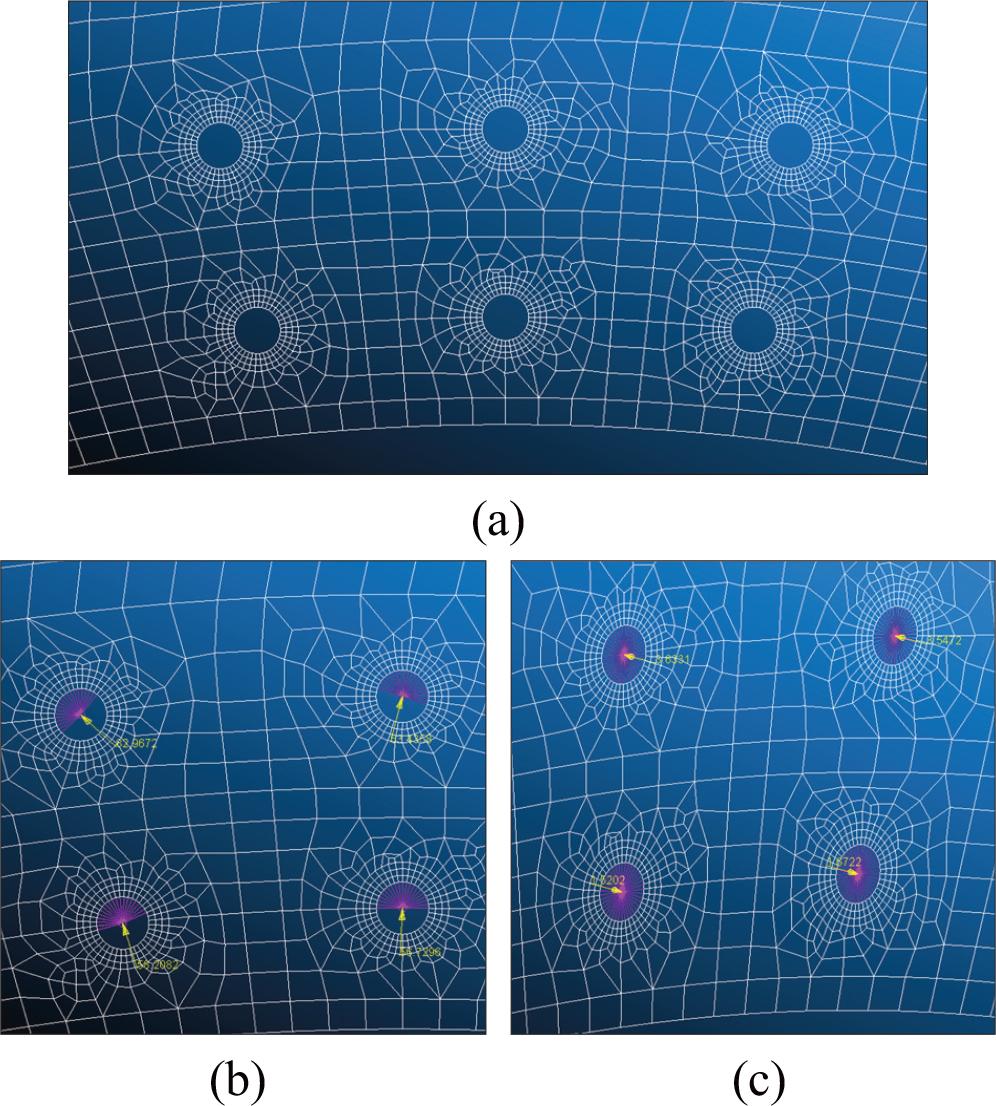

Figure 4.

Figure 5.

Figure 6.

Figure 7.

Coefficient values for different types of joints (Huth, 1986)_

| Joint type | Coefficient values | |

|---|---|---|

| Single shear joint | n = 1 | |

| Double shear joint | n = 2 | |

| Bolted metallic | a = 2/3 | b = 3.0 |

| Riveted metallic | a = 2/5 | b = 2.2 |

| Bolted graphite/epoxy | a = 2/3 | b = 1.2 |

Full-Scale Fatigue Test Scatter factor for Aluminum structures (Federal Aviation Administration, 2024)_

| Notes | Number of tests specimens | Required scatter factor |

|---|---|---|

| Probability of Detectable crack-free safe-life 99.97% (Zp = 3.511) | 1 | 4.96 |

| 2 | 4.0 | |

| 3 | 3.70 | |

| 4 | 3.54 | |

| Standard Deviation of Log fatigue life | ||

| 0.14 for Aluminum structures | ||

Dimensions of the Lower Skin_

| Geometry | Value |

|---|---|

| Length of Lower Skin | 2600 mm |

| Width of Lower Skin | 591 mm |

| Hole Inspections | 240 × 150 mm |

| Rivet Diameter | 3.97 mm |

| Skin width | 2 mm |

| Doubler width | 1.5 mm |

Material properties of Aluminum 2024-T3 (MSC Software Corporation, 2024)_

| Properties | Value |

|---|---|

| Modulus Young | 70 GPa |

| Poisson Ratio | 0.33 |

| Yield Stress | 360 MPa |

| Yield Ultimate | 488 MPa |

| Elongation strain | 23% |

| Hardening coefficient | 450 MPa |

| Hardening exponent | 0.072 |

| Ductility coefficient | 0.409 |

| Ductility exponent | -0.713 |

| Fatigue coefficient | 927 |

| Fatigue exponent | -0.113 |