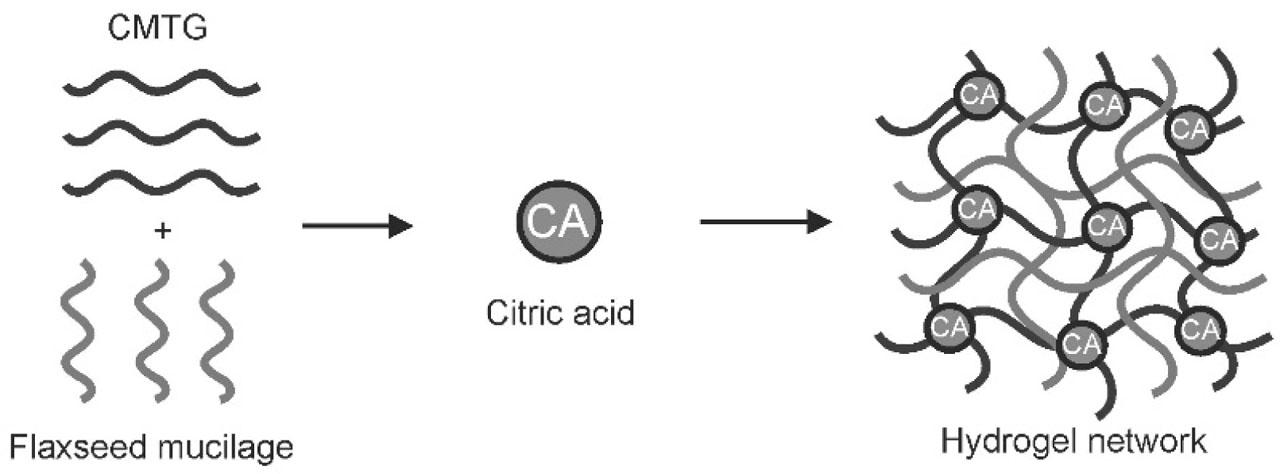

Figure 1.

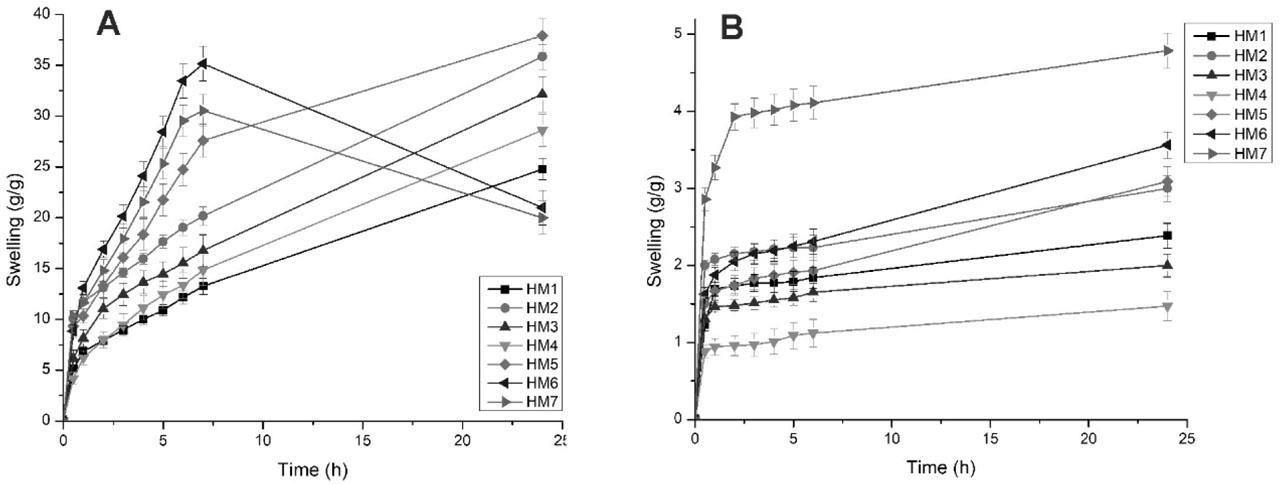

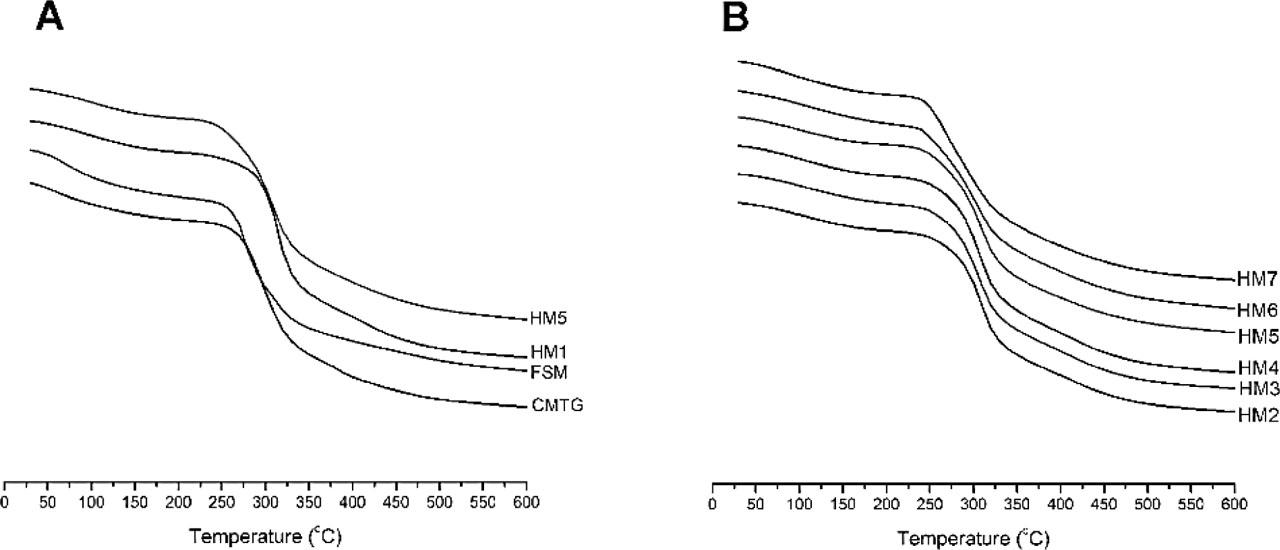

Figure 2.

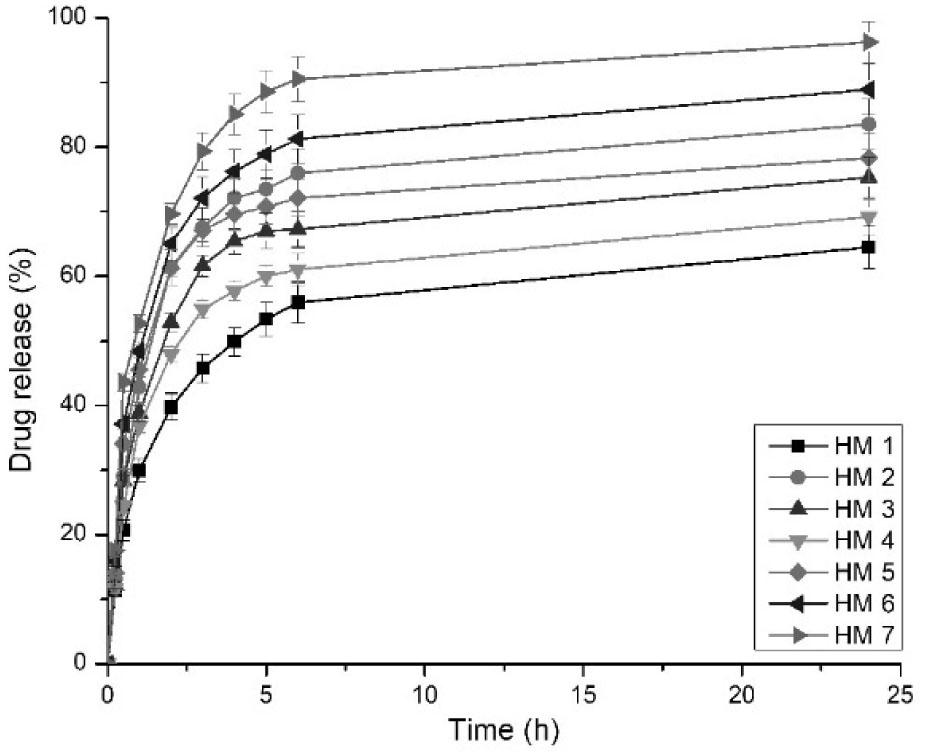

Figure 3.

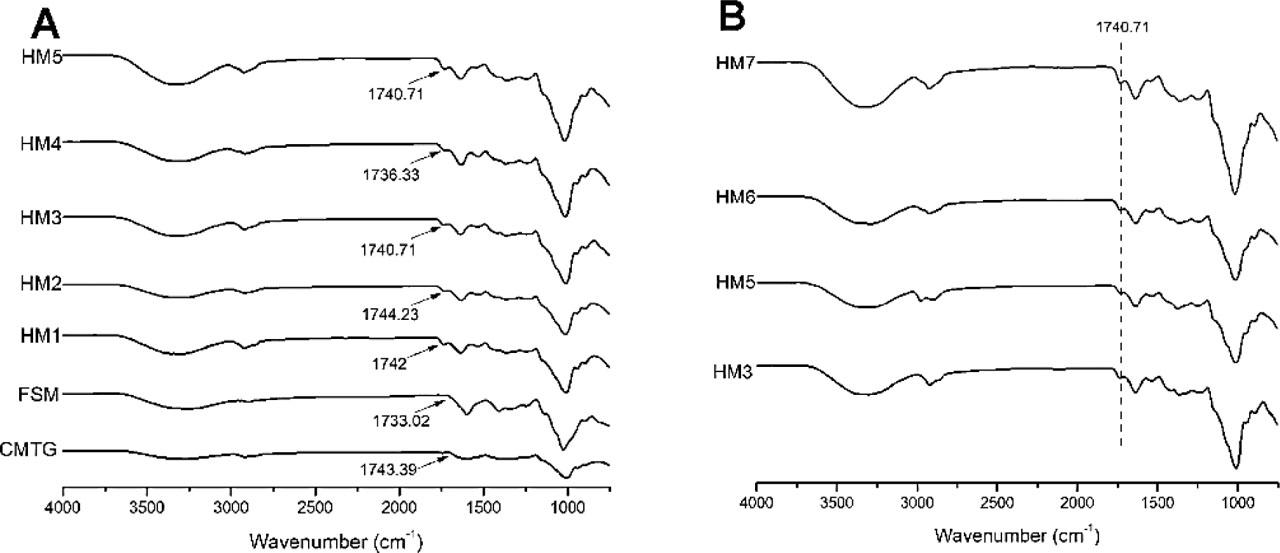

Figure 4.

Figure 5.

Drug loading, drug release, and order of release of composite hydrogel films_

| Batch | Drug loading (mg/g) | Q5h (%)a | Zero order | First order | Higuchi | Korsmeyer–Peppas | Order of release | |

|---|---|---|---|---|---|---|---|---|

| (r2) | (r2) | (r2) | (r2) | n | ||||

| HM1 | 34.58 ± 2.61 | 53.34 ± 2.58 | 0.881 | 0.733 | 0.967 | 0.968 | 0.511 | Non-Fickian |

| HM2 | 37.45 ± 1.27 | 73.52 ± 3.09 | 0.795 | 0.640 | 0.914 | 0.939 | 0.552 | Non-Fickian |

| HM3 | 34.58 ± 1.94 | 67.00 ± 2.77 | 0.798 | 0.637 | 0.916 | 0.931 | 0.567 | Non-Fickian |

| HM4 | 30.45 ± 4.13 | 60.02 ± 1.62 | 0.799 | 0.643 | 0.916 | 0.936 | 0.588 | Non-Fickian |

| HM5 | 36.66 ± 2.77 | 70.74 ± 2.71 | 0.740 | 0.582 | 0.871 | 0.897 | 0.535 | Non-Fickian |

| HM6 | 43.86 ± 3.65 | 78.90 ± 3.73 | 0.792 | 0.623 | 0.908 | 0.908 | 0.523 | Non-Fickian |

| HM7 | 39.99 ± 3.99 | 88.60 ± 3.27 | 0.809 | 0.627 | 0.917 | 0.892 | 0.514 | Non-Fickian |

Percent weight loss, thickness, TCC, and contact angle of CMTG–FSM composite hydrogel films_

| Batch | Weight loss (%) | Thickness (μm) | TCC (mEq/100 g) | Contact angle (°) |

|---|---|---|---|---|

| HM1 | 30.28 ± 7.93 | 575.00 ± 7.26 | 350.33 ± 6.5 | 63.29 ± 0.47 |

| HM2 | 29.89 ± 5.44 | 593.86 ± 4.79 | 370.67 ± 4.4 | 60.31 ± 0.49 |

| HM3 | 32.33 ± 9.74 | 590.00 ± 4.41 | 407.00 ± 3.2 | 65.92 ± 0.38 |

| HM4 | 34.17 ± 11.84 | 578.33 ± 6.01 | 427.35 ± 6.6 | 69.91 ± 0.39 |

| HM5 | 33.03 ± 6.13 | 587.44 ± 7.43 | 390.33 ± 3.8 | 66.64 ± 0.22 |

| HM6 | 35.15 ± 5.35 | 584.33 ± 6.89 | 331.67 ± 6.2 | 69.85 ± 0.55 |

| HM7 | 37.21 ± 6.60 | 572.22 ± 3.47 | 304.33 ± 5.4 | 74.29 ± 0.18 |

Composition of CMTG:FSM composite hydrogel films

| Batch | HM1 | HM2 | HM3 | HM4 | HM5 | HM6 | HM7 |

|---|---|---|---|---|---|---|---|

| CMTG:FSM ratio (2 % w/v) | 1:0 | 9:1 | 9:1 | 9:1 | 8:2 | 7:3 | 1:1 |

| Citric acid (% w/v) | 0.6 | 0.5 | 0.6 | 0.7 | 0.6 | 0.6 | 0.6 |

Water vapor transmission rate, microbial permeability, protein adsorption, and hemolysis of CMTG–FSM composite hydrogel films_

| Batch | WVTR (g/m2) | Microbial permeability | Protein adsorption (mg/cm2) | Hemolysis (%) |

|---|---|---|---|---|

| HM1 | 987.96 | −ve | 0.044 | 4.561 |

| HM2 | 941.13 | −ve | 0.034 | 2.474 |

| HM3 | 905.00 | −ve | 0.040 | 3.464 |

| HM4 | 791.40 | −ve | 0.047 | 4.013 |

| HM5 | 887.36 | −ve | 0.035 | 3.813 |

| HM6 | 843.36 | −ve | 0.032 | 3.318 |

| HM7 | 820.18 | −ve | 0.029 | 2.212 |