Indonesia, a nation with significant potential across various sectors, is on the cusp of a civil engineering revolution, particularly in the development of physical infrastructure. The emergence of numerous innovations – especially in using alternative materials for paved roads – is a testament to this promising future. The potential of this research to contribute to these innovations and the development of physical infrastructure in Indonesia is engaging and exciting (Junkes et al., 2024).

Concrete bricks, commonly called paving blocks, are a construction material that offers more than meets the eye. These blocks represent a marvel of engineering as they are composed of a unique blend of water, aggregate, and portland cement or similar hydraulic adhesive, with or without additional components (National Standardization Agency [NSA], 1996). Renowned for their ability to withstand heavy loads and ease of maintenance, paving blocks are used for road surfaces, sidewalks, parks, and parking areas, showcasing their versatility and superiority within civil engineering and leaving a lasting impression.

Every day, our environment is burdened by various types of waste, including plastic. In Indonesia, the issue of plastic waste has reached alarming proportions, posing a severe threat to the environment and public health. However, the community’s endeavors to combat this issue through the replacement, reduction and refinement principle (called the 3R approach), are inspiring and crucial. The 3R approach is significant as it can substantially mitigate the negative impact of plastic waste, fostering hope for a cleaner and healthier future (Garcia et al., 2024).

Research conducted by university academics has centered on discovering innovative ways to repurpose plastic waste for utilization in construction. For instance, plastic waste has been investigated for enhancing soil properties, road pavement, concrete, and paving blocks. Muzaidi et al. discovered that incorporating 3% of 10 × 10 mm and 10 × 5 mm plastic waste fragments improved the soil’s compressive strength and shear-strength angle (Muzaidi et al., 2022). Handayasari demonstrated that substituting 5% sand with mineral water packaging waste increased concrete compressive strength to 22.741 MPa (Handayasari, 2017). Awoyera and Adesina (2020), and Wendimu et al. (2021) concluded that low-density polyethylene (LDPE) enhanced the compressive strength of bricks compared to clay. Arulrajah et al. (2017) used various types of plastic waste, such as linear low-density polyethylene filled with calcium carbonate (LDCAL), high-density polyethylene (HDPE), and LDPE for road pavement. Khatib et al. (2019) found that replacing coarse aggregate with bottle cap waste did not significantly reduce the flexural strength of concrete blocks. Gour et al. (2022) and Gopinath et al. (2023) suggested substituting aggregate with polypropylene (PP) waste in concrete, which could be used for brickwork, partitions, panels, and canal linings. Iduwin et al. (2023) and Ahmad et al. (2023) showed that using PP for aggregate substitution slightly increased the compressive strength of bricks.

Saxena et al. (2020) and Guo et al. (2024) observed that the compressive strength, flexural strength, and elastic modulus of concrete decreased with increased plastic waste percentage, but abrasion resistance increased. Dadzie et al. (2020) and Haigh (2024) demonstrated that using plastic bottles for walls helped maintain room temperature and reduce energy costs. Soni et al. (2022), Tempa et al. (2022), and Kakerissa and Latuheru (2023) used PP plastic waste mixed with gravel to manufacture paving blocks. They found that a composition of 70% plastic waste and 30% sand produced D-quality paving blocks recommended for mass production due to their significant waste utilization (Widiyono et al., 2024). Krasna et al. (2019) stated that replacing 40% of sand with plastic increased the compressive strength of paving by 30%. There was a decrease in the compressive strength of the red brick in the sample with the percentage of addition of 10% and 15% (Candra et al., 2022; Paikun et al., 2023; Umar & Mustafa, 2023; Dary et al., 2024).

From the description above, this final assignment is interested in testing paving blocks with the innovative use of red brick powder and waste polypropylene plastic with processing to become plastic pellets, which is a key component in the research. The plastic pellet, when used in variations of 10%, 15%, 25%, and 25% red brick powder, is expected to reduce water absorption. The red brick powder, with pozzolanic characteristics, can unite aggregate in making paving blocks to produce suitable products, according to Indonesian standard SNI 03-0691-1996 (NSA, 1996).

According to SNI 03-0691-1996 (NSA, 1996), paving blocks are made of a mixture of portland cement (or similar hydraulic adhesives), water, and aggregates, with or without other additives. Four quality categories are used to group this mixture: Quality A for roads, Quality B for parking lots, Quality C for pedestrian facilities, and Quality D for parks and other uses. Table 1 shows the values of the physical properties of each quality.

Physical properties of paving blocks

| Quality | Size [mm] | Compressive strength [MPa] | Wear resistance [mm·min−1] | Maximum average water absorption [%] | ||

|---|---|---|---|---|---|---|

| AVG | min | AVG | min | |||

| A | 210 × 105 × 50 | 40.0 | 35.0 | 0.090 | 0.103 | 3 |

| B | 210 × 105 × 50 | 20.0 | 17.0 | 0.130 | 0.149 | 6 |

| C | 210 × 105 × 50 | 15.0 | 12.5 | 0.160 | 0.184 | 8 |

| D | 210 × 105 × 50 | 10.0 | 8.5 | 0.219 | 0.251 | 10 |

Source: own work.

The plastic used in processing processes to become plastic pellets was sourced from Cv. Hraltara in Buran, Tasikmadu District, Karanganyar Regency, as shown in Figure 1. The material added to the aggregate was red brick waste in a fine powder form and was obtained from homes of researchers in Ngawi City and Kos Sebastian 2 Jebres District, Surakarta.

Plastic pellets

Source: own work.

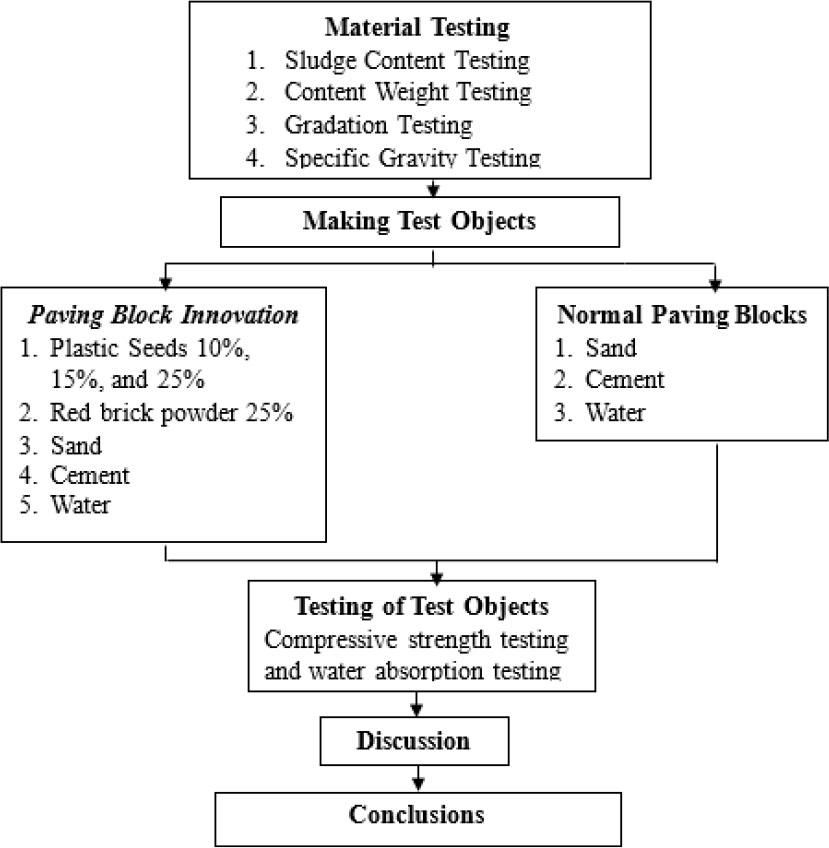

The research methodology used in this study follows a flowchart, as depicted in Figure 2. The entire research includes four main stages, which were carried out according to the following procedure:

Material testing (aggregate analysis):

- –

Aggregate analysis:

Sieve analysis was conducted to determine the particle size distribution.

Specific gravity testing was performed to measure the density of the aggregates.

Absorption testing was carried out to assess the water absorption capacity of the aggregates.

Mud content testing was implemented to evaluate the amount of fine particles in the aggregates.

- –

Specimen preparation:

- –

Paving block specimens were fabricated using a cement-to-sand ratio of 1 : 4.

- –

Various formulations were tested with different proportions of plastic pellets and red brick powder (10%, 15%, and 25% plastic pellets, and 25% red brick powder).

- –

Specimen testing:

- –

Compressive strength evaluation: Specimens were subjected to compressive strength testing for 28 days.

- –

Water absorption measurement: Specimens were immersed in water for 24 h, and their water absorption was measured.

- –

Data analysis and discussion:

- –

The test results were analyzed to evaluate the influence of plastic pellets and red brick powder on the paving blocks’ compressive strength and water absorption.

- –

The findings were compared against the requirements outlined in SNI 03-0691-1996.

- –

The flowchart of the research methodology

Source: own work.

The preparation of concrete paving block materials was checked according to material standards, which involve a series of tests and evaluations to ensure the materials meet the required quality and specifications. Aggregate testing was completed using sieve, absorption, density, and mud content analysis.

The research uses plastic pellets in variations of 10%, 15%, and 25%, and 25% red brick powder. Test specimens are made with a mixture using a cement-to-sand ratio of 1 : 4. Some essential equipment used are compressive strength testing machines with an accuracy of 1 kN, as well as dial gauges. The test specimen was made with dimensions of 21 × 10.5 × 5 cm. After the test specimen hardens, it is cut with a cutting tool from the initial size to a size of 5 × 5 × 5 cm. Testing the robustness and compressive strength of block paving is carried out over 28 days. It is intended to influence the usage of plastic pellets and red brick powder to improve compressive strength, absorb water, and make cost-effective paving blocks.

Table 2 presents the overall content weight of the components in the paving block samples. A mud content test was conducted to determine the mud content in the sand intended for making paving blocks. The test aimed to ascertain the percentage of mud present in the sand. According to SNI 7656:2012 (NSA, 2012), the permissible mud content in the sand should not exceed 5%. However, the results of the test revealed a mud content of 9.4%. This indicates that the sand only meets the requirement of less than 5% mud, a finding of significant concern. The findings suggest that if the mud content exceeds 5%, the sand should be washed correctly before being used in the mixture.

Content weight test results

| Material | Aggregate weight [g] | Container volume [cm3] | Unit weight [g·cm−3] |

|---|---|---|---|

| Sand | 1 090 | 0.001 | 1.09 |

| Red brick powder | 1 060 | 0.001 | 1.06 |

| Plastic pellets | 540 | 0.001 | 0.54 |

Source: own work.

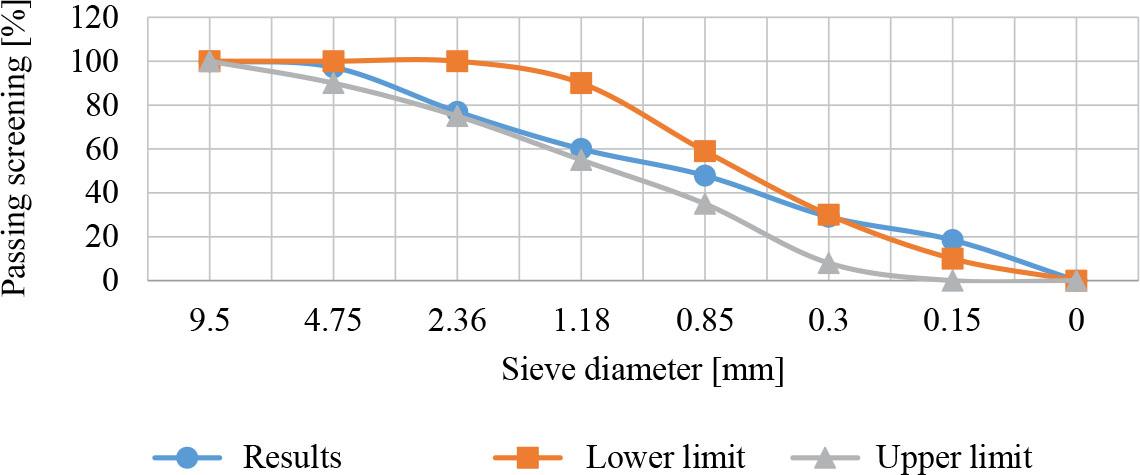

Following the testing of sand gradation, it was determined that the acceptable modulus value of the sand is 2.45, which falls within the specified range (1.5 < MK < 3.8) outlined in SNI 7656:2012 (NSA, 2012). However, during testing, there was a percentage weight loss of 1.25%. This suggests that the aggregate samples are unsuitable for concrete building materials or paving blocks due to excessive weight loss. The detailed gradation test results for sand can be observed in Figure 3.

Sand gradation chart

Source: own work.

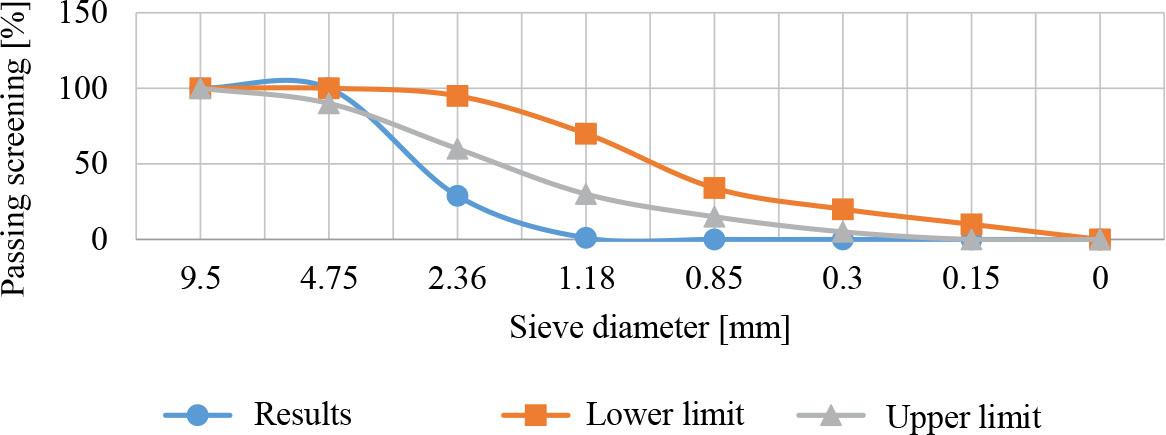

Furthermore, the red brick powder gradation testing indicated an acceptable modulus value of 2.7, which aligns with the specified fineness modulus range. Similar to the sand testing, there was a 1.25% weight loss during testing, highlighting the inadequacy of the red brick powder for concrete or paving block production. The comprehensive gradation test results for red brick powder can be found in Figure 4.

Red brick powder gradation chart

Source: own work.

In contrast, the testing of plastic pellet gradation showcased an acceptable modulus value of 4.7, meeting the provisions of SNI 7656:2012 (NSA, 2012), which stipulate a fineness modulus range of 1.5 < MK < 3.8. Moreover, the weight loss percentage during testing was only 0.25%, well below the permitted maximum of 1%. This points to the suitability of the plastic pellets for inclusion in concrete and paving blocks utilized as building materials. The detailed test result gradation for plastic pellets is visually depicted in Figure 5, further corroborating its appropriateness for the project.

Plastic pellet gradation chart

Source: own work.

The test results for sand show that the bulk specific gravity is 2.3, the bulk SSD specific gravity is 2.38, the apparent specific gravity is 2.49, and the absorption is 3.1%. These values were compared to ASTM C33 specification requirements (Taylor, 2004; Berney & Smith, 2008), which specify that bulk specific gravity, bulk SSD specific gravity, and apparent specific gravity should fall within the range of 1.6–3.3, and absorption should be less than 2%. Adhering to these standards is not just a formality but a crucial step in ensuring our analysis’s quality and reliability.

Furthermore, the test results for red brick powder reveal a significant issue. The bulk specific gravity is 3.4, the bulk SSD specific gravity is 4, the apparent specific gravity is 8.5, and the absorption is 17.6%. Compared to ASTM C33 specification requirements, these results indicate that the red brick powder does not meet the required conditions for bulk specific gravity, bulk SSD specific gravity, apparent specific gravity, and absorption. This non-compliance is an urgent matter that needs to be addressed.

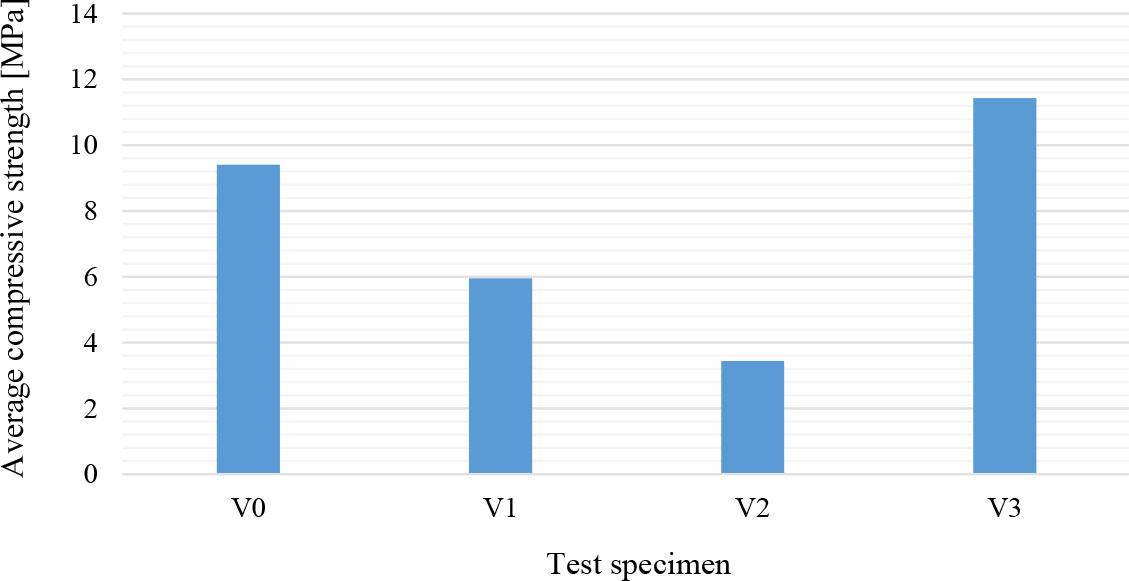

Following the 28-day aging period, a comprehensive evaluation was conducted to assess the strength of the paving blocks, involving meticulous testing of three distinct variations. The detailed findings from the substantial compressive strength test for the paving blocks are meticulously documented in Table 3. Each variation was rigorously marked and precisely compressed by the calculations outlined in the tables. Notably, all variations consistently demonstrated considerable strength in the testing summary. Further nuanced insights into the average compressive strength of the paving blocks are elucidated in Table 4.

Comparison of the compressive strength values from testing paving blocks

| Test | Normal | Compressive strength [MPa] | Innovation | Compressive strength [MPa] | Deviation [MPa] |

|---|---|---|---|---|---|

| 1 | V0 A | 10.69 | V1 A | 6.57 | ‒4.12 |

| 2 | V0 B | 10.21 | V1 B | 7.58 | ‒2.63 |

| 3 | V0 C | 7.33 | V1 C | 3.72 | ‒3.61 |

| 4 | V0 A | 10.69 | V2 A | 3.57 | ‒7.12 |

| 5 | V0 B | 10.21 | V2 B | 3.08 | ‒7.13 |

| 6 | V0 C | 7.33 | V2 C | 3.68 | ‒3.65 |

| 7 | V0 A | 10.69 | V3 A | 12.19 | +1.50 |

| 8 | V0 B | 10.21 | V3 B | 12.36 | +0.15 |

| 9 | V0 C | 7.33 | V3 C | 9.73 | +2.40 |

Note: V0 = 0% plastic pellets + 0% red brick powder, V1 = 10% plastic pellets + 25% red brick powder, V2 = 15% plastic pellets + 25% red brick powder, V3 = 25% plastic pellets + 25% red brick powder.

Source: own work.

A summary of test results for average compressive strength values of paving blocks

| Test specimen | Additional material | Average compressive strength [MPa] | |

|---|---|---|---|

| Plastic pellets [%] | Red brick powder [%] | ||

| V0 A, V0 B, V0 C | 0 | 0 | 9.41 |

| V1 A, V1 B, V1 C | 10 | 25 | 5.95 |

| V2 A, V2 B, V2 C | 15 | 25 | 3.44 |

| V3 A, V3 B, V3 C | 25 | 25 | 11.43 |

Note: V0 = 0% plastic pellets + 0% red brick powder, V1 = 10% plastic pellets + 25% red brick powder, V2 = 15% plastic pellets + 25% red brick powder, V3 = 25% plastic pellets + 25% red brick powder.

Source: own work.

Moreover, Figure 6 visually articulates the profound impact of integrating additional plastic pellets and red brick powder materials, which served as partial sand substitutes, on the paving blocks’ robustness. Noteworthy is the revelation that while the highest average compressive strength was attained with the traditional mixture, a distinct concoction of cement and sand in a 1 : 4 ratio, enhanced with the supplementary materials at a concentration of 25% each, yielded an impressive average compressive strength of 9.09 MPa. Based on these comprehensive and intricate findings, it is evident that only the standard paving blocks and the select three variations can be unequivocally classified as D-quality paving blocks, rendering them eminently suitable for deployment within park environments.

Average compressive strength values for paving blocks

Source: own work.

A comprehensive test was conducted to examine the absorption of water in paving blocks. The process involves immersing the paving block in water for a continuous period of 24 h, followed by subjecting the block to an extreme temperature by placing it in an oven at 110°C for an additional 24 h. This meticulous test is performed when the paving blocks have reached 28 days of age, utilizing three test specimens for each distinct variation. An illustrative example of this examination includes the calculation of absorption of water from a specific paving block test specimen denoted as V1 D. This calculation considers additional components, such as 10% plastic pellets and 25% red brick powder, incorporated with heavy sand.

The calculated results for the absorption of water from each variation of paving blocks are collated and documented comprehensively in Table 5, providing an intricate and detailed overview of the variation in absorption across different compositions. After the detailed calculations in the tables, the amassed data about the average water absorption of paving blocks is meticulously summarized and presented in Tables 6 and 7.

Comparison of testing the water absorption value of paving blocks

| No | Normal | Water absorption [%] | Innovation | Water absorption [%] | Deviation [%] |

|---|---|---|---|---|---|

| 1 | V0 A | 11.70 | V1 A | 13.70 | ‒2.00 |

| 2 | V0 B | 11.34 | V1 B | 15.18 | ‒3.84 |

| 3 | V0 C | 11.18 | V1 C | 14.39 | ‒3.21 |

| 4 | V0 A | 11.70 | V2 A | 14.21 | ‒2.51 |

| 5 | V0 B | 11.34 | V2 B | 13.66 | ‒2.32 |

| 6 | V0 C | 11.18 | V2 C | 16.38 | ‒5.20 |

| 7 | V0 A | 11.70 | V3 A | 14.48 | ‒2.78 |

| 8 | V0 B | 11.34 | V3 B | 15.14 | ‒3.80 |

| 9 | V0 C | 11.18 | V3 C | 14.76 | ‒3.58 |

Note: V0 = 0% plastic pellets + 0% red brick powder, V1 = 10% plastic pellets + 25% red brick powder, V2 = 15% plastic pellets + 25% red brick powder, V3 = 25% plastic pellets + 25% red brick powder.

Source: own work.

Summary of average water absorption test results for paving blocks

| Test specimen | Additional material | Average water absorption [%] | |

|---|---|---|---|

| Plastic pellets [%] | Red brick powder [%] | ||

| V0 A, V0 B, V0 C | 0 | 0 | 11.40 |

| V1 A, V1 B, V1 C | 10 | 25 | 14.43 |

| V2 A, V2 B, V2 C | 15 | 25 | 14.75 |

| V3 A, V3 B, V3 C | 25 | 25 | 14.80 |

Note: V0 = 0% plastic pellets + 0% red brick powder, V1 = 10% plastic pellets + 25% red brick powder, V2 = 15% plastic pellets + 25% red brick powder, V3 = 25% plastic pellets + 25% red brick powder.

Source: own work.

Summary of test results for the optimal average water absorption capacity of paving blocks

| Test object | Additional material | Average compressive strength [MPa] | |

|---|---|---|---|

| Plastic pellets [%] | Red brick powder [%] | ||

| 1 | 0 | 0 | 9.41 |

| 4 | 25 | 25 | 11.43 |

Source: own work.

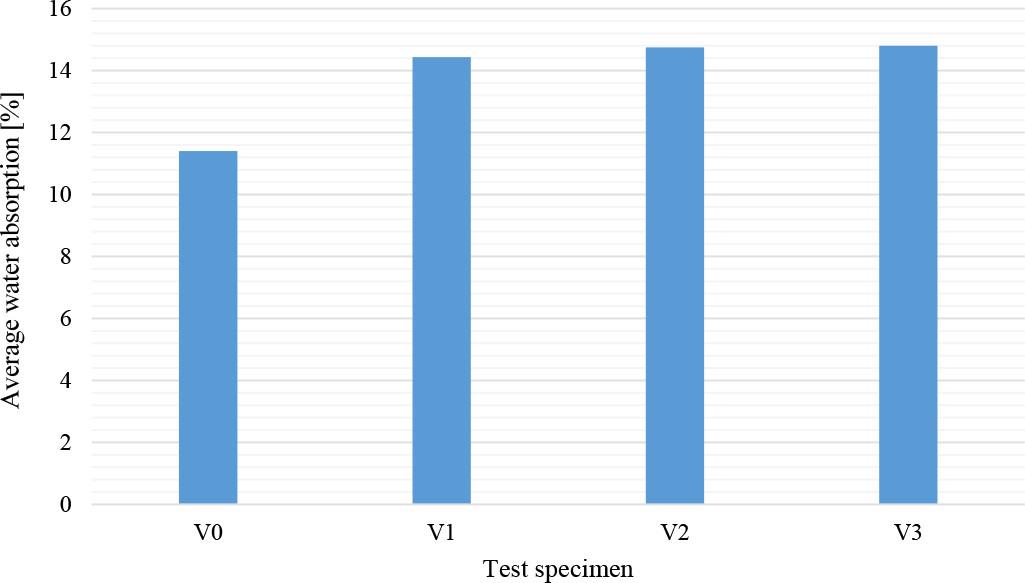

Moreover, Figure 7 presents a detailed graphical representation illustrating the intricate nuances of the increases and decreases in water absorption from paving blocks. This representation provides a visual insight into the variations in water absorption across different compositions and further adds a layer of detailed analysis to the results.

Average water absorption value of paving blocks

Source: own work.

Upon thorough examination of Figure 7, it is evident that the absorption of water consistently demonstrates an ascending trend with each variation. Notably, the highest average water absorption value from the paving blocks is obtained when utilizing a specific mixture of cement and sand at a precise ratio of 1 : 4, coupled with additional materials comprising 25% plastic pellets and 25% red brick powder, resulting in a substantial average water absorption of 14.80%. These comprehensive and detailed findings lead to the significant conclusion that all variations of paving blocks hold the classification of being of high quality, thereby rendering them suitably applicable to diverse park requirements.

Using red brick powder and plastic pellets as fine particles in paving blocks significantly affects their compressive strength and water absorption characteristics. Adding these additives can improve the compressive strength of paving blocks, as evidenced by studies showing that certain mixtures can meet or exceed the standards required for load-bearing applications (Silva et al., 2023). In this study, the addition of 25% plastic pellets has been shown to meet the compressive strength requirements, indicating that the same proportion of red brick powder and plastic pellets can produce beneficial results. In addition, using additives such as red brick powder and plastic pellets increases the strength and affects the durability of paving blocks. Durability testing, including water absorption testing, revealed that the right combination of materials can lower water absorption rates, thereby increasing the life of paving blocks under environmental stress (Widiyono et al., 2024). The interaction between these additives and the base materials, such as cement and aggregate, is critical to optimizing mechanical properties and resistance to water infiltration (Folorunsho et al., 2023). Thus, strategically using red brick powder and plastic pellets can produce strong and durable paving blocks that meet critical performance criteria in construction applications.

This study explored the potential of incorporating waste red brick powder and polypropylene (PP) plastic pellets as alternative aggregates in paving block production. The results demonstrated that the innovative paving block formulations achieved compressive strength values comparable to traditional blocks, particularly those containing 25% red brick powder and 25% plastic pellets. While this formulation met the minimum requirements for category D paving blocks according to SNI 03-0691-1996, it exhibited slightly lower compressive strength than previous findings. Regarding water absorption, the study revealed that adding red brick powder and plastic pellets generally increased water absorption compared to traditional paving blocks. The formulation with 25% red brick powder and 25% plastic pellets exhibited the highest water absorption, exceeding the maximum allowed limit of 10% as per SNI 03-0691-1996.

In conclusion, this study provides valuable insights into the feasibility of utilizing recycled materials in paving block production. The results suggest that these materials can be successfully integrated to create sustainable and durable construction products. Future research should focus on fine-tuning the material composition and production processes to optimize the balance between compressive strength and water absorption, ensuring that the paving blocks meet the specific requirements of various applications while promoting environmental sustainability.