The extensive construction of prefabricated buildings during the latter half of the 20th century constitutes a substantial proportion of the housing stock (Barnaś et al., 2023) in several European countries, including the Czech Republic, Bulgaria, and Poland. In recent decades, significant investments have been directed towards the regeneration of these structures, such as the replacement of outdated windows with modern alternatives possessing better thermal properties, and the application of External Thermal Insulation Composite Systems (ETICS) (Turk et al., 2022; Kubečková, 2023) to prolong their service life and enhance their resilience to climate change (Jakeš, 2023). Despite these interventions, it is anticipated that, over time, the need to demolish or deconstruct these prefabricated buildings (also referred to as panel housing estates) will become inevitable. In Poland, for instance, there has been an ongoing debate regarding whether these buildings should be demolished or their lifespan further extended through refurbishment (Malazdrewicz et al., 2022). In the Czech Republic, a limited number of prefabricated multi-story buildings have already been demolished, either because they were never completely finished or as a result of severe tenant-induced damage. Consequently, it is imperative to develop timely strategies for the effective management of construction waste generated from the future demolition/deconstruction of such structures.

The academic literature defines construction and demolition waste (CDW) as waste produced throughout the entire lifecycle of a building, encompassing construction, repair, maintenance, demolition, and deconstruction activities (Gálvez-Martos et al., 2018). The generation of CDW poses a significant challenge to the construction industry, primarily due to its environmental impact (Kabirifar et al., 2020). Given the considerable proportion of CDW that is landfilled globally (Ajayi et al., 2016), a variety of management strategies have been proposed. These include, but are not limited to, the implementation of CDW management plans, economic instruments (such as landfill taxes to incentivize recycling), site waste management plans, design strategies aimed at minimizing waste, material efficiency practices, building deconstruction, and waste sorting (Gálvez-Martos et al., 2018).

All aforementioned measures align with the principles of the circular economy, which can be integrated from the earliest project stages, such as through green procurement practices (Górecki, 2020), throughout the operational phase via effective maintenance (Cerić et al., 2019; Kilić Pamuković et al., 2020), culminating in end-of-life strategies (Benachio et al., 2020) that prioritize waste separation (Sobotka et al., 2015) and the assessment of material reuse or recycling potential (Sanchez & Haas, 2018). The adoption of such environmentally sustainable approaches yields multiple benefits, including reduced landfill waste, economic gains such as job creation in the recycling sector, and societal advantages, for example, diminished landfill-related nuisances impacting local communities (Plebankiewicz et al., 2016; Androjić & Marović, 2019; Purchase et al., 2021; Bochko et al., 2024). Nevertheless, the construction sector retains significant potential for further waste reduction, as the majority of CDW is non-hazardous and suitable for recovery (Spišáková et al., 2021). In this context, Spišáková et al. (2021) advocate for the execution of a construction and demolition waste audit prior to the commencement of demolition/deconstruction activities.

This study is motivated by two principal factors. First, the volume of CDW generated is exceptionally high; according to the latest available statistics published by the statistical authority (Czech Statistical Office [CSU], 2022), CDW accounted for approximately 70% of total waste produced in the Czech Republic between 2017 and 2021.

Second, there is a notable absence of a suitable methodology for the quantification or prediction of separated CDW arising from the demolition of existing panel buildings. At present, estimates of CDW generated during demolition in the Czech Republic are typically based either on demolition budgets – which provide only aggregate waste quantities without further material separation – or on the subjective assessments of designers drawing on their practical experience. Therefore, the objective of this research is twofold: (a) to develop a methodology for estimating the quantitative recycling potential of waste generated from the demolition of panel buildings, and (b) to assess the associated cost implications within the context of the Czech Republic.

Prefabricated, or panel buildings are typically characterized as multi-story structures composed of factory-made panels for floors and walls, which are interconnected both vertically and horizontally to form a rigid, box-like structure (Malazdrewicz et al., 2022). The vertical wall panels typically span the full height of a single story (Shemie, 1973). In the Czech Republic, a variety of prefabricated construction systems have been implemented, including the GOS, VOS, and VPOS systems, among others (Kubečková & Vrbová, 2021); specific systems are often characteristic of particular regions. For the purposes of this study, the T06B panel system was selected due to its status as the most prevalent prefabricated building system in the Czech Republic. The T06B system itself comprises several regional variants. For analytical purposes, the T06B-KDU variant was chosen, which is predominantly found in the contemporary South Moravian Region, Vysočina Region, as well as the Zlín and Olomouc Regions (Panelaky.info, 2020).

In this study, we focus exclusively on the point-access block configuration of the T06B-KDU panel building system. For the purpose of quantifying CDW disposal costs associated with the demolition of a point-access panel building, the “cube” variant was selected as a representative case study. This building type is exemplified, for example, by structures located in the panel housing estate complex in Brno–Žabovřesky, as illustrated in Figure 1.

View of a point-access panel building

Source: own work.

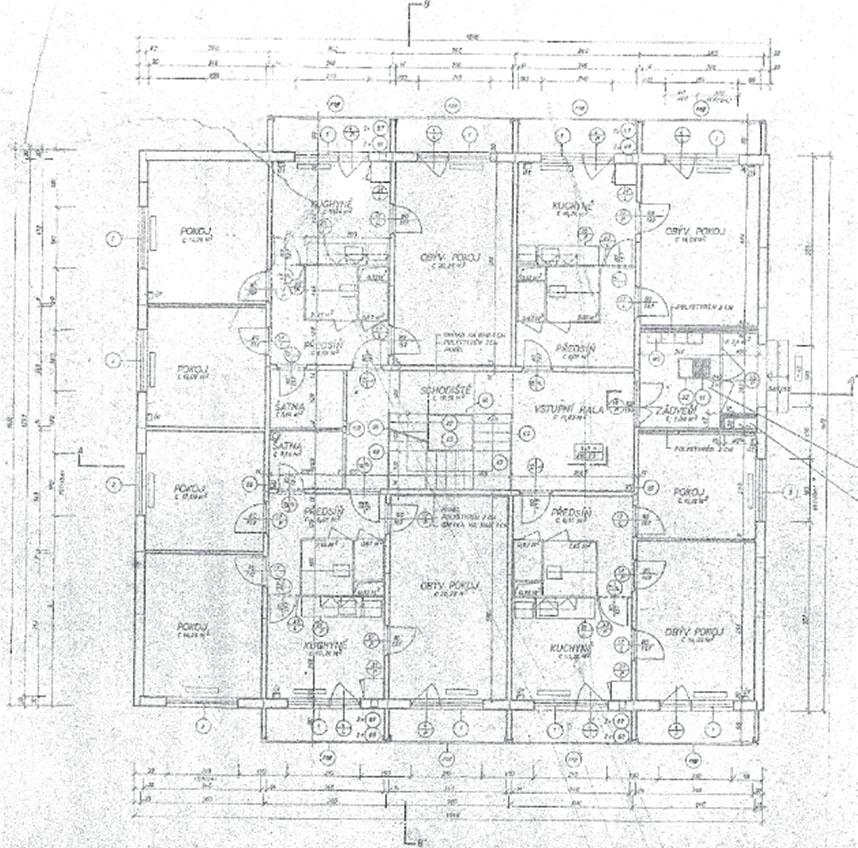

Figure 2 reproduces an excerpt from the original project documentation and depicts a typical floor plan of the analyzed point-access building constructed using the T06B-KDU panel system. Although the graphic quality of the floor plan is relatively low, the authors hereby wish to point out the fact that the original documentation of these buildings is only in paper form of 50-year-old historical documents, the readability of which can be difficult and therefore can complicate CDW estimates.

Typical floor of the surveyed point-access panel building

Source: kindly provided by SBD Průkopník (construction housing cooperative).

The data processing for this study was primarily based on the original project documentation and the associated historical bill of costs. For the analyzed structure, a list of all prefabricated panels, including their respective weights, was obtained from SBD Průkopník (1969). The weights of other structural components were estimated using the BUILDpower S budgeting software at a 2024 price level (RTS a.s., 2024).

The subsequent data analysis categorized the various types of CDW in accordance with the Czech Decree No. 8/2021 Coll. – the Waste Catalogue (Vyhláška č. 8/2021), which classifies CDW based on material characteristics and aligns with the European Waste Classification system EWC-STAT (European Union [EU], 2024). For clarity and auditability, the waste classification was conducted first by construction element and then by the corresponding waste code. Specifically, waste from foundation structures was subdivided into concrete (originating from the foundations), metal (from reinforcement), bitumen strips (from waterproofing layers), and plastic (from plastic sheeting).

Vertical structural components generate CDW comprising concrete (reinforced concrete panels), metals (reinforcement), bricks (brick cores and insulation liners), polystyrene with perlite used in External Thermal Insulation Composite Systems (ETICS), mixtures (internal plaster), and ceramics (ceramic tiles from bathrooms and toilets).

The horizontal structures are divided into three parts: specifically reinforced concrete structures (prefabricated panels), floor construction (floor composition), and roofing (roof composition). Horizontal panels, internal vertical panels, and staircase precast reinforced concrete panels are classified under reinforced concrete structures. Vertical reinforced concrete panels forming the envelope are classified under perimeter casing.

For floor constructions, the following CDW types are expected: concrete (screed), metals (reinforcement), ceramics (tiles), wood (wooden flooring), PVC, carpet materials, and polystyrene. Waste from doors and window fillings is categorized into wood and glass (internal doors), plastic and glass (facade window fillings), and iron and steel (metal garage doors). The roof structure waste consists primarily of aerated concrete insulation (slump layer), bitumen strips (waterproofing), and stones (pebbles).

The results of the analysis were compared with the current approach used for quantifying CDW in the preparation of demolition cost estimates (bill of costs for the demolition). This conventional approach primarily relies on the “demolition” item within the bill of costs, where the critical parameter is the proportional volume of structural components. Specifically, volumes of external walls, internal walls, horizontal load-bearing structures, and staircases are considered without subtracting openings. The volume of these structures is then divided by the total built-up area of the building, which is derived from the adjacent landscaped terrain. Budgeting software typically estimates the total expected waste weight based on internal databases, but does not further disaggregate the waste, e.g., by type.

The analysis encompasses a comparative estimation of the costs associated with recycling separated CDW versus the disposal of mixed waste through landfilling. Cost data (charges) for both recycling and disposal processes were obtained from the RTS price database (RTS a.s., 2024).

Table 1 presents the basic characteristics of the case study panel building previously depicted in Figure 1. The description includes the main dimensions and relevant technical specifications. The building is a residential structure comprising four above--ground floors and one subterranean level. Each residential floor contains four apartment units: two units of type 2 + 1 and two units of type 3 + 1. Here, the notation X + Y denotes the apartment configuration, where X (either 2 or 3) represents the number of rooms, and Y (equal to one) indicates the presence of a separate kitchen.

Input data of a point-access panel building (T06B-KDU)

| Specification | Value | Specification | Value |

|---|---|---|---|

| Number of stories | 4 + 1 | Length [m] | 18.74 |

| Number of tracts | 5 | Width [m] | 16.40 |

| Thermal insulation of the building (yes/no) | yes | Thickness of thermal insulation [m] | 0.14 |

| Paving area [m2] | 171.06 | Built-up area of one story [m2] | 307.34 |

| PVC area [m2] | 595.95 | Built-up space [m3] | 4,598.65 |

| Carpet area [m2] | 198.65 | Facade area [m2] | 580.16 |

| Parquet floor area [m2] | 256.80 | Number of residential units per floor | 4 |

Source: own work.

Table 2 presents the estimated quantities for all the structures included in the analysis. The data include total CDW volumes for the entire building as well as normalized CDW values expressed per 1 m3 of built-up area. The CDW is categorized into seven distinct waste categories, with each waste type specifying the feasibility of recycling based on consultation with recycling centers and landfill sites (Kovosteel recycling, s.r.o., and FCC Czech Republic, s.r.o.).

Analysis results for a point-access panel building

| Waste category | Quantity of waste | Recyclability [yes/no] | |

|---|---|---|---|

| per whole building [t] | per 1 m3 built-up space [t·m−3] | ||

| Foundation construction of which | 276.92978 | 0.06022 | – |

| 17 01 01 Concrete | 272.16255 | 0.05918 | yes |

| 17 03 02 Bituminous mixtures | 4.73030 | 0.00103 | no |

| 17 02 03 Plastic | 0.03693 | 0.00001 | no |

| Perimeter casing of which | 362.18580 | 0.07876 | – |

| 17 01 01 Concrete | 311.36000 | 0.06771 | yes |

| 17 01 01 Iron and steel (reinforcement) | 1.65000 | 0.00036 | yes |

| 17 01 07 Mixtures of bricks | 41.00656 | 0.00892 | yes |

| 17 06 04 Insulation materials | 8.16924 | 0.00178 | no |

| Reinforced concrete structures of which | 1,060.44003 | 0.23060 | – |

| 17 01 01 Concrete | 875.38800 | 0.19036 | yes |

| 17 01 01 Iron and steel (reinforcement) | 27.55200 | 0.00599 | yes |

| 17 01 01 Mixtures (interior plaster) | 157.50003 | 0.03425 | yes |

| Floor construction of which | 151.29183 | 0.03290 | – |

| 17 01 01 Concrete | 136.30226 | 0.02964 | yes |

| 17 01 01 Iron and steel (reinforcement) | 5.66373 | 0.00123 | yes |

| 17 01 07 Mixtures of tiles | 3.88752 | 0.00085 | yes |

| 17 02 01 Wood | 2.97250 | 0.00065 | no |

| 17 06 04 Pure polystyrene | 0.12990 | 0.00003 | no |

| 20 03 07 PVC flooring | 1.93612 | 0.00042 | no |

| 20 03 07 Carpets | 0.39980 | 0.00009 | no |

| Brick core of which | 29.45596 | 0.00641 | – |

| 17 01 07 Mixtures of bricks | 21.54065 | 0.00468 | yes |

| 17 01 07 Mixtures of tiles | 7.91531 | 0.00172 | yes |

| Facade fillings of which | 7.87681 | 0.00171 | – |

| 17 09 04 Wood + glass | 2.07200 | 0.00045 | yes |

| 17 09 04 Plastic + glass | 2.31261 | 0.00050 | yes |

| 17 04 05 Iron and steel (doors) | 3.49220 | 0.00076 | yes |

| Roofing of which | 25.11277 | 0.00546 | – |

| 17 03 02 Bituminous mixtures | 3.00877 | 0.00065 | no |

| 17 05 04 Soils and stones | 15.55025 | 0.00338 | yes |

| 17 01 02 Aerated concrete | 6.55375 | 0.00143 | no |

| Total amount of monitored waste | 1,913.29298 | 0.41606 | – |

Source: own work.

Table 3 summarizes the total quantities of CDW classified by recyclability. The analysis indicates that up to 98% of the waste generated from the demolition of a prefabricated building has the potential for recycling. The remaining 2% is likely to be disposed of via landfilling or incineration. Consultations with recycling facilities revealed that, within the current Czech Republic waste management framework, certain materials – including bitumen strips, plastic sheeting, polystyrene, wooden flooring, PVC and carpet, as well as aerated concrete – are not recyclable.

Recyclability of generated waste

| Waste | Quantity | |

|---|---|---|

| [t] | [%] | |

| Recyclable | 1,885.35567 | 98.54 |

| Non-recyclable | 27.93731 | 1.46 |

Source: own work.

The recyclability potential of CDW has significant cost implications. Waste that is eligible for recycling incurs lower disposal costs, whereas non-recyclable waste is associated with higher expenses (charges) due to its predominant disposal via landfilling or incineration. These cost differentials are detailed in Table 4 (converted to EUR with exchange rate 1 EUR = 25.185 CZK, valid to 31.12.2024).

Waste recycling/disposal costs, source of unit cost data

| Type of waste | Unit waste recycling//disposal costs [EUR/t] | Quantity [t] | Total costs [EUR] |

|---|---|---|---|

| 17 01 01 Lightly reinforced concrete, piece size up to 1,600 cm2 | 12.61 | 1,787.57857 | 22,535.49 |

| 17 01 02 Aerated concrete | 20.13 | 6.55375 | 131.93 |

| 17 01 07 Mixed waste concrete, bricks, tiles, and ceramic products, piece size up to 1600 cm2 | 18.48 | 74.35004 | 1,374.23 |

| 17 02 01 Wood | 62.97 | 2.97250 | 187.19 |

| 17 02 03 Plastic | 240.62 | 0.03693 | 8.89 |

| 20 03 07 PVC floor covering | 240.62 | 1.93612 | 465.87 |

| 20 03 07 Carpets | 240.62 | 0.39980 | 96.20 |

| 17 03 02 Bitumen strips | 240.62 | 7.73907 | 1,862.17 |

| 17 05 04 Soils and stones | 18.05 | 15.55025 | 280.63 |

| 17 06 04 Polystyrene | 240.62 | 8.29914 | 1,996.93 |

| 17 09 04 Wood + glass | 114.35 | 2.07200 | 236.94 |

| 17 09 04 Plastic + glass | 114.35 | 2.31261 | 264.46 |

| 17 04 05 Iron scrap over 4 mm thick | −133.16 | 3.49220 | −465.01 |

| Total | 1,913.29298 | 28,975.91 |

Source: RTS a.s. (2024).

According to the data presented in Table 4, the total estimated cost for the disposal of waste generated from the demolition of the case study panel building (comprising both recycling and landfilling) amounts to approximately EUR 29,000. In contrast, if the waste were not segregated and consequently required full landfilling, the disposal cost would be EUR 240.62 per 1 ton of mixed waste, resulting in a total expense of approximately EUR 460,375.44 for the entire volume of CDW. This reflects a cost differential of approximately EUR 431,000, which can be interpreted as the potential savings attainable through the full utilization of the current recycling capabilities available in the Czech Republic.

Furthermore, these findings were compared with waste quantity estimates derived from the demolition budget generated using the BUILDPower S software. The proportion of the structure in a point-access panel building was found to be approximately 19% of the built-up space, leading to the selection of the budget item “981014713R00 – Demolition of buildings by mechanization, reinforced concrete, construction up to 20%”. This item prescribes a predefined waste generation factor of 0.42 t·m−3 of built-up area. Given the case study building’s built-up volume of 4,598.65 m3, the estimated waste quantity is 1,931.433 tons, which is marginally higher than the estimate obtained via the more detailed analysis proposed by the new methodology.

Additionally, the weight of foundation structures must be considered, with an estimated volume of approximately 108 m3. Based on RTS a.s. data, the expected waste weight from the foundation structures is approximately 215.58 tons. Consequently, the total waste weight estimated from the demolition budget amounts to 2,147.013 tons, representing a discrepancy of roughly 10% compared to the detailed analysis. This difference may be attributed to the exclusion of certain structural components related to construction production, such as building services, locksmith structures, and plumbing installations.

The study introduces a methodology for the economic analysis of CDW management specific to panel buildings in the Czech Republic. This methodology addresses the existing gap in methodologies capable of accurately quantifying the volume of source-separated CDW generated during the demolition of panel buildings. Consequently, it enables the assessment of recycling potential and facilitates the evaluation of associated economic factors, considering both feasible recycling processes and the necessary landfilling.

The analysis yields several key conclusions. First, the results demonstrate that implementing sorting and recycling strategies for CDW can substantially reduce disposal costs compared to the alternative of disposing of the entire waste volume via landfilling. Second, the case study of a point-access panel building indicates that up to 98% of the generated CDW could be recycled based on the structural components considered. Third, the proposed methodology provides the capability to monitor waste quantities by individual material categories, thereby supporting the optimization of recycling capacities.

At a theoretical level, the analyses conducted contribute to an enhanced understanding of the management challenges associated with CDW from prefabricated residential buildings, which constitute a substantial portion of the housing stock in Central, Eastern, and Southeastern Europe. From a managerial perspective, the proposed methodology enables practitioners to effectively plan for waste separation by considering both the necessary technological solutions and the required processing capacities.

This research is not without limitations. The analysis did not evaluate the cost-effectiveness or operational feasibility for builders in separating individual CDW fractions. The primary objective was to develop a methodology for quantifying the volume of source-separated waste while maximizing recycling potential, thereby promoting environmental benefits through the reduction of landfill disposal. Additionally, the analysis excluded certain building components, such as sanitary installations, heating systems, and minor structural elements (e.g., staircase railings, plumbing fixtures), which may contribute to the overall waste generation.

The question remains to what extent technologies for separating and recycling CDW are available in the Czech Republic. Building on the proposed methodology, future research should assess the readiness of recycling facilities to accommodate increased future waste volumes and to process waste types that are presently non-recyclable. At present, demolition and deconstruction of panel buildings in the Czech Republic remain relatively rare. Identification of a suitable panel building scheduled for demolition would provide an opportunity to validate and potentially refine the proposed methodology and its estimations of separated waste quantities.