The construction industry has experienced a notable evolution in recent decades, propelled by the need to satisfy increasing infrastructure demands alongside the necessity of tackling environmental sustainability issues (Ramanna et al., 2024). Contemporary construction methods are progressively focusing on the creation of building materials that fulfill structural performance standards while also aiding in environmental protection and resource efficiency (Shurrab et al., 2019). This significant change has prompted a thorough investigation into alternative materials and cutting-edge construction methods that aim to minimize the environmental impact of infrastructure development, all while preserving or improving both structural and nonstructural integrity and durability (Aslami, 2023).

The historical development of paving materials has been intricately connected to patterns of urbanization and advancements in technology (Arya & Sahu, 2024). Conventional paving techniques, which depended significantly on stone dust and simple concrete mixtures, have slowly transitioned to more advanced methods that utilize engineered materials and innovative mixing processes (You et al., 2018). The shift from traditional asphalt and concrete pavements to modular paving systems marks an important advancement in construction technology, providing enhanced flexibility, maintenance efficiency, and environmental performance when compared to monolithic paving solutions (Sylvester, 2017).

In modern construction material selection, environmental considerations have taken center stage, especially regarding urban infrastructure development (Abouhelal et al., 2023). The idea of sustainable construction highlights the significance of using materials that reduce environmental impact across their entire lifecycle, from the extraction of raw materials to their disposal or recycling at the end of life (Wang, 2025). This approach has encouraged exploration among experts and practitioners for alternative materials that can lessen dependence on conventional cement-based systems while upholding structural performance standards (Blok et al., 2019). The incorporation of waste materials and by-products into construction applications has surfaced as a promising approach for realizing both environmental and economic advantages (Jaya et al., 2025).

The components of paving blocks or concrete pavers include cement or other binding materials, water, quartz powder, and aggregates. These precast building components maintain their quality despite the presence of additional substances (Megawati, 2018). Currently, paving blocks are widely employed by communities for the development of diverse structures, such as sidewalks, parking lots, and yards. Paving blocks are commonly utilized because they can withstand pressures within specific limits and are easy to install. Furthermore, paving blocks offer distinct advantages over traditional pavements, particularly regarding their environmental benefits as water-permeable surfaces, their potential for mass production, and their visual attractiveness.

Stone dust is generally added to the mix alongside cement, aggregates, and water when producing paving blocks. This additive significantly increases the durability of the block while also enhancing its surface finish. Due to escalating prices, diminishing availability, and heightened demand for stone dust, it is essential to explore alternative options. Quartz powder is classified as an admixture during the mixing process. The pulverized substance is integrated into the paving block mixture to enhance the characteristics of the mix or the paving block (Mulyati & Jovari, 2024).

The strength of paving blocks is notably affected by the inclusion of calcium oxide (CaO) and silica (SiO2) in the materials utilized for their preparation, including sand. To improve the durability of the paving blocks, fine aggregates that are abundant in silica and calcium, including quartz sand and river sand, are incorporated (Awolusi et al., 2023). Quartz sand is widely available across all regions of West Kalimantan, with a total accumulation of 630,431,456.75 tons (Dinas Energi dan Sumber Daya Mineral Provinsi Jawa Barat, 2018). Nonetheless, the application of quartz sand as fine aggregate in paving blocks is infrequent, leading to its insufficient utilization. Quartz sand is mainly composed of quartz crystals (SiO2). Quartz sand consists of various components, including CaO (calcium oxide), SiO2 (silicon dioxide), Al2O3 (aluminum oxide), Fe2O3 (iron oxide), TiO2 (titanium oxide), K2O (potassium oxide), and MgO (magnesium oxide). When reduced to the powder scale, these oxide materials will display modified properties, which are then designated as powder materials. Upon refinement, quartz sand with a particle size of less than 0.074 mm will undergo alterations in its properties or functions. Throughout the refinement process, the particle size of the sand is diminished from fine aggregate dimensions to a minuscule size nearing the powder scale (Pradhipta, 2022). After the quartz powder undergoes fine pulverization, it reveals a significant concentration of SiO2. The physical and mechanical properties of paving blocks are expected to improve through the conversion of fine aggregate into powder, recognized as a beneficial additive (Sutandar & Budi, 2024).

Additives are generally divided into two main categories: chemical admixtures and mineral admixtures (Nugroho, 2020). Furthermore, to improve the quality of the paving blocks manufactured in accordance with SNI 03-0691 (BSN, 1996), it is essential to identify the optimal composition of quartz powder to guarantee that the paving blocks produced fulfill the necessary standards (Winanda, 2018). This study will utilize a basic mixture consisting of 1 part cement, 0.2 parts coarse aggregate, and 3.8 parts fine aggregate, derived from earlier studies that yielded Class B quality paving blocks (Milang & Masagala, 2022).

This study aims to develop a formulation for paving block production by substituting stone dust with quartz powder as a mineral admixture (Harimukti, 2022). This formulation will yield Class B paving blocks that adhere to the national standards set forth by Indonesia.

The materials utilized in this study included cement, fine aggregates, coarse aggregate, and quartz sand.

Portland composite cement (PCC) has been identified as the primary binder for the production of paving blocks and concrete (Tw et al., 2023). The findings outlined in this study involved the utilization of PCC. Cement is essentially a hydraulic material, as it hardens when combined with water or an aqueous solution, serving as a bonding agent (BSN, 1990). Table 1 outlines that cement consists of three fundamental components with a defined composition.

Constituents of cement composition

| Specification | Quantity [%] |

|---|---|

| Silicon dioxide (SiO2) | 23.04 |

| Aluminum oxide (Al2O3) | 7.40 |

| Ferric oxide (Fe2O3) | 3.36 |

| Calcium oxide (CaO) | 57.38 |

| Magnesium oxide (MgO) | 1.91 |

| Sulfur trioxide (SO3) | 2.0 |

| Loss on ignition (Lo1) | 3.94 |

| Free lime | 0.56 |

| Insoluble residue | 10.96 |

Source: own research.

The mixture for paving blocks incorporates fine aggregate to improve the strength of the blocks, reduce shrinkage, and lessen the quantity of binders and cement needed (Nofrianto & Hutrio, 2023). Fine aggregate typically consists of natural sand or crushed stone, characterized by a predominant particle size ranging from 0.0625 mm to 2 mm. Fine aggregate is essential in concrete mixes, as it occupies the spaces between coarse aggregates, enhances density, and contributes to the workability and strength of concrete (Nofrianto & Hutrio, 2023). This research indicates that river sand possesses a gritty texture, attributed to its source from the rivers of West Kalimantan. Table 2 presents the physical characteristics of the fine aggregates utilized.

Characteristics of the fine aggregate

| Specification | Quantity |

|---|---|

| Specific gravity [kg·m−3] | 2.646 |

| Fine modulus [-] | 3.030 |

| Bulk density [kg·m−3] | 1,523.65 |

| Fine particles less than 0.0075 mm [%] | 5.43 |

Source: own research.

The coarse aggregate is sourced from crushed stone in the Kalimantan Barat region, consisting of stones with a maximum dimension of 0.5 mm. Table 3 presents the physical characteristics of the coarse aggregate used.

Characteristics of the coarse aggregate’s physical properties

| Specification | Quantity |

|---|---|

| Absorption [%] | 0.188 |

| Bulk density [kg·m−3] | 1.668 |

| Water content [%] | 0.272 |

| Fine modulus | 4.9 |

| Aggregate abrasion [%] | 12.21 |

| Mud content [%] | 2.4 |

| Specific gravity [kg·m−3] | 2.455 |

Source: own research.

Mineral resources represent finite natural assets that generally encompass multiple valuable minerals (Mulyati, 2023). Alongside the primary minerals, the associated minerals can also possess significant economic potential for extraction. The Mandor River basin hosts numerous alluvial gold deposits that are being extracted by the local community. Landak Regency possesses a remarkable abundance of potential mineral resources. Ilmenite (TiO2), magnetite (Fe2TiO4), and zircon (ZrSiO4), along with various other minerals, are commonly found in alluvial gold deposits. The utilization of these accompanying minerals, which encompass rare earth elements (REE), has the potential to enhance product quality across various sectors, including metal, information technology, electronics, oil and gas, and nuclear energy. As a result, there is an anticipated rise in global market demand for REE.

Quartz is found in the research domain as grit that is dispersed within the alluvial deposits, currently associated with artisanal gold mining residues. The sediments in the study area consist of a combination of clay and silica sand (Falah & Muzaki). Quartz powder presents as a whitish-gray substance characterized by granules that range from fine to coarse in texture. The composition includes whitish-green elements of igneous rock and silt (Nabila et al., 2023). The resources of quartz powder are calculated by taking the depth of each borehole, multiplying it by the area of influence associated with each borehole, and subsequently multiplying that result by the specific gravity of quartz. The results of the expected quartz resource assessments at each study site are as follows: The total quantity of quartz sand resources across the five regions of Mandor is 5,245,400 tons, covering an influence area of 322,290 m2 (32.23 ha). The quartz sand in the study area is notably plentiful and typically devoid of impurities such as soil and silt, having undergone a purification process during the gold mining operations. Currently, the local community employs quartz powder as a fundamental resource for construction purposes (Umurrudin et al., 2018). Table 4 presents the physical properties of quartz powder. The physical properties of quartz sand converted into quartz powder are detailed in Table 5.

Results of the chemical analysis of quartz powder

| Specification | Quartz powder content [%] | |

|---|---|---|

| samples from Mandor riverbank | samples from Mandor riverbank | |

| Silicon dioxide (SiO2) | 98.6 | 98.8 |

| Aluminum oxide (Al2O3) | 0.51 | 0.29 |

| Ferric oxide (Fe2O3) | 0.25 | 0.25 |

| Ilmenite dioxide (TiO2) | 0.18 | 0.15 |

| Calcium oxide (CaO) | 0.21 | 0.21 |

| Potassium dioxide (K2O) | 0.012 | 0.028 |

| Magnesium oxide (MgO) | – | – |

| Free calcium oxide | – | – |

| Water (H2O) | – | – |

Source: own research.

Physical properties of quartz sand

| Specification | Quantity |

|---|---|

| Bulk density [kg·m−3] | 1.760 |

| Organic content [%] | 3 |

| Water content [%] | 4.55 |

| Mud content [%] | 2.88 |

Source: own research.

The water utilized in this study is sourced from local water providers (PDAM). The pH of municipal water ranges from 6 to 7, indicating that it is in excellent condition and complies with the quality standards for potable water. This water serves as a crucial component in the preparation of paving block materials, including cement, fine aggregate, coarse aggregate, and quartz powder. The quality of water is crucial for maintaining the integrity of the mix and the strength of the final product, adhering to the established standards for paving block production.

Figure 1 demonstrates the methodology for material combination, whereas Table 6 details the mix proportions employed in the experimental procedures. This study utilizes quartz powder as an alternative to stone dust.

Stepwise procedure for the paving block production

Source: own research.

Mix design for paving blocks (volume of 1 m3)

| Variation | Cement | Fine aggregate | Coarse aggregate | Quartz powder | Water to cement ratio (w/c) |

|---|---|---|---|---|---|

| 0% | 1 | 3.8 | 0.2 | 0 | 0.3 |

| 10% | 1 | 3.8 | 0.2 | 0.1 | 0.3 |

| 20% | 1 | 3.8 | 0.2 | 0.2 | 0.3 |

Source: own research.

Following the casting of the paving blocks, a curing duration of 28 days is necessary. During the testing phase, it is essential that the paving blocks are in a dry state. The measurements of the paving blocks are taken in terms of length, width, and thickness. The examination of the paving block’s surface encompasses the state of the corners, density, and overall surface condition.

The paving block undergoes a drying process in an oven for a duration of 24 hours to achieve a dehydrated state. Once the required data has been gathered, the calculation of the sample’s bulk density is performed using the subsequent equation:

A water absorption test was conducted following BS 1881-122 (BSN, 2011) to determine the amount of water absorbed under the specified conditions. Following a period of 28 days, the paving block samples underwent an oven-drying process at 1,100°C for a duration of 24 hours. Following this, the paving block was completely immersed in water for a duration of 24 hours after establishing the oven-dry weight. The measurement of weight after water immersion was also performed.

The wear testing process is carried out to assess the capacity of the paving block to endure the friction present on the surface layer across each variation of the paving block. The testing is conducted once the paving block has matured for 28 days.

The compressive strength of the samples was evaluated at 7 days, 14 days, 21 days, and 28 days following ASTM C39 (ASTM, 2023) and ALCONPAT protocols, utilizing the universal testing machine. The paving block samples were laid flat on their full face, and the compressive strength value was determined by dividing the maximum test load (up to the point of rupture) by the cross-section of the paving block specimen.

Once the cast paving block samples are fully dried, the testing phase can begin. Prior to testing, the paving blocks undergo a conditioning process involving water application, which guarantees that the sun-dried blocks maintain a uniform moisture content. Following this, the paving blocks were assessed for weight in a dry state after a curing period of 28 days.

Figure 2 depicts the relationship between age and bulk density across three different conditions: 0% quartz powder (blue), 10% quartz powder (orange), and 20% quartz powder (gray). At 3 days of age, the sample containing 10% quartz powder (orange) demonstrates the highest bulk density, followed by the 20% quartz powder (gray), whereas the 0% quartz powder (blue) displays the lowest bulk density. At 7 days of age, the bulk density was still elevated at 20% quartz powder, while the 10% variant showed a slight increase compared to the 0% variant. From 14 to 28 days, the variations begin to converge, leading to a stabilization in bulk density; nonetheless, the 20% quartz powder consistently shows the highest values across various intervals. In the initial stages of interpretation (3 days and 7 days), the samples containing 10% and 20% quartz powder demonstrated higher bulk densities compared to those with 0% quartz powder.

Relationship between bulk density and age for all variations of paving blocks

Source: own research.

This indicates that, during the early stages, the incorporation of extra quartz powder has a beneficial effect on bulk density. As the age advances from 14 days to 28 days, the disparities among the variations lessen, indicating that the initial influence of quartz powder begins to wane or stabilize over time. Samples containing 20% quartz powder demonstrated an increased bulk density at various ages, indicating that in these circumstances, the presence of additional quartz powder had a more pronounced effect compared to other conditions. The variations of 10% and 20% lead to an increase in bulk density during the early stages, especially noticeable at 3 days and 7 days. In the later stages (14‒28 days), the variations show minimal differences; however, the 20% quartz powder continues to demonstrate higher values at certain points. For maintaining a higher bulk density in the long term, incorporating 20% quartz could prove to be more beneficial.

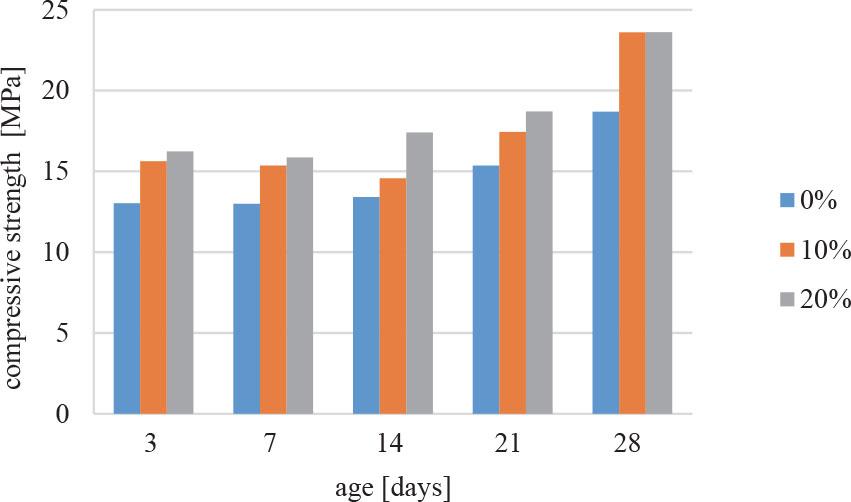

The compressive strength results of the quartz particle variations for paving blocks are illustrated in Figure 3. The compressive strength increases with the curing days, as anticipated, in the range of 13.03‒18.69 MPa, 15.63‒23.60 MPa, and 16.23‒23.61 MPa for the 3-, 7-, 14-, 21-, and 28-day curing periods, respectively. The paving blocks containing different quantities of quartz powder exhibited the greatest compressive strength compared to the other mixtures tested; nonetheless, utilizing quartz powder as a binder did not lead to a noteworthy enhancement in compressive strength. The reduction in strength observed in certain variations can be attributed to the development of less robust interfacial transition zones (ITZ) between the quartz powder and the aggregate. Nonetheless, paving blocks that incorporate quartz powder demonstrate superior compressive strength when compared to those that lack this modification. The maximum compressive strength observed for paving blocks containing 20% quartz powder was 23.61 MPa. Paving blocks that achieve a compressive strength of 20 MPa or greater at 28 days are classified as Class B under Indonesian standards. These blocks are suitable for applications in parking lots, pedestrian zones, and other areas with light loads.

Relationship between compressive strength and age for all variations of paving blocks

Source: own research.

The analysis of variance (ANOVA) performed to assess the effect of quartz powder addition on the compressive strength of paving blocks yields strong statistical evidence concerning the experimental results. The computed F-statistic of 1.574 is significantly lower than the critical F-value of 3.89 at the established significance level of α = 0.05, suggesting that the differences observed among the treatment groups (0%, 10%, and 20% quartz powder addition) lack statistical significance. This finding is supported by the p-value of 0.247, which is above the established alpha threshold, resulting in the retention of the null hypothesis (H0) that posits no significant difference between the mean compressive strengths of the various mixture compositions. The inter-group mean square value of 14.90, when compared to the intra-group mean square of 9.47, indicates that the variation within groups is relatively comparable to the variation between groups. This reinforces the conclusion that the addition of quartz powder at the tested concentrations does not significantly affect the mechanical properties of the paving blocks.

From a practical engineering perspective, this statistical outcome suggests that the use of quartz powder as a partial substitute for traditional aggregates maintains the structural integrity of the paving blocks, thereby endorsing its potential as a sustainable alternative material. The economic implications of these findings are notably important, as the use of quartz powder – a waste material with limited commercial value – at a 10% replacement level could greatly lower manufacturing costs while maintaining the product’s mechanical performance, thereby offering an environmentally and economically sound solution for paving block production.

The data indicates that all variants fall under the Class B category of paving blocks as per the quality standards outlined in SNI 03-0691 (Table 7).

Compressive strength of paving blocks

| Variation | Compressive strength at 28 days of age [MPa] | SNI 03-0691 (paving block classification) | Class | |||

|---|---|---|---|---|---|---|

| A | B | C | D | |||

| 0% | 18.69 | 35 | 17 | 12.5 | 8.5 | B |

| 10% | 23.60 | 35 | 17 | 12.5 | 8.5 | B |

| 20% | 23.61 | 35 | 17 | 12.5 | 8.5 | B |

Source: own research.

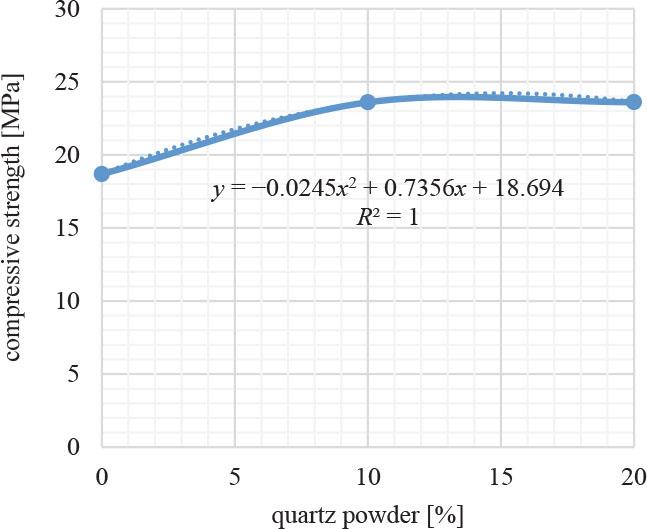

Figure 4 demonstrates the relationship between compressive strength and the percentage of quartz powder. The graph clearly illustrates that the compressive strength rises with an increase in quartz powder percentage until it hits a peak, after which there is a slight decline.

Relationship between compressive strength and quartz powder percentage for all variations of paving blocks

Source: own research.

The model utilized demonstrates a strong alignment with the existing data, as indicated by the quadratic regression equation: y = −0.0245x2 + 0.7356x + 18.694, with an R2 value of 1. This equation effectively accounts for all data points in a satisfactory manner. The addition of quartz powder leads to an increase in compressive strength, as demonstrated by the pattern observed in the graph, ultimately peaking at around 10%. The compressive strength value subsequently shows a slight reduction as the quartz powder content rises to 20%. At a quartz powder level of around 10%, the peak compressive strength reaches approximately 25 MPa. As a result, the optimal level for compressive strength is determined to be 10% quartz powder. It is essential to assess whether the extent of the reduction at elevated levels is significant or if it stays within an acceptable limit beyond the optimal point, given that an increase in quartz powder leads to a slight decline in compressive strength.

The water absorption capacity for each variation of paving block is assessed via absorption testing, conducted once the paving block has matured for 28 days.

The absorption values presented in Table 8 indicate the average absorption percentage of the paving block variations that utilize quartz powder in place of stone dust. The 20% variation demonstrated the lowest absorption value at 6.78%. The 0% variation exhibited the highest absorption value of 9.96%, as established through the tests and calculations performed on all variations of the paving blocks. The absorption test performed according to SNI 03-0691 resulted in Quality C for paving blocks containing 10% and 20% quartz powder, while those with 0% quartz powder received a Quality D rating.

Absorption of paving blocks

| Variation | Present absorption [%] | SNI 03-069 (paving block classification) | Class | |||

|---|---|---|---|---|---|---|

| A | B | C | D | |||

| 0% | 9.96 | 3 | 6 | 8 | 10 | D |

| 10% | 7.84 | 3 | 6 | 8 | 10 | C |

| 20% | 6.78 | 3 | 6 | 8 | 10 | C |

Source: own research.

Figure 5 demonstrates the relationship between the percentage of quartz powder and absorption levels. The observed pattern indicates a decrease in the absorption value with an increase in quartz powder. This suggests that the capacity of the paving blocks to absorb water is diminished due to variations or inconsistencies in the quartz powder. The equation y = 0.0053x2 − 0.265x + 9.96, derived from the graph, indicates that this relationship is quadratic or curved instead of linear. The decrease in absorption is not uniform; rather, it exhibits a distinct pattern that decelerates as the proportion of quartz powder increases.

Relationship between absorption and quartz powder percentage for all variations of paving blocks

Source: own research.

The R2 value of 1 clearly indicates that this equation precisely fits the data. This demonstrates that every tested data point aligns perfectly with the equation, exhibiting no discrepancies. In summary, the water absorption capacity of paving blocks could be diminished by an increased percentage of quartz powder or other influencing factors, such as the method employed. This can serve as an essential consideration in the development of materials that require minimal water absorption, like paving blocks. This graph clearly illustrates the significant role that quartz powder percentages play in maintaining optimal absorption values.

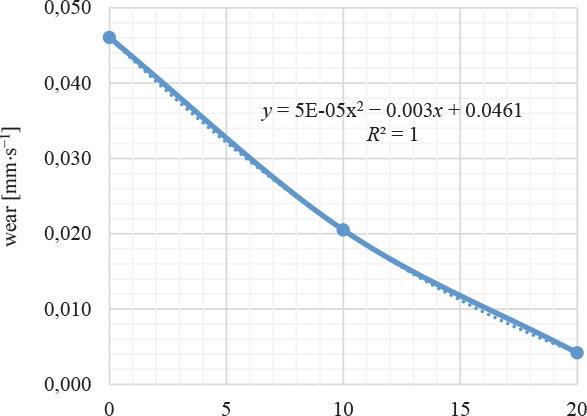

When the paving blocks reach 28 days of age, wear testing is conducted to ascertain their capacity to tolerate friction on the surface layer in each variation of paving blocks (Table 9).

Wear of paving blocks

| Variation | Wear [mm·min−1] | SNI 03-0691 (classification) | Class | |||

|---|---|---|---|---|---|---|

| A | B | C | D | |||

| 0% | 0.046 | 0.103 | 0.149 | 0.184 | 0.251 | A |

| 10% | 0.021 | 0.103 | 0.149 | 0.184 | 0.251 | A |

| 20% | 0.004 | 0.103 | 0.149 | 0.184 | 0.251 | A |

Source: own research.

The wear value in Table 9 represents the average wear percentage of the paving block variations with quartz powder as a substitute for stone dust. In the wear test, all variations of the paving blocks are classified as Quality A according to SNI 03-0691.

Figure 6 illustrates the correlation between age and wear. The observed pattern indicates that wear diminishes with an increase in the level of quartz powder. This indicates a particular effect that reduces the degradation of the paving block material. The graph has produced the equation y = 5E-05x2 − 0.003x + 0.0461, demonstrating a quadratic relationship. This suggests that the effect of quartz powder on wear is characterized by a curvilinear relationship rather than a linear one. With an increase in the level of quartz powder, the impact of reduced wear becomes increasingly pronounced. Furthermore, the equation’s ability to precisely depict the existing data is evidenced by an R2 value of 1. In summary, all the tested data points conform to the established pattern of the equation, without any exceptions. The findings indicate that increasing the percentage of quartz powder in the paving blocks could potentially reduce wear, highlighting a practical approach to enhancing durability. This graph illustrates a strong relationship between wear and quartz powder concentrations, indicating that paving blocks show diminished wear levels as quartz powder increases. This could serve as a basis for designing or optimizing the production of paving blocks to enhance durability and minimize erosion.

Relationship between wear and quartz powder percentage for all variations of paving blocks

Source: own research.

Paving blocks are subjected to a thorough visual inspection to ensure they are level and devoid of any defects or cracks and that their corners and edges can withstand manual handling without breaking. The thickness tolerance of the paving block’s dimensions is approximately 8%. The test is performed once the paving block has attained an age of 28 days (Table 10).

Visual condition of paving blocks

| Variation | Description | Sample condition | According to SNI 03-1691-1996 |

|---|---|---|---|

| 0% | STRUCTURE | ||

| flatness | flat | flat | |

| crack | no crack | no crack | |

| surface texture | rough | smooth | |

| FLANK | |||

| geometry | geometry | geometry | |

| sharpness | sharp | sharp | |

| strength | strong | strong | |

Source: own research.

The findings from the experiments carried out (Table 11) indicate that all variations meet the visual and physical criteria specified in SNI 03-0691.

Size of paving blocks

| Variation | Thickness condition [mm] | Thickness [mm] | Tolerance | Length [mm] | Width [mm] | According to SNI 03-1691-1996 |

|---|---|---|---|---|---|---|

| 0% | 64.20 | 60 | ±8% | 210 | 105 | fulfilled |

| 10% | 59.50 | 60 | 210 | 105 | fulfilled | |

| 20% | 60.78 | 60 | 210 | 105 | fulfilled |

Source: own research.

The thorough experimental study of incorporating quartz powder in the production of paving blocks reveals considerable potential for real-world applications within the construction sector. The findings clearly demonstrate that the ideal 10% quartz powder variation provides exceptional performance traits that directly contribute to improved field applicability and economic feasibility. The decreased bulk density of paving blocks with 10% quartz powder offers significant benefits regarding transportation efficiency, ease of installation, and lower structural loading requirements. This makes them especially appropriate for large-scale infrastructure projects, where material handling costs represent a considerable share of total project expenses. The attainment of Class B compressive strength in all variations guarantees structural integrity for standard paving uses, such as pedestrian pathways, residential driveways, and light commercial surfaces, thus fulfilling essential engineering standards for practical application.

The significant enhancement in water absorption properties, with the 10% and 20% quartz powder variations reaching Class C absorption as opposed to Class D for traditional mixtures, suggests improved durability and longevity under field conditions, especially in tropical climates where moisture-related degradation presents considerable challenges to pavement performance. The outstanding resistance to deterioration and attrition exhibited by all variations, along with satisfactory visual quality traits such as flat surfaces, a crack-free appearance, and accurate geometric dimensions, guarantees that these paving blocks will preserve their aesthetic and functional properties in typical field service conditions. The dimensional stability and thickness compliance across all variations further confirm the manufacturing consistency necessary for effective field implementation, tackling quality control issues that are essential for large-scale production and deployment.

From a practical implementation standpoint, identifying 10% quartz powder as the optimal variation presents a strong argument for immediate field application. This approach offers the advantages of reduced material weight, enhanced moisture resistance, preserved structural integrity, and potential cost savings through the utilization of waste materials. The results offer construction professionals empirically supported information to aid in the specification and implementation of quartz powder-enhanced paving blocks in practical applications, enhancing both sustainable building practices and pavement performance benchmarks. The study lays the groundwork for increasing production and putting in place quality control measures essential for the effective commercial use of this groundbreaking paving block technology.