In 2021, the European Commission formally released a document entitled ‘Industry 5.0: Towards a Sustainable, Human-Centric, and Resilient European Industry’ calling for The Fifth Industrial Revolution (Industry 5.0), a successor to the 10-year older Fourth Industrial Revolution (Industry 4.0) that was first introduced in Germany (Xu et al. 2021). This agenda aims to promote a shift from the core goals of Industry 4.0, which mainly called for the increase in efficiency and productivity through the integration of digital technologies such as artificial intelligence, robotics, blockchain and others, towards principles that promote social fairness and sustainability (Xu et al. 2021; Bennett et al. 2023). According to Ghobakhloo et al. (2022) ‘Industry 4.0 centers around technology-driven productivity … It cannot move past the profit-centricity of the contemporary production and consumption economic models’.

There are three core values that define Industry 5.0: (1) human-centric, (2) sustainability, and (3) resilience. These core values place human well-being at the forefront of this industrial shift (Leng et al. 2022). Particularly, the human-centric pillar aims to serve the human aspect of the industry, addressing their needs and requirements and developing technology that can help enhance social sustainability, where the physical and mental health of workers are the core goals (Xu et al. 2021). This focus may be seen as a response to the outcomes of Industry 4.0 (Battini et al. 2022).

The construction industry is labour-intensive and is renowned for its physically demanding tasks (Bennett et al. 2023; Lindhard et al. 2023). Construction workers are constantly engaged in manual activities performed in dynamic environments, severe exposure conditions, and high levels of uncertainty. Kim et al. (2019) defined construction activities as ‘inherently complex, involving substantial task variability and irregular work periods; repetitive manual handling materials or tool use, often in non-optimal postures; and working at a fast pace in a dynamic and often unstructured or unpredictable work environment’. Most of the activities conducted by construction workers lack automation, leading to reduced productivity and increased risk of injuries (Hossain et al. 2020).

Due to these factors, WMSDs emerge as one of the most reported health complaints. In 2013, 60% of work-related health problems were WMSDs in Europe followed by stress, depression, and anxiety, which accounted for 16% (European Agency for Safety and Health at Work 2019). The large gap between the first and second most prevalent complaints underscores the severity and importance of overcoming WMSDs. The European Agency for Safety and Health at Work (2019) also reported that 52% of WMSD reports come from the construction sector. Recent data highlight the persistent burden of WMSDs in construction. In Denmark, 78.7% of workers reported at least one WMSD (Al-Khiami et al. 2025a, 2025b). Prevalence remains similarly high in the Gulf Cooperation Council region (47%) and in Kuwait specifically, where 52% of construction workers experienced at least one disorder (Al-Khiami et al. 2025b). Al-Khiami et al. (2025b) further noted that pervasive under-reporting may mask an even greater problem. With continued population growth and an ageing workforce projected to drive construction demand, the incidence of WMSDs is expected to escalate unless effective preventive measures are adopted (Alzahrani et al. 2022).

Back pain was reported as the most common WMSD (European Agency for Safety and Health at Work 2019). This is mainly due to workers engaging in repetitive heavy lifting, leading to localised fatigue at the lumbar region (Erezuma et al. 2022).

Loss of productivity due to WMSDs and work injuries is estimated to cost Europe 4% of its gross national product. In Germany alone, €17bn in annual gross is lost due to the increased sick leaves because of WMSDs. On the contrary, the United States compensates workers amounting to US$15bn annually because of WMSDs (Bogue 2018).

Okpala et al. (2019) defined exoskeletons as a ‘mechanism designed to be wrapped around the limbs of an operator, thereby allowing the replication or enhancement of forces at body segments’. Exoskeletons improve the capacity of workers by augmenting their physical activities; providing support to shoulders, arms and back during heavy lifting and overhead works; and providing lower limbs and knee support during kneeling, crawling and squatting activities. As a result, workers would experience reduced strain and fatigue on their musculoskeletal system and potentially reduce WMSDs and improve performance (Kim et al. 2019; Maurice et al. 2020; Chen et al. 2021; Al-Khiami et al. 2024b).

Golovianko et al. (2023) argued that Industry 4.0 and Industry 5.0 cannot exist in isolation, and one cannot replace the other. They proposed Industry 4.0 + Industry 5.0 hybrid, where t echnologies can be revolved around improving performance and maintaining social sustainability. Consequently, exoskeletons are a great example of Industry 4.0 + Industry 5.0 hybrid.

As illustrated earlier, back pain is the most prevalent WMSD, primarily due to repetitive heavy lifting that leads to localised fatigue in the lumbar region (European Agency for Safety and Health at Work 2019; Erezuma et al. 2022). Utilising back exoskeletons can potentially maintain musculoskeletal health, provide support, reduce fatigue and improve muscular endurance.

Many researchers have confirmed the potential of exoskeletons in reducing overall muscle activation under controlled environments (Poon et al. 2019). For instance, based on measurements from electromyography (EMG) sensors and motion capture (MoCap) systems, Iranzo et al. (2022) found that a passive lumbar exoskeleton significantly reduced muscle activity in the erector spinae, semitendinosus, gluteus, and quadriceps during material handling tasks. These results indicate that passive exoskeletons can effectively reduce the physical load on workers, potentially alleviating muscle fatigue and decreasing the risk of WMSDs.

Poon et al. (2019) also evaluated the use of a back exoskeleton during repetitive lifting tasks by measuring oxygen consumption to assess endurance, EMG to measure muscular activation, and conducting a pre- and post-work endurance test. The study found that there was no significant difference in oxygen consumption with and without an exoskeleton during the lifting tasks. However, Iranzo et al.’s (2022) findings showed that muscle activation was reduced. The study also found that post-work endurance time increased by 52% when subjects used the exoskeleton.

While numerous studies have underscored the biomechanical advantages of exoskeletons utilising mainly EMG sensors (Poon et al. 2019; Iranzo et al. 2022), there remains a gap in understanding their effects on the user’s performance, fatigue and consistency throughout a lifting activity. This can be achieved by investigating metrics such as the number of repetitions completed during a repetitive lifting task, the time taken to complete a single repetition throughout the whole duration, consistency in pace, and the overall task duration.

Additionally, Al-Khiami et al. (2024a, 2024b) identified more than 109 different back exoskeleton designs, highlighting the significant variability among exoskeletons. This variability underscores the importance of investigating and comparing the performance of different exoskeleton designs in this context. According to the authors’ knowledge, this has not been extensively explored. Specifically, this study will compare the HAPO SD, which uses a spring-based mechanism, and the BISKO exoskeleton, which relies on an elastic textile design. The evaluation of these two distinct types of exoskeletons provides insights to their effectiveness in improving lifting performance and reducing fatigue.

Therefore, the following RQs are formulated:

RQ1 – How effective are industrial exoskeletons in improving performance and managing fatigue during repetitive lifting tasks?

RQ2 – How different types of industrial exoskeletons (HAPO SD and BISKO Exo) are compared in terms of improving lifting performance and reducing fatigue?

RQ3 – What are the perceived benefits and limitations of using industrial exoskeletons during repetitive lifting activities from the user’s perspective?

The research emphasises the human-centric pillar of Industry 5.0 by focusing on technologies that improve worker well-being and safety. From a strategic management perspective, adopting exoskeletons represents a proactive approach to integrating innovative solutions that not only improve productivity but also contribute to a healthy workplace framework, sustainability and organisational resilience (Nathan 2018; Ghobakhloo et al. 2022; Halliday et al. 2024). This integration is essential for organisations that are aiming to remain competitive in the evolving industrial landscape by prioritising their workforce’s health and adapting to new technological advancements (Alhammadi et al. 2024).

This research contributes to the field by providing empirical evidence on the effectiveness of different exoskeleton designs during repetitive lifting activities. By comparing spring-based and elastic textile designs, the present study offers valuable insights for both manufacturers and end users in selecting appropriate exoskeleton technology. Moreover, the inclusion of user perceptions alongside quantitative performance metrics provides a holistic understanding of exoskeleton usability, potentially influencing future design improvements. Furthermore, the research supports the broader goals of Industry 5.0 by promoting human-centric technological innovations from Industry 4.0 that prioritise worker well-being and sustainability. The outcome of the present study provides insights into the use of industrial exoskeletons for repetitive lifting tasks, with practical implications for improving worker’s safety and productivity, and potentially reducing WMSDs.

In this research, an exploratory, embedded single-case study design was employed, as outlined by Yin (2009), where the first author served as the subject. The primary objective is to explore the performance of the user and fatigue management, comparing two types of back exoskeletons with no exoskeleton in assisting with repetitive lifting activity (RQ1 and RQ2). Each condition serves as a distinct unit of analysis under the broader case of exploring improvements in performance and managing fatigue. Moreover, the case is exploratory in nature as it aims to explore a new phenomenon with relatively limited research and conclude directions for future studies (Ferreira and Lind 2022). Additionally, RQ3 is addressed by noting qualitative observations by the subject when using the exoskeletons.

Two types of exoskeletons were tested in this paper: (1) HAPO SD: A lightweight back exoskeleton, developed by Ergosante, a French company, which specialises in providing ergonomic solutions. This exoskeleton weighs <900 g. It reduces the strain exerted on the back by transferring the upper trunk’s load to the thighs using composite springs (Ergosante 2023). (2) BISKO exoskeleton: A very light textile exoskeleton that weighs around 700 g is Available at ScanExo (ScanExo 2025), a company based in Denmark, which provides various types of exoskeletons for industrial and manufacturing applications ScanExo. This exoskeleton primarily depends on integrated elastic bands found at the back of the exoskeleton. The elastic bands stretch when the user bends, storing energy and releasing it once the lift begins (Orthexo 2024).

In the experiment, a 24 kg kettlebell was used as the weight. This specific weight was chosen to provide a challenging load while ensuring it remained within the upper safe limit recommended by the National Institute for Occupational Safety and Health (NIOSH) (OSHA 2024).

For consistency, the HAPO SD is referred to as Exo A, and the BISKO Exo is referred to as Exo B throughout the paper.

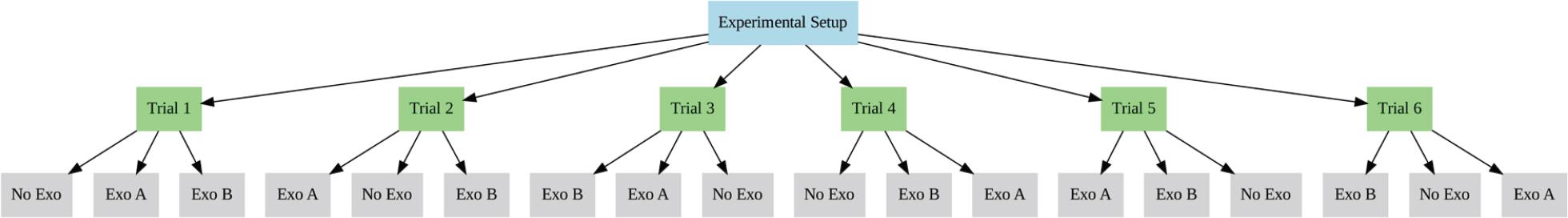

The experiment was conducted over a period of 18 days, comprising a total of six trials, with an average of three rest days between each trial. Each trial consisted of four sets, with each set utilising one of the distinct conditions, such as, Exo A, Exo B or no exoskeleton. Six trials were specifically chosen to account for the reduction in body energy and the accumulation of fatigue that typically occurs in the second, third, and fourth set within each trial, thereby minimising the effects of set sequencing and sequence bias. Each condition was repeated a total of six times, ensuring that each condition appeared once in different sequences across the six trials. A single trial typically lasted for an average of 30 min.

Figure 1 further explains the experimental setup.

Experimental setup and sequence.

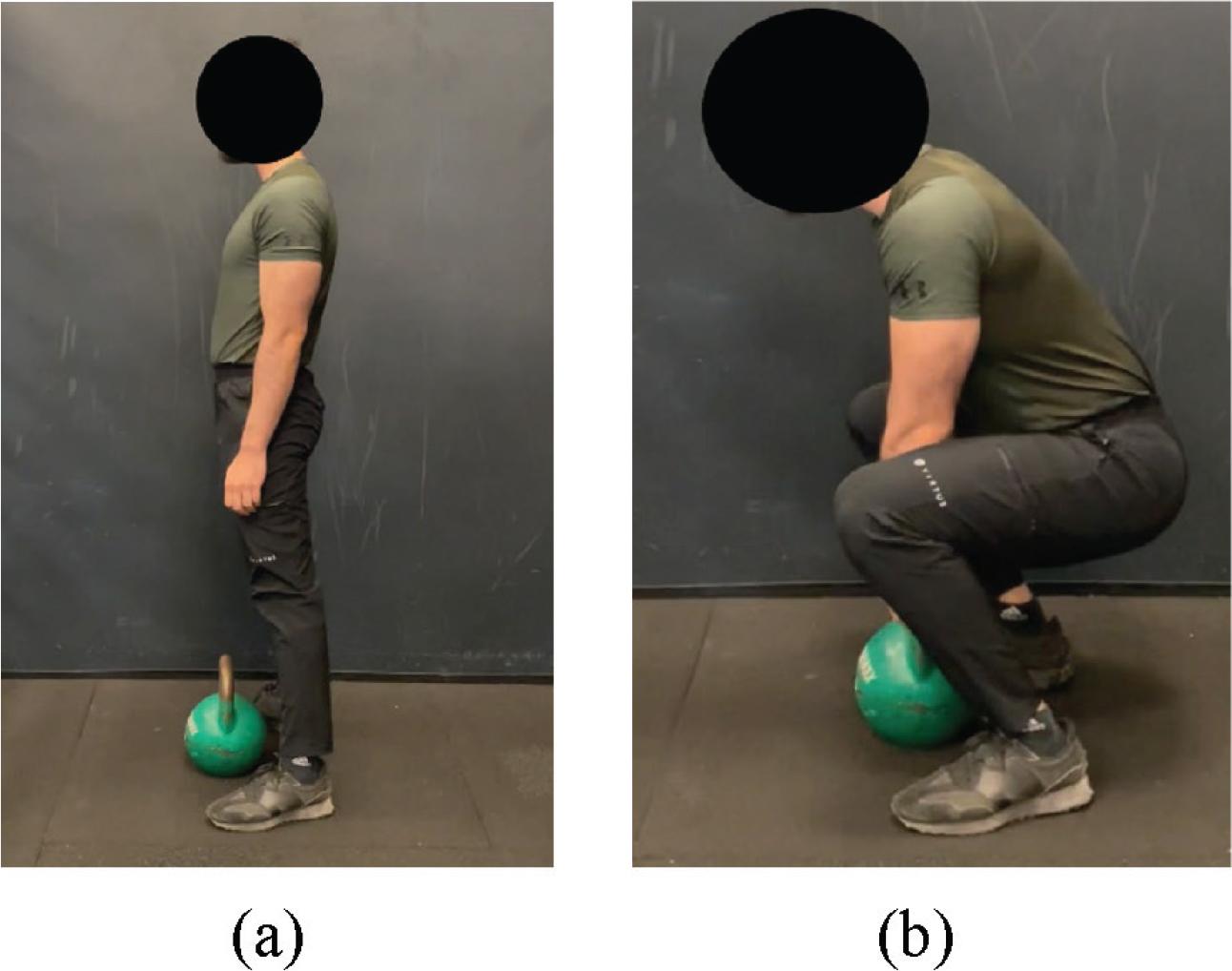

To ensure the validity of the experiment, all trials were conducted with as much uniformity as possible, controlling all variables that could be managed. First, the position of the kettlebell and the distance between the kettlebell and the subject’s feet were fixed. The subject was instructed to stand as close as possible to the kettlebell and maintain a neutral posture prior to the lift. Employing a deadlift technique, where the back remains locked throughout the lift’s duration, the subject was required to lift the kettlebell using both hands for as many repetitions as possible until failure. Figure 2 illustrates the initial position and the lifting position, which were identical across all conducted trials.

(a) Standing position and (b) lifting position.

Between the first and second sets, the subject rested for a total of 10 min before proceeding to the second set. A total of 15 min was allotted between the second and third sets. An additional 5 min of rest was necessary between the second and third sets to facilitate physical recovery to a level comparable to the recovery achieved after the first set.

Before testing, the exoskeletons were adjusted to the subject’s body according to the manufacturer’s recommendations. This adjustment was maintained throughout all trials. Moreover, the support provided by the exoskeletons can be increased or decreased by tightening the straps that connect to the springs or elastic bands. Therefore, for all trials, the straps were tightened to the maximum.

Both quantitative and qualitative data were collected. The quantitative data involved (1) the subject’s demographic profile, including age, weight and height and (2) experimental data. The data here involved the subject’s lifting activity which was video recorded using a smartphone.

The recordings commenced as soon as the subject began the lifting activity and concluded upon reaching failure. The raw videos were subsequently processed to eliminate any buffer time at the start or end of the recordings caused by human error. The number of repetitions and the duration of the entire activity were then documented.

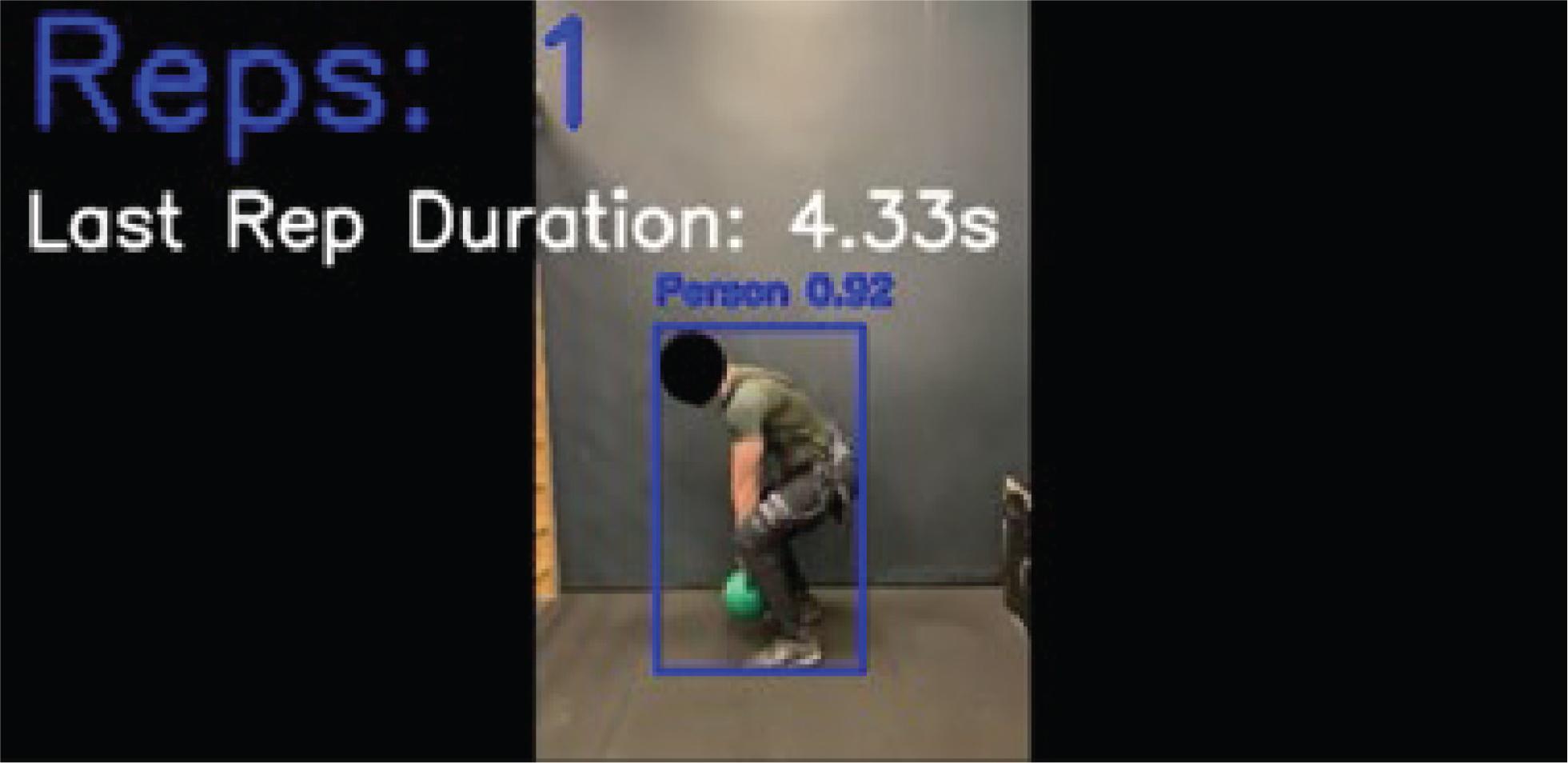

Moreover, the duration of each repetition was also recorded and inserted into an Excel sheet. This was automated using Python 3.9 on a Google Colaboratory Environment. The code utilised the YOLOv8 model for object detection, specifically to identify and track the participant performing the exercise. Each frame of the video was processed to detect the presence and position of the participant, with aspect ratio calculations used to assess body posture (i.e. bent position vs. upright position).

To distinguish between upright and bent postures, the aspect ratio (height-to-width ratio) of the participant’s bounding box was continuously calculated and stored in a buffer. A threshold aspect ratio value of 5 was used to determine the participant’s posture, where values above this threshold indicated an upright position and values below indicated a bent position. The tracking script utiliszed a state-based method to define the stages of a complete repetition cycle (down-up-down-up), using stability checks to ensure that only stable, deliberate movements contributed to the repetition count.

The processed video was then annotated with the repetition count and last repetition duration, saving these annotations directly to the output video file as shown in Figure 3.

Annotated frame of repetition tracking with YOLOv8.

This video, along with the Excel sheet containing detailed repetition timing data, provided a comprehensive record of the exercise session, offering an efficient and accurate method to analyse performance. To enhance pace analysis, the time taken for the initial repetition was removed from the calculations, reducing noise associated with initiating the video recording. This approach provided a detailed and objective understanding of the subject’s pacing throughout the exercise session.

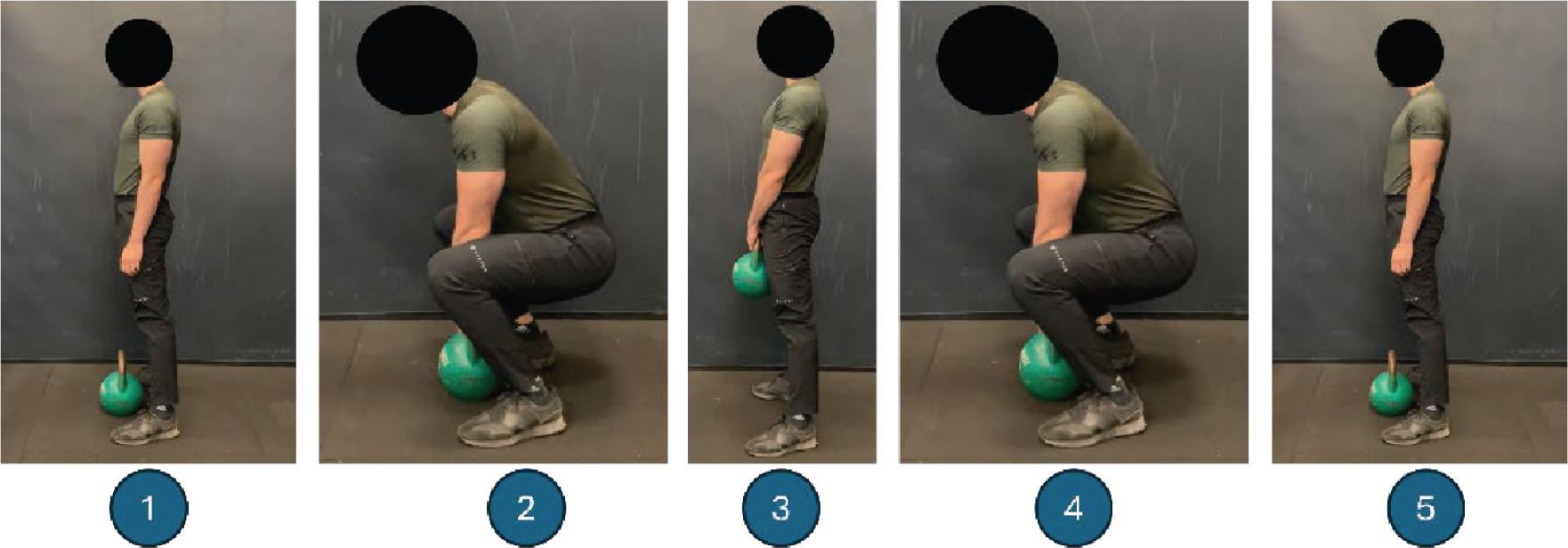

Please note that a full repetition is defined as the subject starting from a standing position, going down to lift the weight, standing up, going down again to drop the weight, and then standing up once more as demonstrated in Figure 4.

Sequence for one full repetition.

Qualitative insights were gathered throughout the experiment to provide further context and understanding of the subject’s experience and performance. These insights are mainly observations by the subject.

All the collected data were saved in a.CSV format. All the statistical analyses were conducted using Python 3 in a Google Colaboratory environment, utilising various Python libraries.

The results section commences with a description of the demographic profile of the subject, including age, weight and height. This is followed by a descriptive analysis of the findings from each trial, comparing the total number of repetitions and differences between each condition.

The subsequent segment of the results focuses on an in-depth examination of the subject’s time taken per repetition, analysed in relation to the specific conditions utilised during the trials. Finally, the results conclude with the subject’s observations and highlight the advantages and disadvantages of using Exo A and Exo B based on the findings.

To contextualises the experiment, the demographic profile of the subject is denoted here, as the results can be greatly influenced by the subject’s profile. The subject is 31 years old with a height of 180 cm and a weight of 84 kg. Based on these points, subject is considered relatively fit with a body mass index of 25.93 kg/m2, which is considered slightly overweight.

This section illustrates the number of repetitions completed across all sets in each trial. Table 1 presents the repetitions performed until failure under three conditions: without an exoskeleton (baseline for natural endurance and fatigue rate), using Exo A, and using Exo B across all six trials. Before analysing the data, it is essential to define fatigue. According to Sargeant (1994), ‘Muscle fatigue can be defined as the failure to generate or maintain the required or expected force or power output, resulting from muscle activity and reversible by rest’. Therefore, a reduction in the number of repetitions indicates a higher failure to maintain the required or expected force or power output.

Number of repetitions per conditions per trial*

| Conditions | Trial 1 | Trial 2 | Trial 3 | Trial 4 | Trial 5 | Trial 6 |

|---|---|---|---|---|---|---|

| No Exo | 20 | 24 | 19 | 25 | 26 | 32 |

| Exo A | 30 | 31 | 27 | 30 | 42 | 44 |

| Exo B | 19 | 22 | 25 | 28 | 32 | 38 |

Please refer to Figure 1 for the sequence of the conditions per trial.

The data show that Exo A consistently enabled more repetitions before failure compared to the other conditions, indicating reduced fatigue accumulation and improved overall performance. On average, Exo A resulted in 34 repetitions across the six trials. Specifically, in trial 1, where Exo A was used second, the subject completed 10 more repetitions than with no exoskeleton or Exo B (see Figure 1 for the order of sequence). However, it is important to note that the order of the sets within each trial likely had an effect on the results. The subject did not fully recover between sets, as full recovery would require a much longer rest period, possibly a full day. This lack of complete rest could contribute to fatigue accumulation and reduced performance in succeeding sets. Conversely, since the experiment was completed more than 18 days, the subject might also experience a training effect, becoming stronger over the course of the trials, which could influence performance across subsequent sets.

In trial 2, Exo A, which was used first, resulted in 31 repetitions, while the No Exo condition, which was used second, showed improved performance over trial 1 but still did not match the repetitions achieved with Exo A. Exo B, which was used third, had a minimal difference of only two repetitions compared to the no-exoskeleton condition.

In trial 3, Exo B was used first, resulting in 25 repetitions, which is higher than the totals in trials 1 and 2. However, Exo A, when used first, still outperformed Exo B in terms of the number of repetitions. Despite the limited number of trials, the data suggest that Exo A offers more support and effectiveness in reducing fatigue and enhancing endurance compared to Exo B.

In trial 4, even though Exo A was used in the last set and recorded a total of 30 repetitions, it still outperformed both the No Exo condition and Exo B, which were utilised in the first and second sets, respectively.

In trials 5 and 6, there was a noticeable increase in the number of repetitions across all conditions. While many uncontrolled variables could have influenced this, it is partly due to the improved performance by the subject resulting from continued training. A similar trend is observed in trials 5 and 6 compared to the previous trials 1–4.

Overall, the findings indicate that Exo A significantly improves endurance and reduces fatigue accumulation more effectively than Exo B or no exoskeleton. This has important implications for enhancing performance and minimising the risk of musculoskeletal disorders in repetitive lifting tasks in the construction sector.

Table 2 shows the percentage difference in repetition count relative to the no-exoskeleton condition. The smallest increase in repetition count when using Exo A is 120%, and it reached up to 162% in trial 5, where it was used first in the sequence. While Exo B generally showed an overall increase in the number of repetitions, in trials 1 and 2, it resulted in a smaller number of repetitions (5% and 8.33%, respectively). In both these cases, Exo B was used last.

Percentage difference in repetition count relative to No Exo

| Condition | Trial 1 (%) | Trial 2 (%) | Trial 3 (%) | Trial 4 (%) | Trial 5 (%) | Trial 6 (%) |

|---|---|---|---|---|---|---|

| Exo A | +150 | +129 | +142 | +120 | +162 | +140 |

| Exo B | –5 | –8.33 | +132 | +112 | +123 | +119 |

Table 3 shows the differences in repetition count relative to Exo B. In all trials, using Exo A led to a higher number of repetitions and delayed fatigue. Trials 3 and 4 (8% and 7%, respectively) show a relatively smaller difference compared to the other trials, which is partially related to the sequence of sets conducted, where Exo B was utilised before Exo A.

Percentage difference in repetitions between Exo A and Exo B relative to Exo B

| Condition | Trial 1 (%) | Trial 2 (%) | Trial 3 (%) | Trial 4 (%) | Trial 5 (%) | Trial 6 (%) |

|---|---|---|---|---|---|---|

| Differences | 58 | 41 | 8 | 7 | 31 | 16 |

The number of repetitions provides insights into the fatigue management ability and endurance when utilising exoskeletons. The rate of time per repetition is also considered an important factor in assessing performance (Moir et al. 2013).

Table 4 shows a descriptive analysis of the time per repetition. Exo A demonstrates a better performance in terms of both power output and consistency. This indicates that Exo A helps maintain higher energy efficiency and reduces fatigue accumulation more effectively than Exo B or no exoskeleton. Generally, the mean time to complete one repetition is higher in No Exo compared with using Exo A or Exo B in all trials other than trial 2. The No Exo condition, in general, shows slower times and higher variability. A higher standard deviation with No Exo is seen, indicating a higher variance in the time per repetition compared to Exo A and Exo B.

Descriptive analysis of time per repetition per condition per trial in seconds

| Trial | Condition | Mean | SD | Min | Max |

|---|---|---|---|---|---|

| Trial 1 | No Exo | 5.353 | 0.413 | 4.501 | 6.198 |

| Exo A | 4.586 | 0.262 | 4.000 | 5.003 | |

| Exo B | 4.609 | 0.330 | 4.249 | 5.550 | |

| Trial 2 | Exo A | 4.008 | 0.258 | 3.500 | 4.500 |

| No Exo | 3.685 | 0.263 | 3.250 | 4.251 | |

| Exo B | 3.796 | 0.226 | 3.250 | 4.250 | |

| Trial 3 | Exo B | 3.912 | 0.247 | 3.500 | 4.499 |

| Exo A | 3.654 | 0.265 | 3.250 | 4.249 | |

| No Exo | 3.931 | 0.268 | 3.500 | 4.499 | |

| Trial 4 | No Exo | 3.836 | 0.277 | 3.251 | 4.252 |

| Exo B | 3.567 | 0.292 | 3.000 | 4.249 | |

| Exo A | 3.500 | 0.291 | 2.999 | 4.001 | |

| Trial 5 | Exo A | 3.559 | 0.245 | 3.000 | 4.249 |

| Exo B | 3.497 | 0.254 | 3.000 | 4.001 | |

| No Exo | 3.730 | 0.322 | 3.000 | 4.250 | |

| Trial 6 | Exo B | 3.703 | 0.219 | 3.249 | 4.001 |

| No Exo | 3.863 | 0.265 | 3.250 | 4.252 | |

| Exo A | 3.557 | 0.206 | 3.248 | 3.999 |

Diving deeper into the data, both Exo A and Exo B show shorter times per repetition (4.586 s and 4.609 s, respectively) compared to No Exo (5.353 s) in trial 1, indicating a higher general power output and a better overall consistency. SD, Standard deviation.

In trial 2, No Exo condition has the shortest mean time, but Exo A shows a more consistent performance (SD = 0.258). Additionally, Exo B has slightly higher variability compared to Exo A. In trial 3, similar to trials 4 and 6, Exo A has the shortest mean time, indicating more consistent energy use and muscle contractions.

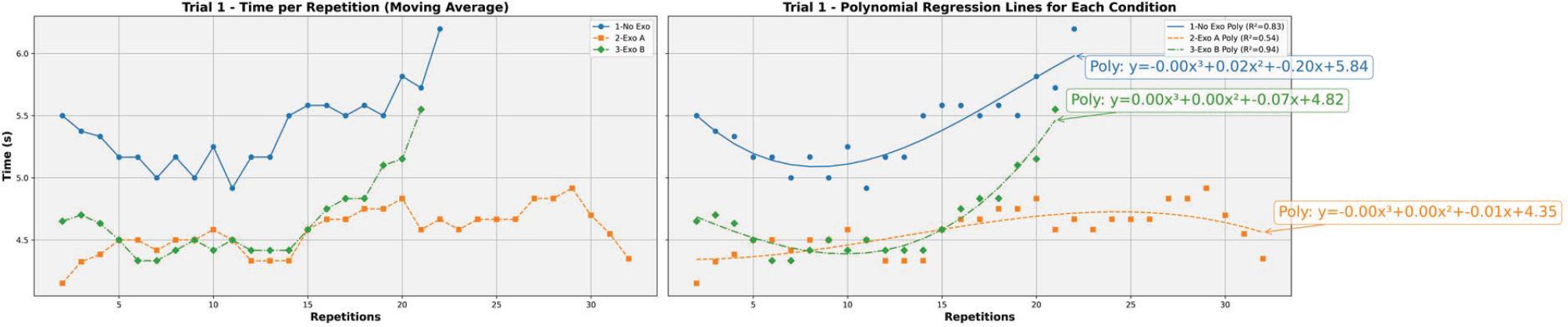

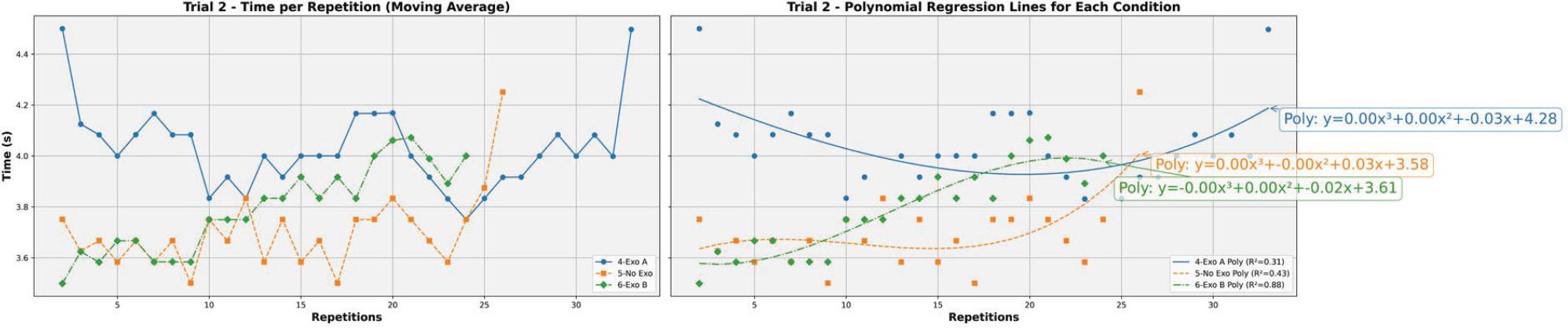

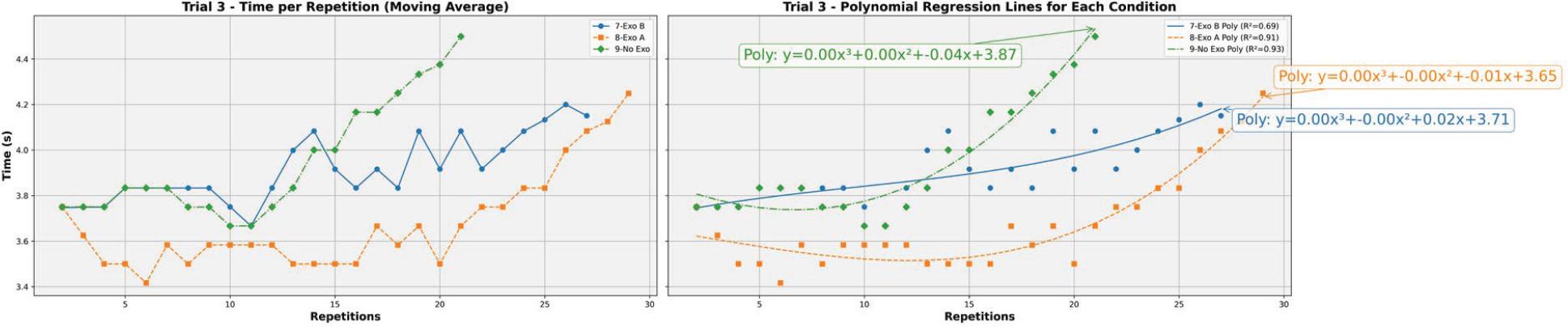

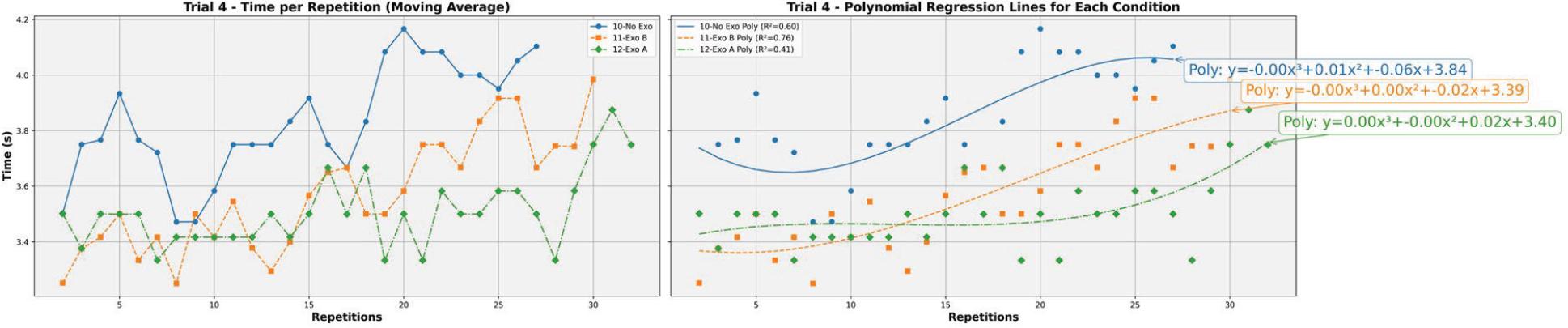

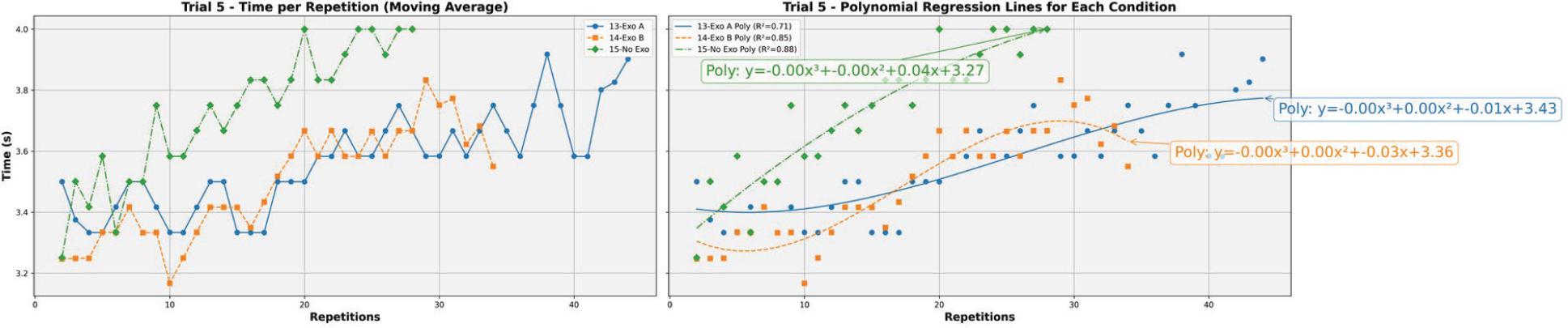

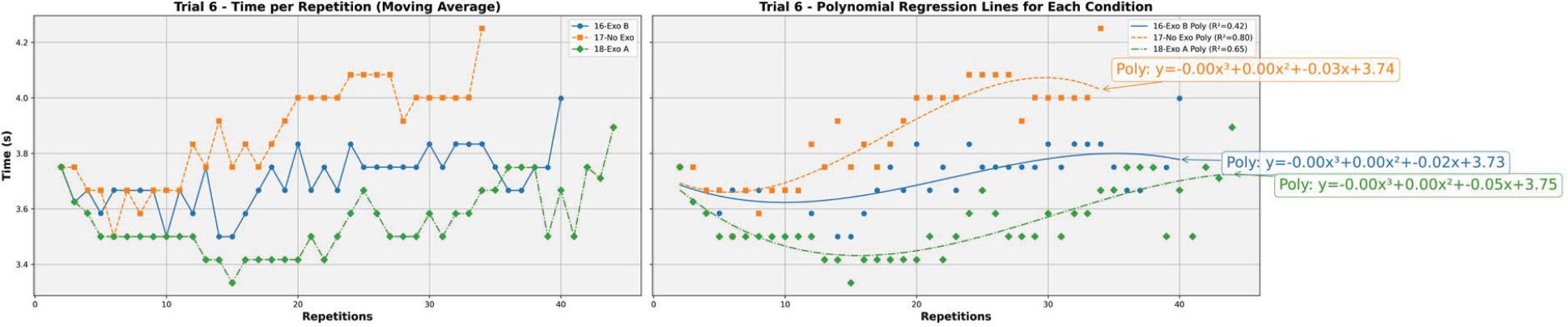

Figures 5–10 illustrate the time per repetition throughout the duration of all sets. To smooth the Figures out, a three-point moving average was used. All conditions were then fit into a third-degree polynomial regression.

Trial 1 time per repetition per condition and polynomial regression fitting.

Trial 2 time per repetition per condition and polynomial regression fitting.

Trial 3 time per repetition per condition and polynomial regression fitting.

Trial 4 time per repetition per condition and polynomial regression fitting.

Trial 5 time per repetition per condition and polynomial regression fitting.

Trial 6 time per repetition per condition and polynomial regression fitting.

To facilitate the discussion of Figures 5–10, three metrics are defined:

Initial power output (IPO): Sargeant (1994) stated that ‘Previous activity may result, for example, in fatigue and reduce the maximum power that can be generated. Investigating the IPO would reflect the subject’s initial strength and ability to perform rapid movements before fatigue sets in’.

Consistency and energy (CE) use: Sustaining a stable rate of repetitions throughout the duration of the set suggests that the muscles can sustain repeated contractions without significant declines in performance due to fatigue or energy loss, demonstrating effective energy management (Spencer and Gastin 2001).

Drop-off rate (DR): This measure highlights the point at which muscular endurance diminishes, and fatigue becomes more apparent, indicating the onset of significant fatigue and the reduced ability to maintain initial performance levels (Morris et al. 2008).

These three metrics – IPO, CE use and DR – will be used to assess the subject’s performance at the initial, middle and end parts of the set, respectively, based on the varying conditions.

Figure 5 illustrates trial 1. Initially, even though No Exo was the first set, it shows a relatively higher time per repetition compared with Exo A and Exo B. On the contrary, IPO in No Exo and Exo B was higher compared to Exo A. Though, Exo A seems to maintain a consistency in time, indicating sustained energy and overall better CE. Moreover, a lower DR compared to Exo B and No Exo was also indicated illustrating the ability to maintain initial performance.

In trial 2, as shown in Figure 6, No Exo shows an overall faster time per repetition, and a relatively sustained CE. Although the subject reached the 20th repetition, a sharp exponential increase in the time is perceived, indicating a high DR, probably attributed to the high-power output that was given initially and the inability to sustain consistent muscular contractions beyond the 20th repetition. This was also seen in Exo B, where CE was inadequate and a high DR at the initial repetition counts. This is also partially due to the order sequence. Here Exo B was conducted last. On the contrary, Exo A, while having a higher mean rate, shows a relatively high IPO and a sustained CE with a lower DR, maintaining the initial performance throughout the whole set.

In trial 3, as illustrated in Figure 7, No Exo performed the least, indicative of the order of sequence where it was executed last. While Exo A shows an overall faster mean rate and a higher IPO, it also shows a higher DR compared to Exo B. Exo B, in this trial, was the first trial and showed a sustained CE but an increase in DR towards the end of the set.

Trial 4, as shown in Figure 8, shows a better performance of Exo A compared with Exo B and No Exo in all metrics, even though it was executed last in the sequence. No Exo had a high IPO, which is probably attributed to it being the first in the order sequence. It also shows the sharpest DR and in consistency in sustaining energy and maintaining the time per repetition throughout.

Similarly, in trial 5 as shown in Figure 9, Exo A performed the best in all aspects, while it is seen to have a higher DR compared to trial 4, it did extend for a longer period where the subject completed 42 repetitions compared to 30 in trial 4. Exo B showed a higher IPO but inadequate CE and a relatively high DR. No Exo in this trial was conducted last which explains why the polynomial behaves this way, a very poor CE and a high DR illustrating a diminish in endurance and accumulation of fatigue.

Trial 6 in Figure 10 demonstrated a similar trend compared to the former trial. Exo A showed a high IPO, a sustained CE and a slight increase in DR. The high IPO can be attributed to the behaviour of the subject. In many of the cases where the use of an exoskeleton succeeded No Exo, a higher IPO is shown. This can be partially attributed to the subject’s behaviour and mental state. Using an exoskeleton might provide a feeling of empowerment, resulting in a higher IPO. Exo B maintained a relatively stable CE and insignificant DR.

This section provides observations noticed by the subject throughout the six trials. Please note that these are solely the subject’s personal observations and cannot be generalised by any means. These observations are broken down into categories and are presented in Table 5.

Qualitative observations comparison between Exo A and Exo B

| Observation | Exo A | Exo B |

|---|---|---|

| Comfort and fit |

|

|

| Ease of use |

|

|

| Support and performance |

|

|

| Failure and recovery |

|

|

IPO, initial power output.

The observations complement the findings collected quantitatively. The subject perceived higher support and was able to maintain his pace for a longer period when using Exo A compared with B. Important insights include that while Exo A was generally more comfortable during lifting, both Exo A and B caused some sort of discomfort. During the lifting phase, the springs on the side of Exo A exerted pressure on the latissimus dorsi muscles, while Exo B resulted in discomfort in the hamstrings due to the elastic bands while shifting from the lifting to a standing position.

When it comes to the fit, Exo B was perceived as better fitting and is closer to the body than Exo A. Moreover, Exo B had fewer straps to adjust, making it less cumbersome and easier to use. Additionally, wearing Exo A required the assistance of another person in trials 1–4, but was easier in the trails 5 and 6. The subject also needed to read the manual carefully to understand what each strap does. The subject was able to wear and adjust Exo B from the very first trial without any assistance or manual.

Construction workers tend to be reluctant to wear and use personal protective equipment (Li 2018). Accordingly, while Exo A provides better overall support, Exo B can particularly be useful in construction sites when used by construction workers, due to its ease of use and adjustability. Workers would find it simple and undemanding, making it more approachable for them.

Based on the initial findings of this study, exoskeletons demonstrate significant potential in reducing muscle fatigue and enhancing overall performance during repetitive lifting tasks. However, when considering their implementation in real construction settings – especially in manual material handling activities – it is essential to recognise that exoskeletons cannot function as standalone solutions. Their adoption must be aligned with established, regulatory and ergonomic frameworks to ensure worker safety and long-term effectiveness.

Specifically, Council Directive 90/269/EEC (European Union 1990) outlines the minimum health and safety requirements for the manual handling of loads, particularly where there is a risk of back injury. This directive emphasises that employers must first attempt to eliminate the need for manual handling altogether, and where this is not feasible, implement appropriate organisational and mechanical measures – including assistive devices – to reduce ergonomic risks by improving working conditions and posture.

Complementing this, the NIOSH Revised Lifting Equation (CDC 2024) is a widely accepted ergonomic model used to estimate safe lifting limits based on task-specific parameters. Integrating this tool into workplace assessments enables practitioners to quantify acceptable load thresholds and proactively mitigate the risk of WMSDs. The study observed improvements in endurance and repetition time with the HAPO and BISKO exoskeletons, suggesting that such devices may help workers remain within safer effort margins defined by both the EU Directive and NIOSH guidelines.

Nonetheless, it is crucial to emphasise that exoskeletons do not eliminate risk and should be considered only one element within a broader ergonomic and safety strategy. A holistic approach – beginning with risk elimination, followed by risk reduction through design, training and appropriate assistive technologies – is essential for responsibly integrating exoskeletons into construction workflows.

Mahmud et al. (2022) highlighted two important concerns regarding the long-term use of exoskeletons in physically demanding tasks. First, by providing external support, exoskeletons may reduce the natural engagement of key muscle groups, which could contribute to muscle atrophy due to underuse. Second, while these devices are designed to alleviate strain in targeted areas (such as the lower back), they may unintentionally shift mechanical loads to other parts of the body, potentially reducing discomfort in one region but increasing it in another. These findings underscore the importance of a comprehensive evaluation of both the short- and long-term physiological impacts of exoskeleton adoption.

While exoskeletons offer notable benefits, it is important not to over-rely on them or assume they eliminate all risks associated with manual lifting. This assumption is misleading. Exoskeletons are designed to support the user, not to replace proper lifting techniques or turn the wearer into a ‘superhuman’ performer. Unrealistic expectations may lead to overexertion, misuse or inappropriate task selection, potentially resulting in new or aggravated injuries.

To avoid these risks, it is essential to set clear expectations regarding what exoskeletons can and cannot do. Their function is to assist and not replace ergonomic best practices. Accordingly, proper training in lifting techniques and safe exoskeleton use remains fundamental. This necessity is underscored in Article 6 of Council Directive 90/269/EEC (European Union 1990), which mandates that employers provide workers with adequate training and information to ensure safe manual handling and the correct use of any supporting equipment. Exoskeleton adoption should therefore be accompanied by structured training programmes, supervision and regular ergonomic evaluations.

This study provides an initial exploration into integrating industrial exoskeletons within the construction industry, highlighting both their potential benefits and limitations. To effectively leverage these devices within the Industry 5.0 paradigm, a structured research framework consisting of multiple sequential phases is proposed to guide future investigations.

Researchers are encouraged to conduct controlled laboratory experiments similar to this study, involving multiple subjects, and multiple exoskeleton designs and target extremities to systematically validate exoskeletons’ potential in enhancing performance, reducing fatigue and mitigating discomfort during repetitive lifting activities. This foundational step ensures preliminary reliability before transitioning to more realistic settings.

Upon confirming benefits in controlled environments, the next stage involves conducting large-scale field evaluations with actual construction workers performing their routine tasks under real working conditions. Comprehensive data collection should combine subjective assessments (e.g. perceived exertion, usability and satisfaction surveys) and objective physiological measures (e.g. heart rate variability, oxygen saturation, EMG). Integrating both subjective and objective data significantly enhances the robustness and interpretability of the findings.

To fully assess the sustained effectiveness and practical utility of exoskeletons, longitudinal studies spanning several months are necessary. These studies would capture long-term user adaptation, training effects, changes in performance metrics over time and potential health-related outcomes. Long-term insights are critical for determining the viability of exoskeleton integration in day-today construction operations.

Finally, addressing the human-centred aspects of exoskeleton adoption requires psychosocial research exploring user acceptance, perceived safety, potential over-reliance on technology and risk-compensation behaviours. Understanding these psychological dimensions will inform training protocols, improve user experience and support more effective deployment strategies.

Construction workers are subject to many risk factors due to the nature of the physical activities conducted. These factors are often found to result in reduced performance and increased WMSDs. The human-centricity pillar of Industry 5.0 necessitates a hybrid approach where Industry 4.0 technology is utilised to serve Industry 5.0 core goals in providing healthy working environments and an improved work-life balance. The use of industrial exoskeletons by construction workers provides a prospective solution to this matter.

This project specifically conducted a single-case study approach to explore the potential of HAPO Spring Design (HAPO SD) and BISKO back exoskeletons in improving performance, reducing muscle fatigue and potentially improving or at the very least, maintaining musculoskeletal health. This was performed by conducting six trials of three sets: No Exo (control experiment), HAPO SD exoskeleton, namely Exo A, and BISKO exoskeleton, namely Exo B.

Using any of the exoskeletons was found highly beneficial in maintaining consistency, managing fatigue and improving muscular endurance during repetitive lifting. Exo A consistently showed a higher repetition count and is less affected by the order sequence in which the sets are conducted, suggesting a robust design in supporting repetitive lifting tasks. The qualitative observations supported the quantitative results, though new nuanced insights were brought into the picture. While both exoskeletons were found to be comfortable, Exo B was convenient and user-friendly, specifically when wearing and adjusting to fit.

In summary, HAPO SD (Exo A) provides better support and consistency in performance but requires assistance to wear initially and is time-consuming to adjust. Overall, it is comfortable during lifting but causes some discomfort due to the springs pressing on the latissimus dorsi muscles. On the contrary, BISKO (Exo B) was found to be easier to wear and adjust, more comfortable overall, but provides less perceived support compared to Exo A. It also caused some discomfort due to elastic bands behind the hamstrings. More approachable for construction workers due to ease of use and comfort.

This study was limited to a single participant, which restricts the generalisability of the findings. The results reflect the performance of one individual and should therefore be interpreted as preliminary. Additionally, the order of sets within each trial may have introduced fatigue effects that influenced performance in subsequent sets. While rest intervals were standardised, full recovery between sets could not be ensured.

The Python-based repetition tracking system, while automated and efficient, was dependent on predefined thresholds and may have introduced errors in detecting transitions between postures. Moreover, no physiological fatigue indicators, such as muscle activity via EMG, heart rate, oxygen saturation or blood pressure, were recorded. These objective metrics would have offered additional insights into physical strain and fatigue beyond performance-based observations.

Finally, the 18-day experimental period may have introduced a training effect, as the subject’s physical strength and endurance could have improved over time, potentially influencing later trial outcomes.

The findings of this study have significant implications for the construction industry and any labor-intensive sectors involving workers who perform repetitive lifting. By demonstrating that exoskeletons such as HAPO SD and BISKO can effectively reduce fatigue and improve muscular endurance, adopting these technologies can lead to increased worker productivity, safety, and overall well-being. Future research should focus on long-term effects and real-world applications across diverse populations to further validate and expand these findings.