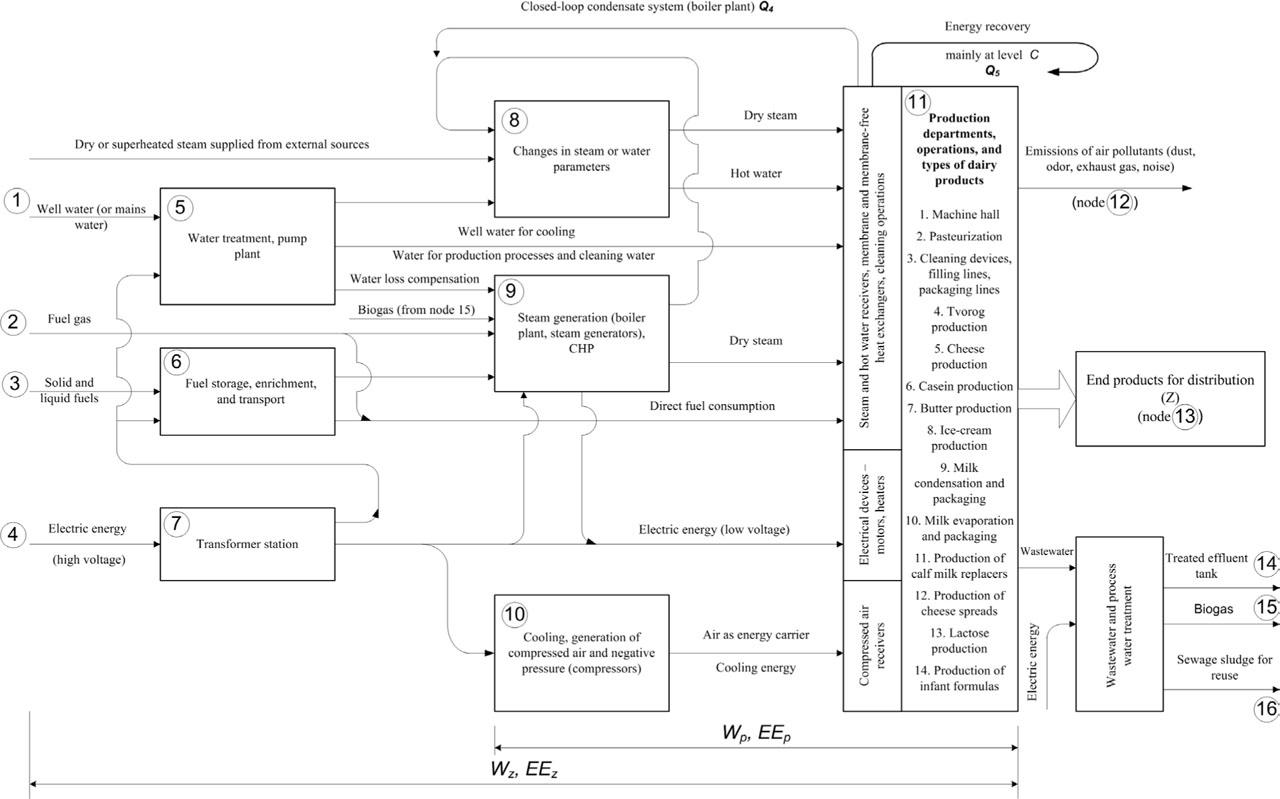

Figure 1.

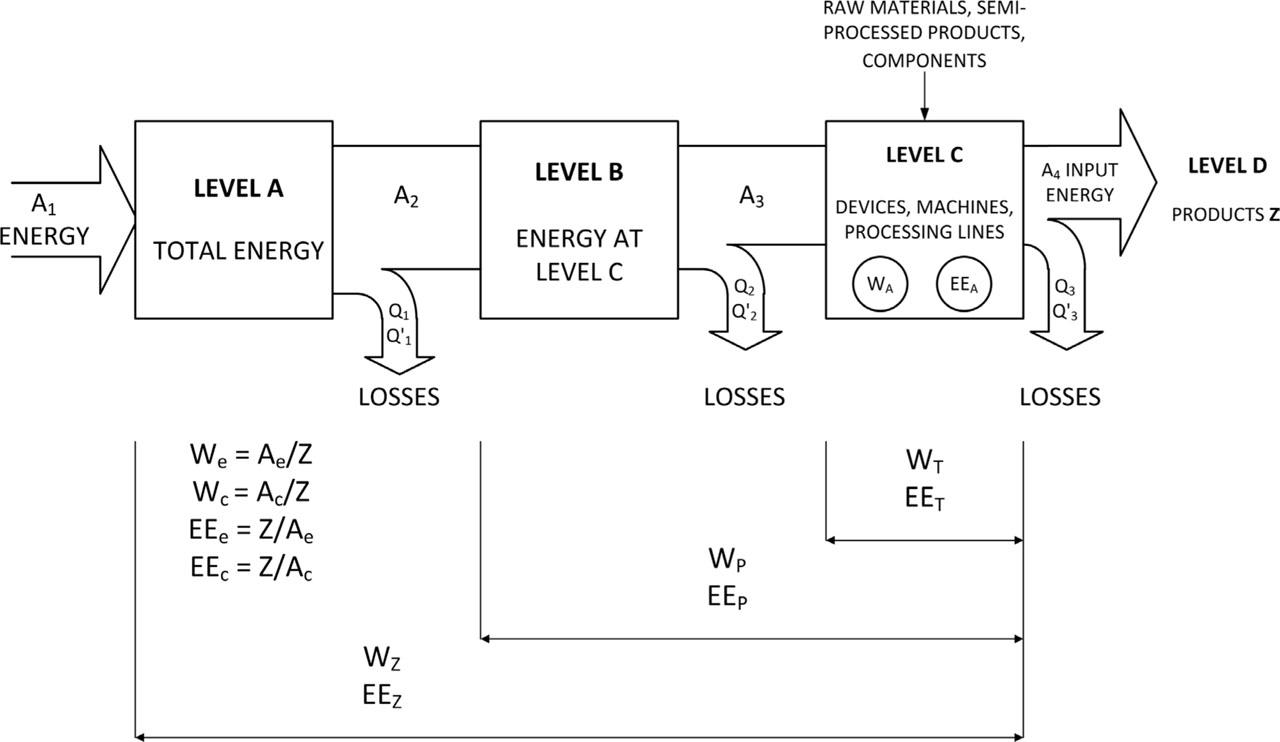

Figure 2.

Figure 3.

Figure 4.

Figure 5.

Figure 6.

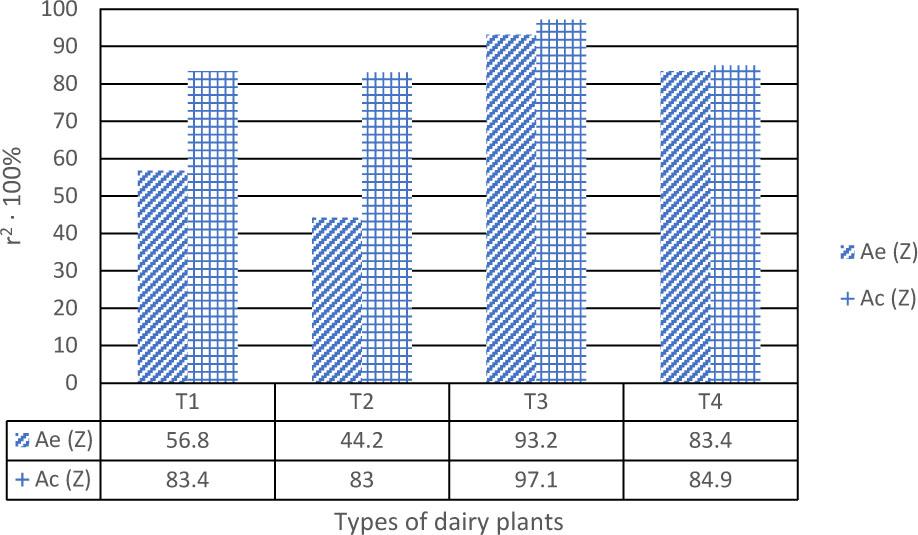

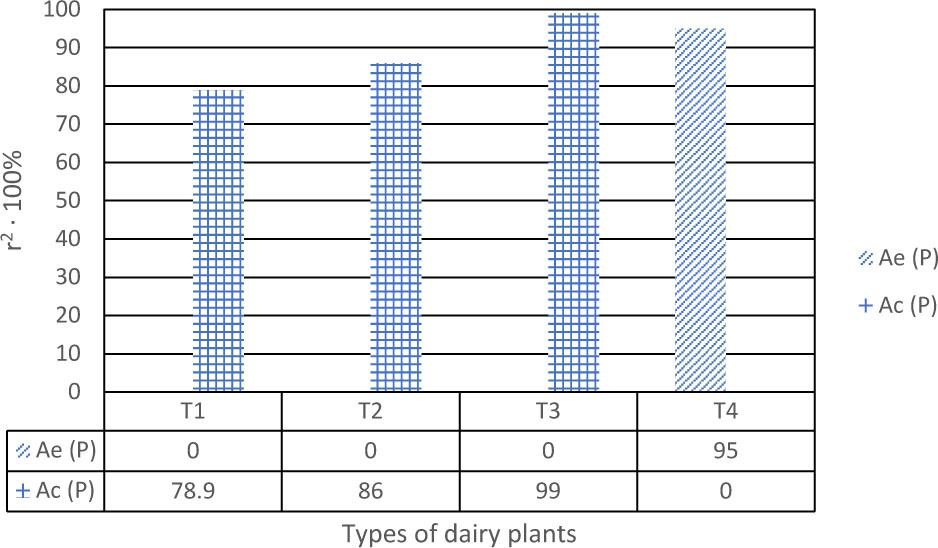

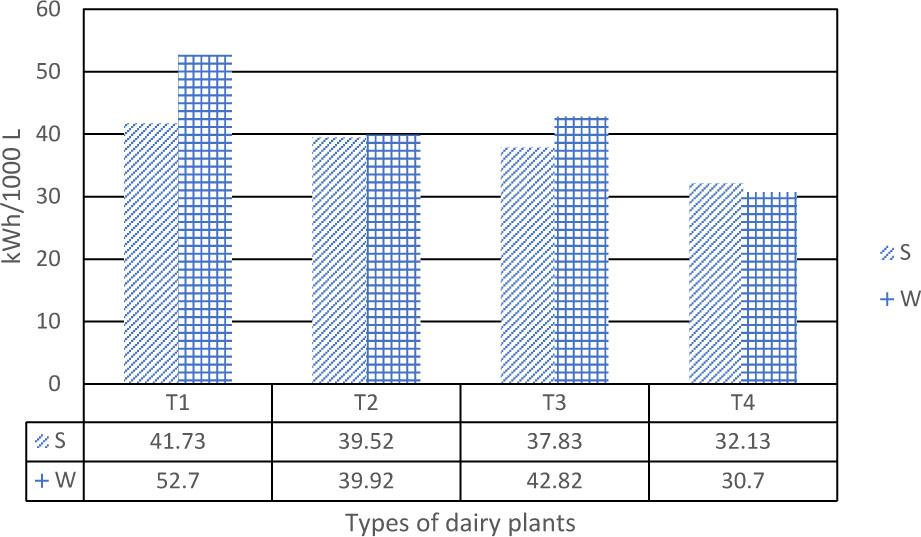

Figure 7a.

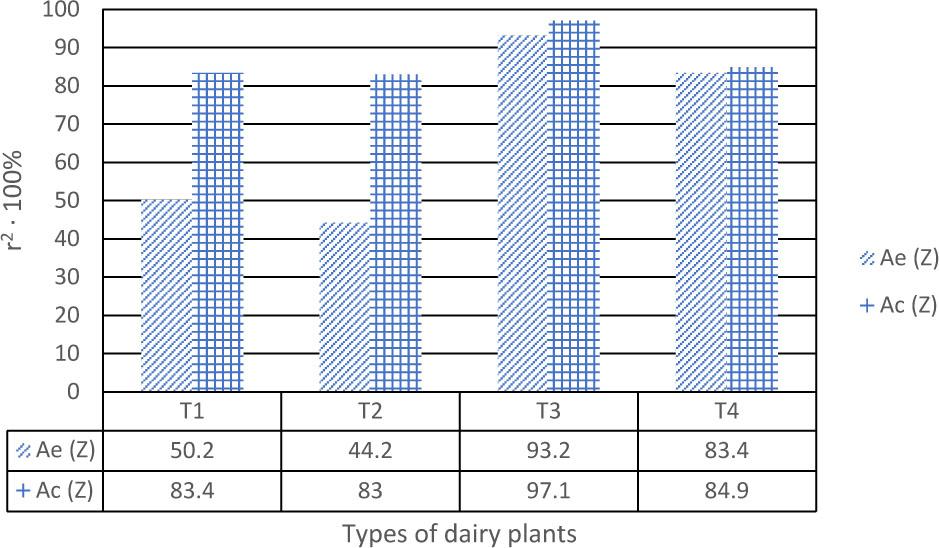

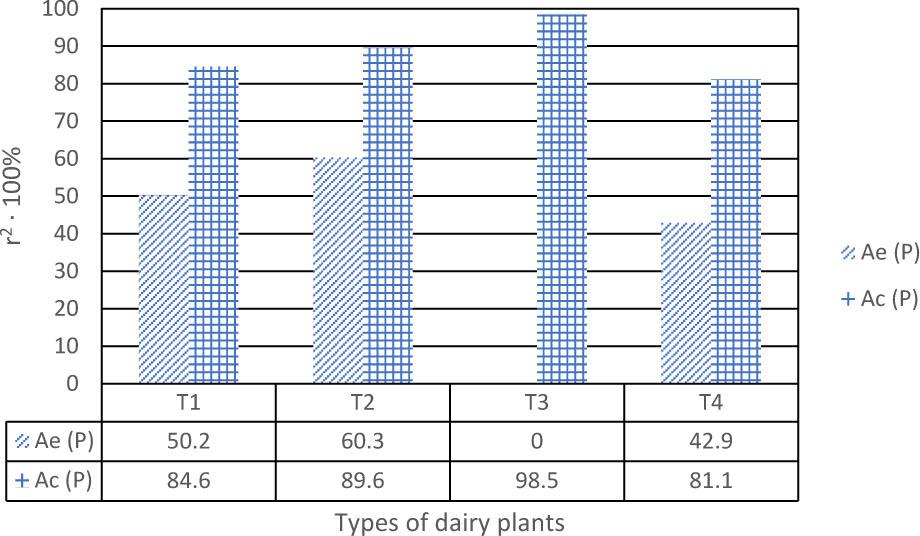

Figure 7b.

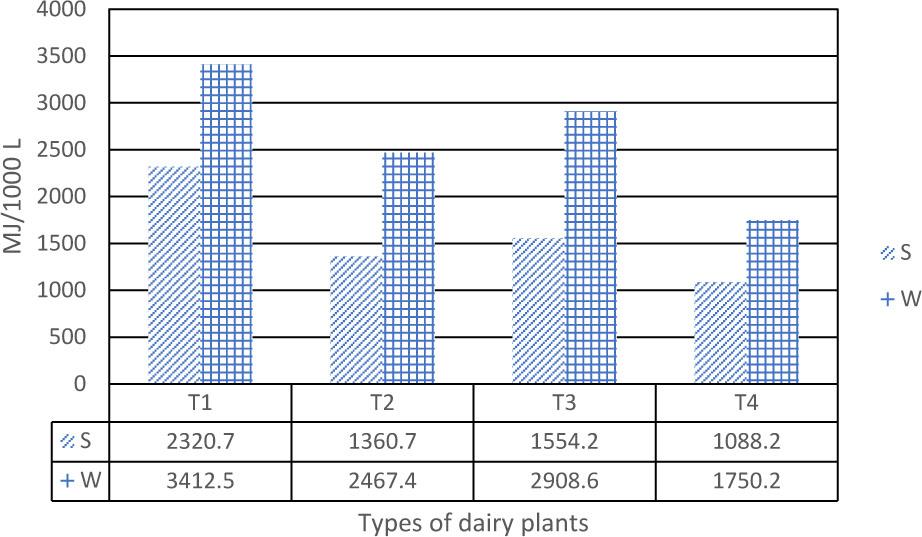

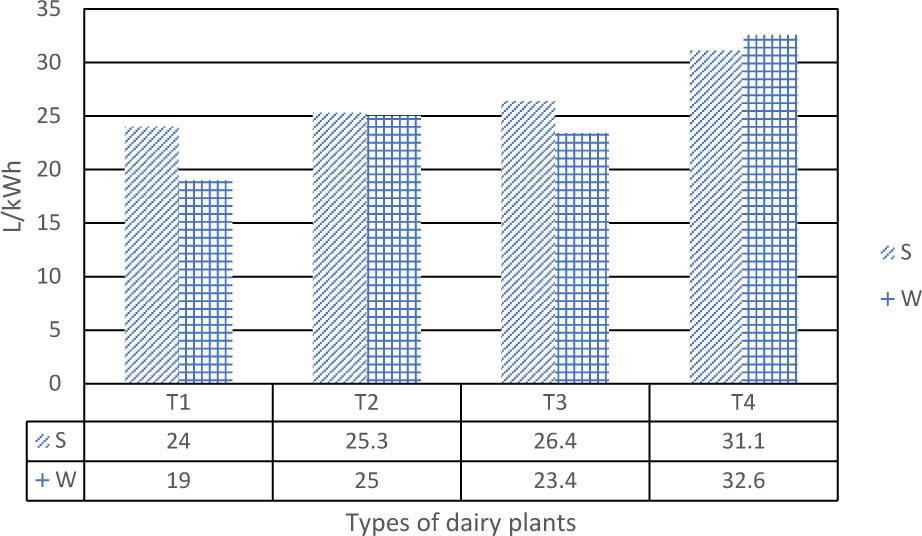

Figure 8a.

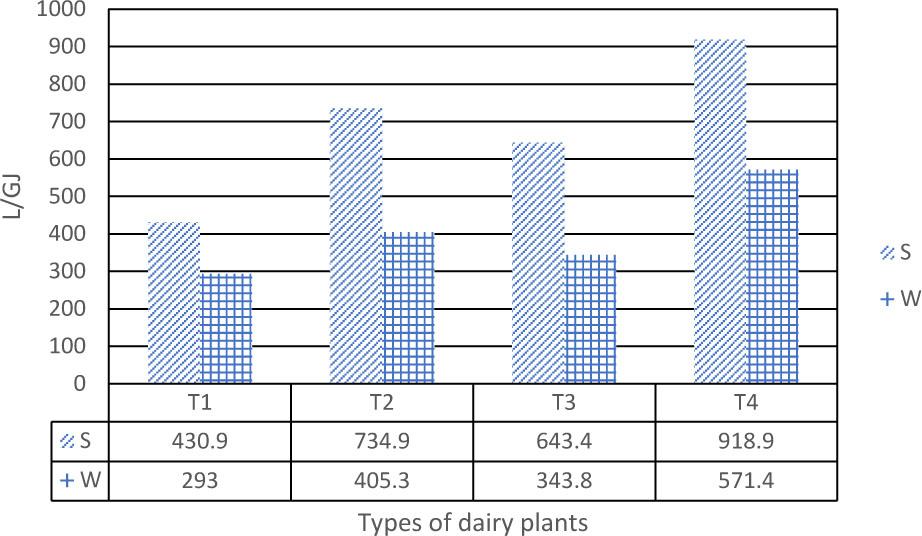

Figure 8b.

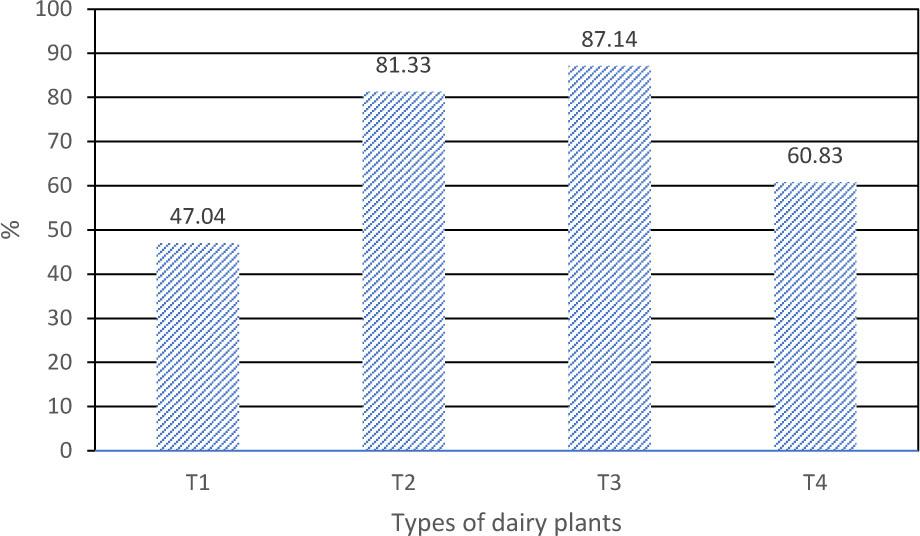

Figure 9.

Technological factors influencing energy demand in selected dairy plants

| Dairy plant specification | Average electric energy consumption | Season | Regression equations | Correlation coefficient r | Independent variables’ range of variation |

|---|---|---|---|---|---|

| Ae = 488731.7 kWh/month | S/W | Ae = 38530 + 21.93Zm | 0.917 | Zm: 4,058.9 – 6348.8 m3/month |

| We = 104.9 kWh/1000L | We = 178.6 - 0.019Zm | −0.982 | |||

| Ae = 1842461 kWh/month | S/W | Ae = 80.184 - 74908Zm | 0.63 |

|

| Ae = 155.75·Z11+84.68·Z12 - 573.45·Z13–11.36·Z14+232.33·Z15 + 139383.53 | 0.72 | ||||

| We = 77.0 kWh/1000 L | We = 0.0002 Zm + 72.558 | Weak correlation | |||

| We = 3∙10−3 Z11 + 7∙10−3·Z12 - 0.017·Z13 - 0.025·Z14 + 3∙10−3·Z16 + 36.5 | 0.31 | ||||

| Ac = 17060.39 GJ/month | Ac = 0.0946Zm + 14799 | Weak correlation | |||

| Ac= −1.49·Z11 - 1.33·Z12 + 3.46·Z13 + 5.84·Z14 + 3.93·Z15 + 16572.40 | 0.65 | ||||

| Wc = 0.71 GJ/1000 L | Wc= −3E-05Zm + 1.3441 | 0.47 | |||

| Wc = −1∙105·Z11 - 3∙105·Z12 + 2∙104·Z13 + 7∙10−6 ·Z14 + 1∙10−5 ·Z15 + 0.99 | 0.83 | ||||

| Ae = 101,516 kWh/month | S/W | Ae = 16.039 Zm + 37632 | 0.741 |

|

| Ae = 0.17·Z16 + 3.38·Z17 + 0.32·Z18 - 0.70·Z19 + 1.62·Z20 + 0.48·Z21 + 0.08·Z22 - 0.84·Z23 - 15048.70 | 0.984 | ||||

| We = 25.94 kWh/1000 L | We = −0.0025 Zm + 35.795 | 0.526 | |||

| We = 5∙10−6 ·Z16 - 0.002·Z17 + 4∙10−6·Z18 - 0.001·Z19 - 0.004·Z20 + 4∙10−6 ·Z21 + 2∙10−6·Z22 + 0.002·Z23 + 59.29 | 0.905 | ||||

| Ae = 10,681 kWh/4d | S/W | Ae = 84.71Z4d - 4676.82 | 0.675 | Z4d: 173,430 – 192,500 L/4d |

| We = 58.87 kWh/m3 | We = 0.1479Z4d + 31.75 | 0.285 | |||

| Ac = 56.93 GJ/4d | Ac = 0.6966Z4d - 69.36 | 0.719 | |||

| Wc = 313.56 MJ/m3 | Wc = 2.00 Z4d - 48.81 | 0.482 |

Influence of the daily production profile and the installed capacity of electrical devices on energy consumption in T4 dairy plants (producing only milk, dairy beverages, tvorog, and, in some cases, also butter)

| Season | Total installed capacity P [kW] | Average energy consumption | Average energy consumption per unit of end product | Multiple regression equation | Coefficient of determination R2 | Range of variation in independent variables | ||

|---|---|---|---|---|---|---|---|---|

| Ae [kWh /24h] | Ac [GJ/24h] | We [kWh/1000 L] | Wc [GJ/1000 L] | |||||

| S | 50.0 – 2,385.0 (34) | 2,374.1 | 59.305 | 32.13 | 1.0882 | Ae = 559.42 + 29.374Z1 | 0.834 | Z1: 2.5 – 80.6 |

| Ae =345.63 + 4.420P1 + 18.787P2 | 0.950 |

| ||||||

| Ac = 18.658 + 0.460 Z1 + 1.766Z2 | 0.849 |

| ||||||

| W | 63.0 – 646.0 (24) | 1,081.4 | 52.366 | 30.70 | 1.7502 | Ae = 358.08 + 35.352Z1 | 0.672 | Z1: 1.0 – 59.1 |

| Ae = 463.75 + 6.235P3 | 0.429 | P3: 6.0 – 250.0 | ||||||

| Ac = −0.121 + 0.531P1 − 1.899P7 | 0.811 |

| ||||||

| Ac = 30.777 + 1.054Z1 | 0.441 | Z1: 1.0 – 59.1 | ||||||

Types of examined dairy plants

| Type | Production profile |

|---|---|

| T1 | Milk, dairy beverages, cream, tvorog, cheese, butter, casein, milk powder |

| T2 | Identical to T1 plants, excluding milk powder |

| T3 | Identical to T1 plants, excluding milk, dairy beverages, cream, and tvorog |

| T4 | Milk, dairy beverages, cream, and tvorog only |

Literature on energy consumption and environmental performance of dairy plants

| Research topic | Authors |

|---|---|

| Energy consumption (direct) and energy conservation | Budny & Weiss [2000], Baker & McKenzie [2005], Benedetti et al. [2016], Biglia et al. [2015], Boutaghriout et al. [2016], Bühler et al. [2018], Cosgrove et al. [2016], De Lima et al. [2018], Domínguez-Niño et al. [2017], Energy Performance Indicator Report [2001], Fushimi & Fukui [2014], Gugała et al. [2015], IFC – World Bank Group [2007], Herbst & Griffiths [1993], Kalla et al. [2017], Kapela et al. [2015], Marchi et al. [2022], Masanet et al. [2014], Milani et al. [2011], Pradella et al. [2017], Rad & Lewis [2014], Ramirez et al. [2006], Rao [1986], Samarin et al. [2020], Srinivasan et al. [2018], Wardrop Engineering Inc. [1997], WS Atkins [1998], Wojdalski [1991], Xu & Flapper [2009], Xu et al. [2012], Zhang et al. [2018]. |

| Heat recovery | Atkins et al. [2011], Atkins et al. [2010], Jbira et al. [2023] |

| Energy consumption in wastewater treatment | Kowalczyk & Karp [2005], Dąbrowski & Żyłka [2015], Grala et al. [2010], Kowalczyk & Bąbała [2010], Krzemińska et al. [2013]. |

| Renewable energy | Schnitzer et al. [2007], Coskun et al. [2012] |

| Cleaner production standards | Bosworth et al. [2000], Honkasalo et al. [2005]. |

| Best available techniques | Bosworth et al. [2000], WS Atkins [2005] |

| Environmental performance | Burnett & Hansen [2008], Honkasalo [2003], Honkasalo et al. [2005], Maxime et al. [2006], Prasad et al. [2004], Prasad & Pagan [2006], Zielińska-Chmielewska [2020]. |

| Energy efficiency and optimization of selected production processes | Alves et al. [2014], Baker [2005], Bouman et al. [1993], Brush et al. [2011], Dobry et al. [2009], Đurić et al. [2005], Erbay et al. [2015], Gawałek & Wesołowski [2008], Jin & Chen [2009; 2011], Johnson & Langrish [2017], Jokandan et al. [2015], Kaleta & Chojnacka [2009], Kemp [2012], Leszczyńska & Lee [2016], Marks & Gut [2007], Moejes & Van Boxtel [2017], Munir et al. [2016], Murphy et al. [2013], Niamsuwan et al. [2013], Palianechka et al. [2022], Patel et al. [2009], Philipp et al. [2018], Písecký [2005; 2012], Raghavan et al. [2004], Seydel et al. [2006], Sikirica et al. [2003], Sorgüven & Özilgen [2012], Taghizadeh-Tabari et al. [2016], Walmsley et al. [2013], Yildirim & Genc [2017]. |

| Financial and environmental implications of energy management | Aymerich et al. [2015], Chauhan et al. [2006], Dalton et al. [2002], Egas et al. [2021], Geary et al. [2010]. |

| Process integration | Atkins et al. [2010; 2011], Chen et al. [2022], Kapustenko et al. [2008], Jbira et al. [2023], Kemp [2005], Lincoln et al. [2022], Schlossera et al. [2019], Walmsley et al. [2016; 2018]. |

| Pulsed electric field processing | Bendicho et al. [2002], Guerrero-Beltrán et al. [2010], Sepulveda et al. [2005] |

| Solar energy | Boutaghriout et al. [2013], Camci [2020], Panchal et al. [2018]), Schnitzer et al. [2007] |

| Electric power substitution/electrification | Bühler et al. [2019] |

| Life cycle assessment (LCA), carbon footprint (CF), sustainable development standards | Djekič et al. [2014], Egas et al. [2021], Kim et al. [2013], Prakash & Henham [2014], Vasilaki et al. [2016], Vergé et al. [2007], Von Keyserlingk et al. [2013], Walmsley et al. [2015] |

| Cleaner production and the environmental impact of dairy production | Dvarionienė et al. [2012], Dyer et al. [2008], Komisja Europejska [2010], Nutter et al. [2013], Özbay & Demirer [2007], Patankar et al. [2010], Saunders & Barber [2007] |

| Cleaning of production equipment | Jeurnink & Brinkman [1994], Mierzejewska & Diakun [2011], Muthukumaran et al. [2004], Piepiórka-Stepuk et al. [2017] |

General characteristics of the analysed types of dairy plants in summer and winter

| FR1 | Type of plant (Summer) | Type of plant (Winter) | ||||||

|---|---|---|---|---|---|---|---|---|

| T1 | T2 | T3 | T4 | T1 | T2 | T3 | T4 | |

| Kp1 | 0.59 – 3.10 | 0.36 – 5.66 | 0.54 – 3.10 | 0.62 – 2.42 | 0.32 – 2.90 | 0.22 – 2.99 | 0.25 – 2.90 | 0.40 – 1.16 |

| Kp2 | 0.35 – 1.33 | 0.23 – 3.54 | 0.30 – 2.13 | 0.14 – 0.82 | 0.19 – 1.18 | 0.13 – 2.46 | 0.13 – 1.35 | 0.18 – 0.90 |

| Uen1 | 3.52 – 17.74 | 3.93 – 40.46 | 5.30 – 31.67 | 1.13 – 21.40 | 4.13 – 17.74 | 1.16 – 39.55 | 1.17 – 17.74 | 2.26 – 13.53 |

| Uen2 | 2.43 – 12.91 | 1.26 – 23.75 | 3.06 – 23.75 | 0.49 – 8.93 | 0.70 – 13.16 | 1.02 – 32.41 | 1.08 – 11.92 | 1.31 – 8.77 |

| Km | 3.74 – 13.69 | 2.63 – 28.79 | 4.02 – 28.79 | 0.99 – 24.66 | 1.76 – 24.66 | 1.99 – 34.33 | 1.99 – 32.26 | 3.38 – 24.64 |

Influence of the daily production profile and the installed capacity of electrical devices on energy consumption in T3 dairy plants (not producing milk, dairy beverages or tvorog)

| Season | Total installed capacity P [kW] | Average energy consumption | Average energy consumption per unit of end product | Multiple regression equation | Coefficient of determination R2 | Range of variation in independent variables | ||

|---|---|---|---|---|---|---|---|---|

| Ae [kWh/24h] | Ac [GJ/24h] | We [kWh/1000 L] | Wc [GJ/1000 L] | |||||

| S | 83.0 – 1,923.0 (22) | 3,079.5 | 148.151 | 37.83 | 1.5542 | Ae = 953.19 + 29.707Z4 + 430.898Z6 | 0.932 |

|

| We = 42.633 - 0.481Z5 | 0.346 | Z5: 0 – 80.3 | ||||||

| Ac = −36.781 + 0.607P1 - 0.523P3 + 1.037P4 + 0.968P6 + 5.555P10 | 0.990 |

| ||||||

| Wc = 1.476 + 0.001P4 - 0.012P6+0.013P10 | 0.662 | |||||||

| Ac = 41.899 - 0.964Z3 + 2.204Z4 + 15.219Z6 | 0.971 |

| ||||||

| Wc = 1.6316-0.006Z3 + 0.003Z4 - 0.013Z5 | 0.608 | |||||||

| W | 30.3 – 1,938.0 (20) | 3,548.8 | 230.243 | 42.82 | 2.9086 |

|

|

|

| Ac = 1.145 + 0.444P1 + 0.936P4 + 1.275P7 | 0.985 |

| ||||||

| Wc = 2.2652 + 0.028P7 | 0.627 | |||||||

| Ac = 117.423 + 62.187Z6 | 0.399 | Z6: 0 – 7.9 | ||||||

| Wc = 2,3795 + 0.291Z6 | 0.563 | |||||||

Factors that influence energy consumption in dairy production

| Group of factors | Measured parameters | Symbols* |

|---|---|---|

| FR1 | Basic operating parameters and process automation | Km, Kp1, Kp2, N1, N2, P, Uen1, Uen2, Z, Zm, Z4d |

| FR2 | Production profile** | Z1, Z2, Z3, Z4, Z5, Z6, Z7, Z8, Z9, Z10, Z11, Z12, Z13, Z14, Z15, Z16, Z17, Z18, Z19, Z20, Z21, Z22, Z23 |

| FR3 | Technical equipment | P1, P2, P3, P4, P5, P6, P7, P8 |

Influence of the daily production profile and the installed capacity of electrical devices on energy consumption in T1 dairy plants (producing milk powder)

| Season | Total installed capacity P [kW] | Average energy consumption | Average energy consumption per unit of end product | Multiple regression equation | Coefficient of determination R2 | Range of variation in independent variables | ||

|---|---|---|---|---|---|---|---|---|

| Ae [kWh/24h] | Ac [GJ/24h] | We [kWh/1000 L] | Wc [GJ/1000 L] | |||||

| S | 454.0 – 2,421.7 (21) | 7,682.1 | 432.650 | 41.73 | 2.3207 | Ae = 3944.70 + 37.110 Z4 | 0.568 | Z4:19.0 – 335.8 |

| Ac = 134.293 + 0.546P2 + 0.760P4 | 0.789 |

| ||||||

| Ac = 140.56 + 2.433Z4 + 1.977Z5 + 0.815 Z8 | 0.834 |

| ||||||

| W | 318.0–2,548.0 (19) | 6,246.0 | 396.632 | 52.70 | 3.4125 | Ae = 4289.00 + 41.401Z4 for Wc R2 < 0.20 | 0.502 | Z4: 10.4 –282.7 |

| Ac = 83.369 + 0.530P2 + 0.644P4 + 0.857P10 for Wc R2 < 0.34 | 0.846 |

| ||||||

| Ac = 246.86 + 3.168 Z4 | 0.546 | Z4: 10.4 – 282.7 | ||||||

Selected indicators and factors for analysing the energy performance of dairy plants

| Indicators and factors for analysing energy performance | Unit of measure | Type of plant/production profile/product | Indicators | Source | ||

| Range according to Fig. 2 | Mean | Interval/season | ||||

| Electric energy consumption | kWh/m3 of raw milk | Total production | WZ | 90 | 10 – 680 | WS Atkins [1998] |

| kWh/m3 of milk | Milk powder, cheese, butter, yogurt, dairy desserts | 27 | - | Budny & Weiss [2000] | ||

| Cheese, tvorog, yogurt, dairy desserts | 32 | - | ||||

| Cheese, butter, yogurt, dairy desserts | - | 34 – 52 | ||||

| Butter, milk powder, yogurt, dairy desserts | - | 53 – 57 | ||||

| Cheese, milk powder, butter | 64 | |||||

| Cheese, butter | 65 | |||||

| Yogurt, dairy desserts, tvorog, butter | 66 | |||||

| kWh/m3 of milk | Cheese | WT | - | 2.9 – 6.6 | ||

| kWh/Mg of butter | Butter (continuous method) | - | 12.9 – 17.0 | |||

| kWh/Mg of milk | Milk processing output (based a study of three dairy plants) | WZ | - | 30 – 80 | Boutaghriou et al. [2016] | |

| kWh/Mg of end product | Milk powder | WZ | 429.9 | 377.0 – 482.9 | Budny et al. [1984a] | |

| Heat consumption | GJ/m3 of raw milk | Total production | WZ | 2.01 | 0.12 – 14 | WS Atkins [1998] |

| MJ/m3 of processed milk | Milk powder, cheese, butter, yogurt, dairy desserts | 1348 | - | Budny & Weiss [2000] | ||

| Cheese, tvorog, yogurt, dairy desserts | 1439 | - | ||||

| Cheese, butter, yogurt, dairy desserts | - | 1583 – 2380 | ||||

| Butter, milk powder, yogurt, dairy desserts | - | 2733 – 3171 | ||||

| Cheese, milk powder, butter | 2882 | - | ||||

| Cheese, butter | 1884 | - | ||||

| Yogurt, dairy desserts, tvorog, butter | 2698 | - | ||||

| GJ/Mg of evaporated water | Spray-drying | WA | 4.87 | 3 – 20 | Baker & McKenzie [2005] | |

| GJ/Mg of processed milk | Modern dairy plants with heat recovery systems | WZ | 0.34 | - | Bosworth et al. [2001] | |

| Modern plants where hot water is used as an energy carrier | 0.50 | - | ||||

| Older plants where steam is used as an energy carrier | 2.00 | - | ||||

| Total energy consumption | MWh/Mg of milk powder | Milk powder (mechanical vapor recompression, MVR) | WP | 3.08 | - | Bühler et al. [2019] |

| GJ/Mg of product | Milk powder | WZ | 29.95 | 26.41–33.49 | Budny et al. [1984a] | |

| MWh/Mg of dry product | Spray-drying of cheese whey | WA | 2.049 | - | Domínguez-Niño et al. [2018] | |

| Fuel gas | kWh/Mg of milk | Total production (based on a study of three production plants) | WZ | - | 100 – 220 | Boutaghriou et al. [2016] |

| Total energy consumption | GJ/m3 of processed milk* | Milk, tvorog (based on a study of a selected dairy plant) | - | 3.04 | 1.93 – 2.47 Summer | Wojdalski et al. [2007] |

| 3.63 – 4.19 Winter | ||||||

| GJ/m3 of processed milk** | WZ | 2.46 | 1.40 –1.96 Summer | |||

| 3.04 – 3.55 Winter | ||||||

| Total energy consumption | kWh/kg of evaporated water | Three-phase evaporator | WA | 0.14 | - | Prasad et al. [2004] |

| Five-phase evaporator | 0.085 | - | Prasad et al. [2004] | |||

| Total energy consumption expressed in fuel equivalents | kg of fuel equivalent/m3 of processed milk* | Milk, tvorog (based on a study of a selected dairy plant) | WZ | 104 | 66 – 84 Summer | Wojdalski et al. [2007] |

| 124 –143 Winter | ||||||

| kg of fuel equivalent/m3 of processed milk** | 84 | 48 – 67 Summer | ||||

| 103–121 Winter | ||||||

| Energy consumption in wastewater treatment | kWh/kg BOD5 | Total production | WT | - | 0.89 – 3.22 | Kowalczyk & Karp [2005] |

| kWh/m3 of wastewater | - | 1.94 – 6.32 | ||||

| SO2 emissions | kg/m3 of raw milk | Total production | WZ | 1.65 | 0.05 – 22.4 | WS Atkins [1998] |

| kg/m3 of processed milk | - | 0.83 | - | Wojdalski et al. [2007] | ||

| NOx emissions | kg/m3 of raw milk | Total production | WZ | 0.49 | 0.03 – 6.4 | WS Atkins [1998] |

| kg/m3 of processed milk | - | 0.60 | - | Wojdalski et al. [2007] | ||

| CO2 emissions | kg/m3 of raw milk | Total production | WZ | 1.97 | 0.01 – 9.23 | WS Atkins [1998] |

| kg/m3 of processed milk | 1.25 | - | Wojdalski et al. [2007] | |||

| Carbon footprint of end products | kg CO2eq/kg of butter | Butter | WZ | 8.1 | - | Flysjö et al. [2014] |

| kg CO2eq/kg of milk powder | Milk powder | 7.4 | - | |||

| kg CO2eq/kg of cheese | Cheese | 6.5 | - | |||

| kg CO2eq/kg of dairy beverage | Dairy beverages | 1.2 | - | |||

| Particulate-matter emissions | kg/m3 of raw milk | Total production | 1.3 | 0.01 –14.4 | WS Atkins [1998] | |

| kg/m3 of processed milk | Total production | WZ | 1.15 | - | Wojdalski et al. [2007] | |

| Black carbon emissions | kg/m3 of raw milk | Total production | WZ | 19 | 0.01 – 193 | WS Atkins [1998] |

| kg/m3 of processed milk | Total production | - | 0.04 | - | Wojdalski et al. [2007] | |

Structure of energy consumption in the analysed dairy plant

| Process/operation | [kJ/Mg of milk] | Percent share [%] | ||||

|---|---|---|---|---|---|---|

| Steam | Direct fuel consumption | Refrigeration | Other machines and devices | Total | ||

| End product storage | - | - | 41,868 | - | 41,868 | 9.46 |

| Packing | - | 3,489 | - | - | 3,489 | 0.71 |

| Storage before packing | - | - | 20,934 | - | 20,934 | 4.73 |

| Deodorissation | 5,815 | - | - | - | 5,815 | 1.32 |

| Cooling | - | - | 19,771 | - | 19,771 | 4.47 |

| Homogenisation | - | - | - | 2,326 | 2,326 | 0.53 |

| Pasteurisation | 213,992 | - | - | - | 213,992 | 48.30 |

| Separation | - | - | - | 41,868 | 41,868 | 9.46 |

| Clarification/Standardisation | - | - | - | 20,934 | 20,934 | 4.73 |

| Reception and Storage | - | 30,238 | 41,868 | - | 72,106 | 16.29 |

| Total | 219,807 | 33,727 | 124,441 | 65,128 | 443,103 | 100 |

Influence of the daily production profile and the installed capacity of electrical devices on energy consumption in T2 dairy plants (not producing milk powder)

| Season | Total installed capacity P [kW] | Average energy consumption | Average energy consumption per unit of end product | Multiple regression equation | Coefficient of determination R2 | Range of variation in independent variables | ||

|---|---|---|---|---|---|---|---|---|

| Ae [kWh/24h] | Ac [GJ/24h] | We [kWh/1000 L] | Wc [GJ/1000 L] | |||||

| S | 83.0 – 2,935.0 (37) | 3,289.9 | 118.909 | 39.52 | 1.3607 | Ae= 748.34 + 60.1453Z1 + 39.4929Z3 + 22.079Z5 + 75.286Z8 for We R2 < 0.32 | 0.442 |

|

| Ac= 1.152 + 0.310P1 + 1.266P2 + 1.082P6 for Wc R2 < 0.37 | 0.860 |

| ||||||

| Ac= 18.295 + 1.501Z1 + 1.748Z2 + 0.990Z3 +1.006 Z5 −5.385 Z7 + 5.265 Z8 | 0.830 |

| ||||||

| W | 30.3 – 1,938.0 (24) | 2129.3 | 120.581 | 39.92 | 2.4672 | Ae = 864.92 + 94.4138Z2 + 104.032Z8 for We R2 < 0.20 | 0.603 |

|

| Ac = −4.109+0.364P1 +0.989P2+ 1.080P7 + 0.191P10 for Wc R2 < 0.33 | 0.896 |

| ||||||

| Ac = 26.259+2.981Z1 +2.492Z3 + 15.157Z7 + 6.733Z8 | 0.693 |

| ||||||