In 2021, Polish industrial plants consumed 1,079,886 TJ of electricity and 253,285 TJ of heat. Twenty food processing sectors were responsible for 8% of the total energy consumption and 6% of the total heat consumption in the food industry [SWAID 2023].

Milk and dairy production are among the largest sectors of this industry. In 2018, dairy plants purchased 9,043 million litres of milk, which accounts for 75.0% of the total output of Polish milk farms. Dairy plants also have a high demand for energy and water. The energy consumption of Poland’s food-processing sector has increased by around 10% in recent years, but there are no reliable data for assessing the dairy sector’s contribution to that increase. It has been established, however, that the Polish dairy sector is the second largest energy consumer on the agri-food market. The demand for heat in Polish dairy plants accounts for approximately 87 – 90% of total energy demand.

Dairy plants differ in output and production technology, and this affects their energy demands. Food-processing plants generally have been striving to implement more stringent food hygiene standards, reduce water consumption, and increase the effectiveness of their wastewater management systems [Chang et al. 2016]. The microbiological qualities of milk determine its thermal processing requirements, which may include the demand for cooling water in heat exchangers and the demand for cleaning water. Research on energy consumption in the food processing sector can provide valuable inputs for the transition to renewable energy [Mitroczuk 2022].

- –

To conduct a detailed analysis of energy consumption in four types of dairy plants with different production profiles, and to identify the most energy-intensive operations in these plants;

- –

To generate new information for modelling energy consumption in dairy plants based on a review of the literature and descriptive statistics;

- –

To describe correlations between engineering and production factors, including production profile, output, equipment, and energy consumption, in four types of dairy plants (taking into account the automation of production processes); and

- –

To formulate recommendations for industrial-practice and environmental-performance guidelines that could reduce energy consumption in the dairy sector, increase energy efficiency in dairy production, and promote the implementation of cleaner production standards.

These research aims are based on the objectives formulated by Bunse et al. [2011], who pointed out the gap between the research needs reported by manufacturing plants and the existing published scientific literature. The research problem formulated for this study was validated empirically based on the results of both qualitative and quantitative research. Qualitative research involved descriptive analysis, while quantitative research involved the systematization of statistical data from the analysed sources.

Based on descriptive statistics, the literature on energy consumption and the environmental performance of the dairy sector is presented in Table 1. The relevant information can be used to generate databases, optimize production processes, reduce energy consumption and pollutant emissions in the dairy sector. In Table 1, published studies and source materials have been grouped according to their topic and their most important findings.

Literature on energy consumption and environmental performance of dairy plants

Research on rational energy consumption in dairy plants (Table 1) has demonstrated that the impact of technical and technological factors on energy consumption and energy efficiency of dairy production in various seasons of the year has not been fully elucidated. The studies reviewed here examine the structure of energy demand in different production sectors, as well as the overall energy consumption in dairy plants. Milk is processed into various products, and energy consumption per unit of end product cannot be accurately determined. According to the Energy Performance Indicator Report, the energy consumption of Clean-In-Place (CIP) systems in Canadian dairies reaches 0.1 – 93.0 kWh/m3 of milk.

Water is also an energy carrier in cooling operations and in the production of steam for thermal processing. In most dairy plants around the world, water consumption ranges from 1 – 10 m3/1000 L of milk [Wojdalski et al. 2013]. Water consumption determines the amount of generated wastewater, which affects the plant’s overall energy demand. Energy consumption in wastewater treatment stations operated by dairy plants was analysed by Kowalczyk & Karp [2005] and Kowalczyk & Bąbała [2010]. The results of these studies are presented in Table 2.

Selected indicators and factors for analysing the energy performance of dairy plants

| Indicators and factors for analysing energy performance | Unit of measure | Type of plant/production profile/product | Indicators | Source | ||

| Range according to Fig. 2 | Mean | Interval/season | ||||

| Electric energy consumption | kWh/m3 of raw milk | Total production | WZ | 90 | 10 – 680 | WS Atkins [1998] |

| kWh/m3 of milk | Milk powder, cheese, butter, yogurt, dairy desserts | 27 | - | Budny & Weiss [2000] | ||

| Cheese, tvorog, yogurt, dairy desserts | 32 | - | ||||

| Cheese, butter, yogurt, dairy desserts | - | 34 – 52 | ||||

| Butter, milk powder, yogurt, dairy desserts | - | 53 – 57 | ||||

| Cheese, milk powder, butter | 64 | |||||

| Cheese, butter | 65 | |||||

| Yogurt, dairy desserts, tvorog, butter | 66 | |||||

| kWh/m3 of milk | Cheese | WT | - | 2.9 – 6.6 | ||

| kWh/Mg of butter | Butter (continuous method) | - | 12.9 – 17.0 | |||

| kWh/Mg of milk | Milk processing output (based a study of three dairy plants) | WZ | - | 30 – 80 | Boutaghriou et al. [2016] | |

| kWh/Mg of end product | Milk powder | WZ | 429.9 | 377.0 – 482.9 | Budny et al. [1984a] | |

| Heat consumption | GJ/m3 of raw milk | Total production | WZ | 2.01 | 0.12 – 14 | WS Atkins [1998] |

| MJ/m3 of processed milk | Milk powder, cheese, butter, yogurt, dairy desserts | 1348 | - | Budny & Weiss [2000] | ||

| Cheese, tvorog, yogurt, dairy desserts | 1439 | - | ||||

| Cheese, butter, yogurt, dairy desserts | - | 1583 – 2380 | ||||

| Butter, milk powder, yogurt, dairy desserts | - | 2733 – 3171 | ||||

| Cheese, milk powder, butter | 2882 | - | ||||

| Cheese, butter | 1884 | - | ||||

| Yogurt, dairy desserts, tvorog, butter | 2698 | - | ||||

| GJ/Mg of evaporated water | Spray-drying | WA | 4.87 | 3 – 20 | Baker & McKenzie [2005] | |

| GJ/Mg of processed milk | Modern dairy plants with heat recovery systems | WZ | 0.34 | - | Bosworth et al. [2001] | |

| Modern plants where hot water is used as an energy carrier | 0.50 | - | ||||

| Older plants where steam is used as an energy carrier | 2.00 | - | ||||

| Total energy consumption | MWh/Mg of milk powder | Milk powder (mechanical vapor recompression, MVR) | WP | 3.08 | - | Bühler et al. [2019] |

| GJ/Mg of product | Milk powder | WZ | 29.95 | 26.41–33.49 | Budny et al. [1984a] | |

| MWh/Mg of dry product | Spray-drying of cheese whey | WA | 2.049 | - | Domínguez-Niño et al. [2018] | |

| Fuel gas | kWh/Mg of milk | Total production (based on a study of three production plants) | WZ | - | 100 – 220 | Boutaghriou et al. [2016] |

| Total energy consumption | GJ/m3 of processed milk* | Milk, tvorog (based on a study of a selected dairy plant) | - | 3.04 | 1.93 – 2.47 Summer | Wojdalski et al. [2007] |

| 3.63 – 4.19 Winter | ||||||

| GJ/m3 of processed milk** | WZ | 2.46 | 1.40 –1.96 Summer | |||

| 3.04 – 3.55 Winter | ||||||

| Total energy consumption | kWh/kg of evaporated water | Three-phase evaporator | WA | 0.14 | - | Prasad et al. [2004] |

| Five-phase evaporator | 0.085 | - | Prasad et al. [2004] | |||

| Total energy consumption expressed in fuel equivalents | kg of fuel equivalent/m3 of processed milk* | Milk, tvorog (based on a study of a selected dairy plant) | WZ | 104 | 66 – 84 Summer | Wojdalski et al. [2007] |

| 124 –143 Winter | ||||||

| kg of fuel equivalent/m3 of processed milk** | 84 | 48 – 67 Summer | ||||

| 103–121 Winter | ||||||

| Energy consumption in wastewater treatment | kWh/kg BOD5 | Total production | WT | - | 0.89 – 3.22 | Kowalczyk & Karp [2005] |

| kWh/m3 of wastewater | - | 1.94 – 6.32 | ||||

| SO2 emissions | kg/m3 of raw milk | Total production | WZ | 1.65 | 0.05 – 22.4 | WS Atkins [1998] |

| kg/m3 of processed milk | - | 0.83 | - | Wojdalski et al. [2007] | ||

| NOx emissions | kg/m3 of raw milk | Total production | WZ | 0.49 | 0.03 – 6.4 | WS Atkins [1998] |

| kg/m3 of processed milk | - | 0.60 | - | Wojdalski et al. [2007] | ||

| CO2 emissions | kg/m3 of raw milk | Total production | WZ | 1.97 | 0.01 – 9.23 | WS Atkins [1998] |

| kg/m3 of processed milk | 1.25 | - | Wojdalski et al. [2007] | |||

| Carbon footprint of end products | kg CO2eq/kg of butter | Butter | WZ | 8.1 | - | Flysjö et al. [2014] |

| kg CO2eq/kg of milk powder | Milk powder | 7.4 | - | |||

| kg CO2eq/kg of cheese | Cheese | 6.5 | - | |||

| kg CO2eq/kg of dairy beverage | Dairy beverages | 1.2 | - | |||

| Particulate-matter emissions | kg/m3 of raw milk | Total production | 1.3 | 0.01 –14.4 | WS Atkins [1998] | |

| kg/m3 of processed milk | Total production | WZ | 1.15 | - | Wojdalski et al. [2007] | |

| Black carbon emissions | kg/m3 of raw milk | Total production | WZ | 19 | 0.01 – 193 | WS Atkins [1998] |

| kg/m3 of processed milk | Total production | - | 0.04 | - | Wojdalski et al. [2007] | |

- heat and electric energy consumption, converted to primary energy, where 1 kWh = 3.6 MJ/0.3 (an energy conversion efficiency ratio of 0.3 indicates that energy is effectively converted and transported);

- heat and electric energy consumption, converted to primary energy, where 1 kWh = 3.6 MJ

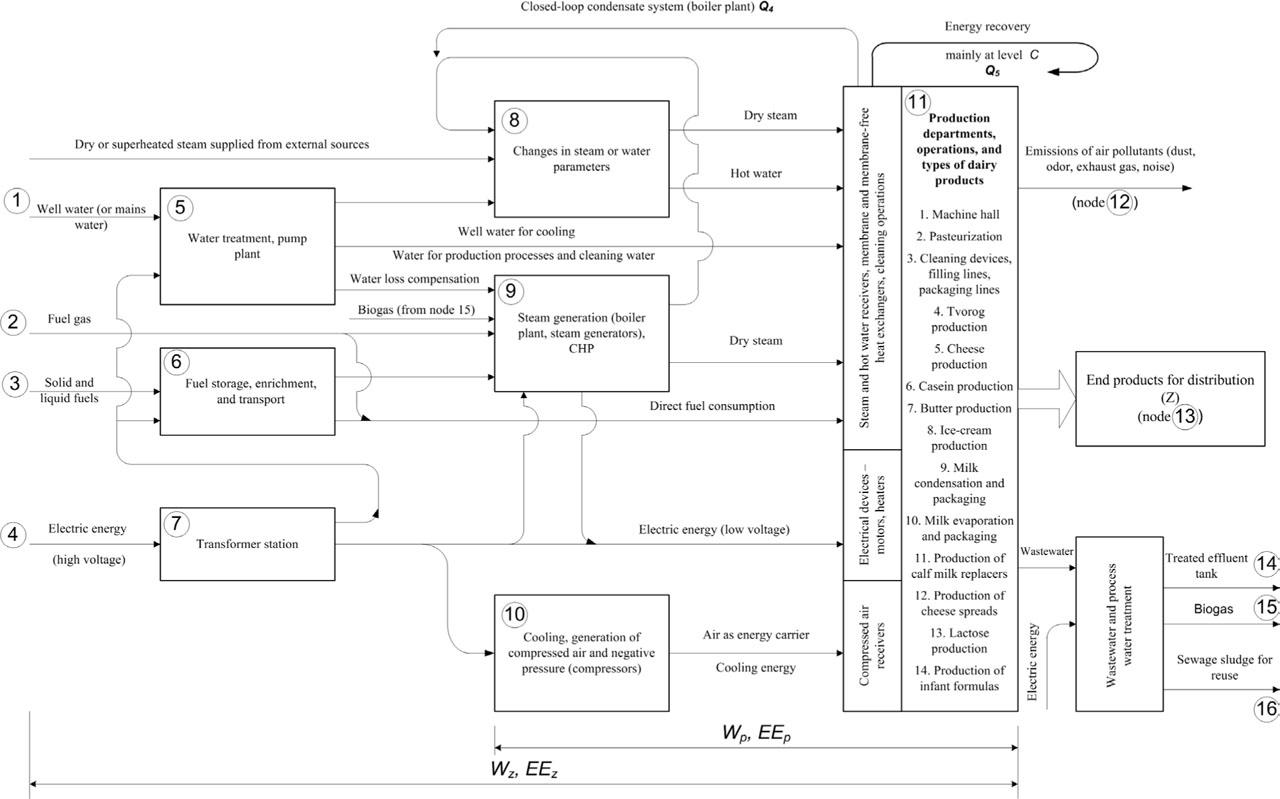

The data presented in Table 1 indicate that the energy consumption and environmental impact of dairy plants are complex phenomena. Various indicators have been applied to assess energy management and the conversion efficiency of different energy carriers. A diagram of a dairy plant as a user of energy carriers is presented in Figure 1 to organise the results of the study.

Energy and water consumption in a dairy plant (detailed explanations in the text)

Energy efficiency in dairy plants, including energy consumption, is usually evaluated based on indicators of energy consumption per unit of end product (WP, WZ) or using energy efficiency indicators (EE). Energy efficiency is determined by dividing a plant’s output by the amount of energy input in the production process (energy consumption).

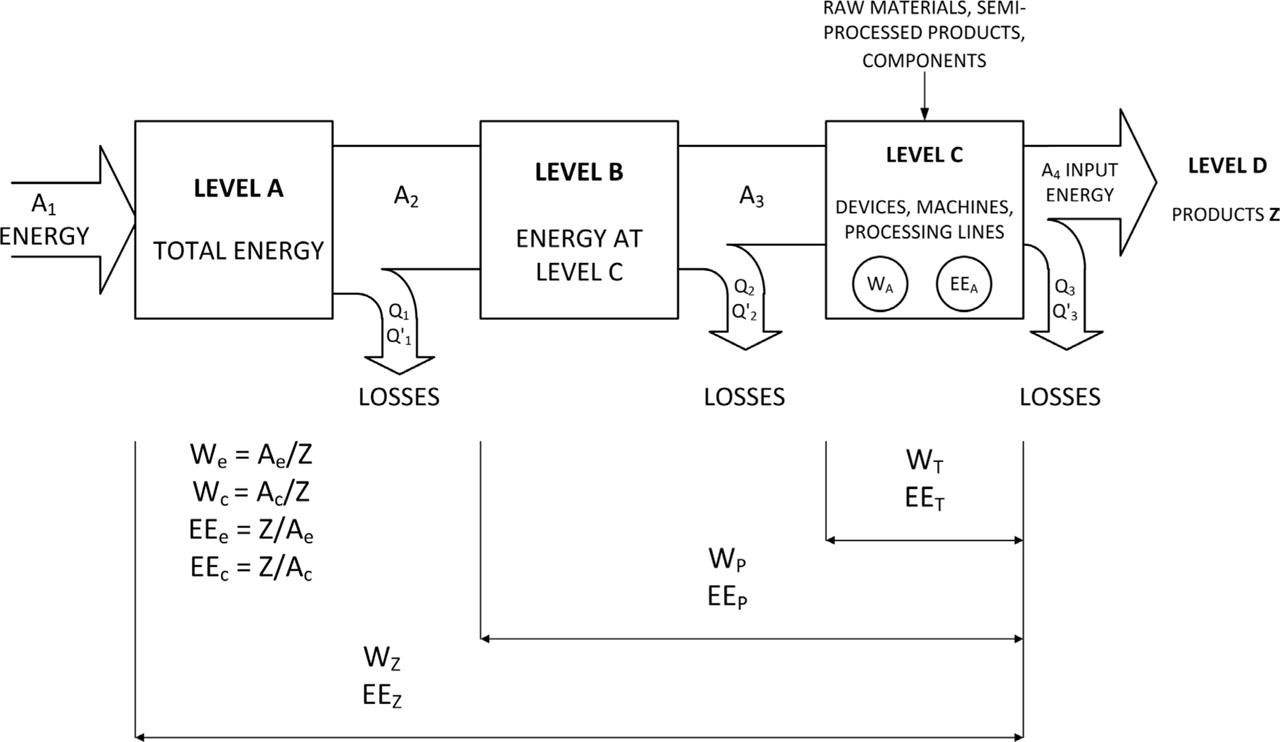

Energy consumption in the production process can thus be analysed based on a model of a dairy plant as a user of energy carriers (Fig. 1). Energy consumption per unit of end product (WZ) is calculated by analysing all production processes where energy is used and converted to other forms of energy. Indicators of aggregate energy consumption (WA), energy consumption per technological process (WT), and energy consumption per production process (WP) (Fig. 2) are less informative in analyses of energy consumption and energy efficiency (EE) in a dairy plant.

Indicators of energy consumption per unit of end product in a dairy plant (detailed explanations are in the text)

In reference to Figure 1, a band diagram of energy transformation processes at different reference levels, with energy changes (Qn) at different stages/levels of energy transformation (Q2, Q3) and energy losses (Q1,), is presented in Figure 2.

As shown in Figures 1 and 2, energy consumption in dairy plants can be divided into the following stages:

The consumption of energy (Ae, Ac) supplied by devices 5 – 7 (Fig. 1) to nodes 1 – 4 is measured at level A. The results are used to calculate energy consumption per unit of end product (We, Wc) and energy efficiency (indicators EE, EEel, and EEtherm, which are the inverse of indicators We and Wc). The demand for energy is estimated at level A [Trojanowska 2010] to optimise electric energy consumption in the plant [Aymerich et al. 2015; Bergamini et al. 2021; Olkowski et al. 2023; Rad & Lewis 2014].

Energy conversion and further transformation of parameters from level A (items 8 –10 in Fig. 1). The production indicators of energy consumption per unit of end product (WP) and the energy efficiency of production (EEP) are presented in Figure 2. Energy and heat can be co-generated at this stage. For example, biogas supplied by a biogas plant (item 15 in Fig. 1) can be used as a source of energy [Bassols et al. 2002; Cannistraro et al. 2016; Leal & Silveira 2002].

Energy consumption. This level involves the machines and devices used in the analysed plant (item 11 in Fig. 1), as well as energy inputs into production processes that have not been converted to other energy carriers – e.g., fuel consumption in the milk evaporator; diesel consumption in transport; hot water in the heat exchanger; steam heat; heat generated by machines; cooling; lighting; and generation of negative pressure. This stage can be significantly expanded in plants where waste energy is recovered (e.g., streams Q4 and Q5 in Fig. 2). Energy recovery can thus be taken into consideration in the Sankey diagram. This level also involves energy consumption per technological process (WT). Indicators of the aggregate energy consumption of the machines and devices that make up specific processing lines (WA) and energy efficiency indicators (EET and EEA) are less informative. In Figure 1, item 12 denotes the overall stream of waste products and pollutants emitted into the air. Item 14 denotes treated wastewater. Sewage sludge (item 16) can be used in fertilizer production [Chmielina & Kondrat 2024].

Total energy consumption, namely the overall energy input (A4) required to manufacture the end product (Z; item 13 in Fig. 1) in a dairy plant. Level D is the theoretical reference level for input energy. Calculations of final energy consumption were presented by Rusen et al. [2018] and Walker et al. [2017].

Table 2 presents a synthesis of selected research findings and data from the cited sources regarding energy consumption and energy efficiency in various types of dairy plants with different production profiles, including pollutant emissions. These numerical values can be used by dairy plants to compare with or verify data obtained in practice. Andersson et al. [2018] and Elmaraghy et al. [2017] benchmarked the energy performance of production plants relative to either the top performers in a sector or best-practice techniques.

Energy consumption in different departments of the analysed dairy plant is presented in Table 3. Steam generation was the most energy-intensive process, accounting for 48.3 – 49.6% of the total energy consumption of the plant (including operations and the structure of energy carriers). Heat accounted for 57.2% of the total energy consumed by the plant when direct fuel consumption was included in the analysis.

Structure of energy consumption in the analysed dairy plant

| Process/operation | [kJ/Mg of milk] | Percent share [%] | ||||

|---|---|---|---|---|---|---|

| Steam | Direct fuel consumption | Refrigeration | Other machines and devices | Total | ||

| End product storage | - | - | 41,868 | - | 41,868 | 9.46 |

| Packing | - | 3,489 | - | - | 3,489 | 0.71 |

| Storage before packing | - | - | 20,934 | - | 20,934 | 4.73 |

| Deodorissation | 5,815 | - | - | - | 5,815 | 1.32 |

| Cooling | - | - | 19,771 | - | 19,771 | 4.47 |

| Homogenisation | - | - | - | 2,326 | 2,326 | 0.53 |

| Pasteurisation | 213,992 | - | - | - | 213,992 | 48.30 |

| Separation | - | - | - | 41,868 | 41,868 | 9.46 |

| Clarification/Standardisation | - | - | - | 20,934 | 20,934 | 4.73 |

| Reception and Storage | - | 30,238 | 41,868 | - | 72,106 | 16.29 |

| Total | 219,807 | 33,727 | 124,441 | 65,128 | 443,103 | 100 |

Source: Brush et al. [2011] (based on Sikirica et al. [2003])

It should be noted that in the literature [Bosworth et al. 2000; WS Atkins Poland 2005] energy consumption per unit of end product was calculated based on measurements conducted across a small number of dairy plants. In other sources [IFC-WBG 2007], the detailed characteristics of dairy plants were not considered in the process of calculating energy consumption per unit of end product. In several studies, partial attempts were made to explain the correlations between selected factors related to production technology and technical equipment vs. energy consumption in dairy plants [Budny et al. 1982, 1984 a, b; Baker & McKenzie 2005; EPIR 2001]. The literature review conducted as part of the present study provided valuable information about the correlations between engineering and production factors, production profile, technical factors, and energy consumption in dairy plants.

The calculations and the study were conducted based on input data, the results of measurements, and the materials obtained from 140 dairy plants analysed in summer and 79 plants analysed in winter. Dairy plants for the study were selected randomly with regard to their daily milk processing outputs, production profiles, and technical equipment, with a special emphasis on the installed capacity of the electrical equipment. As in the study by WS Atkins [1998], energy consumption was determined based on the results of energy audits and questionnaires completed by dairy plants. Polish dairy plants were divided into four types (T1–T4) based on similarities in their production profiles (Table 4).

Types of examined dairy plants

| Type | Production profile |

|---|---|

| T1 | Milk, dairy beverages, cream, tvorog, cheese, butter, casein, milk powder |

| T2 | Identical to T1 plants, excluding milk powder |

| T3 | Identical to T1 plants, excluding milk, dairy beverages, cream, and tvorog |

| T4 | Milk, dairy beverages, cream, and tvorog only |

Each type of dairy plant (Table 4) was characterized using the three groups of factors (FR1-FR3) that are presented in Table 5. The energy consumption indicators Wc and We – defined by Budny et al. [1984 a, b] and Wojdalski & Dróżdż [2012] – were used in the study because of their applicability to industrial practice.

Factors that influence energy consumption in dairy production

| Group of factors | Measured parameters | Symbols* |

|---|---|---|

| FR1 | Basic operating parameters and process automation | Km, Kp1, Kp2, N1, N2, P, Uen1, Uen2, Z, Zm, Z4d |

| FR2 | Production profile** | Z1, Z2, Z3, Z4, Z5, Z6, Z7, Z8, Z9, Z10, Z11, Z12, Z13, Z14, Z15, Z16, Z17, Z18, Z19, Z20, Z21, Z22, Z23 |

| FR3 | Technical equipment | P1, P2, P3, P4, P5, P6, P7, P8 |

- the analysed parameters are explained in the Symbols and Abbreviations subsection at the beginning of the paper

- the production profile includes the organisation of production processes

Group FR1 factors for each type of analysed dairy plant (T1, T2, T3, and T4) are presented in Table 6.

General characteristics of the analysed types of dairy plants in summer and winter

| FR1 | Type of plant (Summer) | Type of plant (Winter) | ||||||

|---|---|---|---|---|---|---|---|---|

| T1 | T2 | T3 | T4 | T1 | T2 | T3 | T4 | |

| Kp1 | 0.59 – 3.10 | 0.36 – 5.66 | 0.54 – 3.10 | 0.62 – 2.42 | 0.32 – 2.90 | 0.22 – 2.99 | 0.25 – 2.90 | 0.40 – 1.16 |

| Kp2 | 0.35 – 1.33 | 0.23 – 3.54 | 0.30 – 2.13 | 0.14 – 0.82 | 0.19 – 1.18 | 0.13 – 2.46 | 0.13 – 1.35 | 0.18 – 0.90 |

| Uen1 | 3.52 – 17.74 | 3.93 – 40.46 | 5.30 – 31.67 | 1.13 – 21.40 | 4.13 – 17.74 | 1.16 – 39.55 | 1.17 – 17.74 | 2.26 – 13.53 |

| Uen2 | 2.43 – 12.91 | 1.26 – 23.75 | 3.06 – 23.75 | 0.49 – 8.93 | 0.70 – 13.16 | 1.02 – 32.41 | 1.08 – 11.92 | 1.31 – 8.77 |

| Km | 3.74 – 13.69 | 2.63 – 28.79 | 4.02 – 28.79 | 0.99 – 24.66 | 1.76 – 24.66 | 1.99 – 34.33 | 1.99 – 32.26 | 3.38 – 24.64 |

For example, in type T1 dairy plants (Table 6) producing milk powder, the value ranges of the analysed indicators were generally determined to be Km = 3.8 – 13.7 kW/1000 L; Uen1 = 5.3 – 13.5 kW/person; and Kp1 = 600 – 3100 L/person. In type T3 dairy plants, these ranges of these indicators were generally determined to be Km = 4.1 – 28.0 kW/1000 L; Uen1 = 6.0 – 17.0 kW/person; and Kp1 = 600 – 2800 L/person. It was assumed that technological and technical factors in dairy plants (FR2, FR3) (Table 5) were correlated with energy consumption (Ae, Ac, We, and Wc). Similar groups of factors were used by other researchers (e.g., Budny et al. [1984b]) to evaluate their correlations with energy consumption in the dairy sector. Group FR1 consists of 11 factors describing overall production profile, along with selected engineering and production factors. Previous studies demonstrated that total installed capacity (P) and daily milk processing output (Z) are useful parameters for evaluating energy consumption in dairy plants.

In the present study, these factors were analysed jointly as the FR1 group of factors. Previous research methods were adapted for this study. A review of the literature revealed that these factors play an important role in industrial practice, which is why FR1 factors were included in mathematical calculations to describe the complexity of the studied problem.

Cause-and-effect relationships in energy consumption were also analysed. The independent variables examined express the research concept adopted at the level of plant design. The automation of production processes, relative to employment in production departments, total employment, and the organization of production processes, were expressed by indicators Uen1, Uen2, and Km, respectively. Daily milk processing output per employee was expressed by indicators Kp1 and Kp2. These indicators can be used to evaluate a plant’s technical equipment and the organization of production processes.

Group FR2 consists of 11 technological factors denoting the analysed plants’ production profiles and total output. Selected FR2 group factors were identified in the analysed plants (Table 2). Group FR3 factors represent the installed capacity of production machinery and processing lines, and are related to the technical equipment in the analysed plants. The respective correlations (r) between group FR2 and FR3 factors and dependent variables Ae, Aw, We, and Wc, were determined in the statistical analysis. The value of the correlation coefficient (r) was also used to determine the strength of the relationships (coefficient of determination, R2) between the analysed factors and energy consumption (Ae and Ac), as well as the energy consumption per unit of end product (We and Wc).

The results obtained for each group of dairy plants, as well as for individual plants, were processed statistically using the stepwise regression method. Stepwise multiple regression was chosen due to the large number of variables with different levels of significance. Energy consumption (Ae, Ac, We, or Wc) in the studied types of plants was determined using the following general formula:

Equations that met all of the below criteria were selected:

- –

Correlation (r) and determination (R2) coefficients reached high values (r > 0.60 and R2 > 0.40) in the analysed types of dairy plants (T1 – T4);

- –

The number of independent variables did not exceed 4, and the equation did not have a complex form and involved group FR2 and FR3 factors (Table 5);

- –

The equation contained factors that were not bound by a cause-and-effect relationship (i.e., coincidence);

- –

Fobl > Ftabl in the F-distribution test at α = 0.05;

- –

tobl > ttabl in Student’s t-test (α = 0.05) for the group consisting of FR1, FR2, and FR3 factors.

The formulas that met the above criteria:

Tables 7 – 10 present the results of the analysis examining the impact of the installed capacity of electrical devices and the production profile of different types of dairy plants (Tables 4 and 6) on total energy consumption as well as energy consumption per unit of end product.

Influence of the daily production profile and the installed capacity of electrical devices on energy consumption in T1 dairy plants (producing milk powder)

| Season | Total installed capacity P [kW] | Average energy consumption | Average energy consumption per unit of end product | Multiple regression equation | Coefficient of determination R2 | Range of variation in independent variables | ||

|---|---|---|---|---|---|---|---|---|

| Ae [kWh/24h] | Ac [GJ/24h] | We [kWh/1000 L] | Wc [GJ/1000 L] | |||||

| S | 454.0 – 2,421.7 (21) | 7,682.1 | 432.650 | 41.73 | 2.3207 | Ae = 3944.70 + 37.110 Z4 | 0.568 | Z4:19.0 – 335.8 |

| Ac = 134.293 + 0.546P2 + 0.760P4 | 0.789 |

| ||||||

| Ac = 140.56 + 2.433Z4 + 1.977Z5 + 0.815 Z8 | 0.834 |

| ||||||

| W | 318.0–2,548.0 (19) | 6,246.0 | 396.632 | 52.70 | 3.4125 | Ae = 4289.00 + 41.401Z4 for Wc R2 < 0.20 | 0.502 | Z4: 10.4 –282.7 |

| Ac = 83.369 + 0.530P2 + 0.644P4 + 0.857P10 for Wc R2 < 0.34 | 0.846 |

| ||||||

| Ac = 246.86 + 3.168 Z4 | 0.546 | Z4: 10.4 – 282.7 | ||||||

Influence of the daily production profile and the installed capacity of electrical devices on energy consumption in T2 dairy plants (not producing milk powder)

| Season | Total installed capacity P [kW] | Average energy consumption | Average energy consumption per unit of end product | Multiple regression equation | Coefficient of determination R2 | Range of variation in independent variables | ||

|---|---|---|---|---|---|---|---|---|

| Ae [kWh/24h] | Ac [GJ/24h] | We [kWh/1000 L] | Wc [GJ/1000 L] | |||||

| S | 83.0 – 2,935.0 (37) | 3,289.9 | 118.909 | 39.52 | 1.3607 | Ae= 748.34 + 60.1453Z1 + 39.4929Z3 + 22.079Z5 + 75.286Z8 for We R2 < 0.32 | 0.442 |

|

| Ac= 1.152 + 0.310P1 + 1.266P2 + 1.082P6 for Wc R2 < 0.37 | 0.860 |

| ||||||

| Ac= 18.295 + 1.501Z1 + 1.748Z2 + 0.990Z3 +1.006 Z5 −5.385 Z7 + 5.265 Z8 | 0.830 |

| ||||||

| W | 30.3 – 1,938.0 (24) | 2129.3 | 120.581 | 39.92 | 2.4672 | Ae = 864.92 + 94.4138Z2 + 104.032Z8 for We R2 < 0.20 | 0.603 |

|

| Ac = −4.109+0.364P1 +0.989P2+ 1.080P7 + 0.191P10 for Wc R2 < 0.33 | 0.896 |

| ||||||

| Ac = 26.259+2.981Z1 +2.492Z3 + 15.157Z7 + 6.733Z8 | 0.693 |

| ||||||

Influence of the daily production profile and the installed capacity of electrical devices on energy consumption in T3 dairy plants (not producing milk, dairy beverages or tvorog)

| Season | Total installed capacity P [kW] | Average energy consumption | Average energy consumption per unit of end product | Multiple regression equation | Coefficient of determination R2 | Range of variation in independent variables | ||

|---|---|---|---|---|---|---|---|---|

| Ae [kWh/24h] | Ac [GJ/24h] | We [kWh/1000 L] | Wc [GJ/1000 L] | |||||

| S | 83.0 – 1,923.0 (22) | 3,079.5 | 148.151 | 37.83 | 1.5542 | Ae = 953.19 + 29.707Z4 + 430.898Z6 | 0.932 |

|

| We = 42.633 - 0.481Z5 | 0.346 | Z5: 0 – 80.3 | ||||||

| Ac = −36.781 + 0.607P1 - 0.523P3 + 1.037P4 + 0.968P6 + 5.555P10 | 0.990 |

| ||||||

| Wc = 1.476 + 0.001P4 - 0.012P6+0.013P10 | 0.662 | |||||||

| Ac = 41.899 - 0.964Z3 + 2.204Z4 + 15.219Z6 | 0.971 |

| ||||||

| Wc = 1.6316-0.006Z3 + 0.003Z4 - 0.013Z5 | 0.608 | |||||||

| W | 30.3 – 1,938.0 (20) | 3,548.8 | 230.243 | 42.82 | 2.9086 |

|

|

|

| Ac = 1.145 + 0.444P1 + 0.936P4 + 1.275P7 | 0.985 |

| ||||||

| Wc = 2.2652 + 0.028P7 | 0.627 | |||||||

| Ac = 117.423 + 62.187Z6 | 0.399 | Z6: 0 – 7.9 | ||||||

| Wc = 2,3795 + 0.291Z6 | 0.563 | |||||||

Influence of the daily production profile and the installed capacity of electrical devices on energy consumption in T4 dairy plants (producing only milk, dairy beverages, tvorog, and, in some cases, also butter)

| Season | Total installed capacity P [kW] | Average energy consumption | Average energy consumption per unit of end product | Multiple regression equation | Coefficient of determination R2 | Range of variation in independent variables | ||

|---|---|---|---|---|---|---|---|---|

| Ae [kWh /24h] | Ac [GJ/24h] | We [kWh/1000 L] | Wc [GJ/1000 L] | |||||

| S | 50.0 – 2,385.0 (34) | 2,374.1 | 59.305 | 32.13 | 1.0882 | Ae = 559.42 + 29.374Z1 | 0.834 | Z1: 2.5 – 80.6 |

| Ae =345.63 + 4.420P1 + 18.787P2 | 0.950 |

| ||||||

| Ac = 18.658 + 0.460 Z1 + 1.766Z2 | 0.849 |

| ||||||

| W | 63.0 – 646.0 (24) | 1,081.4 | 52.366 | 30.70 | 1.7502 | Ae = 358.08 + 35.352Z1 | 0.672 | Z1: 1.0 – 59.1 |

| Ae = 463.75 + 6.235P3 | 0.429 | P3: 6.0 – 250.0 | ||||||

| Ac = −0.121 + 0.531P1 − 1.899P7 | 0.811 |

| ||||||

| Ac = 30.777 + 1.054Z1 | 0.441 | Z1: 1.0 – 59.1 | ||||||

The obtained regression equations present change trends in energy consumption in the analysed types of dairy plants. The regression coefficient denotes the influence of a given independent variable on the dependent variable in each type of dairy plants on the assumption that the remaining independent variables in the equation are constant. In analyses of dairy production, changes in energy consumption can be reliably predicted with the use of regression equations.

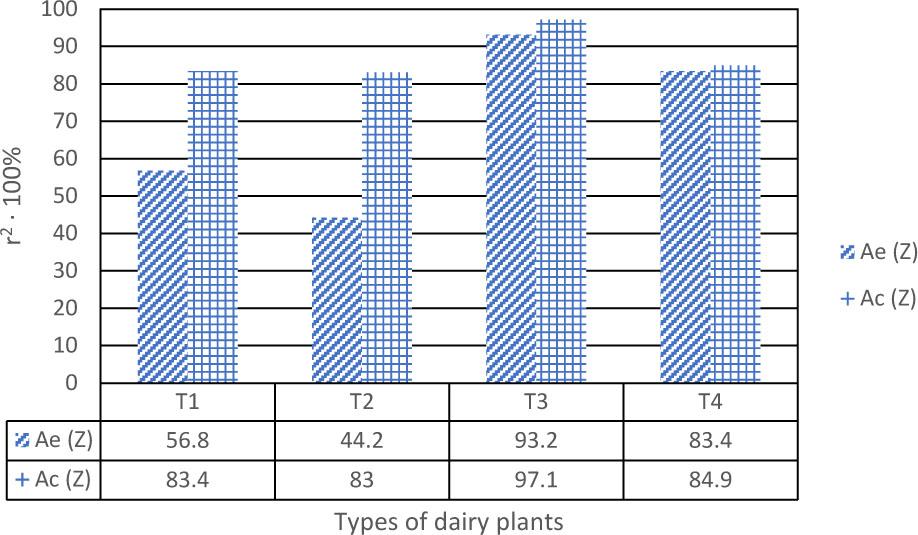

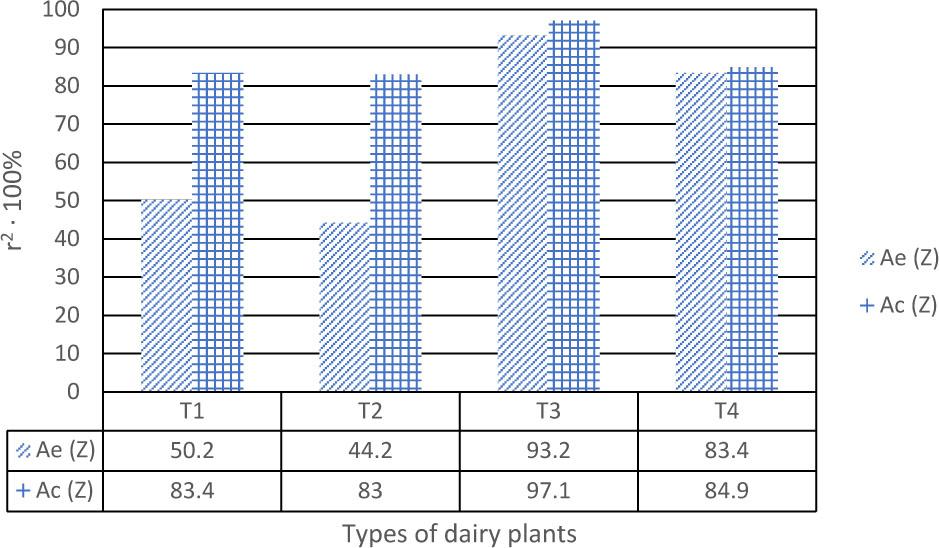

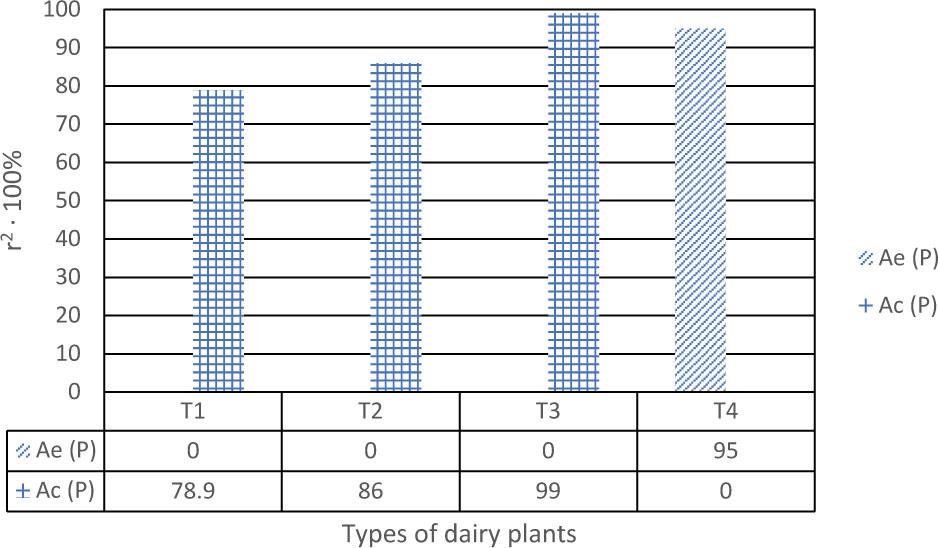

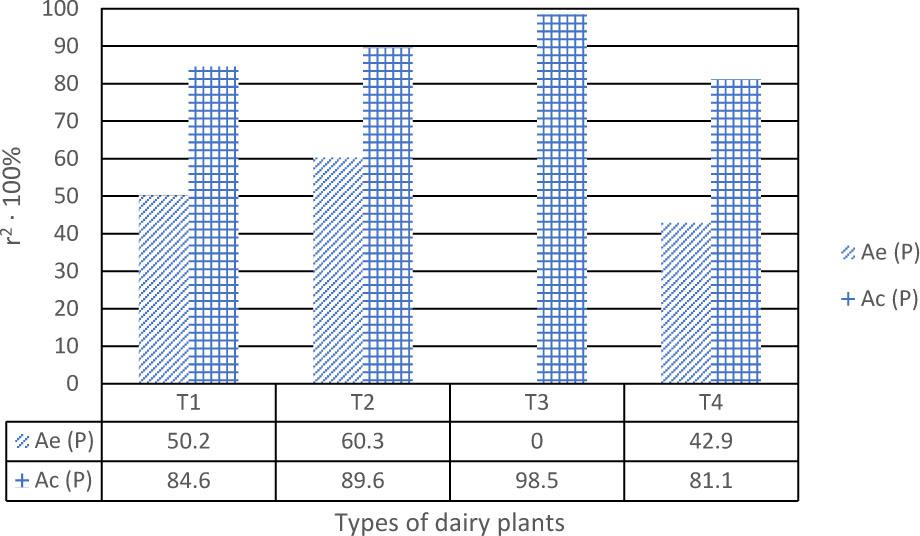

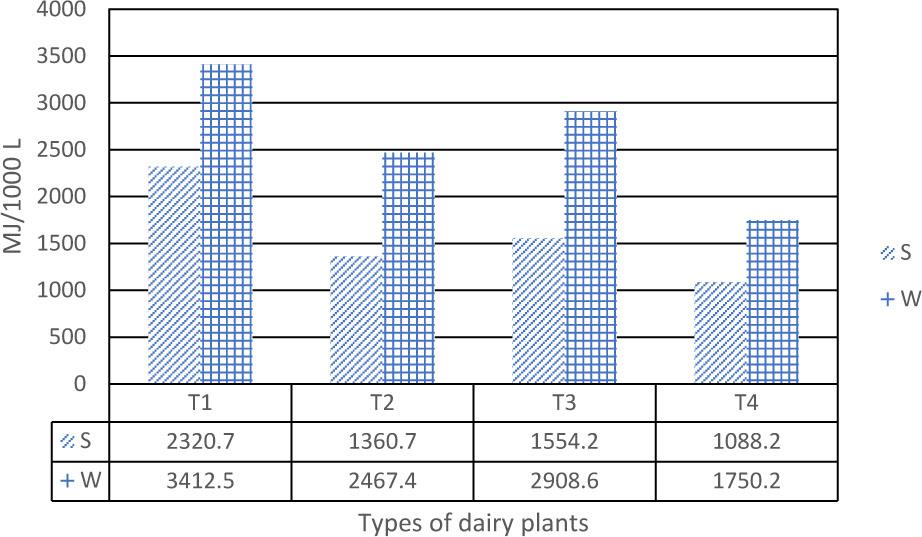

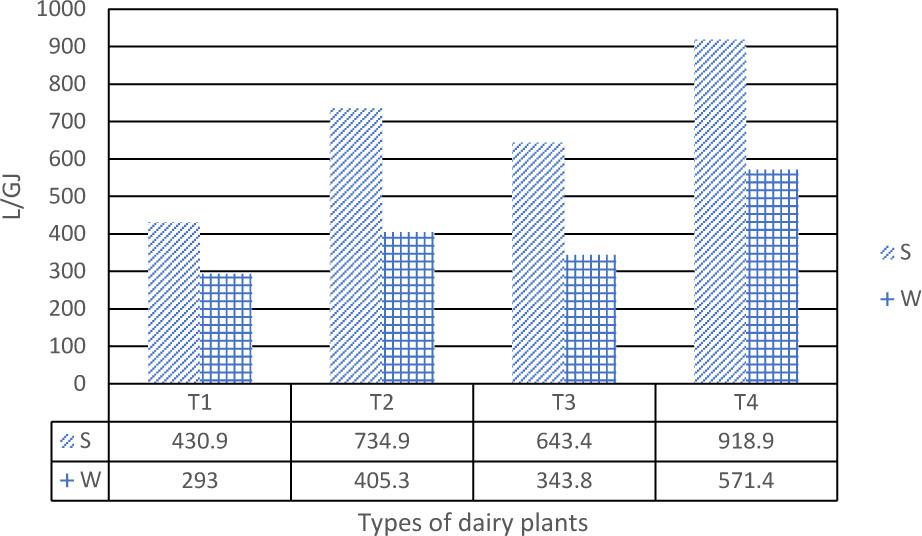

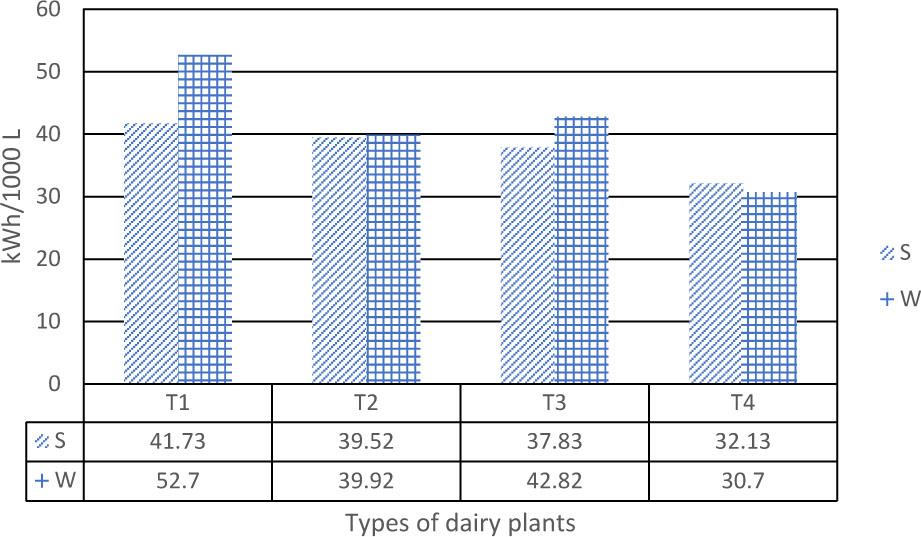

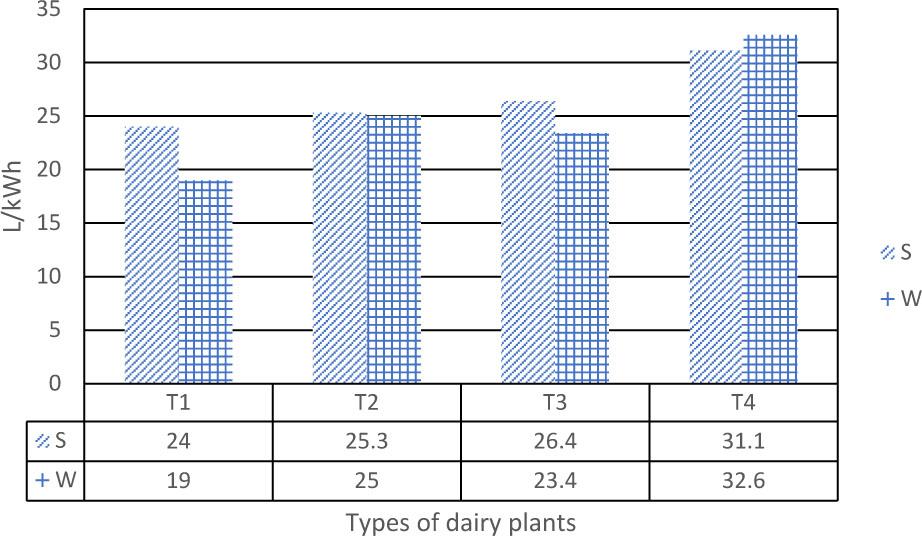

The data presented in Tables 7 – 10 were visualized in Figures 3 – 6 to compare the results of the calculations.

The influence of the production profile on electric energy and heat consumption (summer)

The influence of the production profile on electric energy and heat consumption (winter)

The influence of the installed capacity of electrical devices on electric energy and heat consumption (summer)

The influence of the installed capacity of electrical devices on electric energy and heat consumption (winter)

In summer, the production profile of the studied plants exerted a greater influence on heat consumption than on electric energy consumption. For example, in T3 plants, R2∙100% was determined to be 97.1% and 93.2%, respectively. In winter, the above trend was seen only in T1 and T2 plants.

Installed capacity exerted a significant effect, mostly on heat consumption (Ac). The greatest influence was noted in T3 plants, where R2∙100% reached 98.5 – 99.0% in both summer and winter. At the same time, production profile and installed capacity only exerted a significant influence on heat consumption in T3 plants.

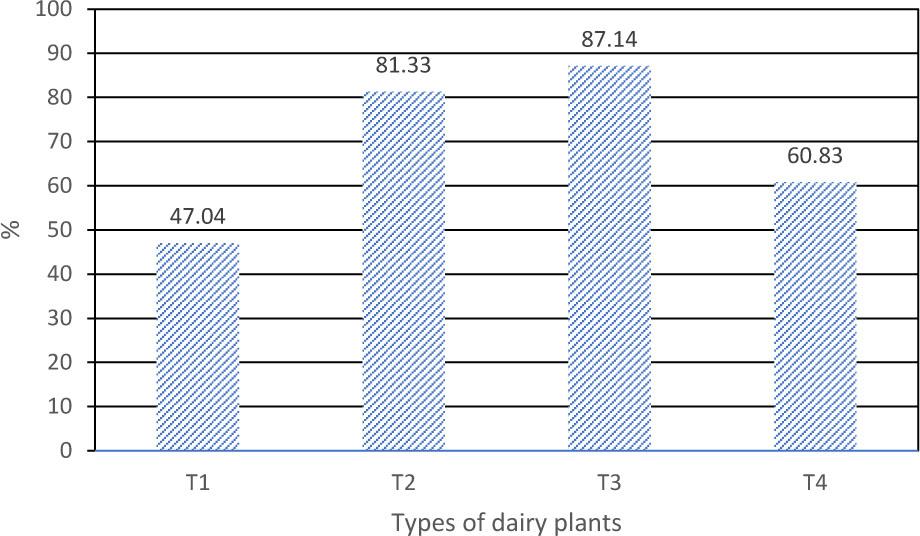

Season significantly affected energy and heat consumption in the types of dairy plants that were compared. Heat consumption per unit of end product (Wc) was higher by 47.0 – 87.14% in winter than in the summer. The greatest increase in heat consumption was noted in T3 plants. Electric energy consumption per unit of end product (We) increased by 13.3 – 27.2%, but only in T1 and T3 plants producing milk powder.

T1 plants were characterised by having the highest overall energy consumption (Figs. 7a and 8a). Milk powder production was the main technological factor making the greatest contribution to this, as shown by the values calculated for the T1(1) plant (Table 11)’s energy consumption in the production of milk powder (Table 2).

Variation in the indicators of heat consumption per unit of end product in the different types of dairy plants analysed

Thermal efficiency (EEtherm) in the different types of dairy plants analysed

Variation in the indicators of electric energy consumption per unit of end product in the different types of dairy plants analysed

Electric energy efficiency (EEel) in the different types of dairy plants analysed

Technological factors influencing energy demand in selected dairy plants

| Dairy plant specification | Average electric energy consumption | Season | Regression equations | Correlation coefficient r | Independent variables’ range of variation |

|---|---|---|---|---|---|

| Ae = 488731.7 kWh/month | S/W | Ae = 38530 + 21.93Zm | 0.917 | Zm: 4,058.9 – 6348.8 m3/month |

| We = 104.9 kWh/1000L | We = 178.6 - 0.019Zm | −0.982 | |||

| Ae = 1842461 kWh/month | S/W | Ae = 80.184 - 74908Zm | 0.63 |

|

| Ae = 155.75·Z11+84.68·Z12 - 573.45·Z13–11.36·Z14+232.33·Z15 + 139383.53 | 0.72 | ||||

| We = 77.0 kWh/1000 L | We = 0.0002 Zm + 72.558 | Weak correlation | |||

| We = 3∙10−3 Z11 + 7∙10−3·Z12 - 0.017·Z13 - 0.025·Z14 + 3∙10−3·Z16 + 36.5 | 0.31 | ||||

| Ac = 17060.39 GJ/month | Ac = 0.0946Zm + 14799 | Weak correlation | |||

| Ac= −1.49·Z11 - 1.33·Z12 + 3.46·Z13 + 5.84·Z14 + 3.93·Z15 + 16572.40 | 0.65 | ||||

| Wc = 0.71 GJ/1000 L | Wc= −3E-05Zm + 1.3441 | 0.47 | |||

| Wc = −1∙105·Z11 - 3∙105·Z12 + 2∙104·Z13 + 7∙10−6 ·Z14 + 1∙10−5 ·Z15 + 0.99 | 0.83 | ||||

| Ae = 101,516 kWh/month | S/W | Ae = 16.039 Zm + 37632 | 0.741 |

|

| Ae = 0.17·Z16 + 3.38·Z17 + 0.32·Z18 - 0.70·Z19 + 1.62·Z20 + 0.48·Z21 + 0.08·Z22 - 0.84·Z23 - 15048.70 | 0.984 | ||||

| We = 25.94 kWh/1000 L | We = −0.0025 Zm + 35.795 | 0.526 | |||

| We = 5∙10−6 ·Z16 - 0.002·Z17 + 4∙10−6·Z18 - 0.001·Z19 - 0.004·Z20 + 4∙10−6 ·Z21 + 2∙10−6·Z22 + 0.002·Z23 + 59.29 | 0.905 | ||||

| Ae = 10,681 kWh/4d | S/W | Ae = 84.71Z4d - 4676.82 | 0.675 | Z4d: 173,430 – 192,500 L/4d |

| We = 58.87 kWh/m3 | We = 0.1479Z4d + 31.75 | 0.285 | |||

| Ac = 56.93 GJ/4d | Ac = 0.6966Z4d - 69.36 | 0.719 | |||

| Wc = 313.56 MJ/m3 | Wc = 2.00 Z4d - 48.81 | 0.482 |

According to Atkins et al. [2010], heat recovery from spray-drying in the production of milk powder can decrease hot air consumption by up to 21%. Domínguez-Niño et al. [2018] studied the influence of spray-drying on energy consumption, production costs, and the physicochemical characteristics of cheese whey. The analysed factors were inlet air temperature (180 – 220°C), outlet air temperature (80 – 100°C), and silica and maltodextrin additives (2% and 5%, respectively, w/w). Analysis of variance revealed that inlet and outlet air temperature and the applied additives exerted a significant effect (p < 0.10) on the response variables. The optimal drying conditions were an inlet air temperature of 180°C, outlet air temperature of 80° C, and additive content of 5%. Under these conditions, the output of spray-dried whey reached 0.2165 kg/h. The resulting product had a moisture content of 2.08% and water activity of 0.125. Production cost reached USD $17.06/kg, and energy consumption was determined to be 2.0490 kW · h/kg of dry product.

Bergamini et al. [2021] identified key measurement points for monitoring energy consumption in the production of milk powder. The greatest proportion of variance in energy consumption per unit of end product was explained in T3 plants. In the other types of dairy plants, the correlation coefficients (r), denoting the relationship between independent variables and indicators We and Wc, ranged from 0.40 to 0.60. The high energy consumption of T1 plants can be attributed to the fact that these plants produced up to nine different products. In turn, energy consumption was lowest in T4 plants, whose production profiles consisted of only 3 – 4 products. In all analysed cases, an increase in the number of different products manufactured increased energy consumption and energy losses (streams Q3 and Q′3 in Fig. 2).

Weaker correlations between the variables presented in Tables 7 – 10 indicate that energy was consumed outside the production process. The energy efficiency (EE) indicators of the studied plants (milk processing output per 1 GJ of consumed energy) are presented in Figures 8a and 8b.

Heat consumption accounted for 85 – 90% of total energy consumption, with the demand for thermal energy varying between seasons. The winter increase in heat consumption in the analysed types of dairy plants relative to the summer season is presented in Figure 9.

Winter increase in heat consumption per unit of end product in the types of dairy plants analysed, relative to the summer season

Measurements were conducted in selected individual T1 and T4 plants that were characterised by significant differences in energy consumption, with the goal of providing a more detailed view of the results obtained in these groups. The results of the analyses conducted in four dairy plants selected from the examined groups of plants are presented in Table 11 to illustrate the strong effect of the production profile on energy consumption.

Energy production was higher in T1 than in T2 plants. The values of indicator Wc were nearly twice as high (Figure 7a), and the values of indicator We were 30% – 70% higher in T1 than in T2 plants (Figure 8a). Additional parameters of the selected plants – installed capacity and the values of indicator Km – are provided in Table 11. Selected correlation coefficients (r < 0.6) are also presented in Table 11.

Monthly milk processing output (Zm) and four-day milk processing output (Z4d) (FR1, Table 5) are the independent variables in Table 11 relative to the values presented in Tables 7–10. In the T1(1) plant (producing milk powder), monthly milk processing output (Zm) was responsible for 84.0% of its electric energy consumption (r = 0.917). Monthly milk processing output (Zm) also explained 96.4% of the variance in electric energy consumption per unit of end product (We) (r = 0.982). An increase in milk-processing output led to a significant decrease in electric energy consumption per unit of end product (We).

Strong correlations between production profile and energy consumption were observed in T4 plants. In the T4(1) plant, the production profile explained 68.9% of the variance in heat consumption per unit of end product, while in the T4(2) plant, the production profile explained 96.8% of the variance in electric energy consumption (Ae) and 81.9% of the variance in electric energy consumption per unit of end product (We). The correlations between independent variables were weaker for four-day milk processing output (Z4d), as demonstrated by the results of the calculations for the T4(3) plant.

The literature on the factors influencing energy consumption and the environmental impact of dairy plants was reviewed in this study. Various indicators were used to assess the management of energy carriers in the analysed plants. A diagram of a dairy plant as a user of energy carriers was presented to organise the results of the study. A detailed analysis of energy consumption was conducted in four different types of dairy plants with different production profiles. Information for modelling energy consumption in dairy plants and generating databases was provided. The results of the performed calculations and statistical analyses provide new insights about the correlations among the four types of dairy plants between engineering and production factors, production profile (milk processing and manufacture of end-products), technical equipment, and energy consumption. The results were used to formulate recommendations for reducing energy consumption, increasing energy efficiency, and implementing cleaner production standards in industrial practice.

The following conclusions can be formulated based on the results of the present study:

- –

Heat consumption is highest in T1 dairy plants, which specialize in milk powder but may produce up to 8 other dairy products;

- –

Installed capacity was a more effective predictor of heat consumption than technological factors describing a plant’s production profile, particularly in the summer (0.88 > r > 0.99). This observation can be used by designers to promote energy conservation measures during plant operation;

- –

Production profile was the most effective predictor of electric energy consumption in dairy plants producing 2 – 4 products, in particular in T4 plants;

- –

Energy consumption per unit of end-product varied across seasons and was correlated with technical equipment and process automation, but only in smaller T3 plants;

- –

Energy efficiency was highest in T4 plants when they were analysed individually, due to their smaller range of thermal processing operations;

- –

In analyses of individual dairy plants, energy consumption per unit of end-product was strongly correlated with both milk processing output and production profile. This indicates that work conditions and the results of energy audits should be analysed separately in individual plants;

- –

The empirical formulas developed in this study, in particular the regression coefficients, can be used to perform detailed analysis, generate new data and reference materials, and model energy consumption processes in dairy plants;

- –

Due to the structure of their independent variables, the presented empirical formulas can also be used to optimise energy consumption in different types of equipment.