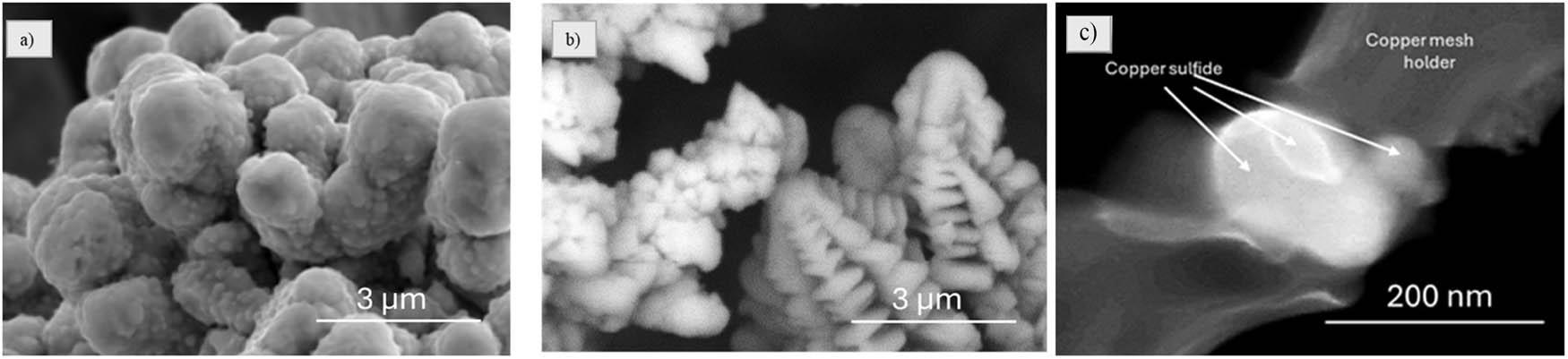

Figure 1

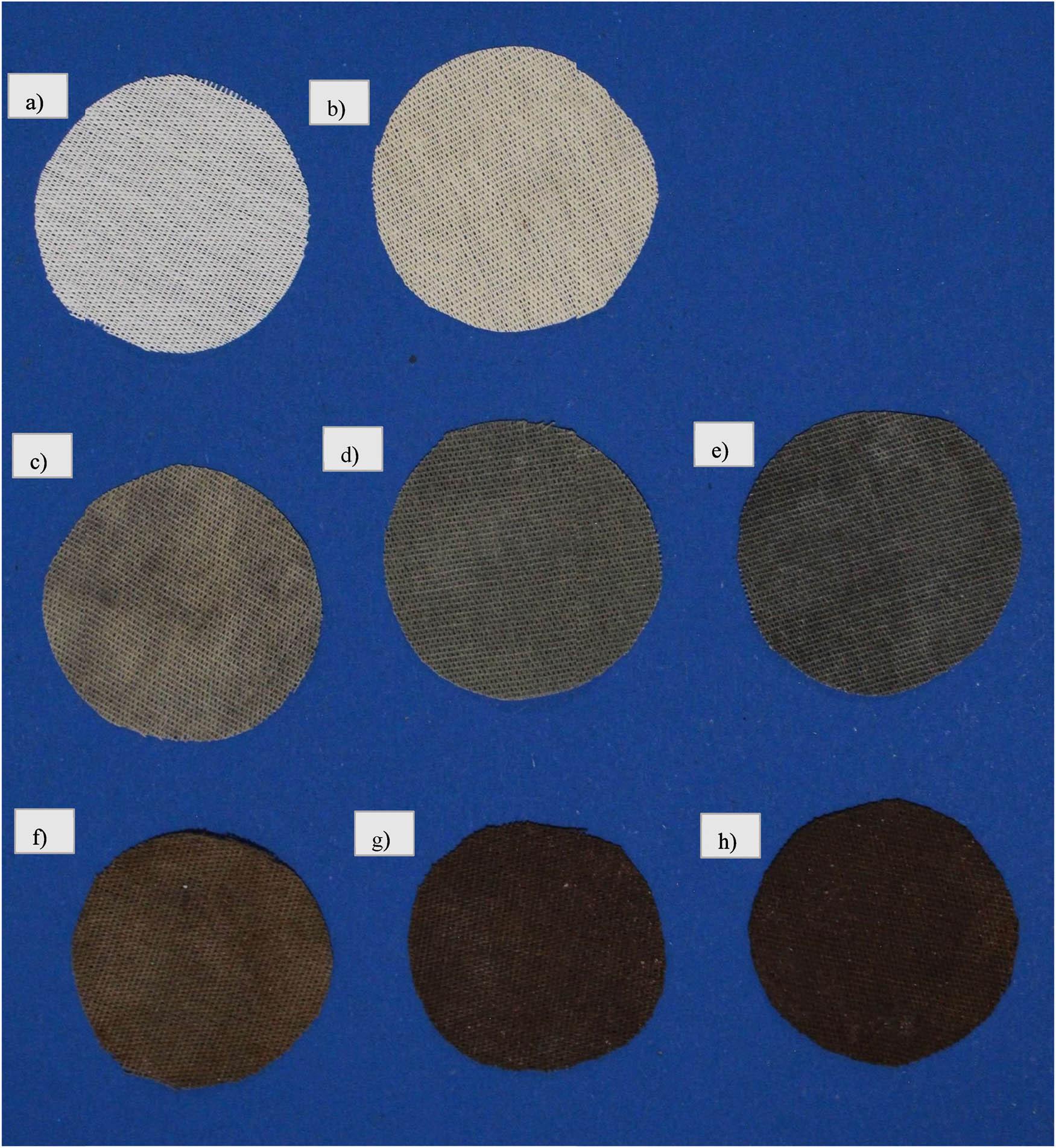

Figure 2

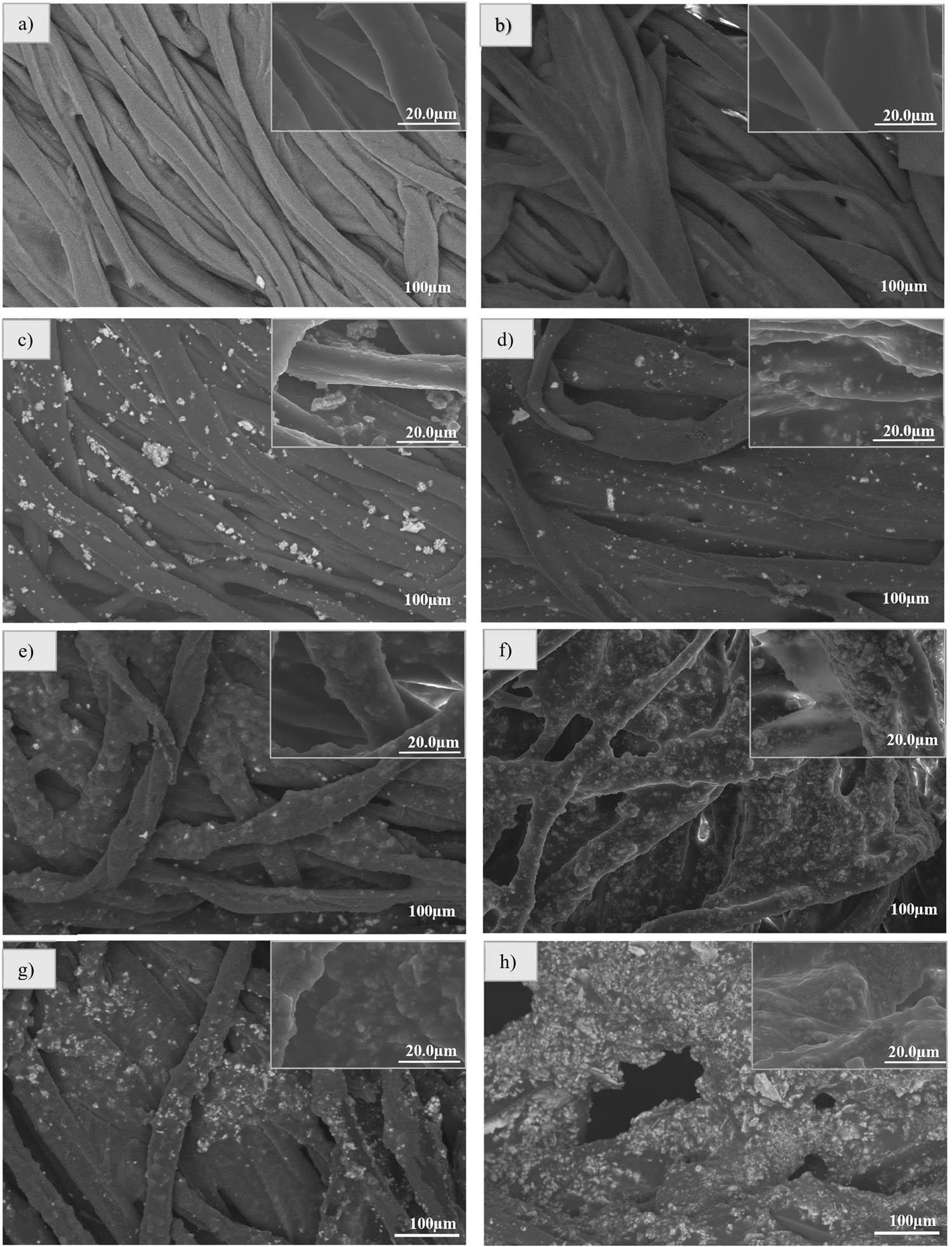

Figure 3

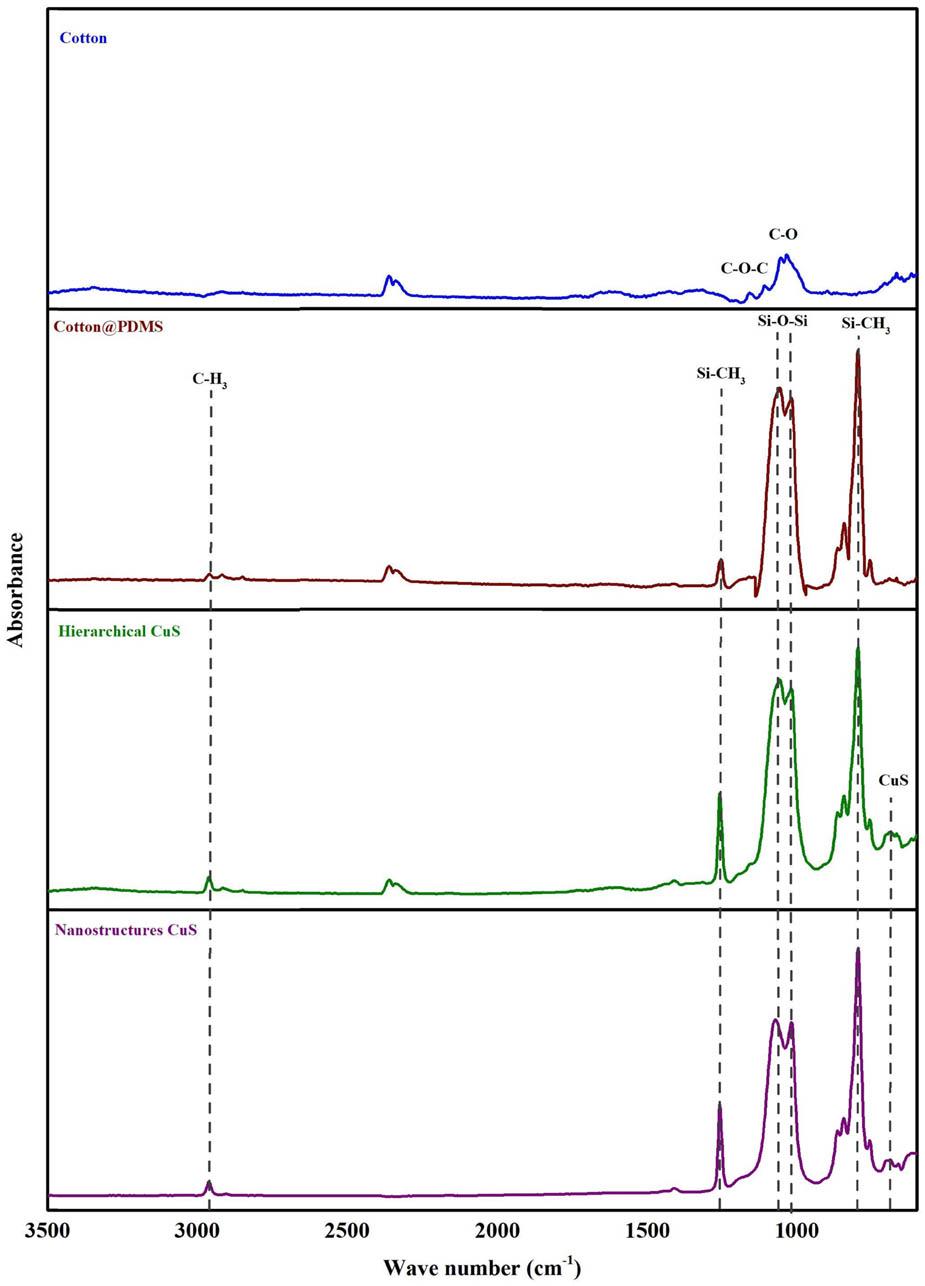

Figure 4

Figure 5

Figure 6

Figure 7

Figure 8

Figure 9

Oil absorption on the membrane_

| Number of cycles | Cotton | Cotton@PDMS | H 1% | N 1% | H 2% | N 2% | H 4% | N 4% |

|---|---|---|---|---|---|---|---|---|

| 0 | 0.8551 | 0.9849 | 1.1933 | 1.2409 | 1.2324 | 1.3624 | 1.3219 | 1.5311 |

| 10 | 2.0315 | 2.9851 | 3.2713 | 2.9003 | 3.3039 | 3.4356 | 3.509 | 2.9571 |

Water blocking efficiency_

| Number of cycles | Cotton | Cotton@PDMS | H 0.12 | N 0.12 | H 0.25 | N 0.25 | H 0.5 | N 0.5 |

|---|---|---|---|---|---|---|---|---|

| 1 | ☒ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 2 | ☒ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 3 | ☒ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 4 | ☒ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 5 | ☒ | ☒ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 6 | ☒ | ☒ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| 7 | ☒ | ☒ | ☒ | ✓ | ☒ | ✓ | ✓ | ✓ |

| 8 | ☒ | ☒ | ☒ | ✓ | ☒ | ✓ | ✓ | ✓ |

| 9 | ☒ | ☒ | ☒ | ✓ | ☒ | ✓ | ✓ | ✓ |

| 10 | ☒ | ☒ | ☒ | ✓ | ☒ | ✓ | ✓ | ✓ |

Images of water droplets on membranes_

| 0 s | 300 s | |

|---|---|---|

| Cotton |

|

|

| Cotton@PDMS |

|

|

| Hierarchical 1 |

|

|

| Hierarchical 2 |

|

|

| Hierarchical 4 |

|

|

| Nanostructure 1 |

|

|

| Nanostructure 2 |

|

|

| Nanostructure 4 |

|

|