Fig. 1.

![RAC50-3 specimen details: (a) longitudinal-section and (b) cross-section [26]](https://sciendo-parsed.s3.eu-central-1.amazonaws.com/666047fedd1c3d1f87135322/j_msp-2024-0026_fig_001.jpg?X-Amz-Algorithm=AWS4-HMAC-SHA256&X-Amz-Content-Sha256=UNSIGNED-PAYLOAD&X-Amz-Credential=AKIA6AP2G7AKOUXAVR44%2F20251204%2Feu-central-1%2Fs3%2Faws4_request&X-Amz-Date=20251204T154609Z&X-Amz-Expires=3600&X-Amz-Signature=a40a2d53d2e22289bfde1872806af3e1954cce59129bf53c1583d91b0b2ca93b&X-Amz-SignedHeaders=host&x-amz-checksum-mode=ENABLED&x-id=GetObject)

Fig. 2.

![H50-100 specimen details: (a) longitudinal-section and (b) cross-section [15]](https://sciendo-parsed.s3.eu-central-1.amazonaws.com/666047fedd1c3d1f87135322/j_msp-2024-0026_fig_002.jpg?X-Amz-Algorithm=AWS4-HMAC-SHA256&X-Amz-Content-Sha256=UNSIGNED-PAYLOAD&X-Amz-Credential=AKIA6AP2G7AKOUXAVR44%2F20251204%2Feu-central-1%2Fs3%2Faws4_request&X-Amz-Date=20251204T154609Z&X-Amz-Expires=3600&X-Amz-Signature=7d26a50034fb9be0462d02f11fd4ae374ebfb672d88616c5fa50b360896c9c2e&X-Amz-SignedHeaders=host&x-amz-checksum-mode=ENABLED&x-id=GetObject)

Fig. 3.

![Stress–strain curve equations for the concrete’s compression behavior [34]](https://sciendo-parsed.s3.eu-central-1.amazonaws.com/666047fedd1c3d1f87135322/j_msp-2024-0026_fig_003.jpg?X-Amz-Algorithm=AWS4-HMAC-SHA256&X-Amz-Content-Sha256=UNSIGNED-PAYLOAD&X-Amz-Credential=AKIA6AP2G7AKOUXAVR44%2F20251204%2Feu-central-1%2Fs3%2Faws4_request&X-Amz-Date=20251204T154609Z&X-Amz-Expires=3600&X-Amz-Signature=6aebe98e93884b296f9d6b6a0db29074c24fbab4ab5f2089f3a67f880c15192b&X-Amz-SignedHeaders=host&x-amz-checksum-mode=ENABLED&x-id=GetObject)

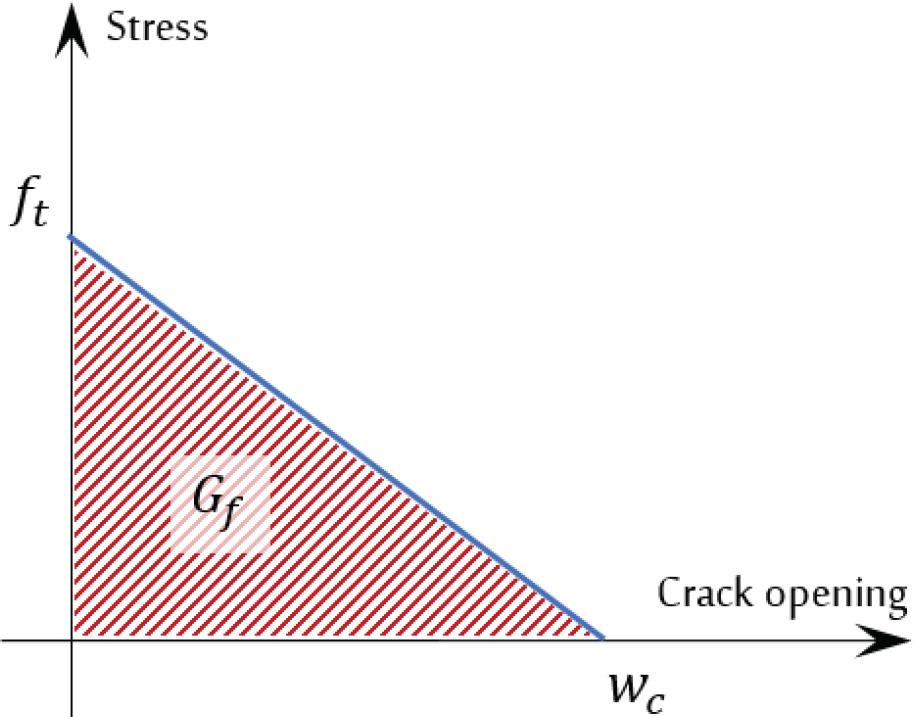

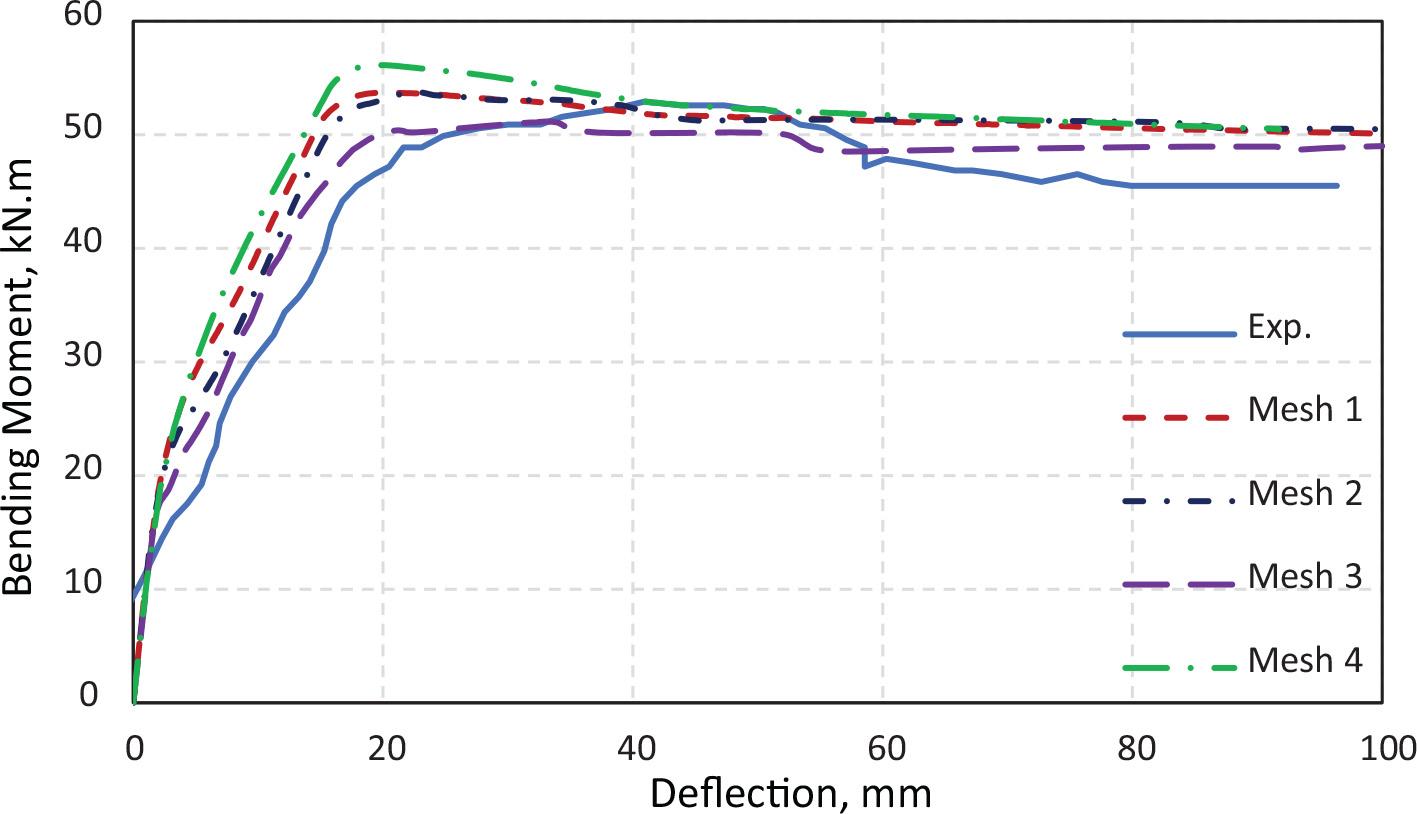

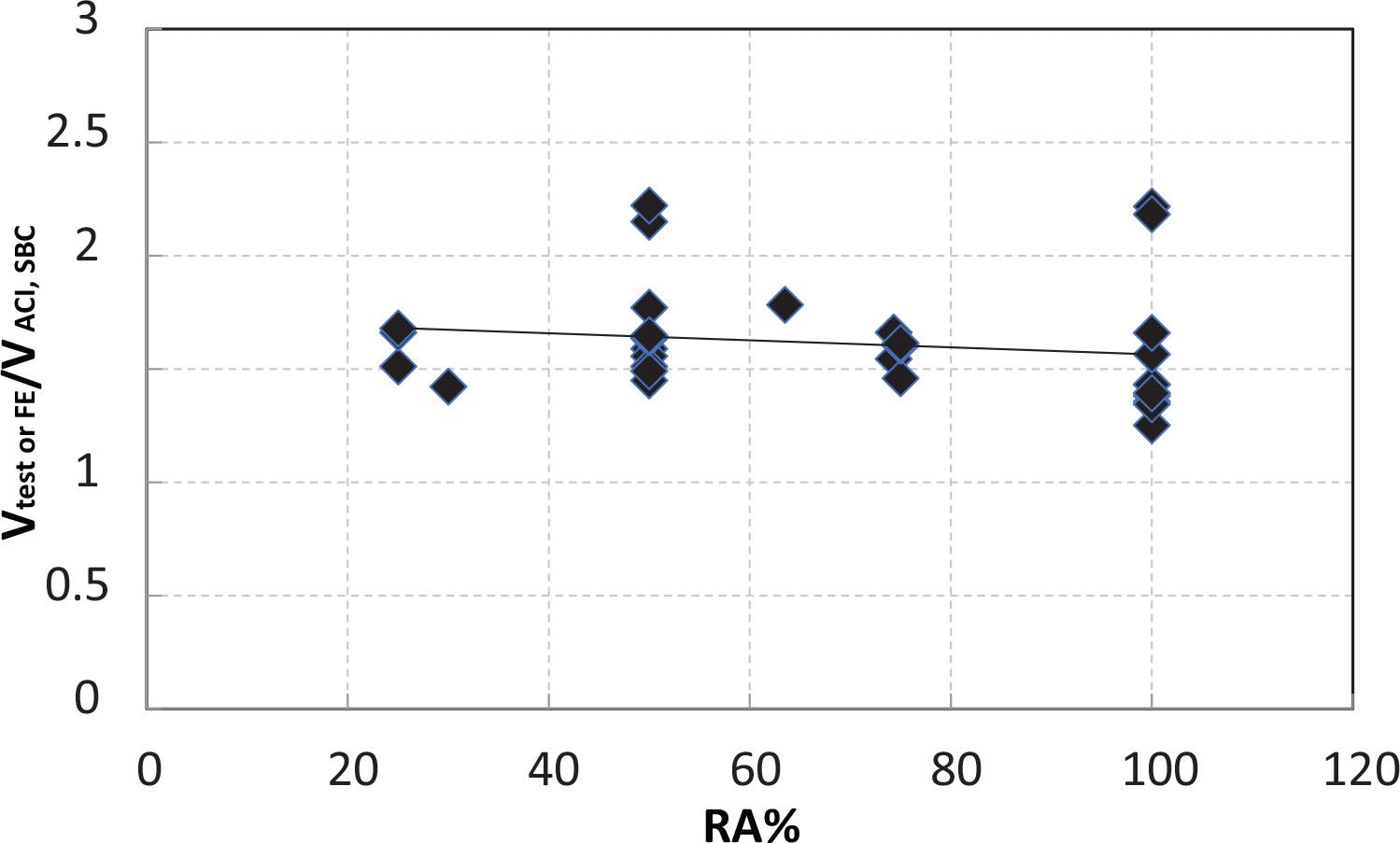

Fig. 4.

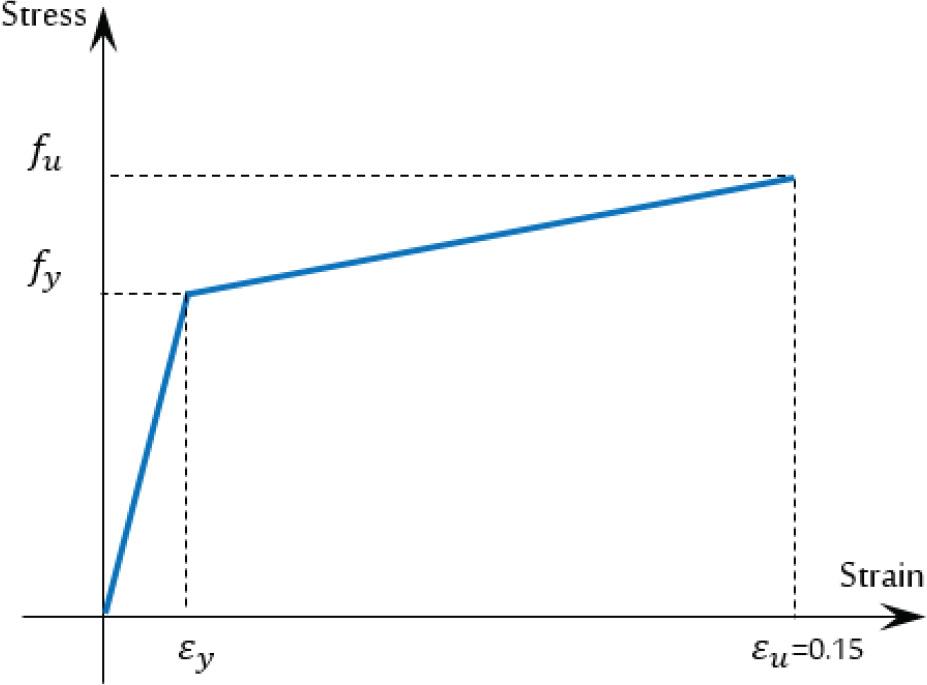

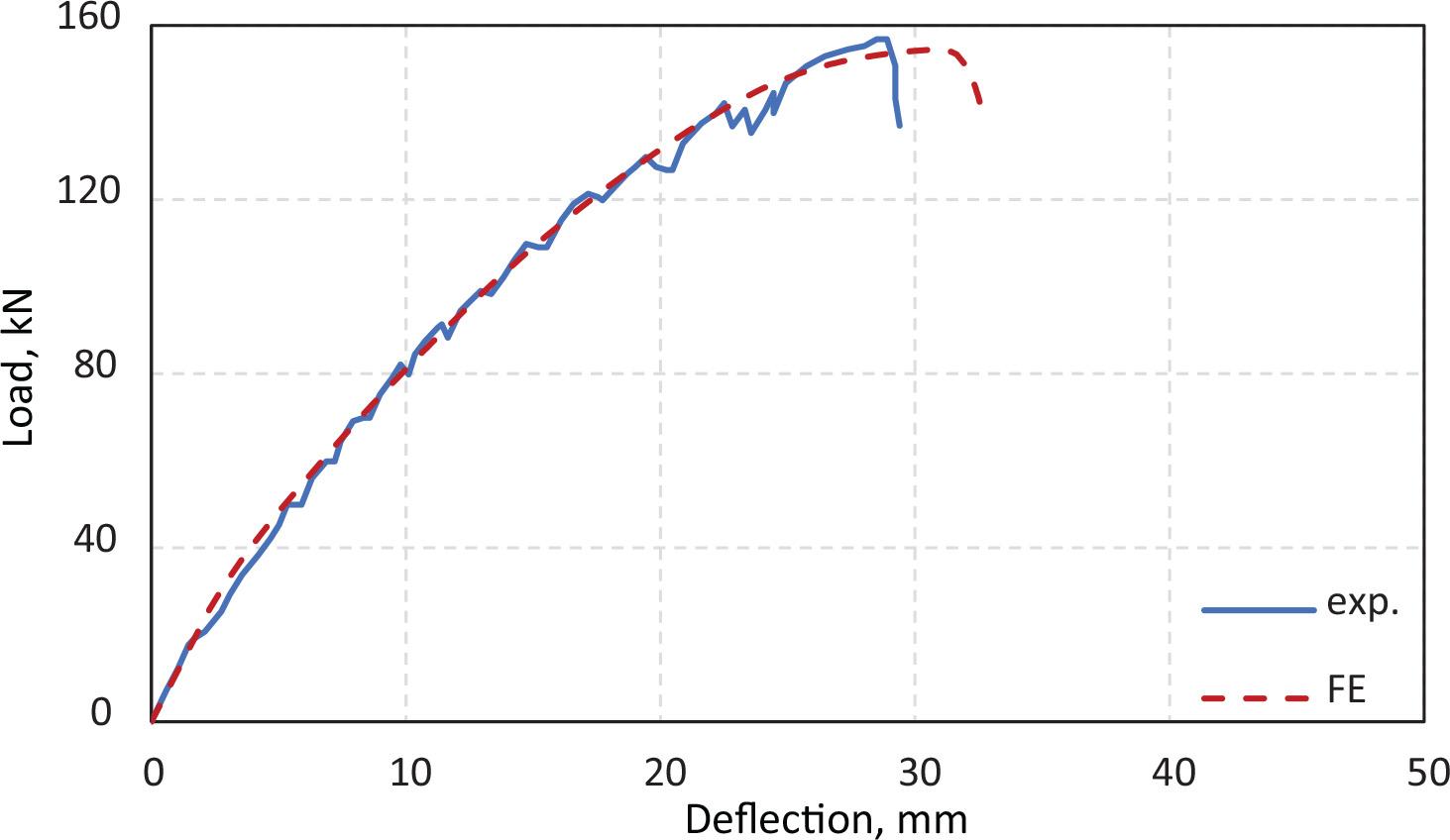

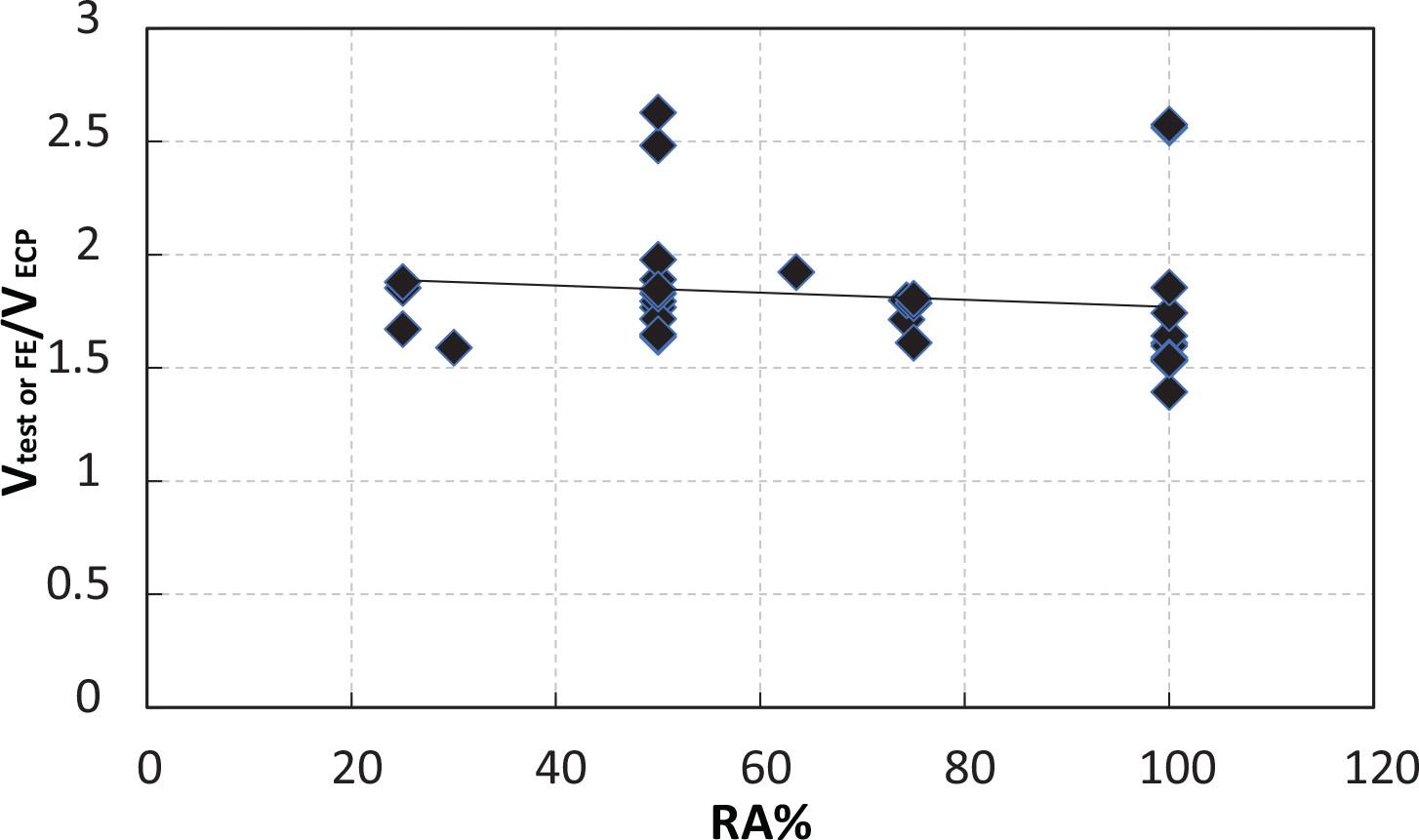

Fig. 5.

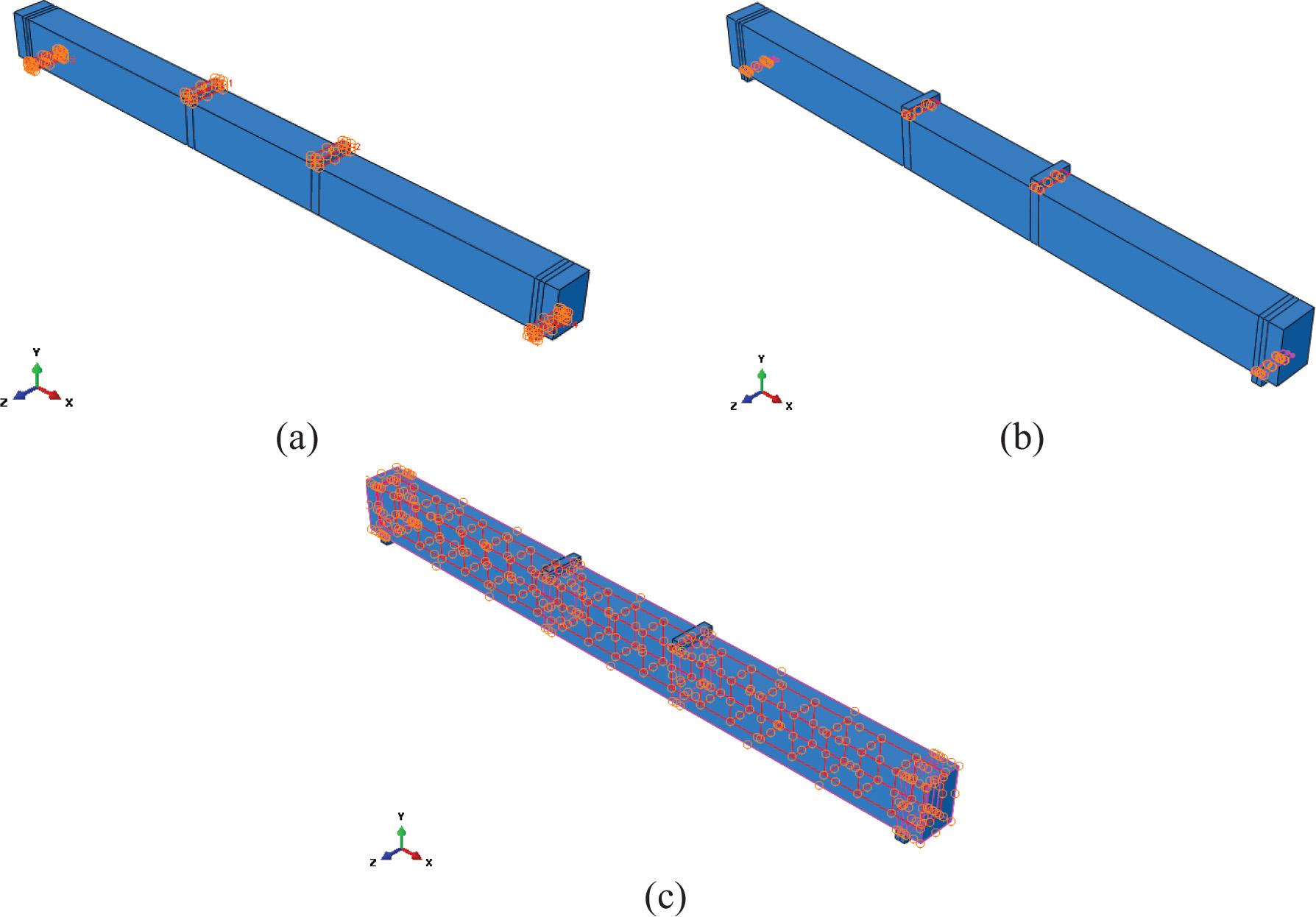

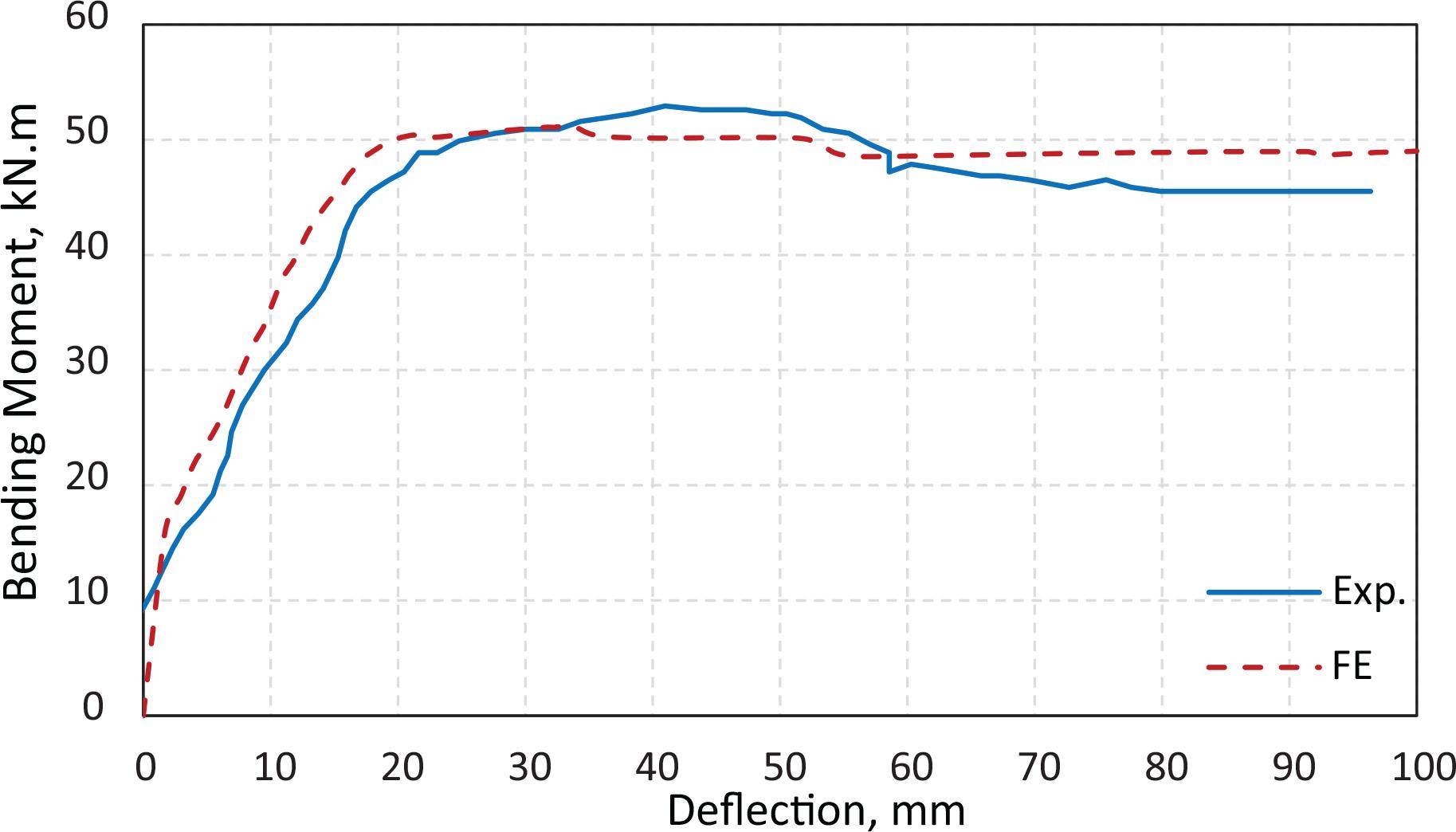

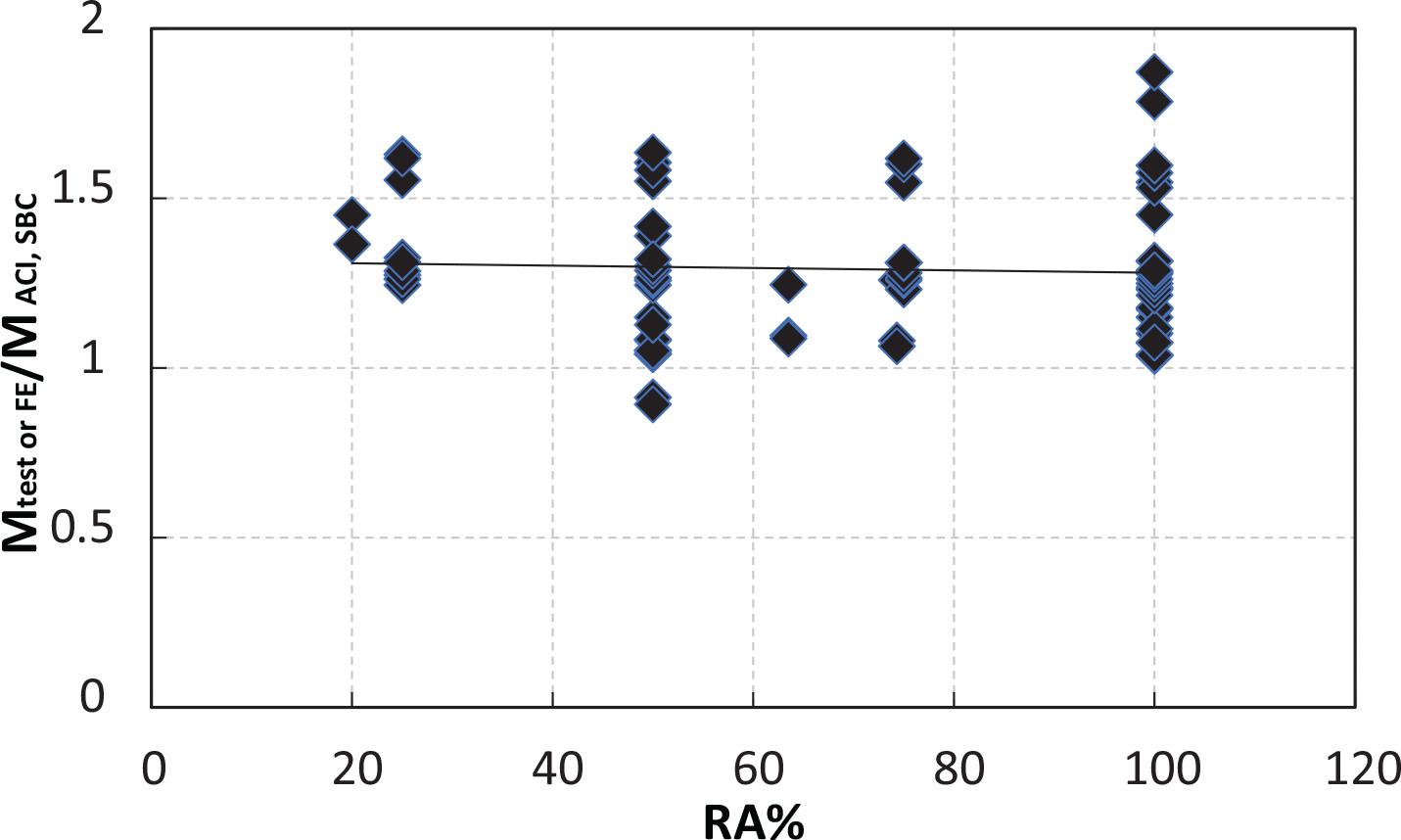

Fig. 6.

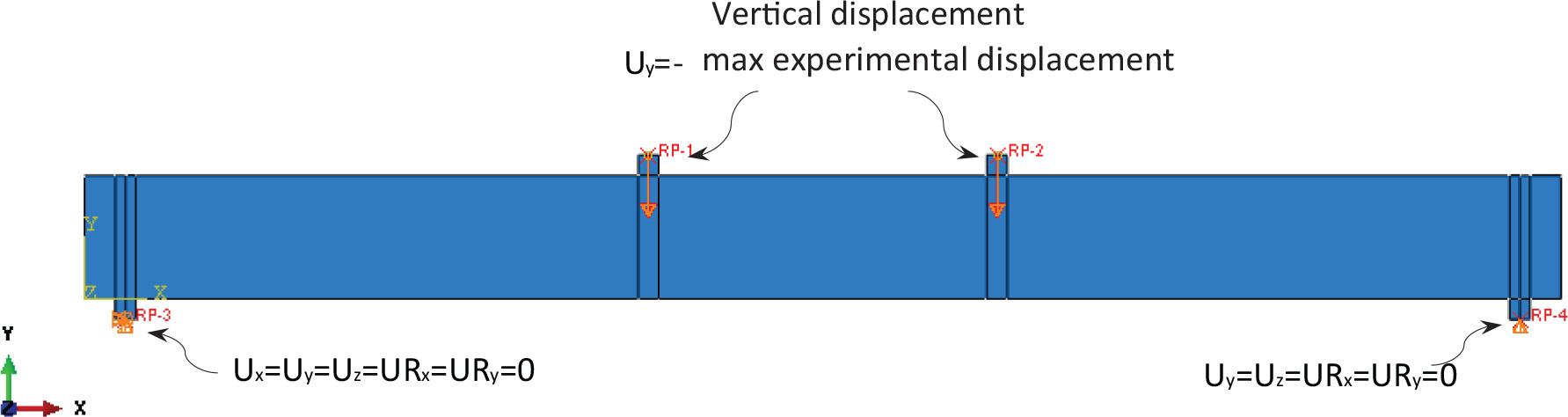

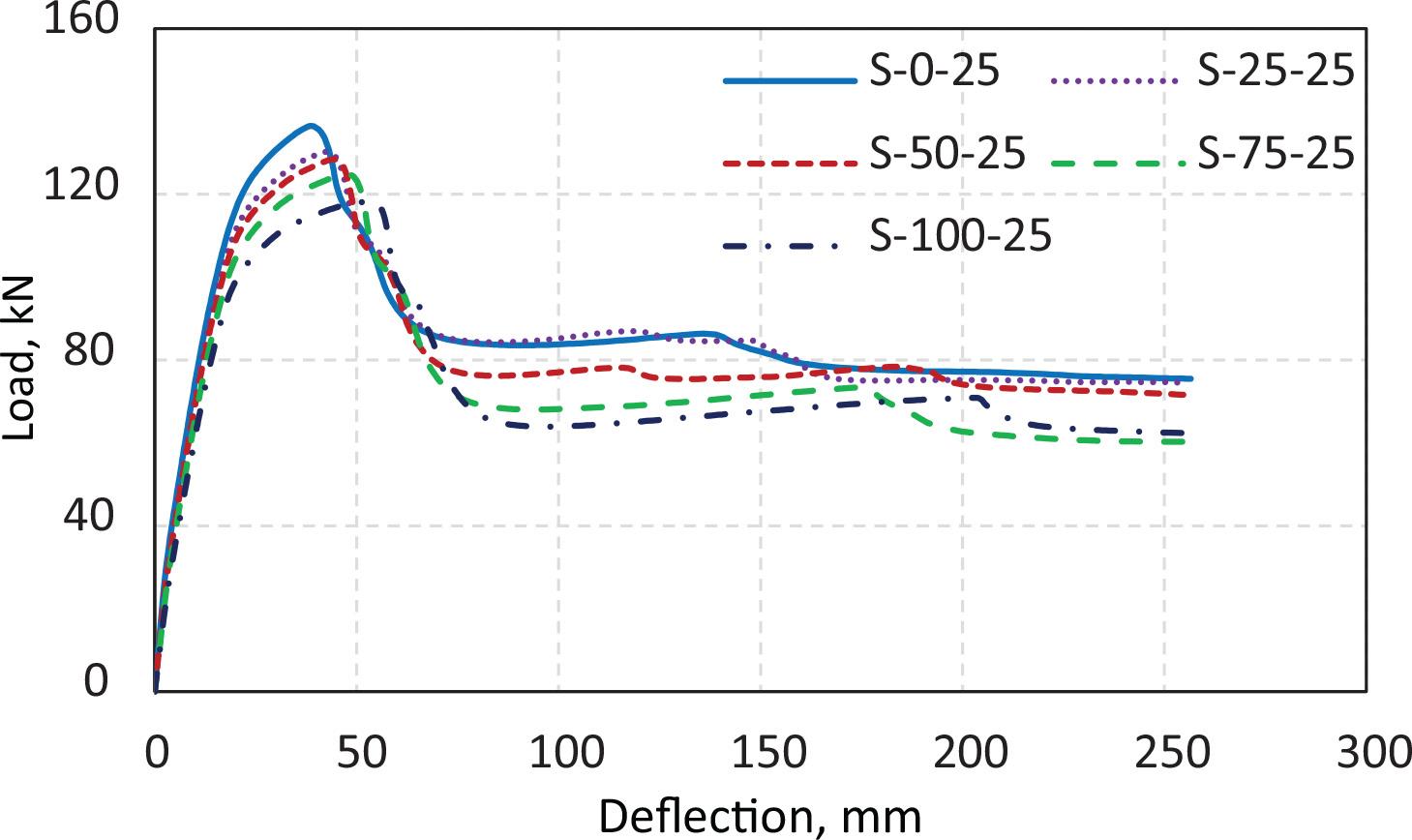

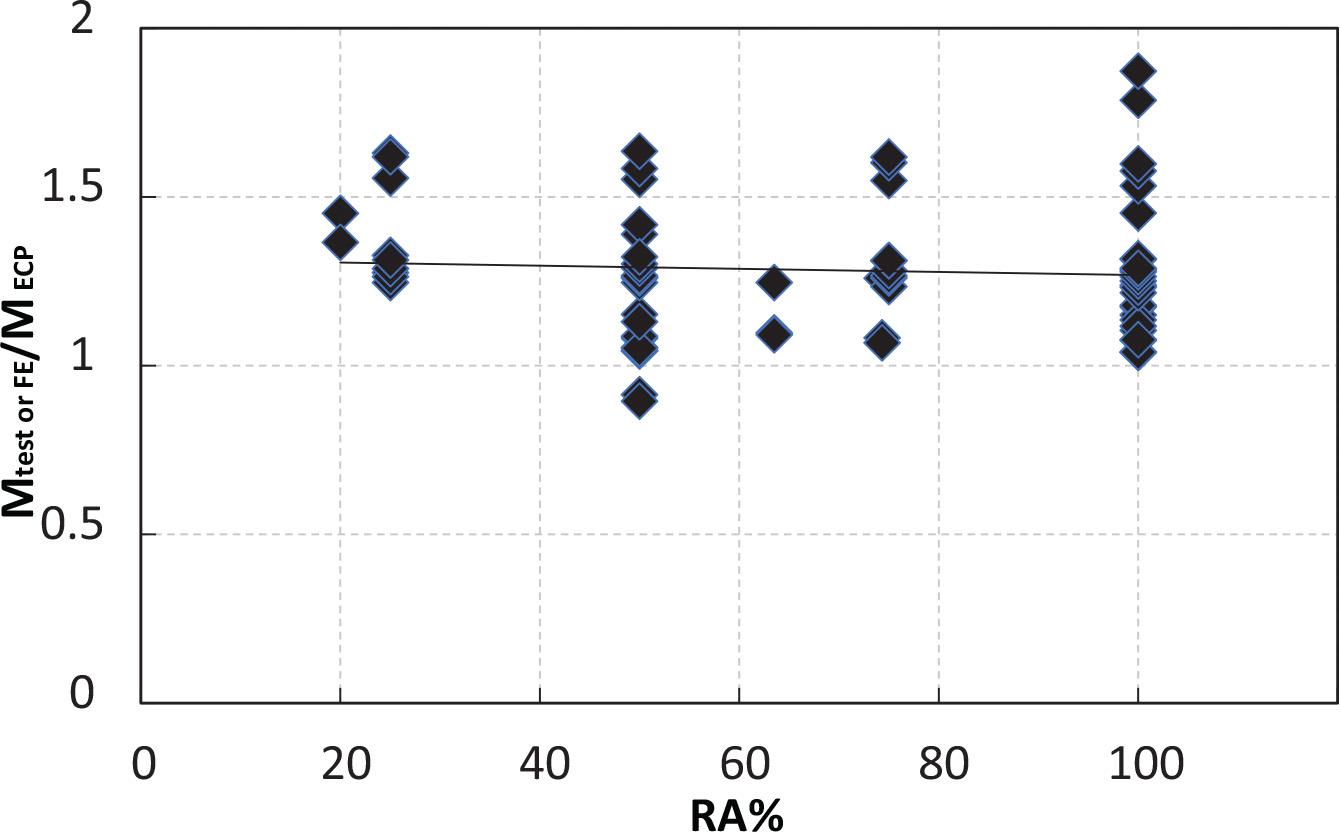

Fig. 7.

Fig. 8.

Fig. 9.

Fig. 10.

Fig. 11.

Fig. 12.

Fig. 13.

Fig. 14.

Fig. 15.

Fig. 16.

Fig. 17.

Fig. 18.

Fig. 19.

CDPM parameters utilized in this study

| Parameters Dilation angle (ψ) Stress ratio (fb0/fc0) | Compressive meridian (Kc) | Eccentricity (ε) | Viscosity (μ) | ||

|---|---|---|---|---|---|

| Value | 27 (calibrated value) | 1.16 (default value [20]) | 0.667 (default value [20]) | 0.1 (default value [20]) | 0.001 default value [20]) |

Details of the FE analysis matrix

| Scenarios | Specimen ID | RCA ratio | Concrete strengths | Main rebar diameter | No. of specimens |

|---|---|---|---|---|---|

| Beams Failing in Flexural | F-0-18-(25/35/40) | 0% | 25/35/40 MPa | 2T18 mm | 3 |

| F-25-18-(25/35/40) | 25% | 3 | |||

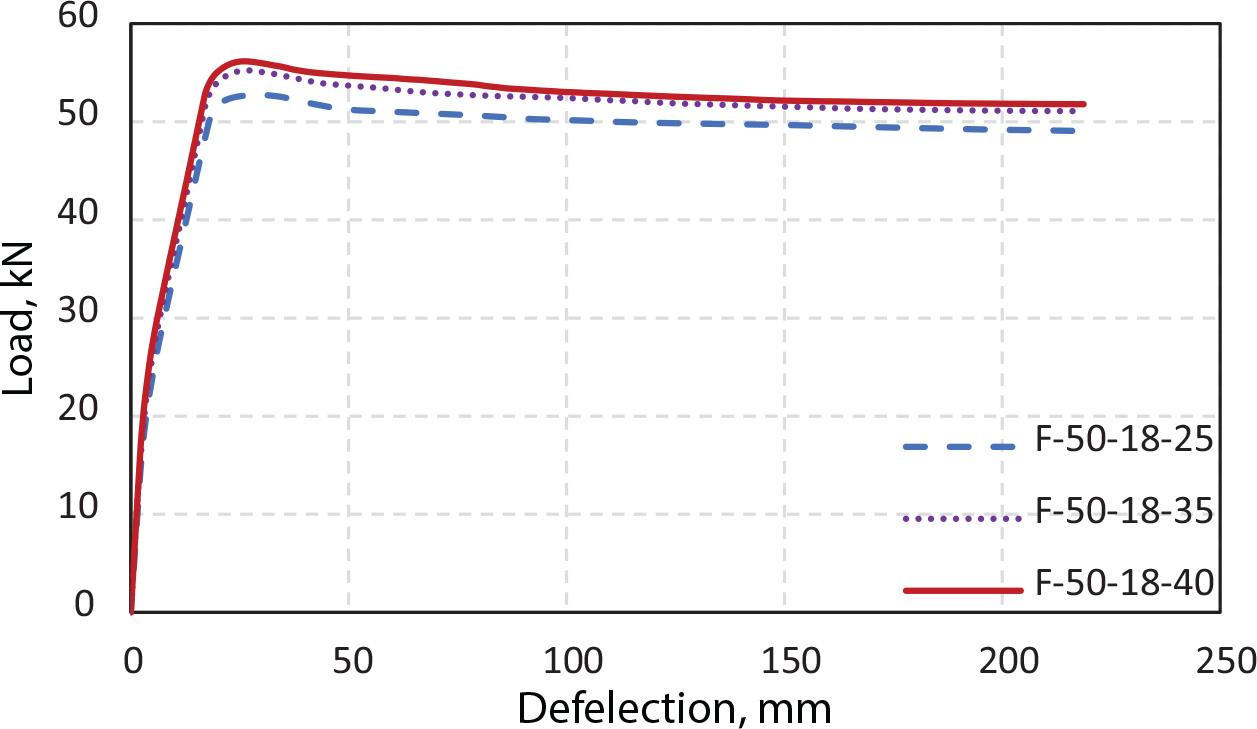

| F-50-18-(25/35/40) | 50% | 3 | |||

| F-75-18-(25/35/40) | 75% | 3 | |||

| F-100-18-(25/35/40) | 100% | 3 | |||

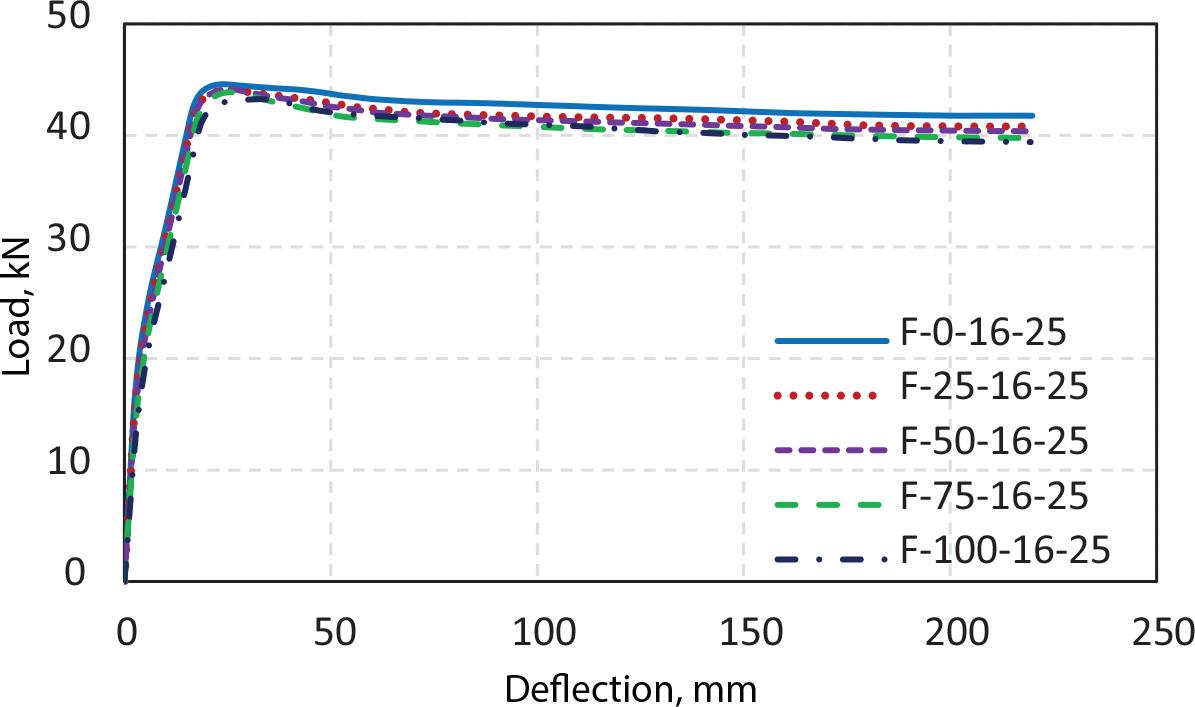

| F-0-16-(25/35/40) | 0% | 25/35/40 MPa | 2T16 mm | 3 | |

| F-25-16-(25/35/40) | 25% | 3 | |||

| F-50-16-(25/35/40) | 50% | 3 | |||

| F-75-16-(25/35/40) | 75% | 3 | |||

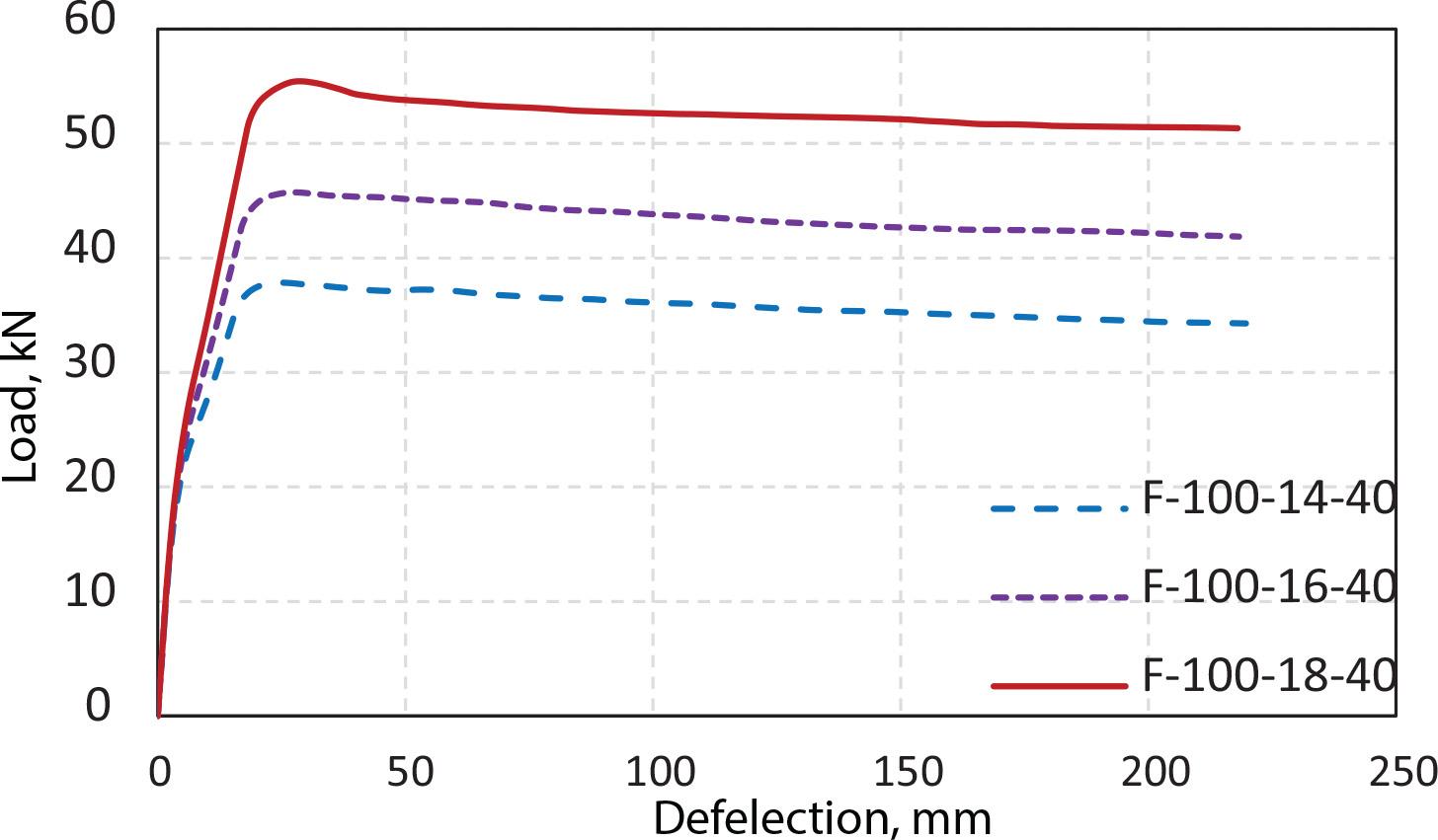

| F-100-16-(25/35/40) | 100% | 3 | |||

| F-0-14-(25/35/40) | 0% | 25/35/40 MPa | 2T14 mm | 3 | |

| F-25-14-(25/35/40) | 25% | 3 | |||

| F-50-14-(25/35/40) | 50% | 3 | |||

| F-75-14-(25/35/40) | 75% | 3 | |||

| F-100-14-(25/35/40) | 100% | 3 | |||

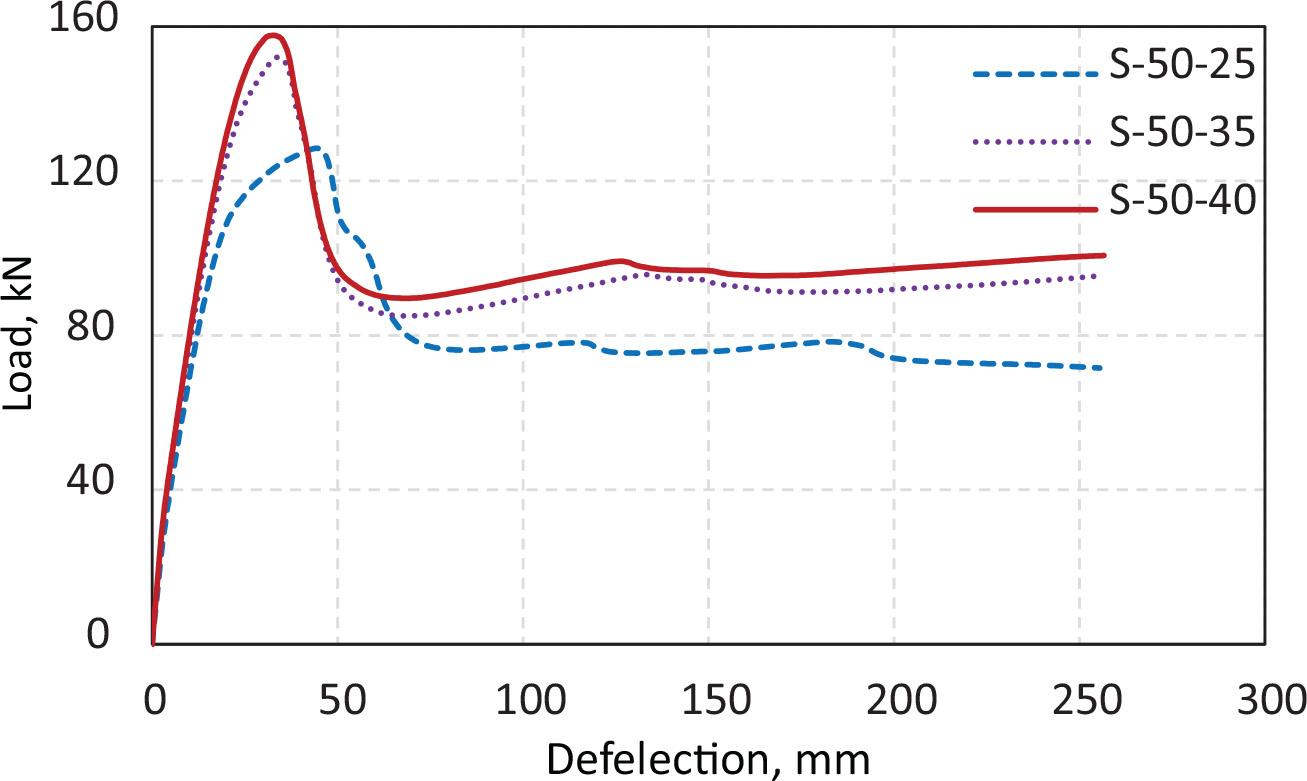

| Beams Failing in Shear | S-0-150-(25/35/40) | 0% | 25/35/40 MPa | 2T16 + 4T22 | 3 |

| S-25-150-(25/35/40) | 25% | 3 | |||

| S-50-150-(25/35/40) | 50% | 3 | |||

| S-75-150-(25/35/40) | 75% | 3 | |||

| S-100-150-(25/35/40) | 100% | 3 | |||

| Total Number of Specimens | 60 | ||||