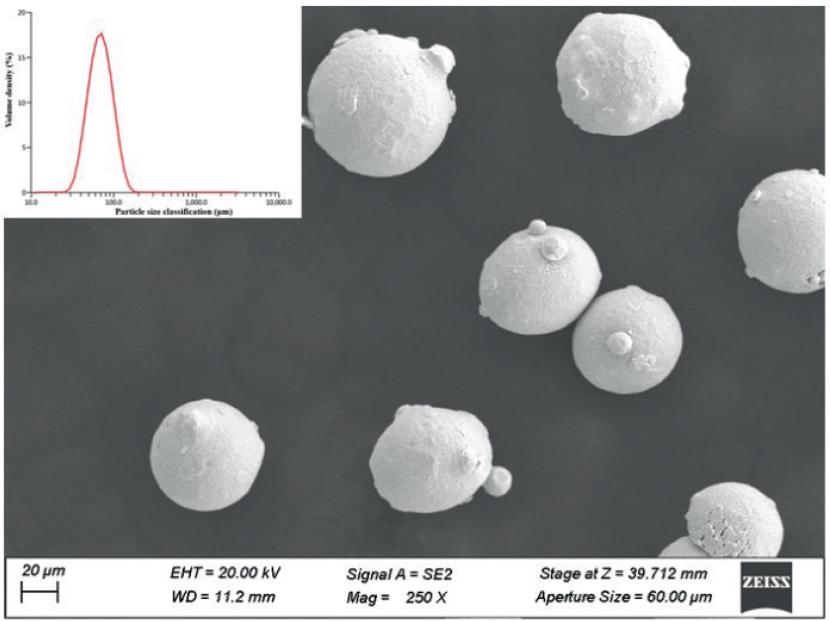

Fig. 1.

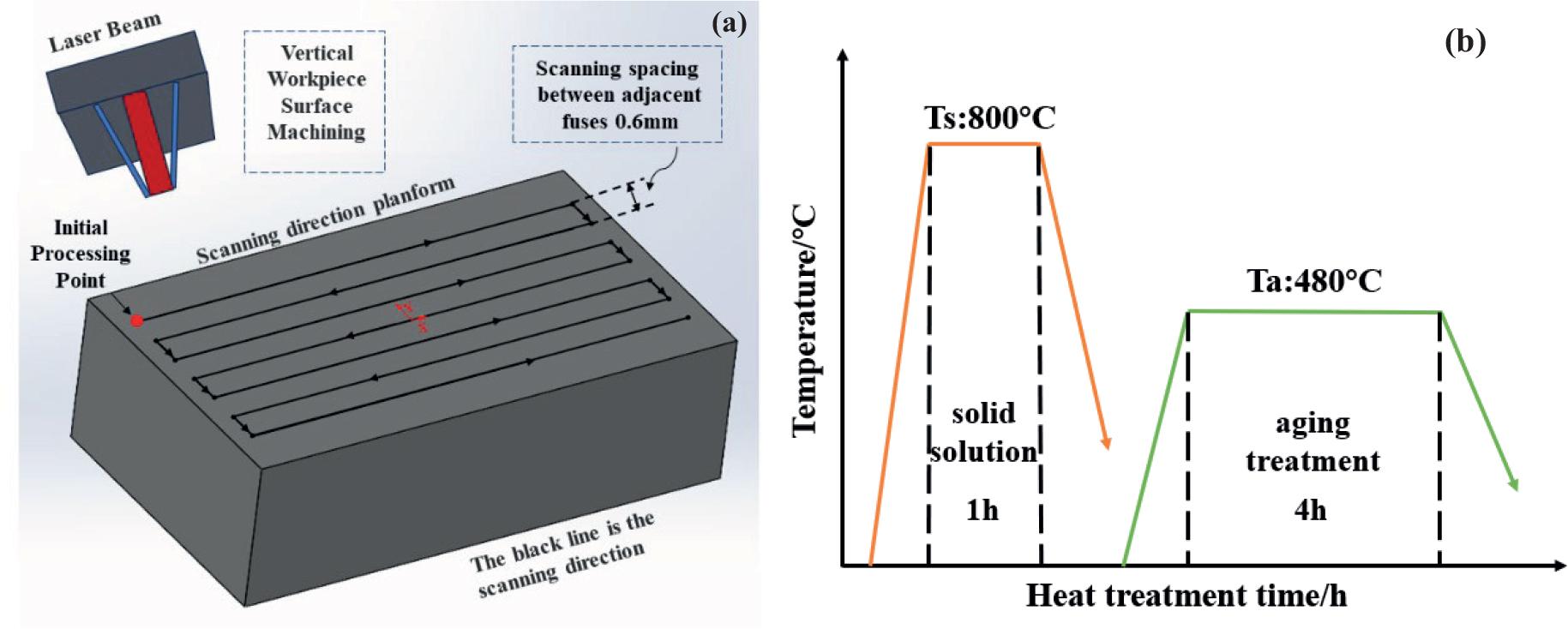

Fig. 2.

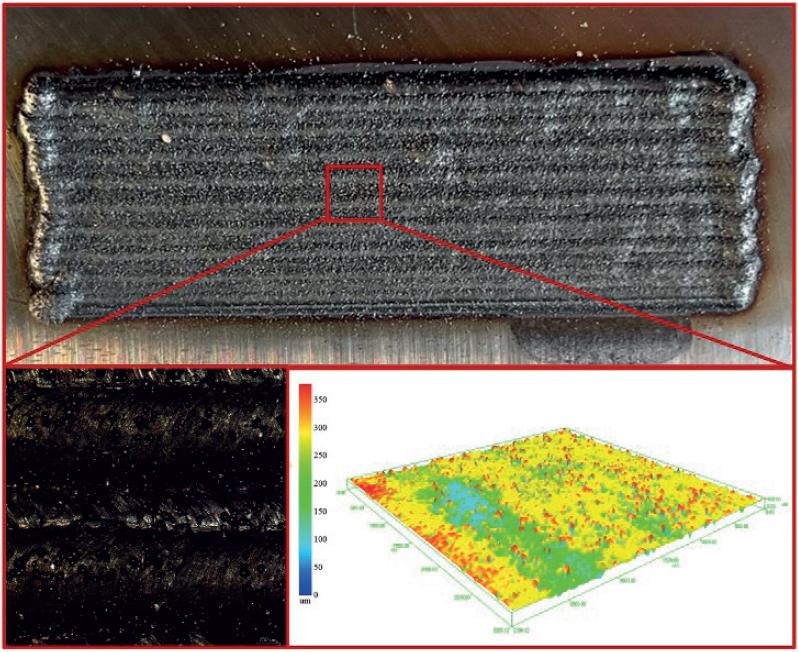

Fig. 3.

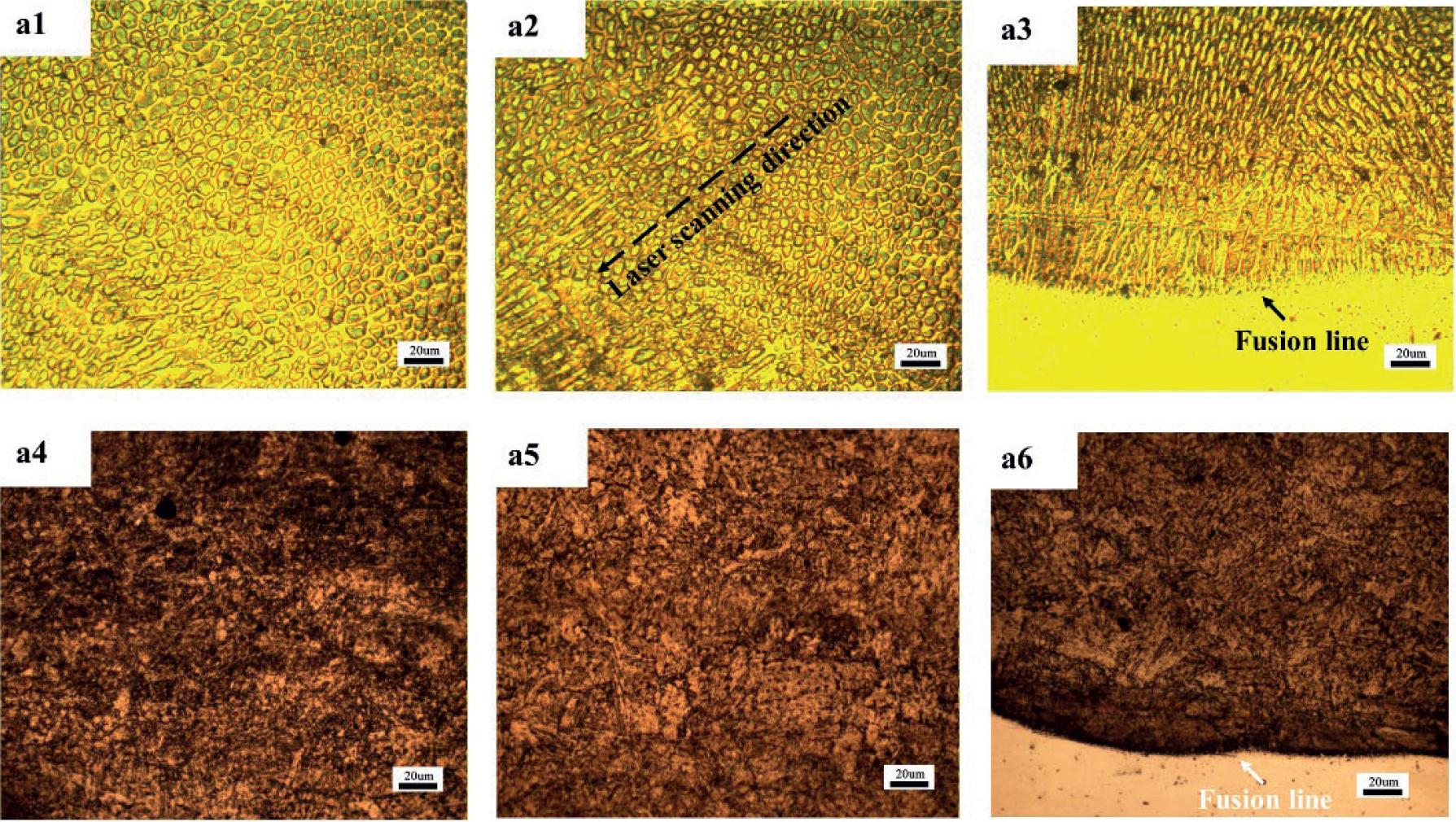

Fig. 4.

Fig. 5.

Fig. 6.

Fig. 7.

Fig. 8.

Fig. 9.

Fig. 10.

Fig. 11.

Elemental composition of 18Ni300 powder (wt%)

| Ni | Co | Mo | Ti | Al | Cr | P | Mn | Si | C | S | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 18.3 | 8.9 | 4.7 | 0.70 | 0.20 | 0.10 | 0.05 | 0.02 | 0.03 | 0.05 | 0.03 | Bal. |

Experimental process parameters

| Laser power W | Scan speed mm/s | Speed of power feeding g/min | Sweep spacing mm |

|---|---|---|---|

| 1300 | 2 | 10 | 0.6 |