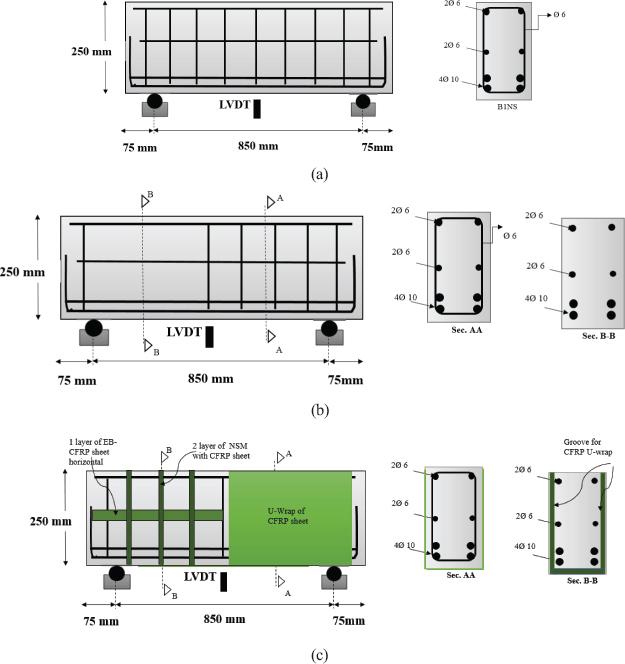

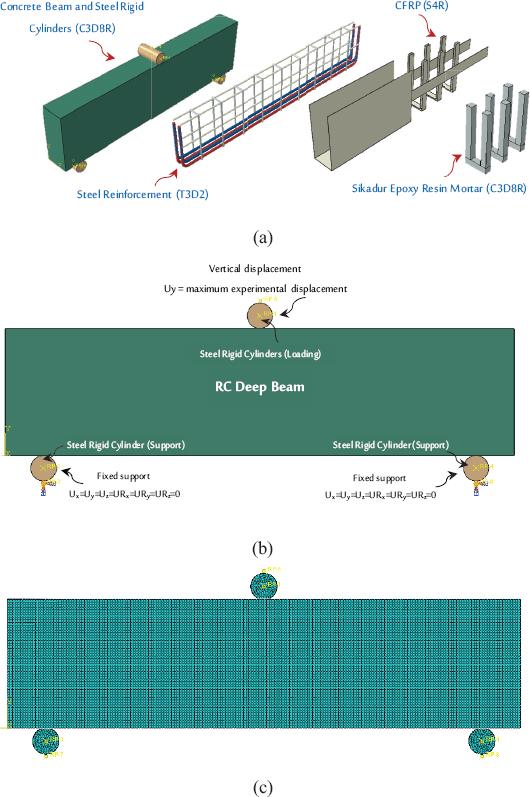

Fig. 1.

Fig. 2.

Fig. 3.

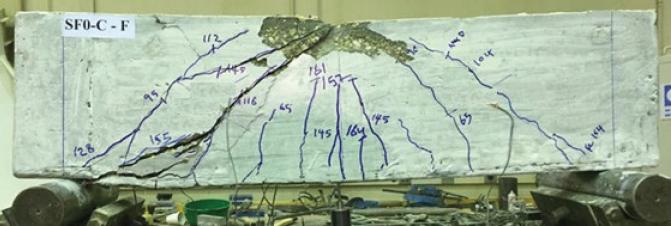

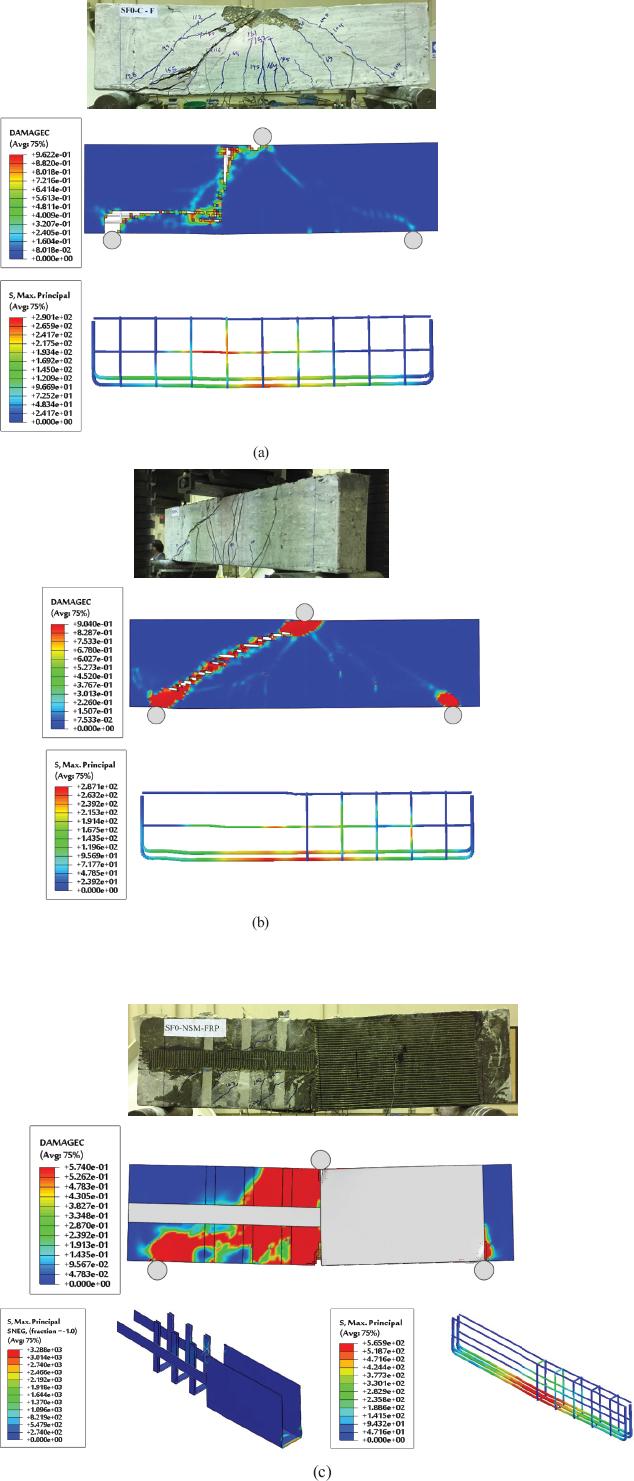

Fig. 4.

Fig. 5.

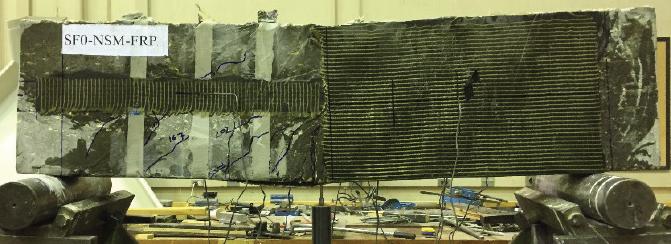

Fig. 7.

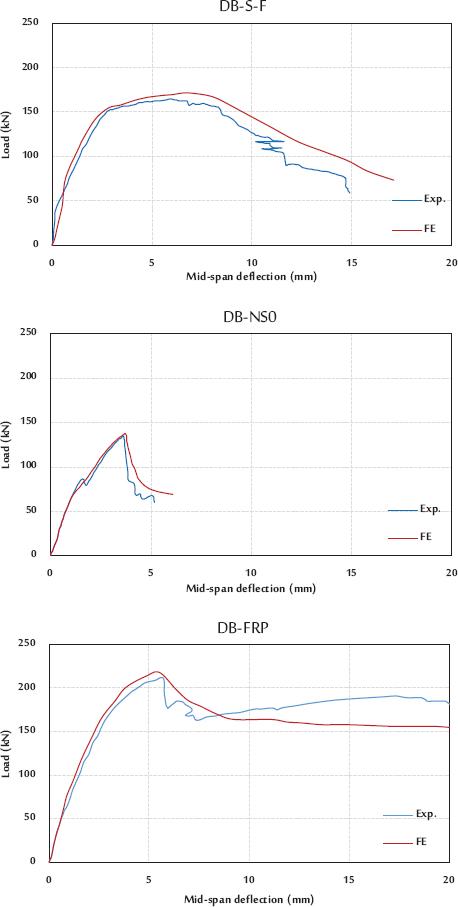

Fig. 9.

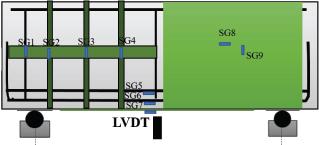

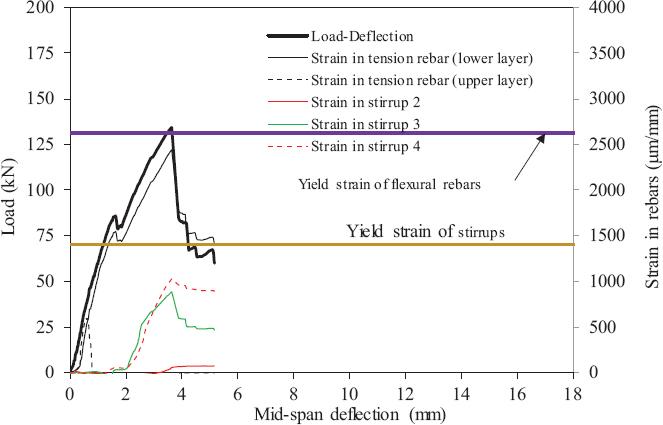

Fig. 6.

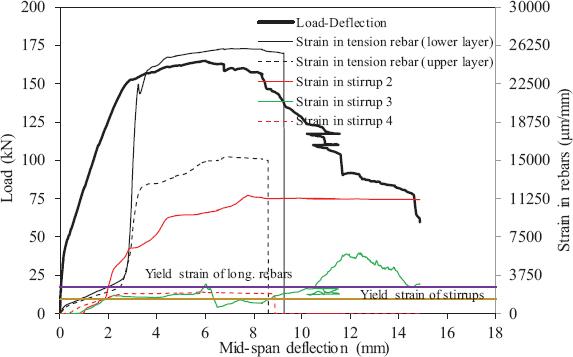

Fig. 8.

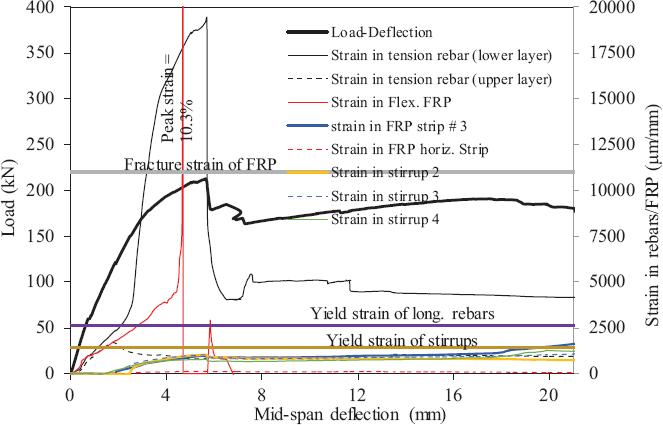

Fig. 10.

Fig. 11.

Fig. 12.

Test results of all tested specimens

| Beam description of half span part | Shear strength (kN) | Note |

|---|---|---|

| Beam part with no stirrups | 67.1 (DB-NS0) | – |

| Beam part having stirrups in all span | 82.5 (DB-S-F) | 23% improvement as compared to DB-NS0 |

| RC beam part with no stirrups but strengthened using NSM U-wrap CFRP strips | 112 (DB-FRP) | 82% improvement as compared to DB-NS0 |

Constitutive material models parameters of concrete, Sikadur resin, and CFRP

| Material | Parameters | Values | Denotation |

|---|---|---|---|

| Concrete | Dilation angle (ψ) | 32° | Calibrated value |

| Eccentricity (ε) | 0.1 | ABAQUS (default value) | |

| Stress ratio (σb0/σc0) | 1.16 | ABAQUS (default value) | |

| Shape factor (Kc) | 0.667 | ABAQUS (default value) | |

| Sikadur mortar | Dilation angle (ψ) | 40° | Calibrated value |

| Eccentricity (ε) | 0.1 | ABAQUS (default value) | |

| Stress ratio (σb0/σc0) | 1.16 | ABAQUS (default value) | |

| Shape factor (Kc) | 0.667 | ABAQUS (default value) | |

| CFRP sheet | Poisson’s ratio (ν) | 0.3 | Widely used in FE modeling |

| Modulus of Elasticity (E) | 230000 MPa | Given by the manufacturer | |

| Tensile strength (longitudinal: σt1) | 1122 MPa | Experimental Value | |

| Compressive strength (longitudinal: σc1) | 10 MPa | Al-Mekhlafi, et al. [11] | |

| Shear strength (longitudinal: τf1) | 10 MPa | ||

| Transversal tensile strength (σt2) | 10 MPa | ||

| Compressive strength (transversal: σc2) | 10 MPa | ||

| Shear strength (transversal: τf2) | 10 MPa |

Mixture composition of concrete mixture

| Material | Weight (kg/m3) |

|---|---|

| Cement | 650 |

| Silica sand | 528 |

| Coarse aggregate (Nominal size = 10 mm) | 770 |

| Crush sand | 264 |

| Water (w/c = 0.25) | 162.5 |

| Super-plasticizer(Gli-110) | 3 Liters |

Overview of test samples

| Specimen | Left half span | Right half span | ||

|---|---|---|---|---|

| Shear stirrups | Shear strengthening | Shear stirrups | Shear strengthening | |

| DB-S-F | 2L-f6@100 | None | 2L-f6@100 | None |

| DB-NS0 | 2L-f6@100 | None | None | None |

| DB-FRP | 2L-f6@100 | Yes | None | The specimen has two layers of U-wraps of FRP (25 mm wide) spaced at 100 mm intervals, along with a single layer of horizontally bonded FRP strips (50 mm wide) placed at the mid-depth on each face. |

Comparison of experimental and FE results

| Specimen ID | Exp. flexural strength (kN) | FE flexural strength (kN) | Error % |

|---|---|---|---|

| DB-S-F | 165 | 172 | 4.07% |

| DB-NS0 | 134 | 137 | 2.19% |

| DB-FRP | 212 | 218 | 2.75% |

Mechanical characterization of steel reinforcement

| Mechanical Property | Bar diameter | Test Standard | |

|---|---|---|---|

| 10 mm | 6 mm | ||

| Yield strength, (MPa) | 525 | 280 | ASTM A370 (2017) |

| Ultimate strength, (MPa) | 578 | 380 | |

| Modulus of elasticity, (GPa) | 200 | 200 | |

Characteristics of the strengthening materials

| Item | Value |

|---|---|

| CFRP composite | |

| Type of FRP | Unidirectional CFRP sheet |

| Longitudinal elastic modulus of the primary fibers. (GPa) | 77.3 |

| Transverse elastic modulus relative to the primary fiber direction. (MPa) | 40.6 |

| Strain at fracture along the primary fiber direction (%) | 1.1 |

| Maximum tensile strength along the primary fiber direction (MPa) | 846 |

| Thickness of each individual layer, tf (mm) | 1.0 |

| Epoxy | |

| Density (kg /l) | 1.16 |

| Tensile strength of the adhesive (MPa) | > 4.0 (7 days) |

| Tensile modulus of elasticity (GPa) | 3.5 (7 days) |

| Sikadur_31 Thixotropic epoxy_resin mortar | |

| Tensile strength of the adhesive (MPa) | 15 |

| Density (kg /l) | 1.65 |

| Modulus of Elasticity (GPa) | 4.3 |

Mesh convergence analysis results

| Mesh types | Beam elements size | Experimental flexural strength (kN) | FE flexural strength (kN) | Experimental/FE |

|---|---|---|---|---|

| Type 1 | 25 | 165 | 185 | 89.2% |

| Type 2 | 15 | 178 | 92.7% | |

| Type 3 | 7 | 172 | 95.6% |