Fig. 1.

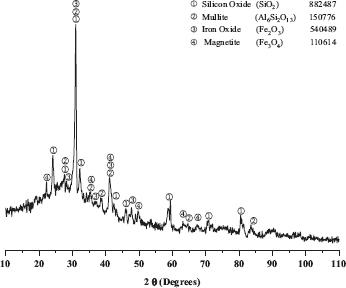

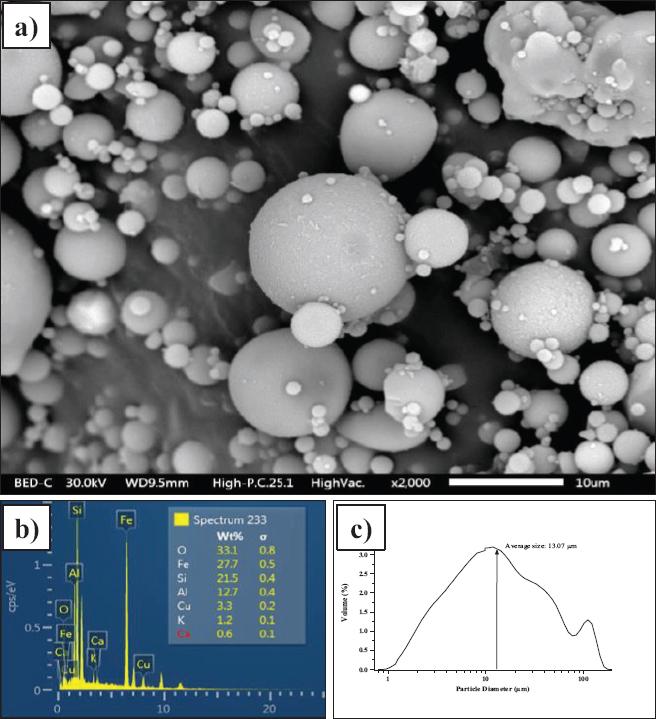

Fig. 2.

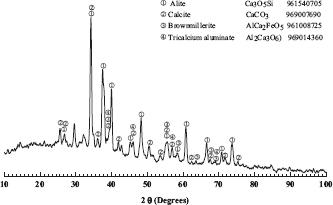

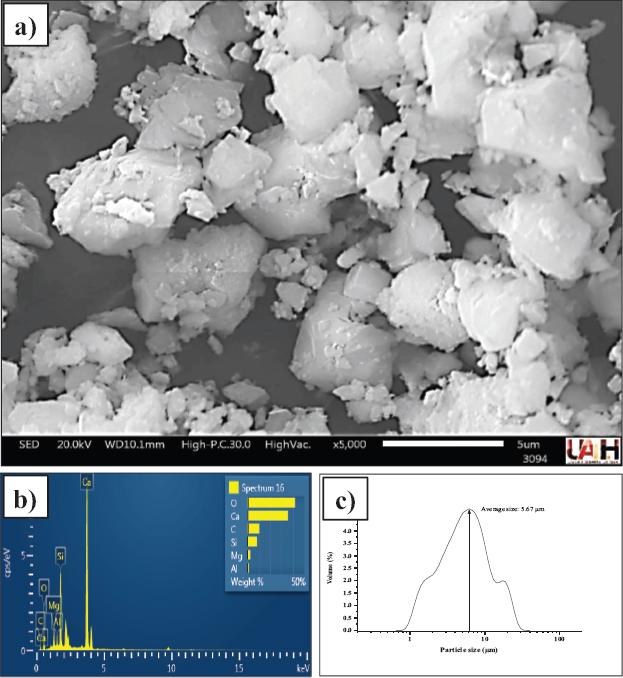

Fig. 3.

Fig. 4.

Fig. 5.

Fig. 6.

Fig. 7.

Fig. 8.

Fig. 9.

Fig. 10.

Fig. 11.

Fig. 12.

Physical properties of fly ash and Portland cement

| Materials | Median particle size (μm) | Specific Gravity | Passing 45 μm sieve (%) | Blaine fineness (m2/kg) |

|---|---|---|---|---|

| Portland cement (CPC-30R) | 5.67 | 3.10 | 98 | 348 |

| Fly ash | 13.07 | 2.02 | 79 | 302 |