Fig. 1

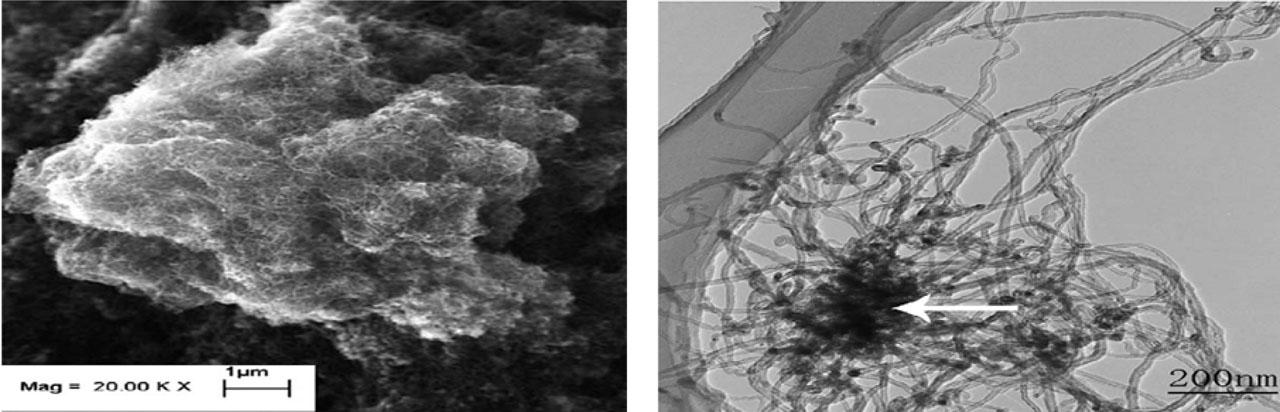

Fig. 2

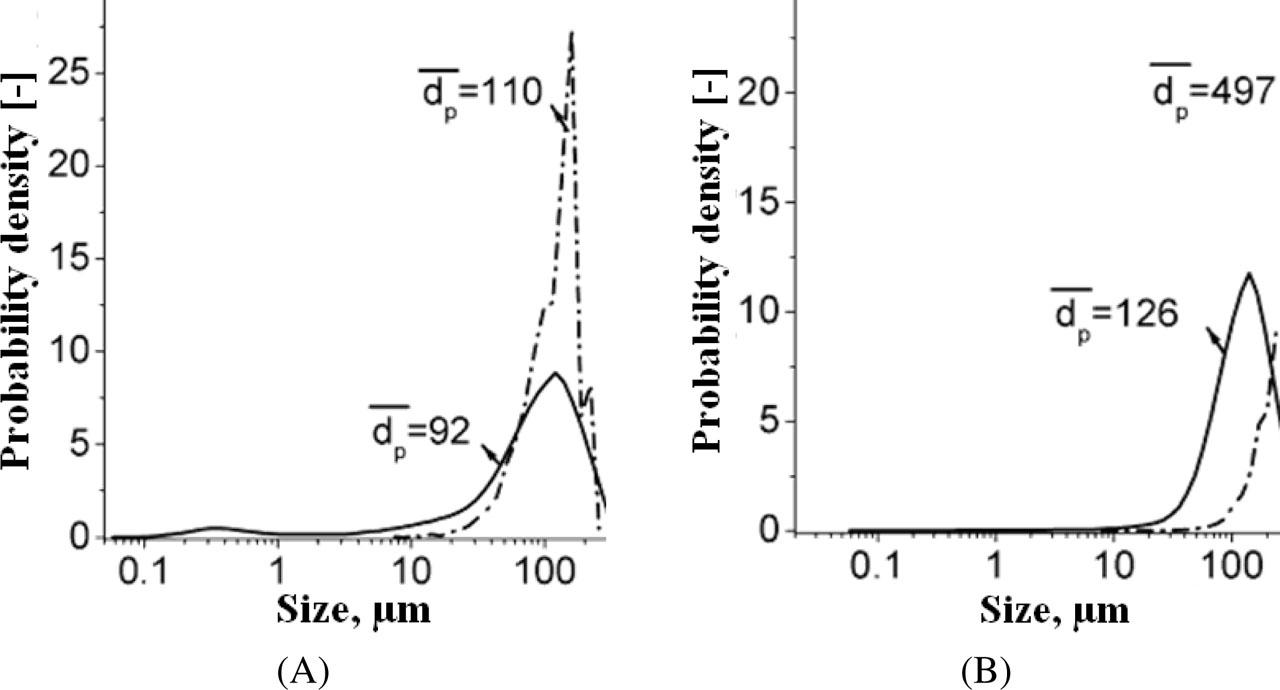

Fig. 3

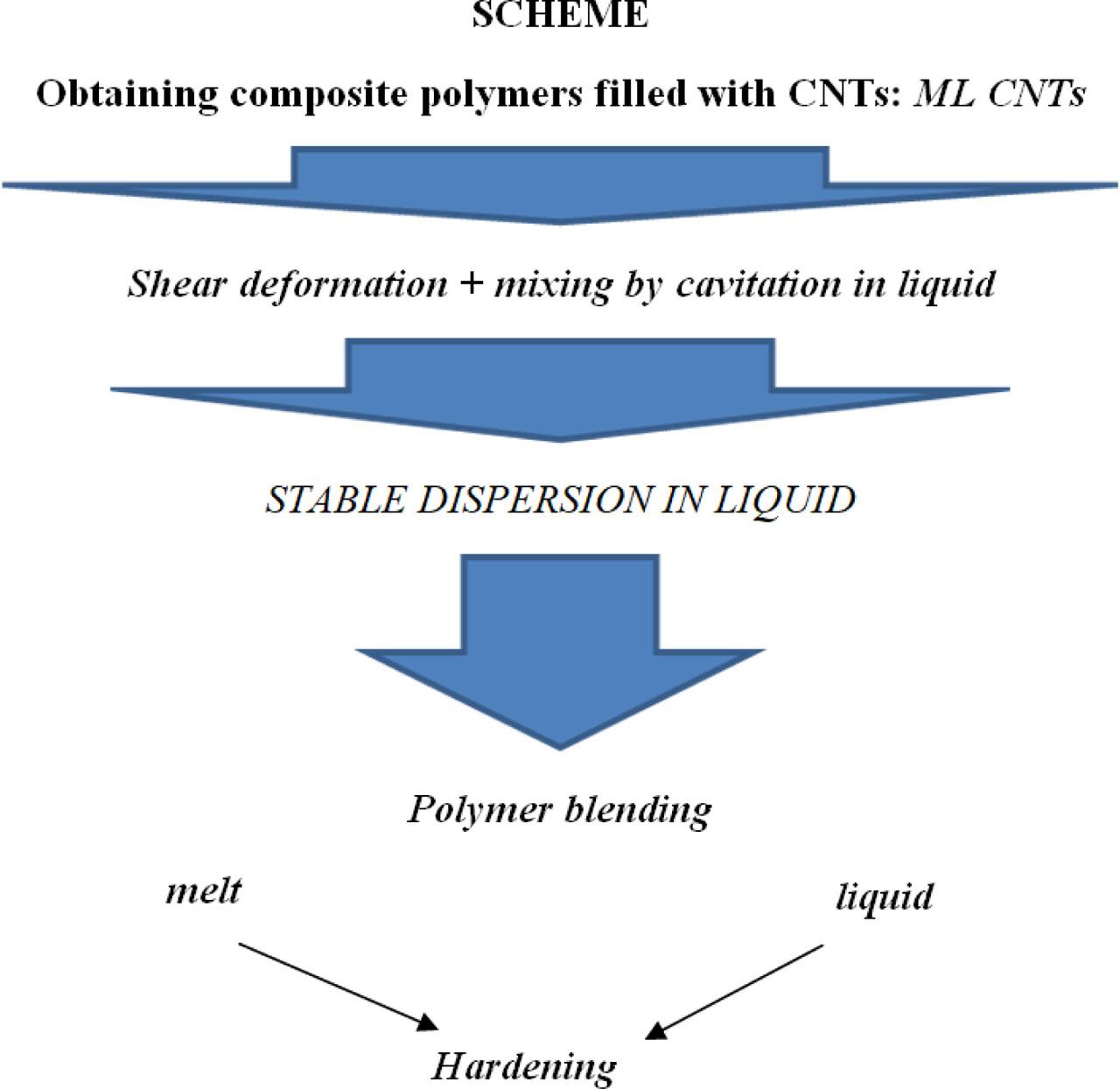

Fig. 4

Fig. 5

Physical and mechanical characteristics of bitumen (original and modified)

| Bitumen 90/130 with additive, wt.% | Temperature, °C | Plasticity interval, Pa | Needle penetration depth at 25°C/0°C, 0.1 mm | Stretch at 25°C/0°C, cm | Elasticity at 25°C, % | Surface grip | |

|---|---|---|---|---|---|---|---|

| Fragility to Fraasu | Softening according to KiSh | ||||||

| 0 | −21 | 44 | 65 | 124/29 | 57/5.6 | 5 | Fair |

| 2 | −25 | 47 | 72 | 126/32 | 78/18 | 27 | Good |

| 3 | −31 | 48 | 79 | 128/35 | 86/28 | 46 | Excellent |

| 4 | −37 | 52 | 89 | 130/42 | ?100/34 | 57 | Excellent |

| 8 | −24 | 54 | 78 | 162/83 | 77/33 | 28 | Fair |

Properties of CNT made of fly ash

| Indicator | Physical and mechanical properties of fiber of fly ash |

|---|---|

| Average fiber diameter, μm | 1–15.0 |

| Non-fibrous additives, % | 2–3 |

| Density, g/cm3 | 2.65 |

| Temperature, °C | −269 to +700 |

| Water resistance, % | 99.6 |

| Chemical resistance, % | 93.4 77.3 98.5 |

| 0.5H NaOH | |

| 2H NaOH | |

| 2H H2SO4 | |

| Hygroscopicity, % | ≤ 1.0 |

| Mechanical strength, MPa | 4,100 |

| Modulus of elasticity, MPa | 120 |

| Elongation at break, % | 3.1 |

Composition of rubber and CNT

| Sample | NR, g | BR9000, g | CNT, % (by weight of rubber) | CNT, g | N220, g |

|---|---|---|---|---|---|

| S-0 | 1,330 | 224 | 0 | 0 | 666.4 |

| S-1* | 1,330 | 224 | 0.65 | 9.7 | 656.7 |

| S-2** | 1,330 | 224 | 0.65 | 9.7 | 656.7 |

| S-3 | 1,330 | 224 | 2.5 | 38.8 | 627.6 |

| S-4 | 1,330 | 224 | 1.25 | 19.4 | 647 |

| S-5 | 1,330 | 224 | 0.65 | 9.7 | 656.7 |

| S-6 | 1,330 | 224 | 0.325 | 4.8 | 661.6 |

| S-8 | 1,330 | 224 | 0.16 | 2.4 | 664 |

| S-9*** | 1,330 | 224 | 0.65 | 9.7 | 656.7 |

| S-7 | 1,330 | 224 | 20 | 310.8 | 0 |

Classification of modifying additives for bitumen

| Modifying additive | Plasticizing | Structuring | Adhesive | Temperature improvers | |

|---|---|---|---|---|---|

| Polyimproved compounds | LM | + | |||

| PV | + | + | |||

| LMWP | + | + | |||

| BSC | + | + | |||

| DST | + | + | |||

| PVB | + | + | |||

| PPR | + | ||||

| R + HPT | + | + | + | ||

| LMWAA-A | + | + | + | ||

| LMWAA-B | + | + | + | ||

| Surfactants | DEG | + | + | + | |

| TEG | + | + | + | ||

| MEA | + | + | |||

| DEA | + | + | + | ||

| BSU | + | + | |||

| Additive adhesive BP-3M | + | + | |||

| ORSK-superplasticizer | + | ||||

Results of the study on aging and wear resistance

| Samples | S0 | S1 | S2 | S3 | S4 | S5 | S6 | S8 | S9 |

|---|---|---|---|---|---|---|---|---|---|

| Vulcanization 150°C×30′ | |||||||||

| Hardness A, rel.un. | 61 | 63 | 65 | 62 | 63 | 62 | 65 | 65 | 61 |

| Boundary tensile strength, MPa | 19.7 | 23.4 | 22.4 | 20.5 | 24.2 | 23.6 | 23.6 | 24.4 | 22.6 |

| Relative elongation at break, % | 486 | 483 | 478 | 486 | 501 | 491 | 514 | 476 | 505 |

| 100°C*168 h Aging | |||||||||

| Hardness A, rel.un. | 62 | 65 | 68 | 64 | 67 | 62 | 67 | 64 | 65 |

| Boundary tensile strength, MPa | 12.4 | 14.2 | 14.2 | 12.3 | 15.9 | 14.6 | 16.7 | 16.4 | 13.7 |

| Relative elongation at break, % | 349 | 314 | 295 | 326 | 332 | 338 | 357 | 326 | 339 |

| Wear resistance, J/mm3 | 98 | 102 | 100 | 94 | 92 | 103 | 100 | 93 | 105 |

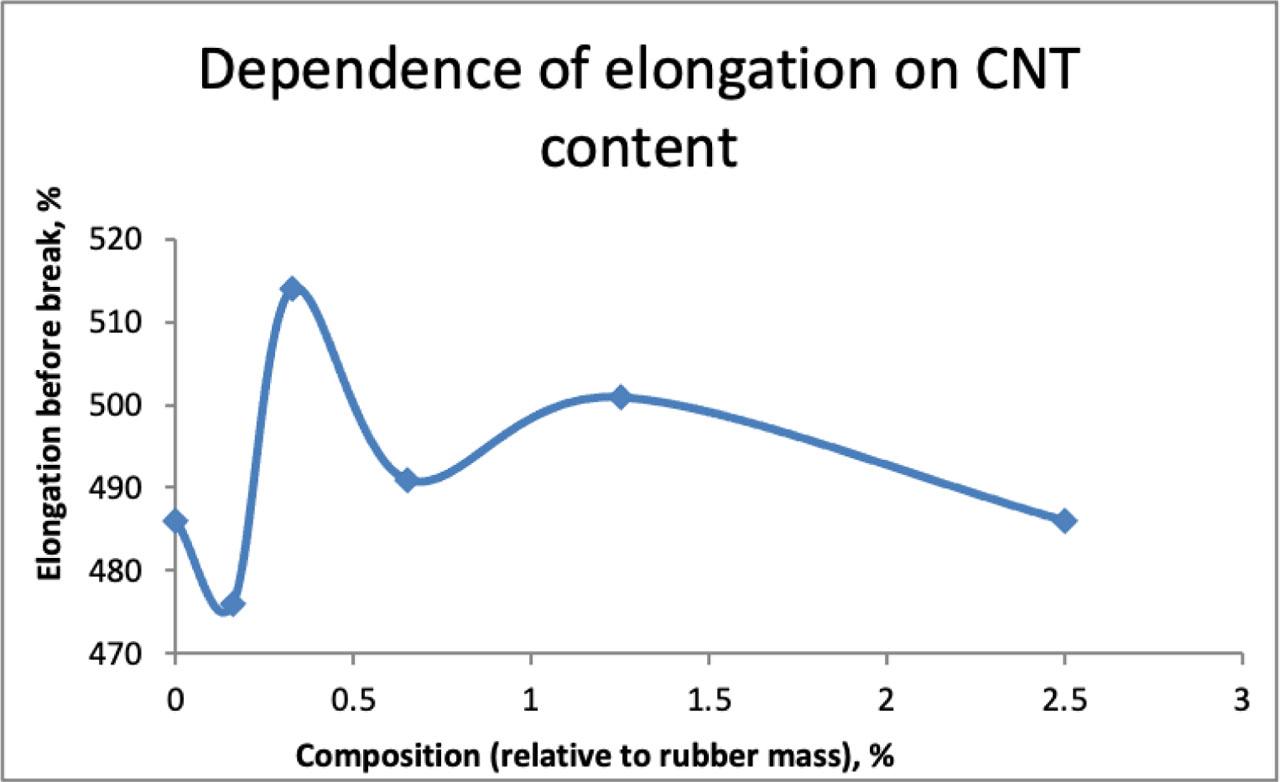

Sample test results

| MWCNT, wt.% | Breaking strength, MPa | Elongation at break, % | Compressive strength, MPa | Shore hardness, c.od. |

|---|---|---|---|---|

| 0 | 19.7 | 486 | 12 | 61 |

| 0.16 | 24.4 | 476 | 9 | 65 |

| 0.325 | 23.6 | 514 | 7.4 | 65 |

| 0.65 | 23.6 | 491 | 8.1 | 62 |

| 1.25 | 24.2 | 501 | 7.5 | 63 |

| 2.5 | 20.5 | 486 | 9.1 | 62 |

Measured data of the experimental results

| Sample | Hardness, A, relative units | Boundary tensile strength, MPa | Relative elongation at break, % | Break, % | |||

|---|---|---|---|---|---|---|---|

| S0 | 61 | 21.8 | 19.7 | 539 | 486 | 12.863 | 12.043 |

| 18.3 | 479 | 10.534 | |||||

| 19.7 | 483 | 12.043 | |||||

| 20.2 | 504 | 13.337 | |||||

| 19.3 | 486 | 10.416 | |||||

| S1 | 63 | 24.6 | 23.4 | 470 | 483 | 6.983 | 8.384 |

| 23.4 | 490 | 8.384 | |||||

| 23.6 | 483 | 11.762 | |||||

| 22.9 | 494 | 9.653 | |||||

| 22.7 | 448 | 6.867 | |||||

| S2 | 65 | 22.3 | 22.3 | 449 | 478 | 7.286 | 9.53 |

| 22.4 | 487 | 10.289 | |||||

| 23.1 | 492 | 10.079 | |||||

| 22.4 | 478 | 8.686 | |||||

| 22.3 | 429 | 9.53 | |||||

| S3 | 62 | 22 | 20.5 | 485 | 486 | 9.089 | 9.089 |

| 21.1 | 478 | 6.74 | |||||

| 20.5 | 486 | 9.576 | |||||

| 19.9 | 499 | 11.099 | |||||

| 19.7 | 494 | 8.991 | |||||

| S4 | 63 | 23.4 | 24.2 | 471 | 501 | 9.399 | 7.52 |

| 24.5 | 502 | 6.896 | |||||

| 24.6 | 519 | 7.52 | |||||

| 22.8 | 465 | 7.832 | |||||

| 24.2 | 501 | 6.283 | |||||

| S5 | 62 | 24.5 | 23.6 | 503 | 491 | \ | 8.1 |

| 22.7 | 470 | 8.693 | |||||

| 24 | 511 | 8.259 | |||||

| 23.1 | 480 | 7.541 | |||||

| 23.6 | 491 | 7.899 | |||||

| S6 | 65 | 24.9 | 23.6 | 514 | 514 | 7.426 | 7.426 |

| 24.4 | 520 | 8.298 | |||||

| 23.6 | 476 | 7.612 | |||||

| 23.7 | 538 | 6.513 | |||||

| 23.7 | 507 | 7.393 | |||||

| S8 | 65 | 24.5 | 24.4 | 487 | 476 | 9.484 | 8.997 |

| 24.8 | 493 | 6.696 | |||||

| 24.4 | 446 | 8.997 | |||||

| 24.2 | 476 | 6.521 | |||||

| 23.8 | 452 | 10.213 | |||||

| S9 | 66 | 24.1 | 22.6 | 556 | 505 | 8.615 | 11.319 |

| 22.6 | 489 | 13.937 | |||||

| 21.9 | 462 | 11.319 | |||||

| 22.4 | 519 | 11.497 | |||||

| 22.8 | 505 | 11.274 | |||||