Fig. 1

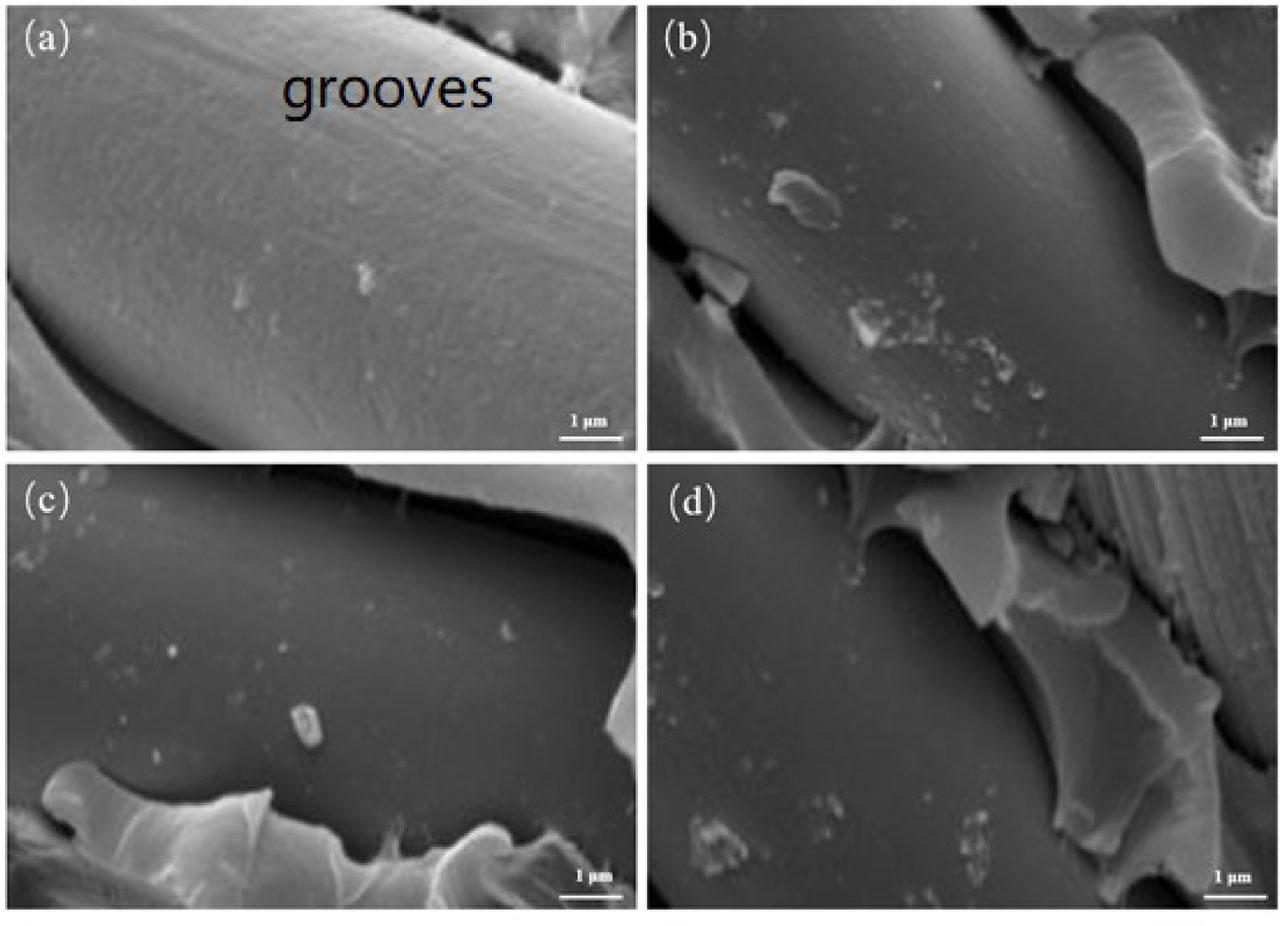

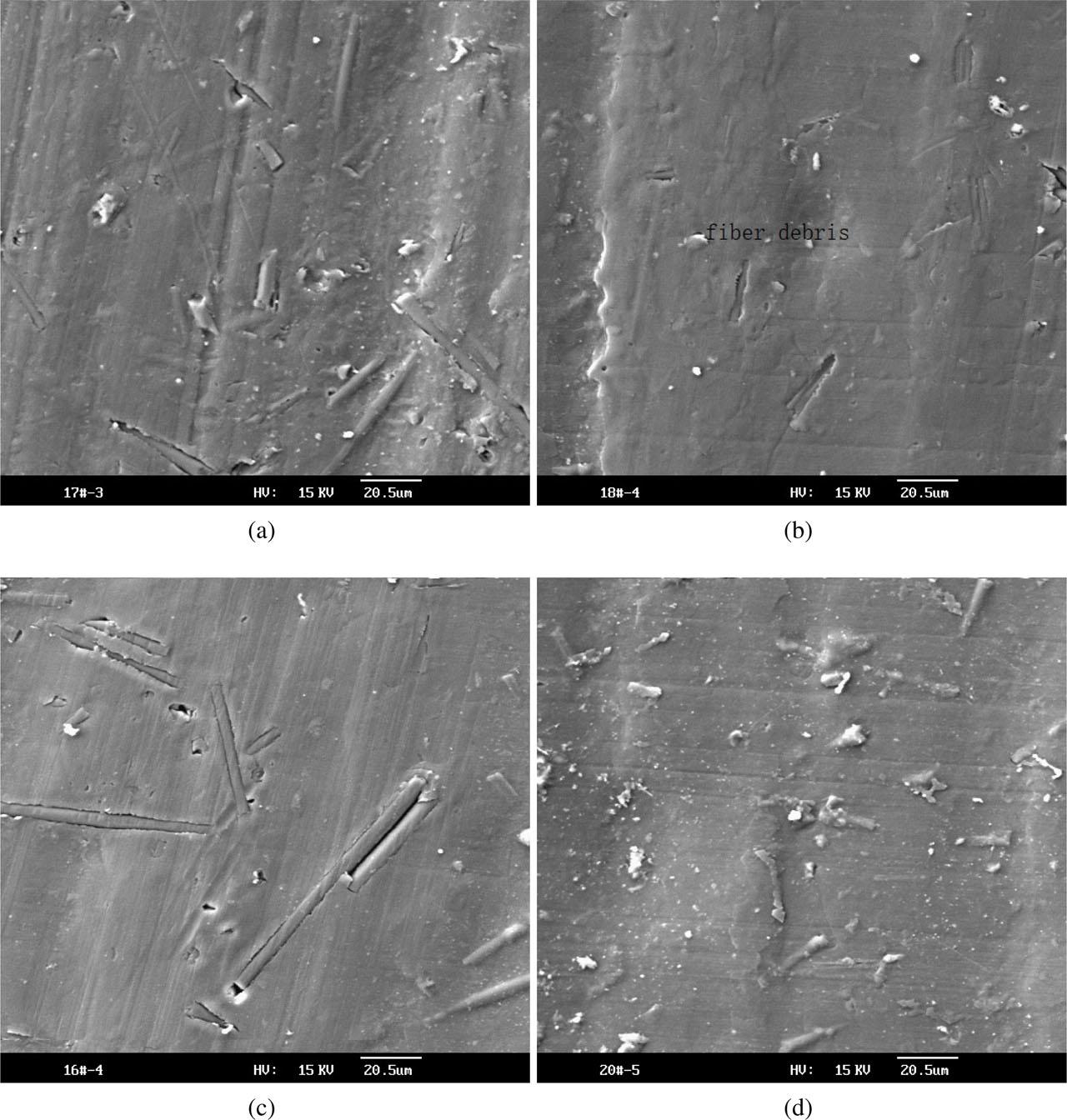

Fig. 2

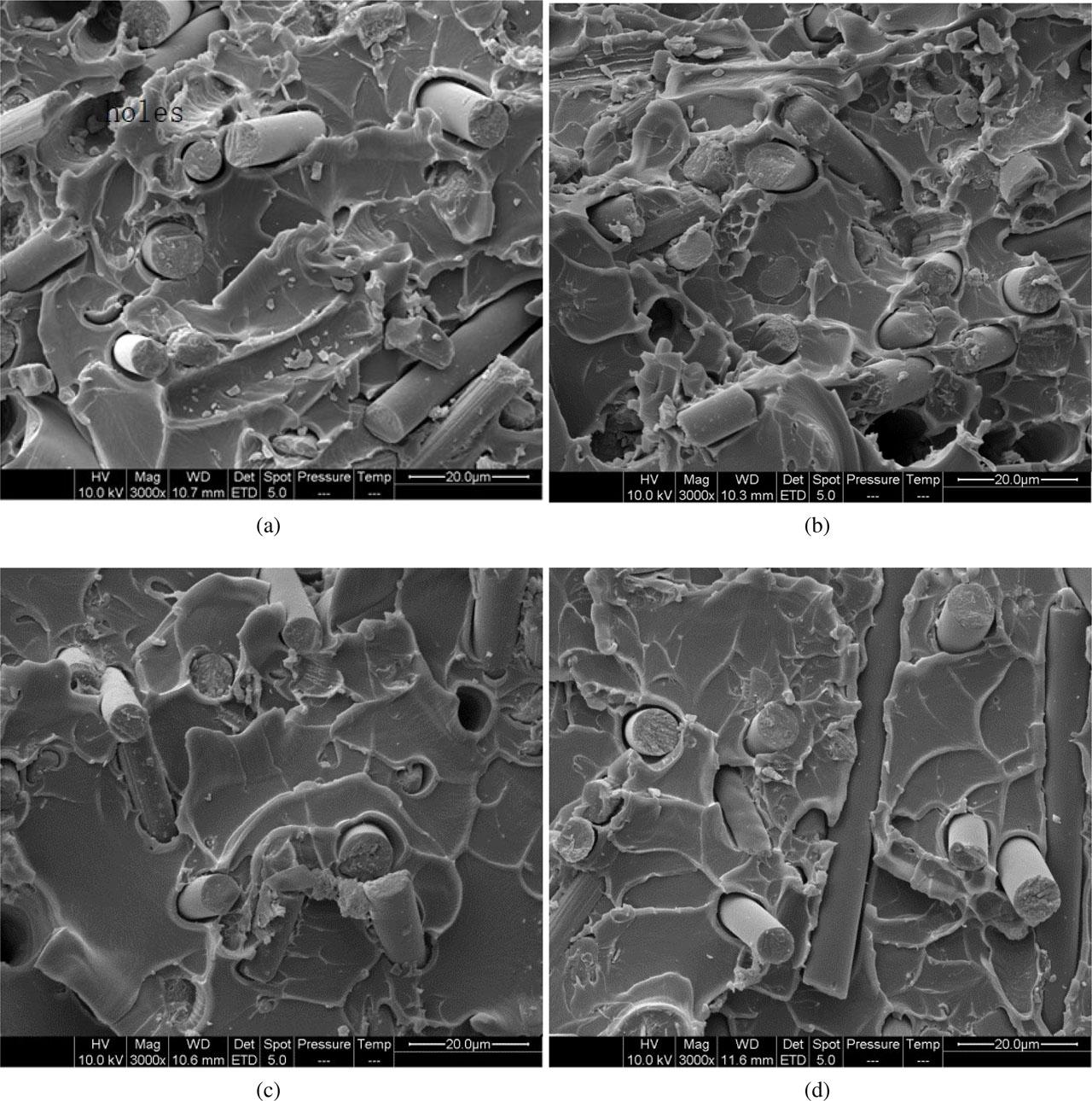

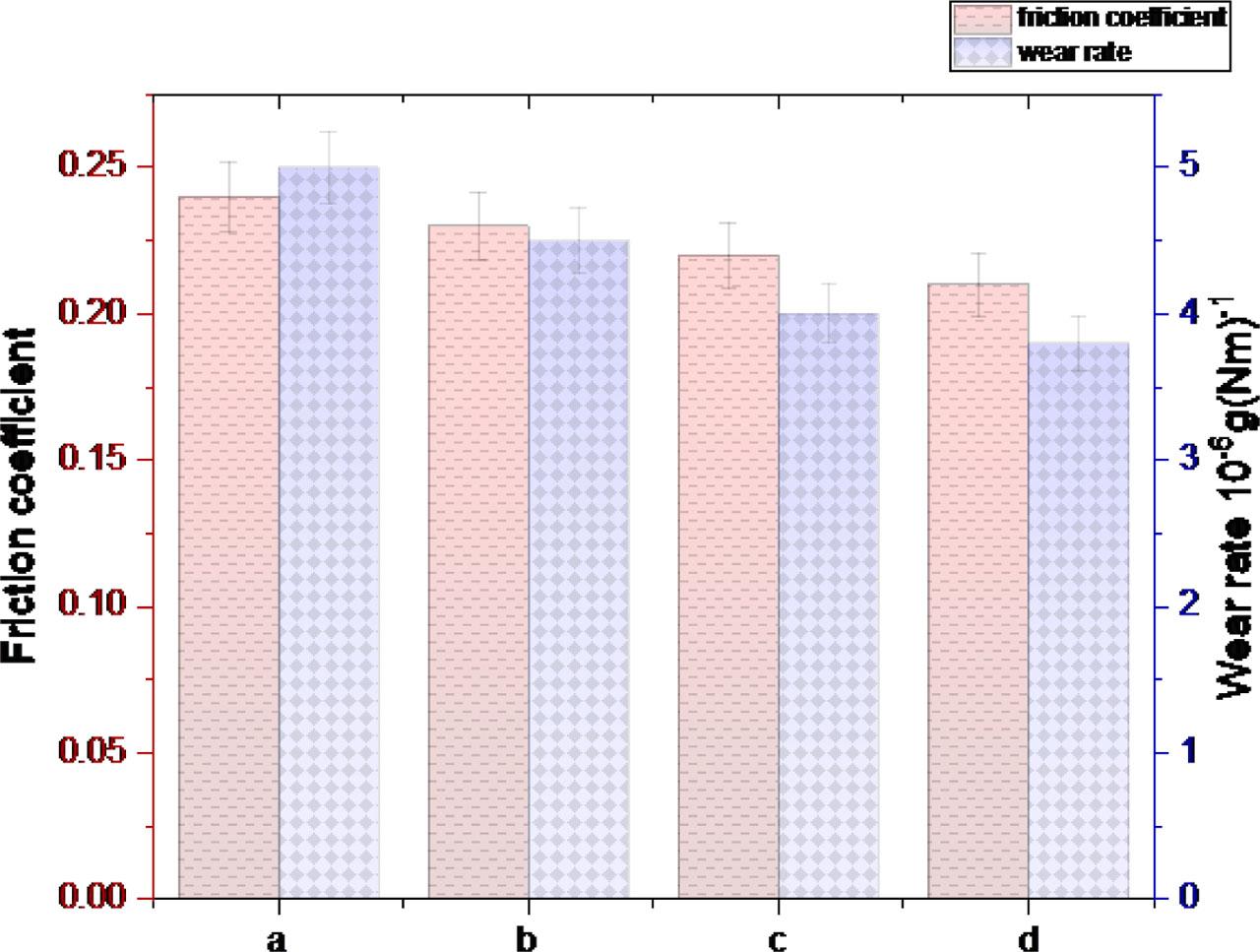

Fig. 3

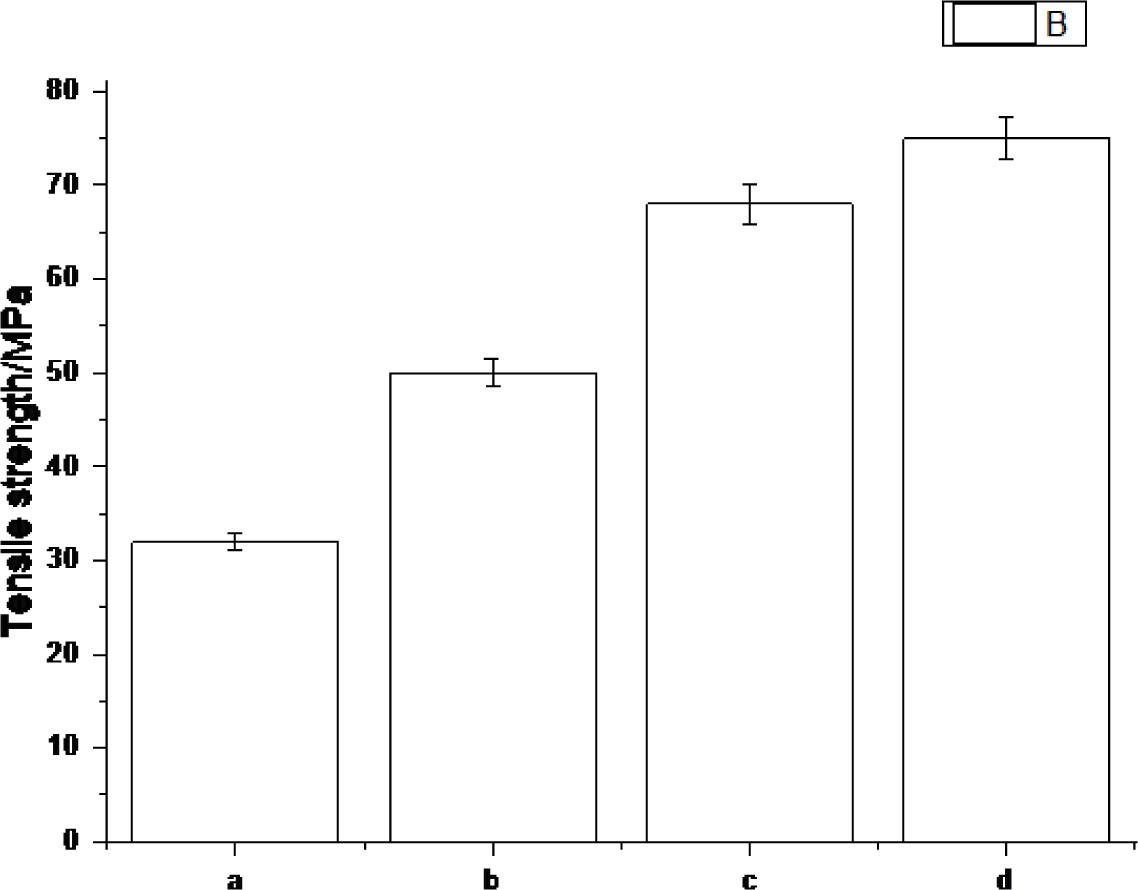

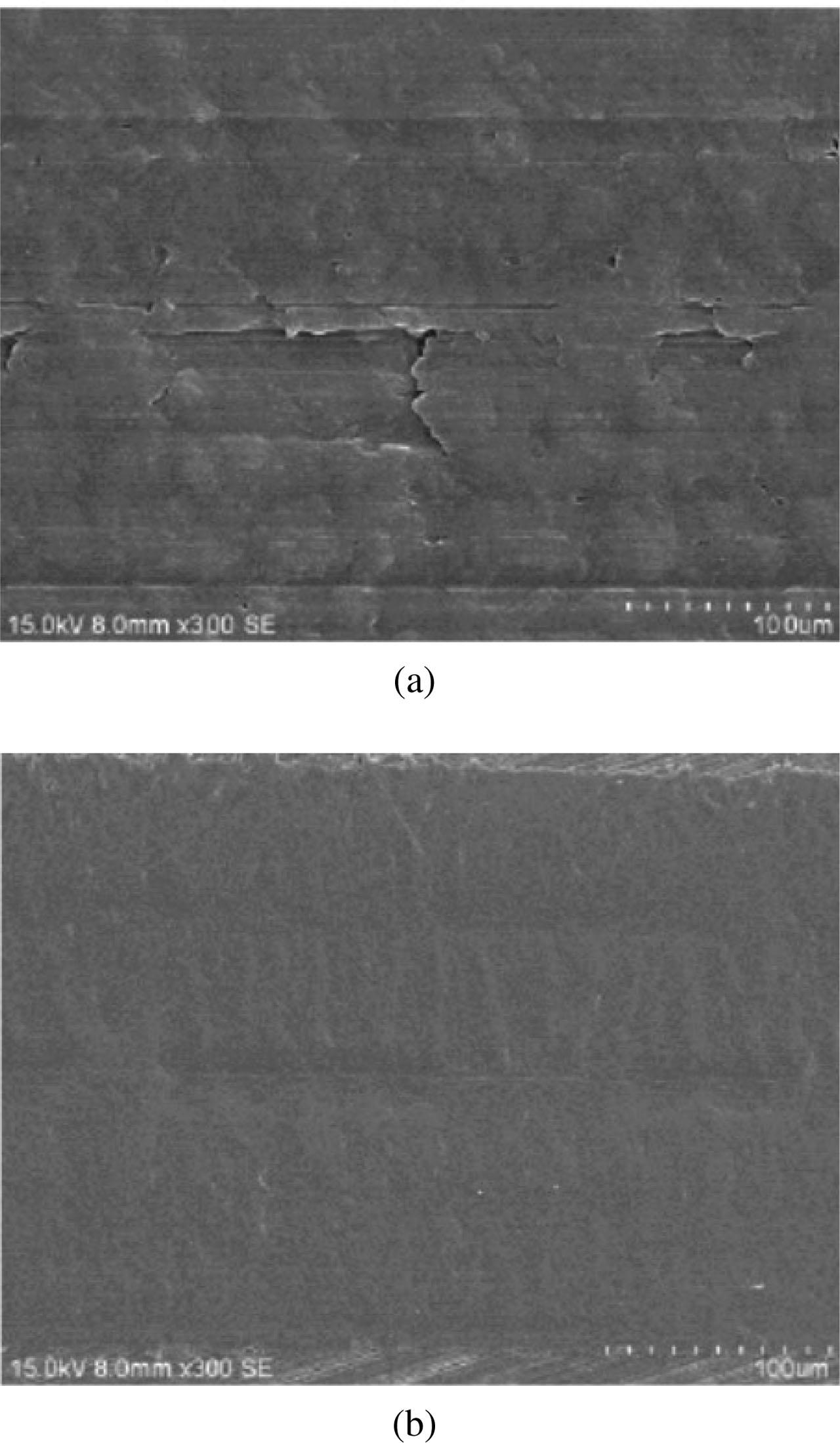

Fig. 4

Fig. 5

Fig. 6

Fig. 7

Surface elementary composition of carbon fibers_

| Surface treatment | Elementary composition / % | Atom ratio / % | ||||

|---|---|---|---|---|---|---|

| C | O | N | Si2p | O/C | N/C | |

| Untreated | 82.3 | 10.2 | 7.5 | – | 12.4 | 8.9 |

| 0.1% coating | 77.7 | 13.1 | 8.4 | 0.8 | 16.9 | 10.7 |

| 0.2% coating | 75.3 | 14.4 | 9.1 | 1.2 | 19.1 | 12.1 |

| 0.3% coating | 76.9 | 13.2 | 8.47 | 1.42 | 17.2 | 11.0 |

Main properties of PI (GCTPTM)_

| Density (kg/m3) | 1350 | Impact strength (kJ/m2) | 25 |

| Tensile Strength (MPa) | 95 | Thermal expansion coefficient (°C−1) | 4.8 × 10−5 |

| Elongation at break (%) | 7 | Tg (°C) | 260 |

| Flexural strength (MPa) | 150 | Thermal decomposition temperature (°C) | 240 |

Chemical composition of GCr15 steel (wt %)_

| C | Si | Mn | Cr | P | S | Fe |

|---|---|---|---|---|---|---|

| 0.95–1.05 | 0.15–0.35 | 0.2–0.4 | 1.30–1.65 | ⩽ 0.027 | ⩽ 0.02 | Remainder |