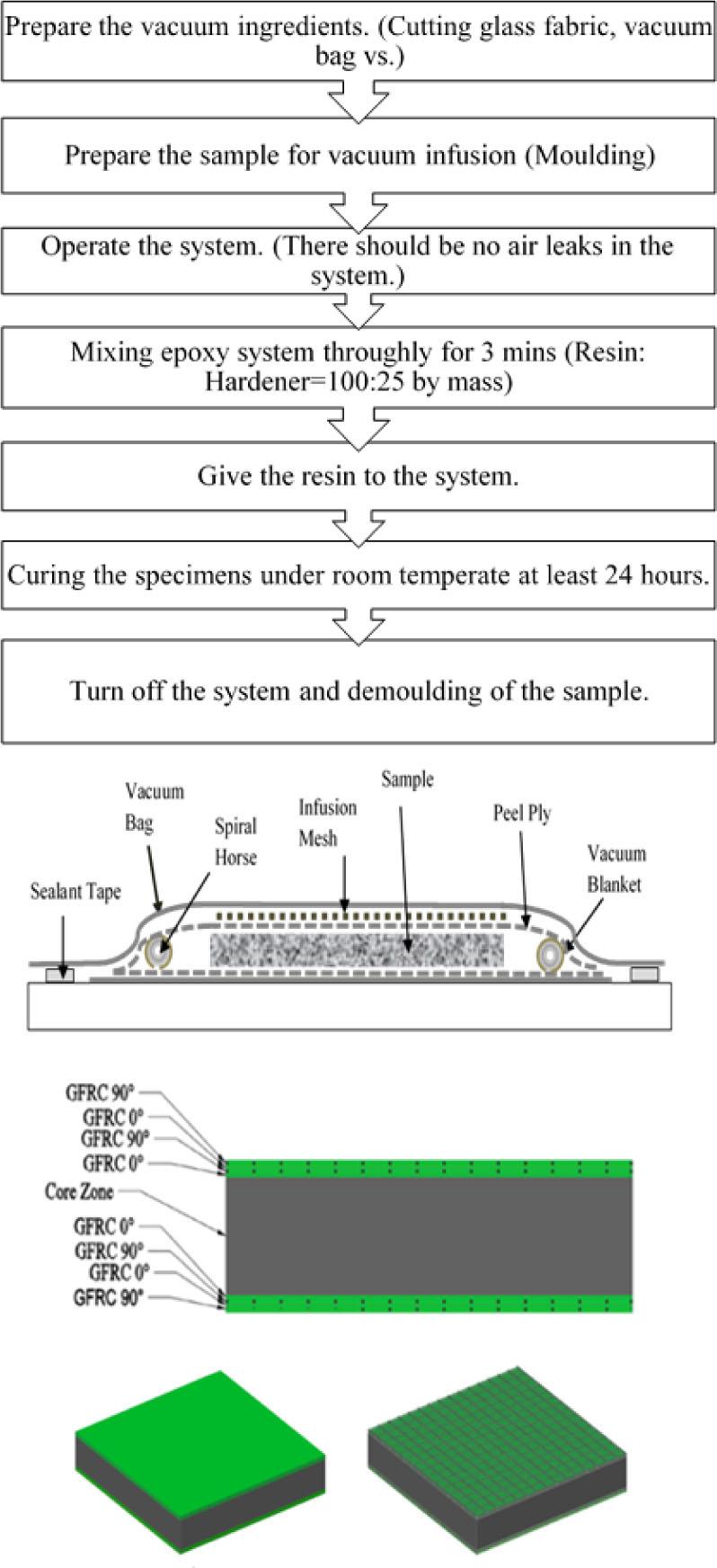

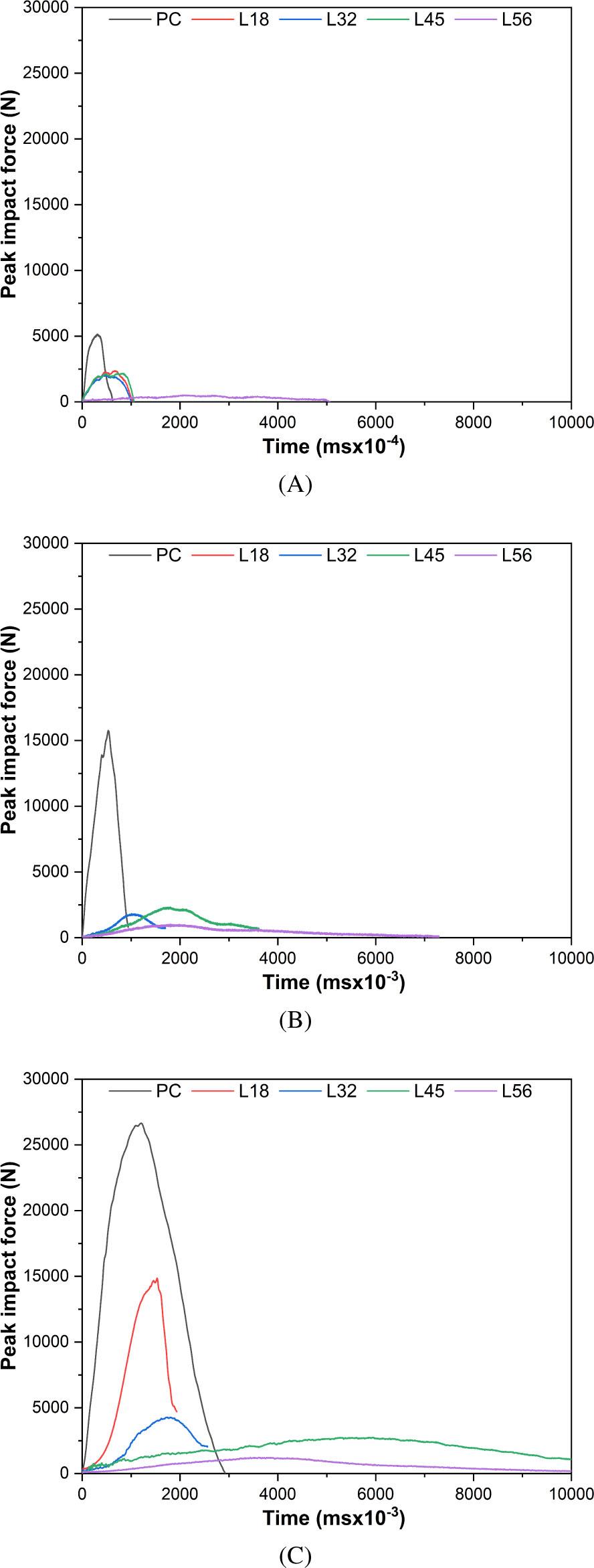

Fig. 1

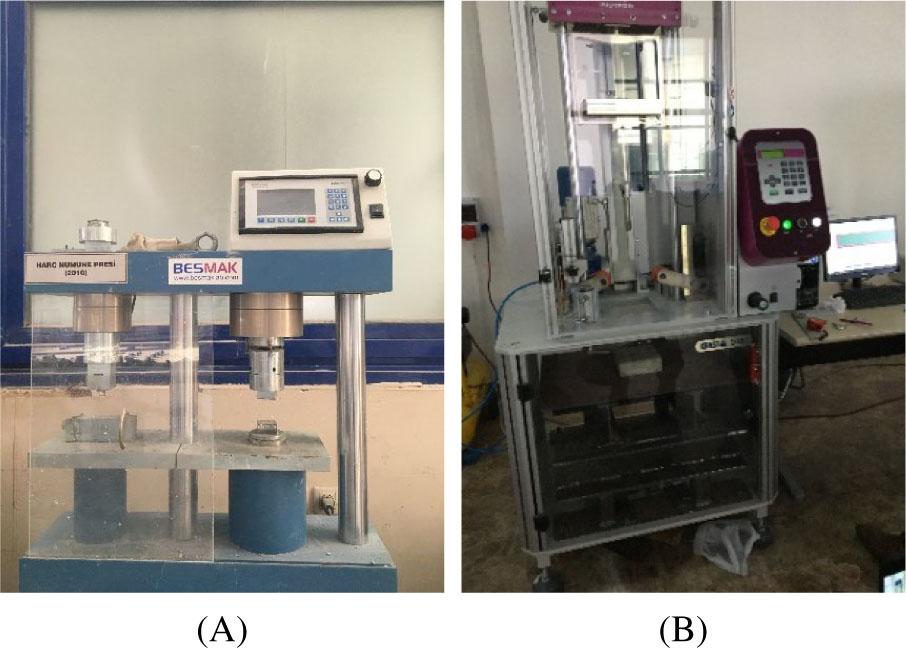

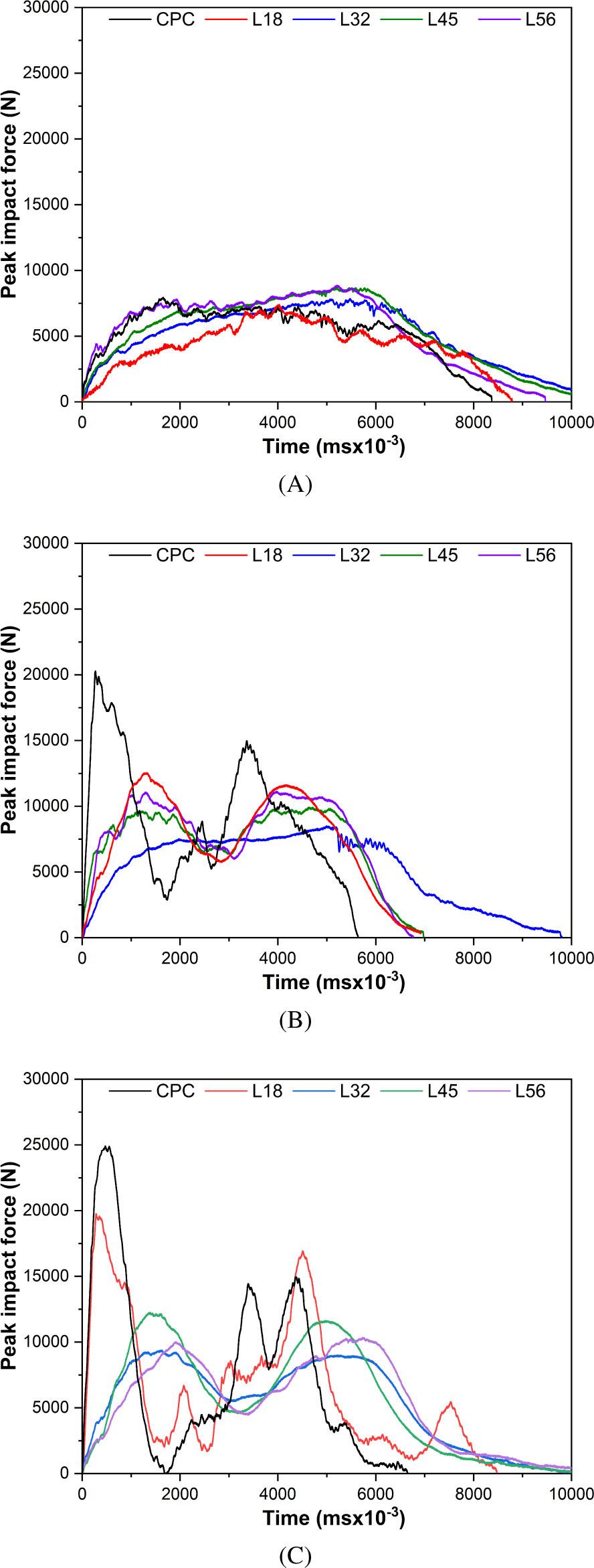

Fig. 2

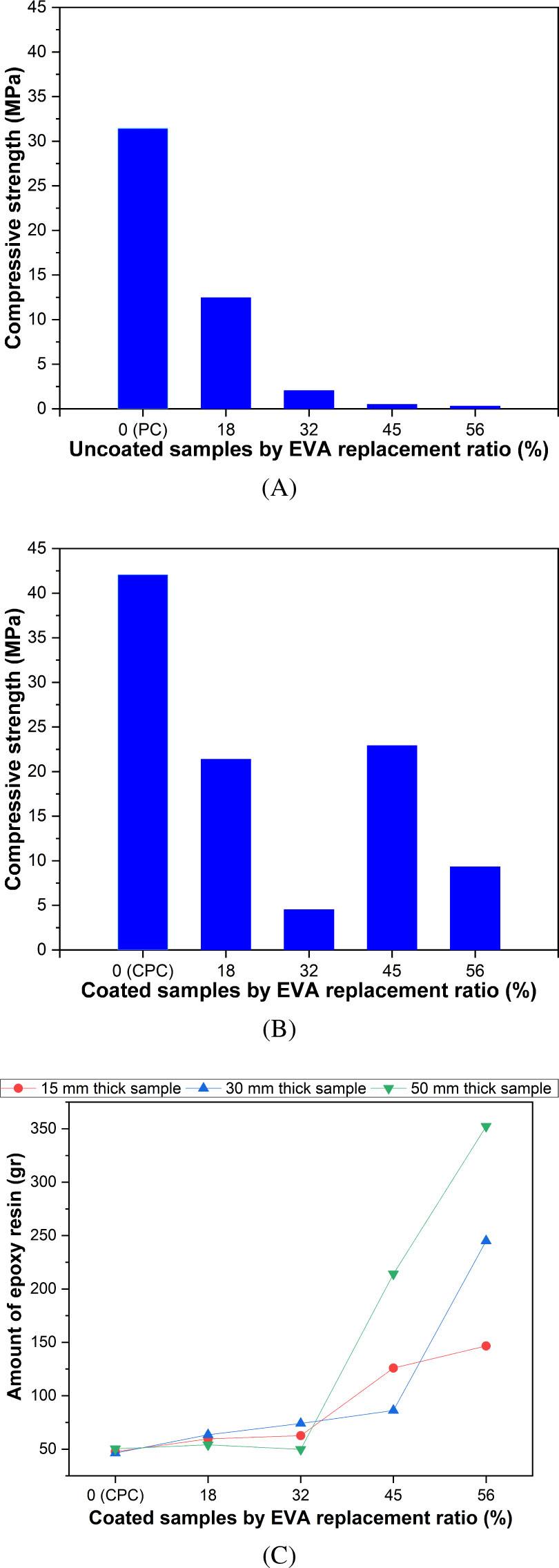

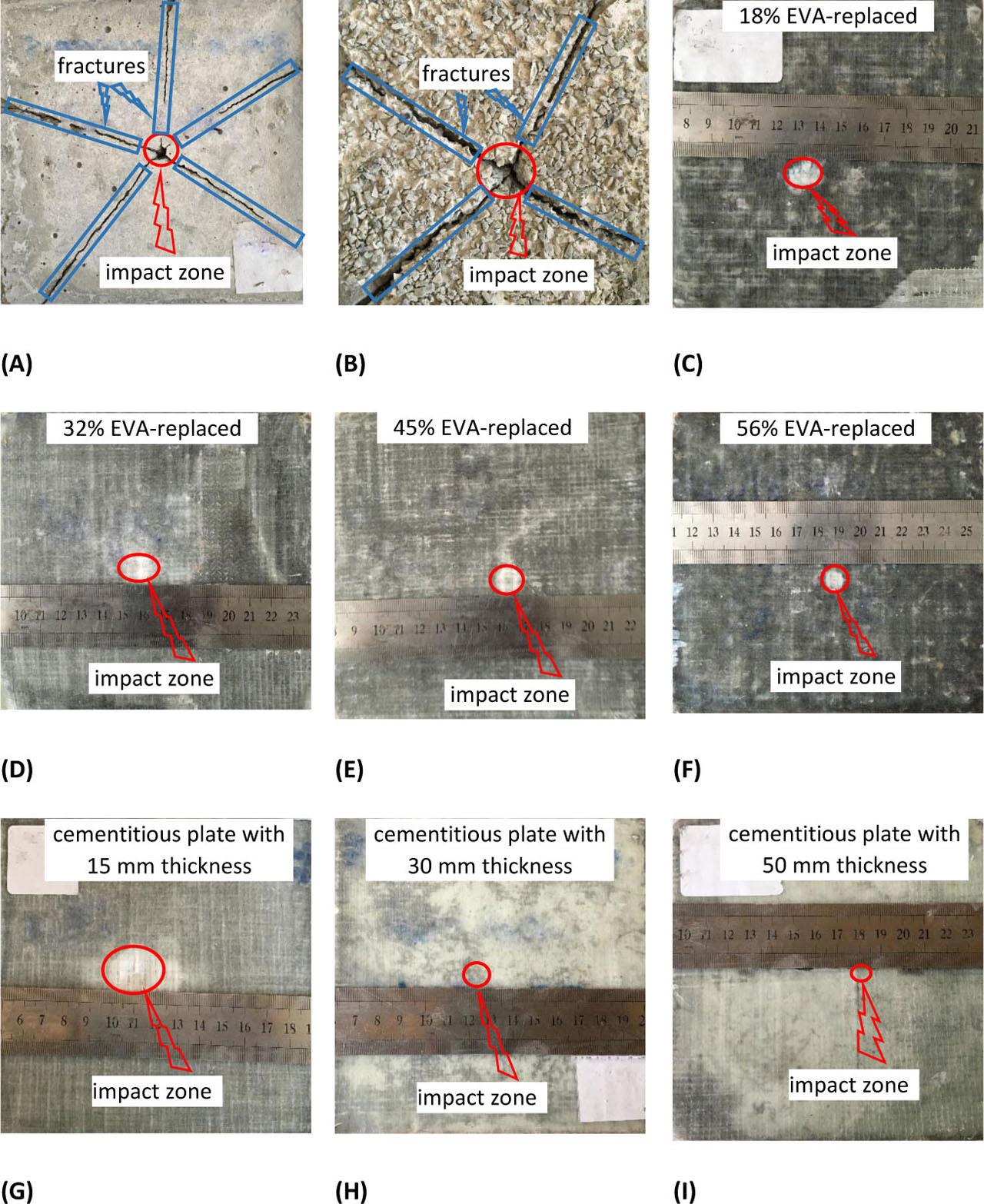

Fig. 3

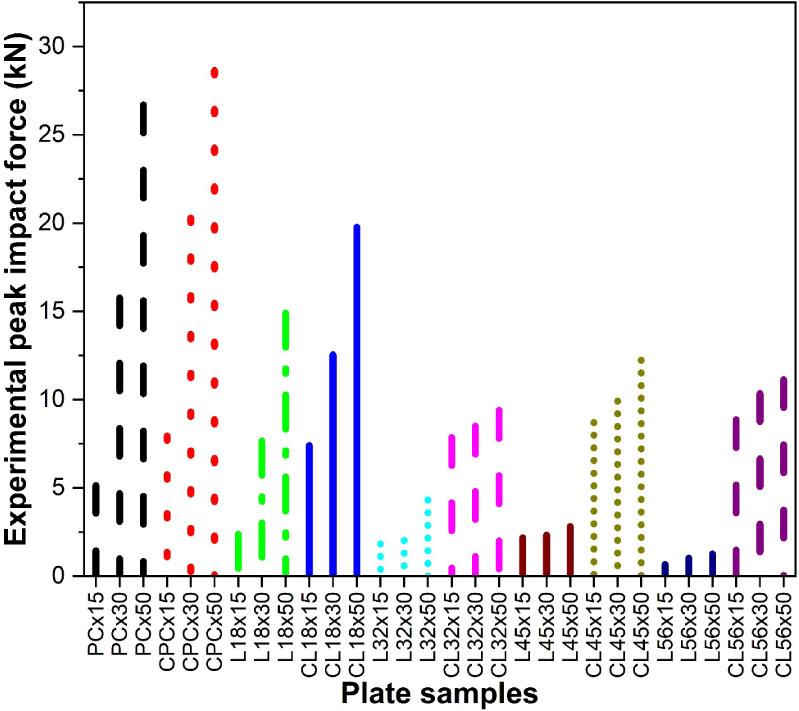

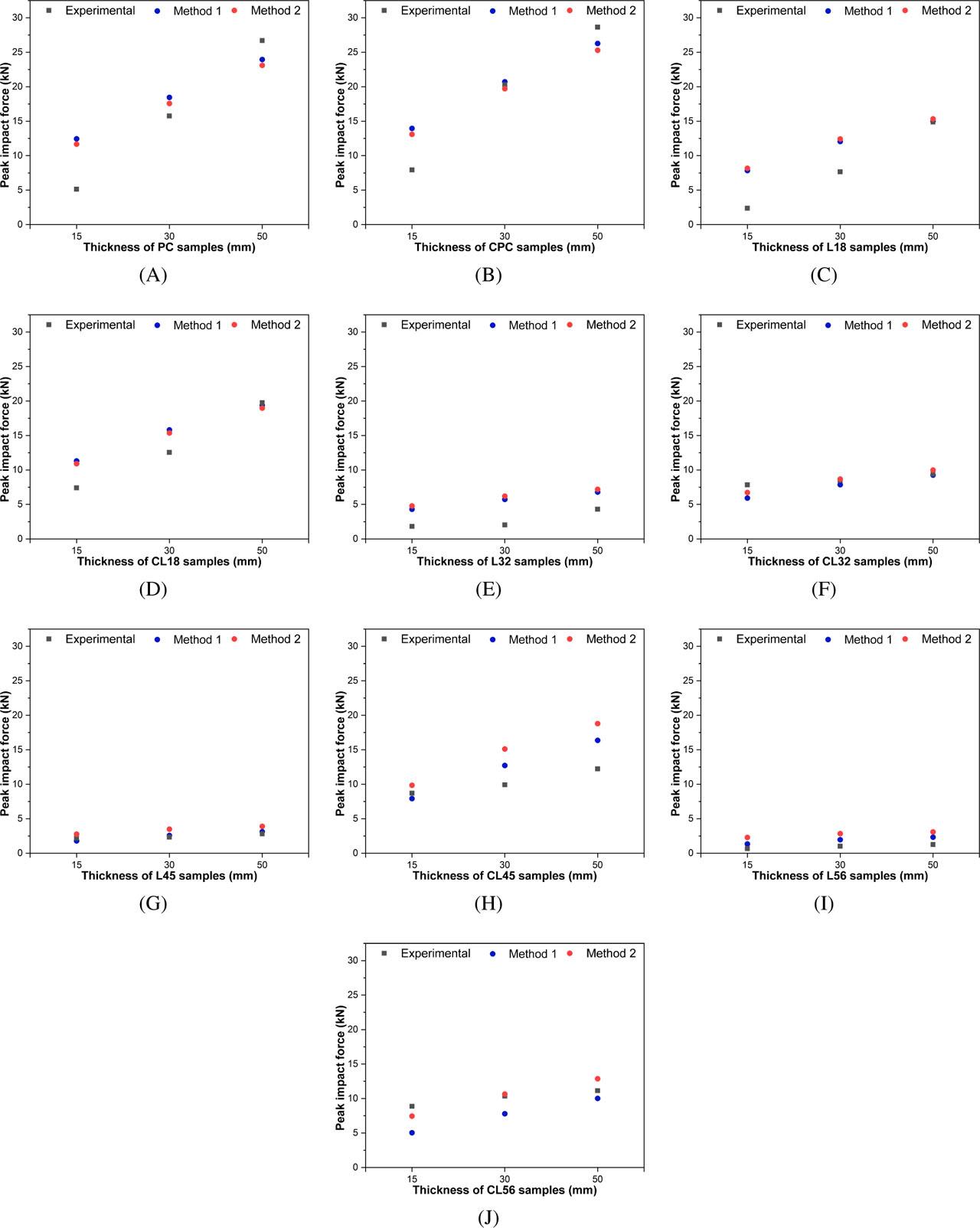

Fig. 4

Fig. 5

Fig. 6

Fig. 7

Fig. 8

Fig. 9

![Mass-plate impact sketch and equivalent system [30]](https://sciendo-parsed.s3.eu-central-1.amazonaws.com/647252b2215d2f6c89dc41de/j_msp-2021-0041_fig_009.jpg?X-Amz-Algorithm=AWS4-HMAC-SHA256&X-Amz-Content-Sha256=UNSIGNED-PAYLOAD&X-Amz-Credential=AKIA6AP2G7AKOUXAVR44%2F20251204%2Feu-central-1%2Fs3%2Faws4_request&X-Amz-Date=20251204T150711Z&X-Amz-Expires=3600&X-Amz-Signature=17452e57b516f9beb135c62502476e7dbc8642240487ae9d6028e3a8f8745e4c&X-Amz-SignedHeaders=host&x-amz-checksum-mode=ENABLED&x-id=GetObject)

Fig. 10

Properties of glass fiber woven fabric

| Fiber type | Woven fabric (g/m2) |

|---|---|

| Areal weight | 600 g (±5%) |

| Style/Pattern | Biax 0–90 – stitch |

| Tensile strength | 3,500 (MPa) |

| Tensile modulus | 72 (GPa) |

Concrete mix design

| Sample | Weight cement (kg) | Weight water (kg) | Weight plasticizer (kg) | Weight aggregate (kg) | Weight EVA (kg) |

|---|---|---|---|---|---|

| PC | 507.28 | 253.64 | 2.54 | 1,521.83 | 0 |

| L18 | 507.28 | 253.64 | 2.54 | 1,369.65 | 61.46 |

| L32 | 507.28 | 253.64 | 2.54 | 1,217.47 | 122.92 |

| L45 | 507.28 | 253.64 | 2.54 | 1,065.28 | 184.38 |

| L56 | 507.28 | 253.64 | 2.54 | 913.10 | 245.83 |

Properties of the materials that make up cementitious plates

| Materials | Properties | Type |

|---|---|---|

| Cement | Density: 3.15 (g/cm3) | Type I blane fineness: 3,250 (kg/m2) |

| Aggregates | Density: 2.6 (g/cm3) | Sand 4 mm |

| EVA | Density: 0.55 (g/cm3) | 2–4 mm |

| Water | Potable | |

| Superplasticizer | Specific gravity (20°C): 1.069–1.109 (kg/l) | Polycarboxylic ether based |

Properties of resin epoxy and resin hardener

| L160 | H160 | |

|---|---|---|

| Density (g/cm3) | 1.13–1.17 | 0.96–1.00 |

| Viscosity (MPa) | 700–900 | 10–50 |

| Epoxy equivalent (g/equivalent) | 166–182 | |

| Epoxy value (value/100 g) | 0.55–0.60 | |

| Refractor index | 1.5480–1.5530 | 1.5200–1.5210 |

| Measurement conditions | 25°C | 25°C |

| Flexural strength (MPa) | 110–140 | |

| Modulus of elasticity (GPa) | 3.2–3.5 | |

| Tensile strength (MPa) | 70–80 | |

| Elongation at break (%) | 5.0–6.5 |

Nomenclature of the produced cementitious plate samples

| Plate designation | Replacement ratio of EVA (by volume) | Coating GFRP |

|---|---|---|

| PC | 0 | – |

| L18 | 18 | – |

| L32 | 32 | – |

| L45 | 45 | – |

| L56 | 56 | – |

| CPC | 0 | Coated |

| CL18 | 18 | Coated |

| CL32 | 32 | Coated |

| CL45 | 45 | Coated |

| CL56 | 56 | Coated |