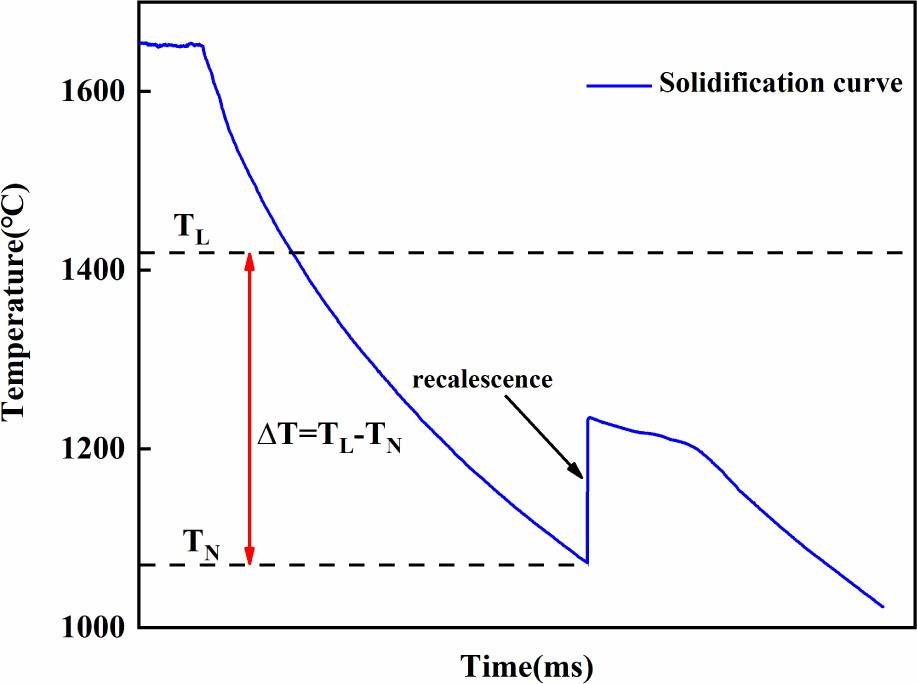

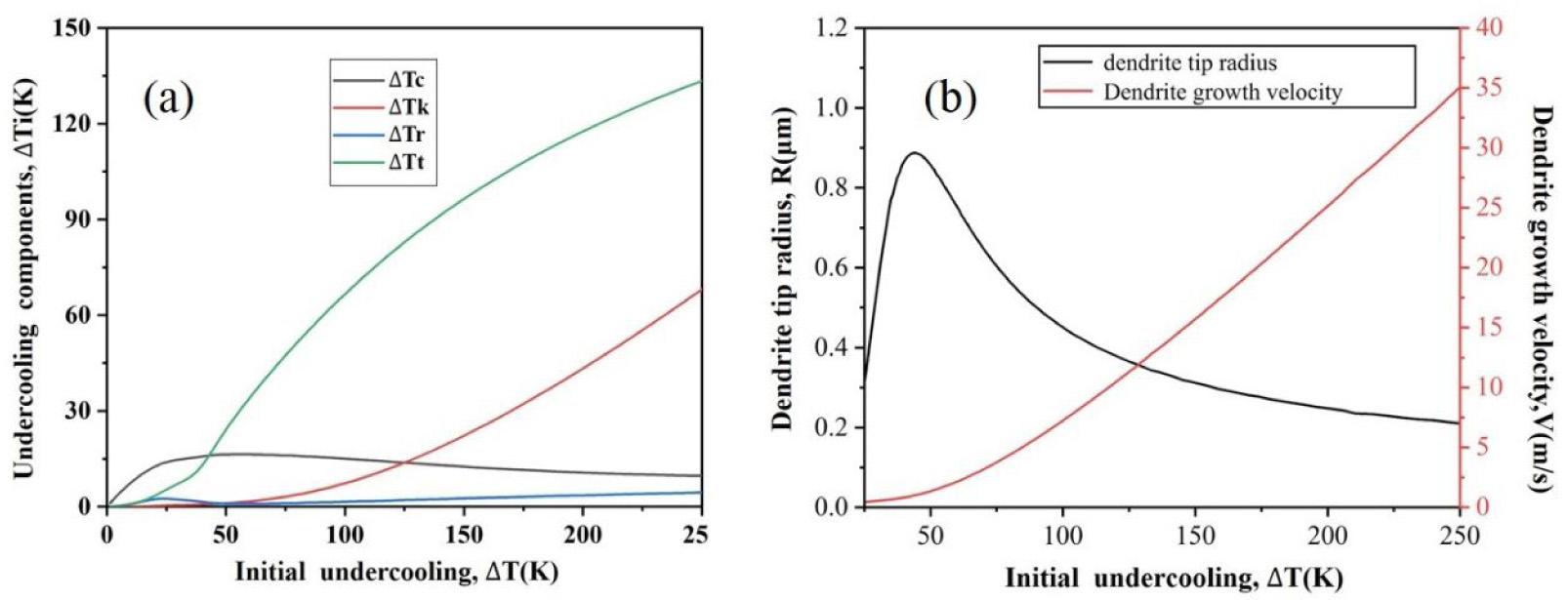

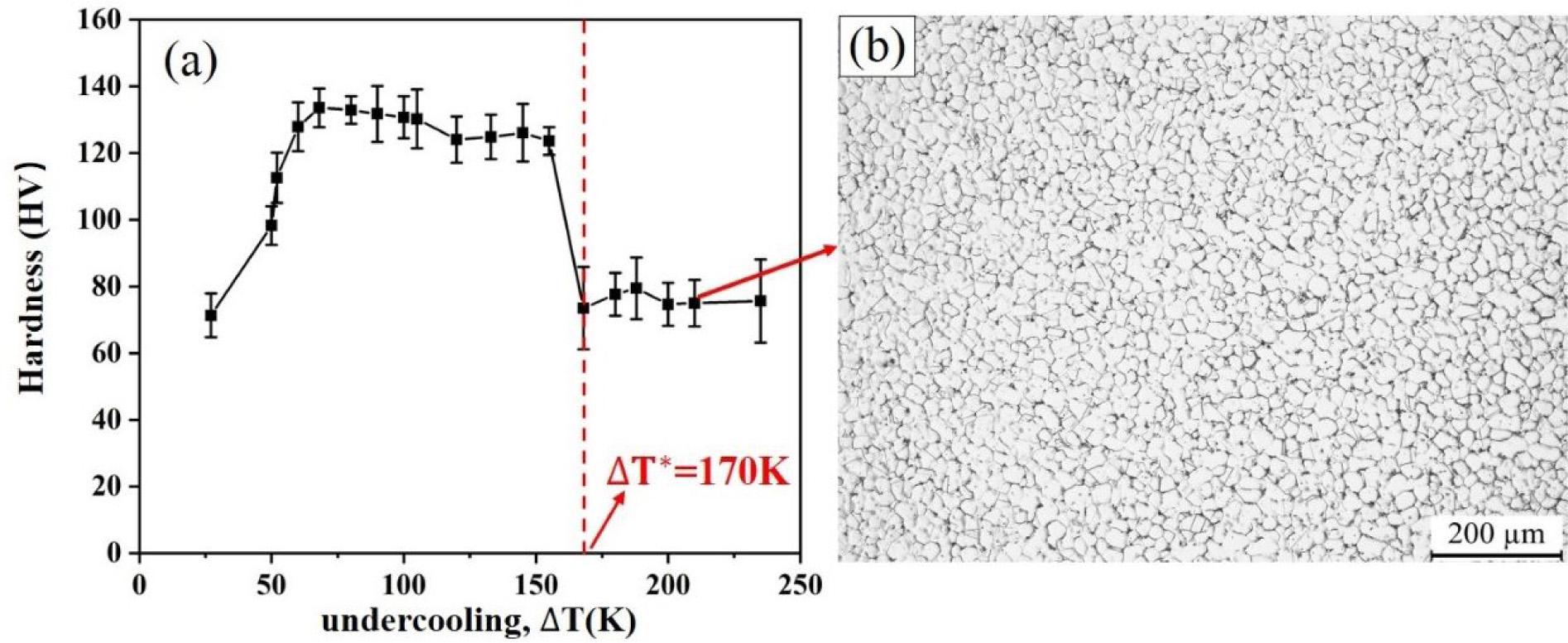

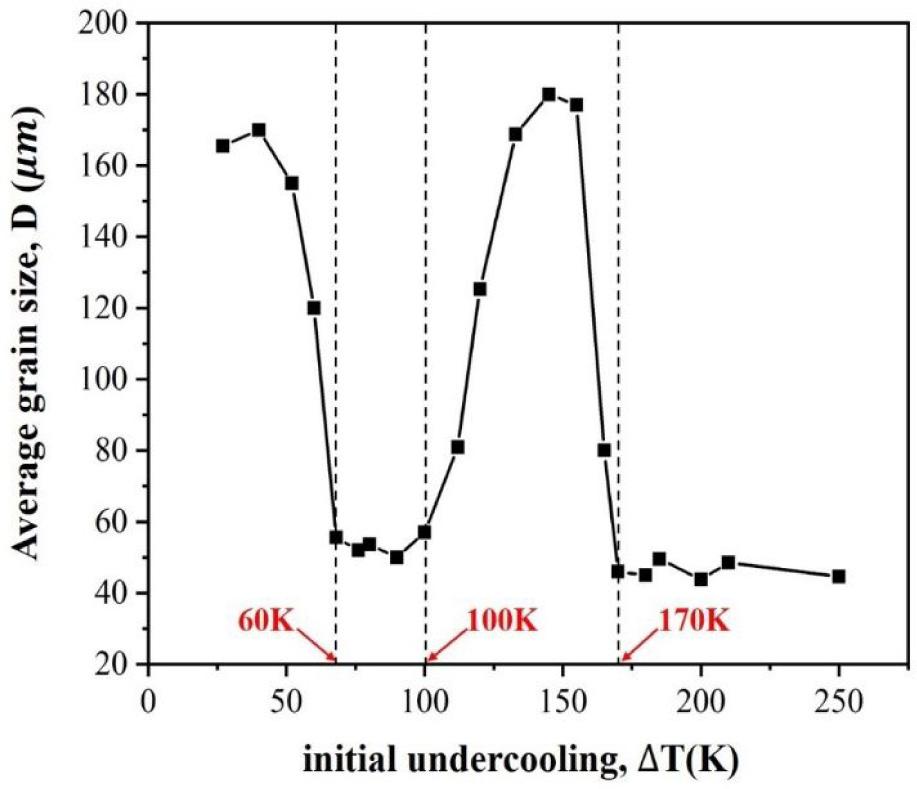

Fig. 1

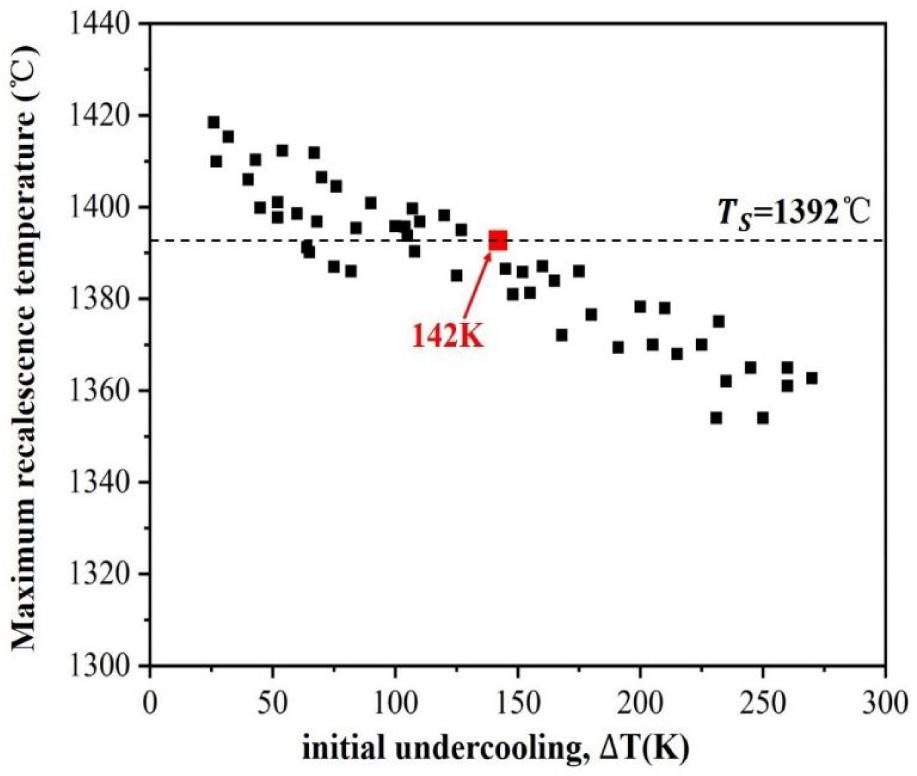

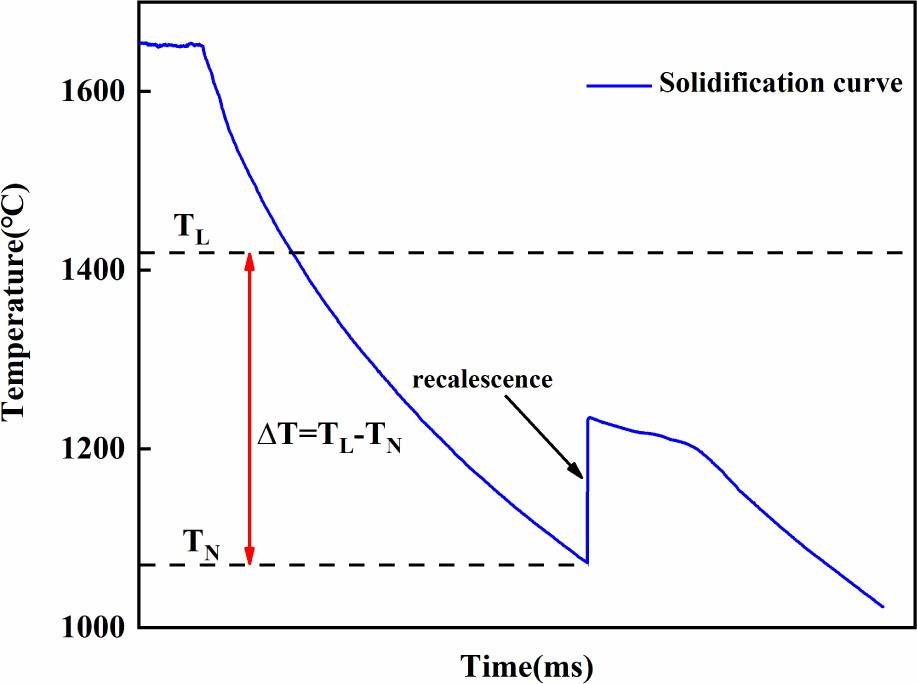

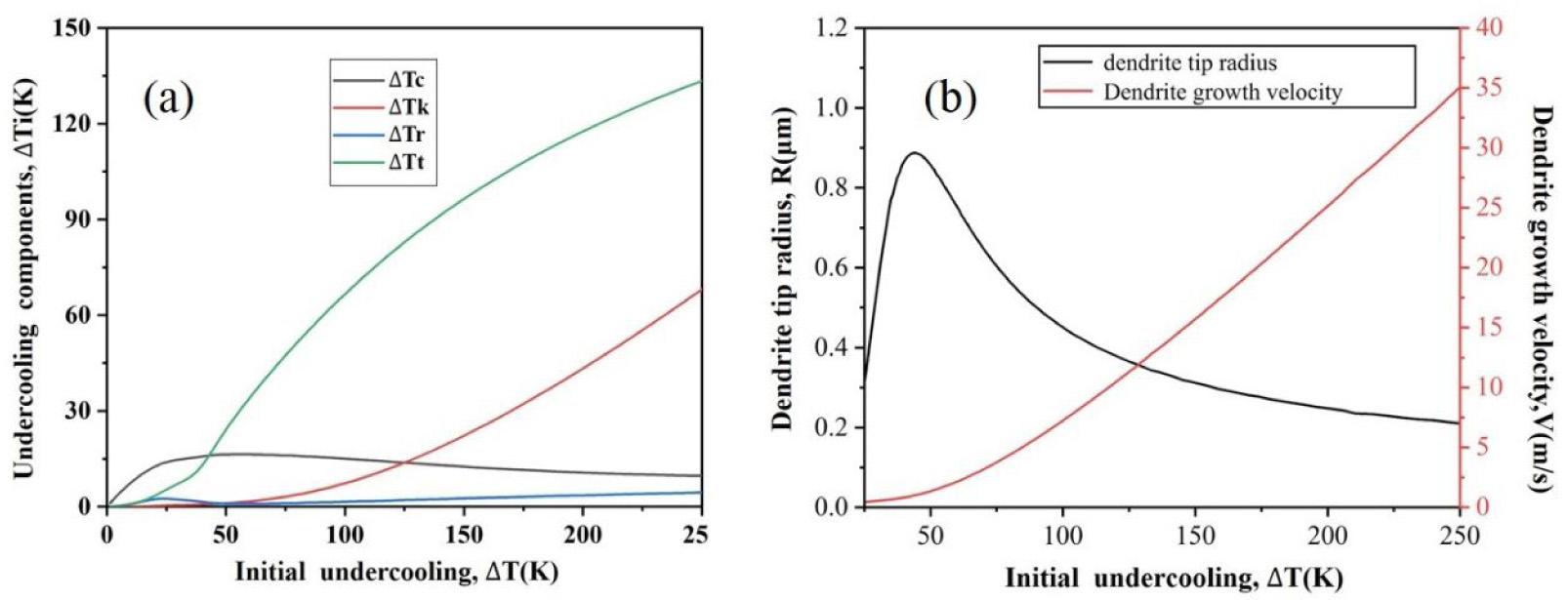

Fig. 2

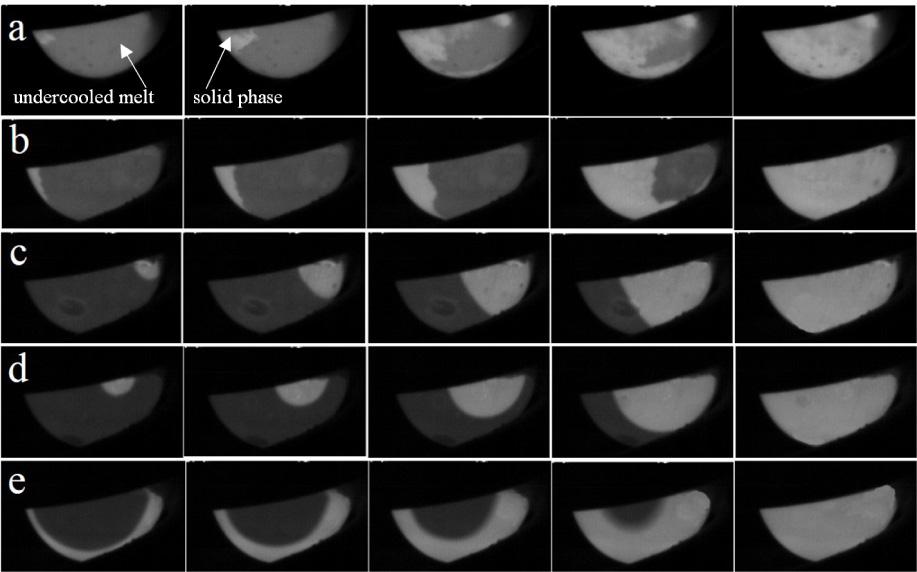

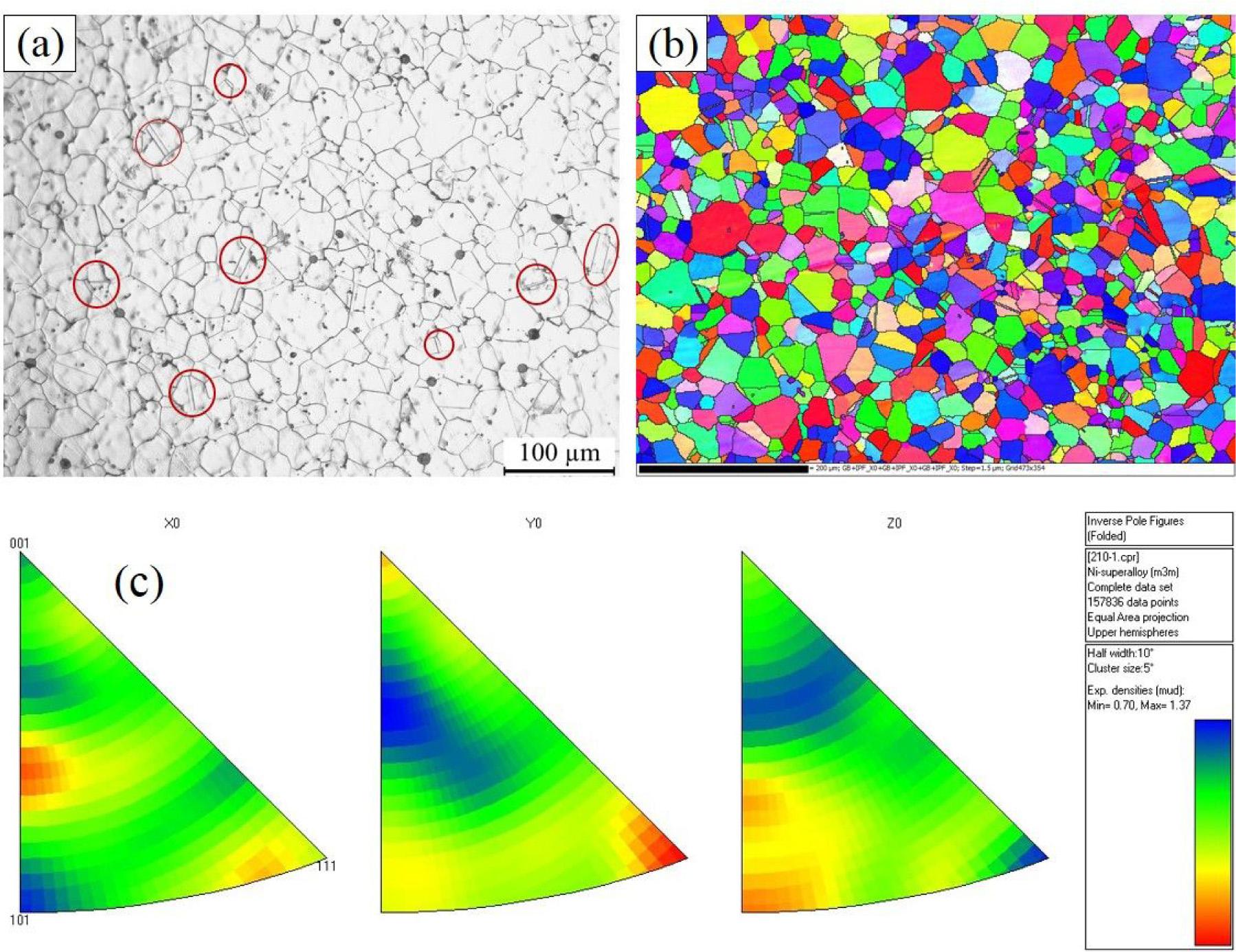

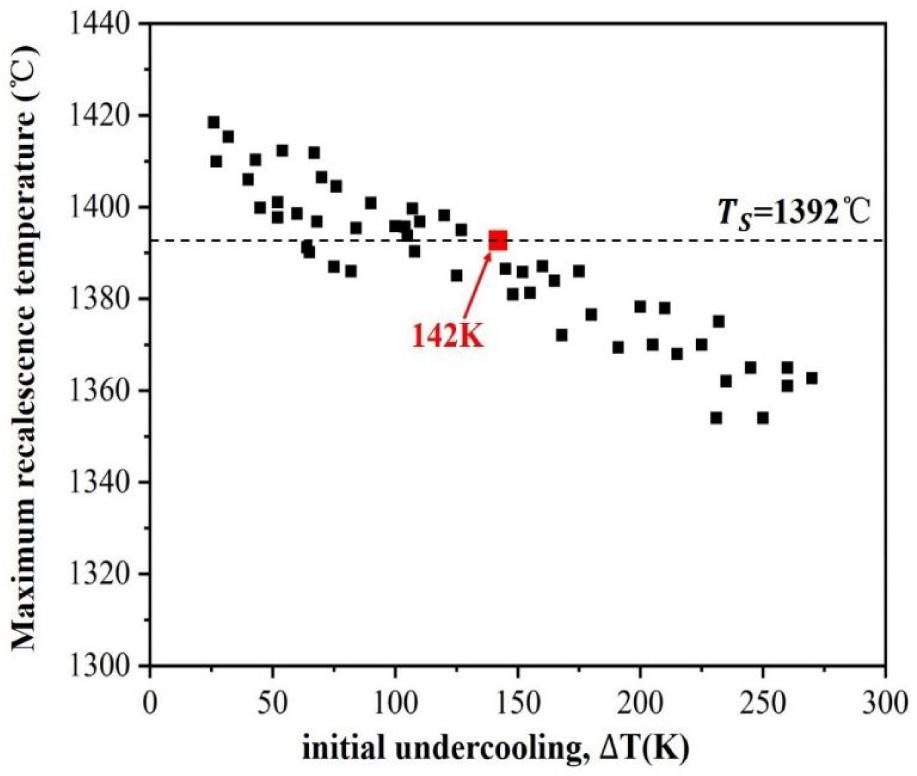

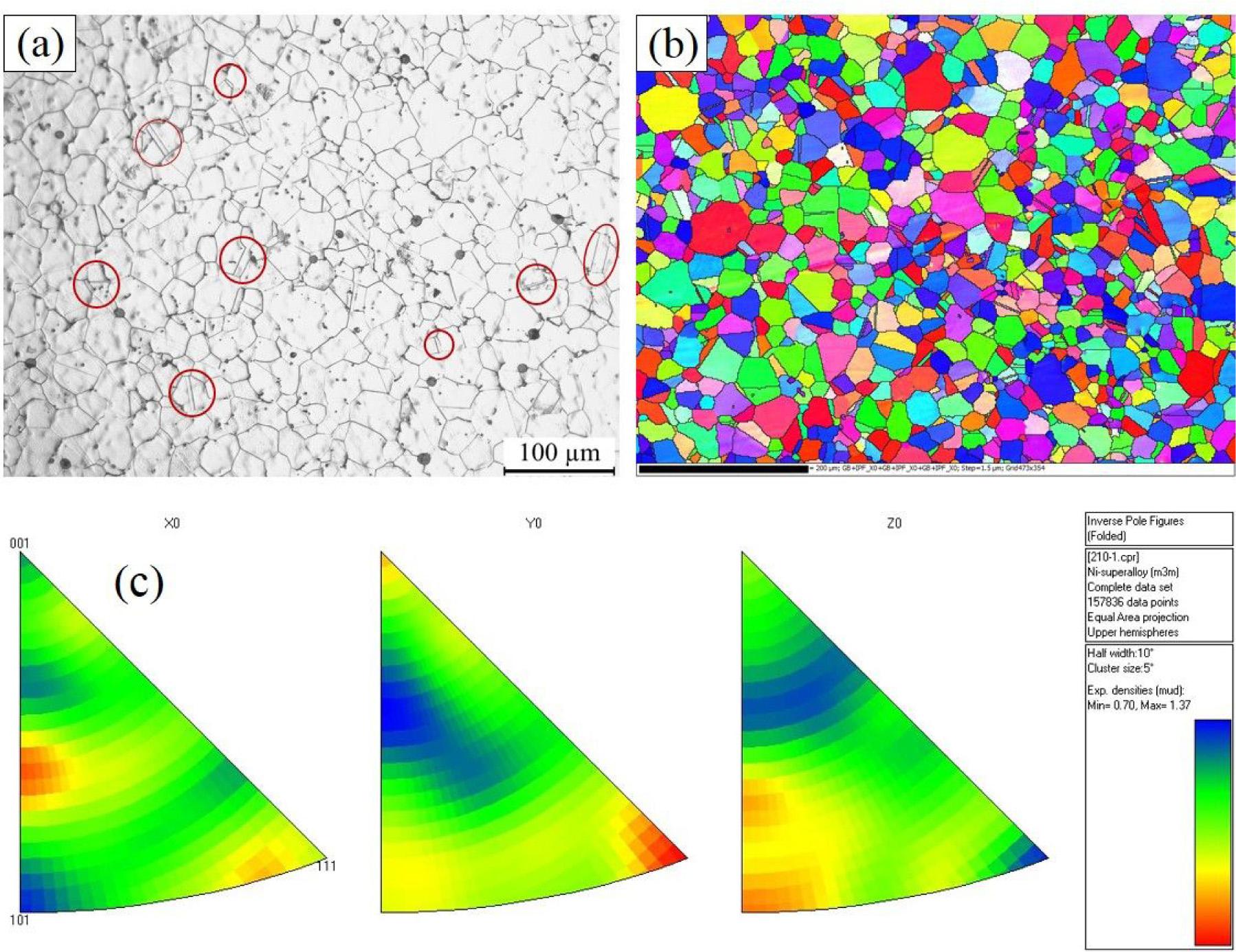

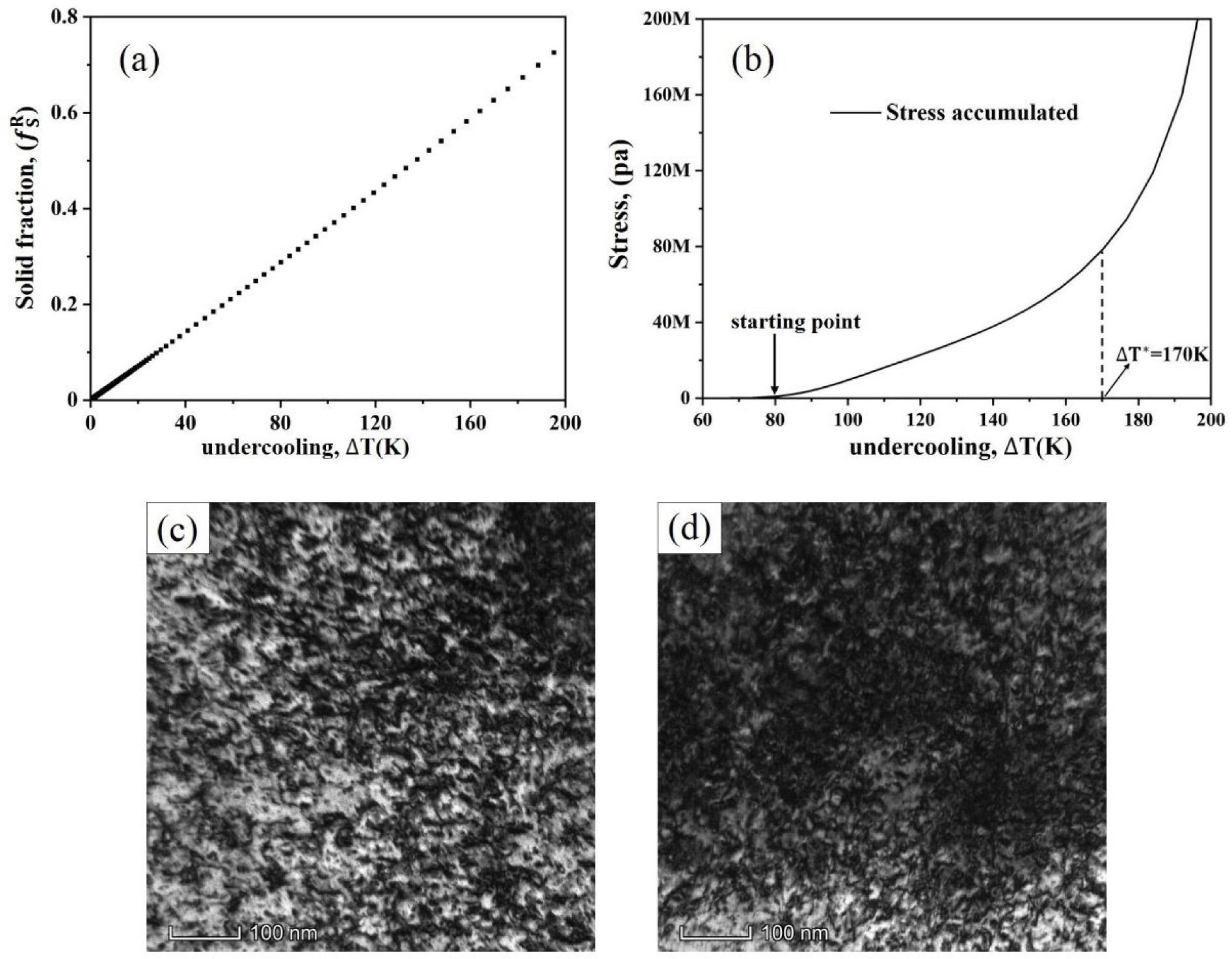

Fig. 3

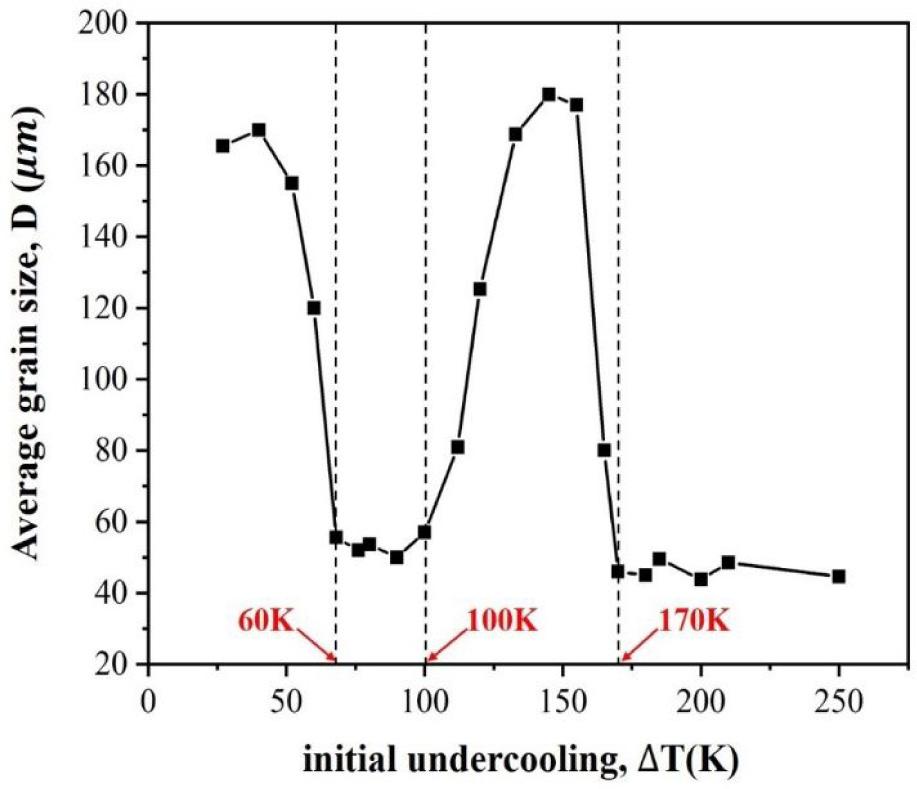

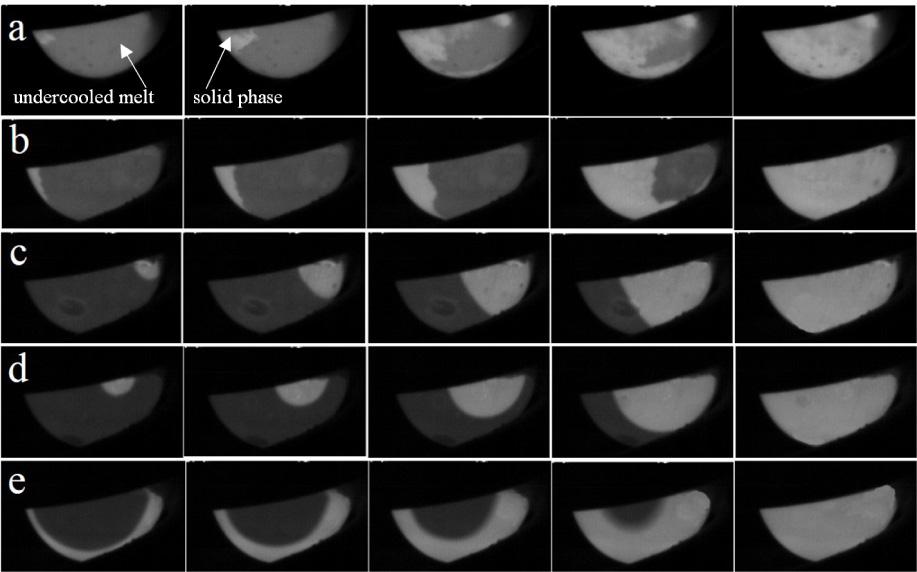

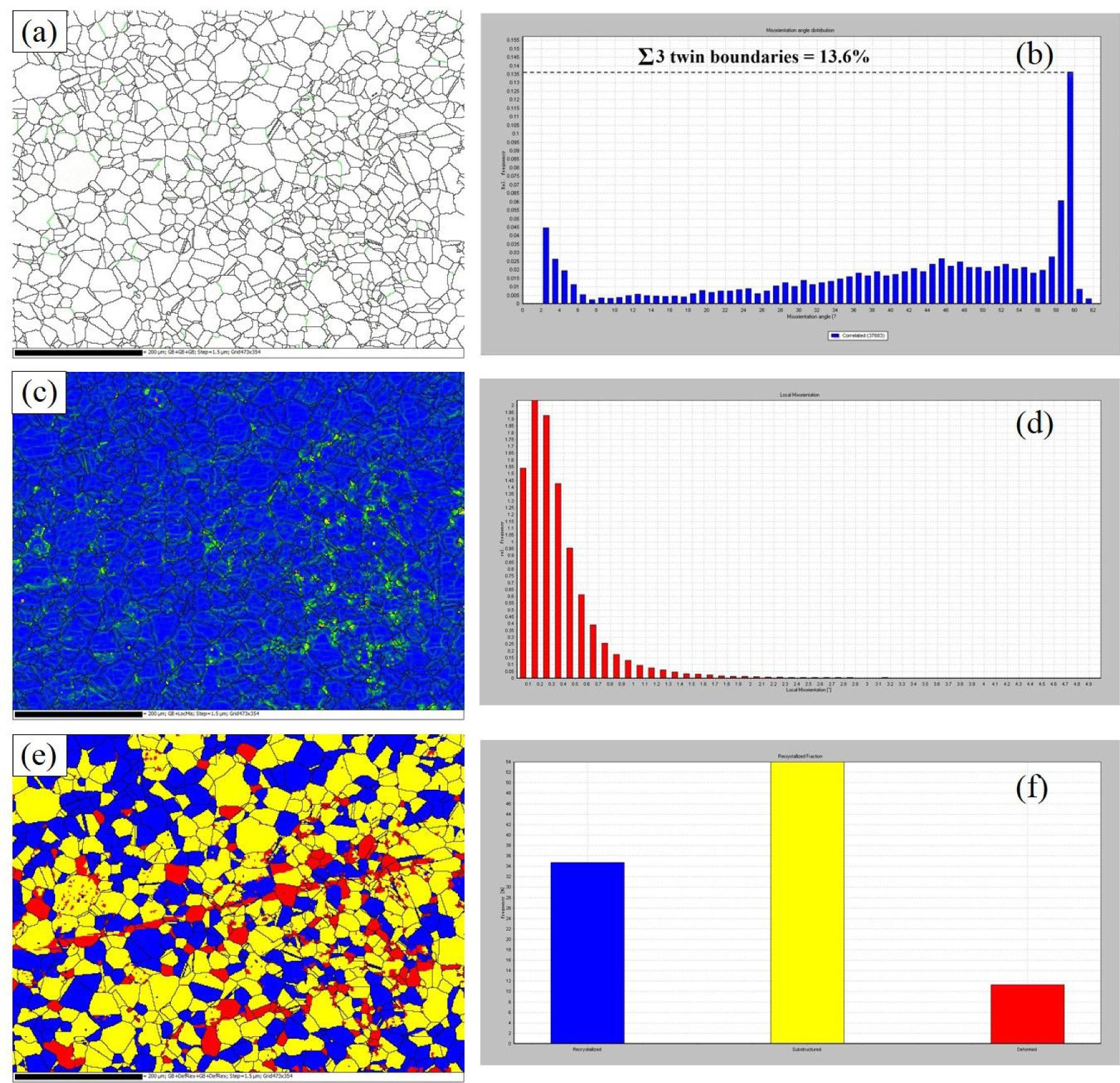

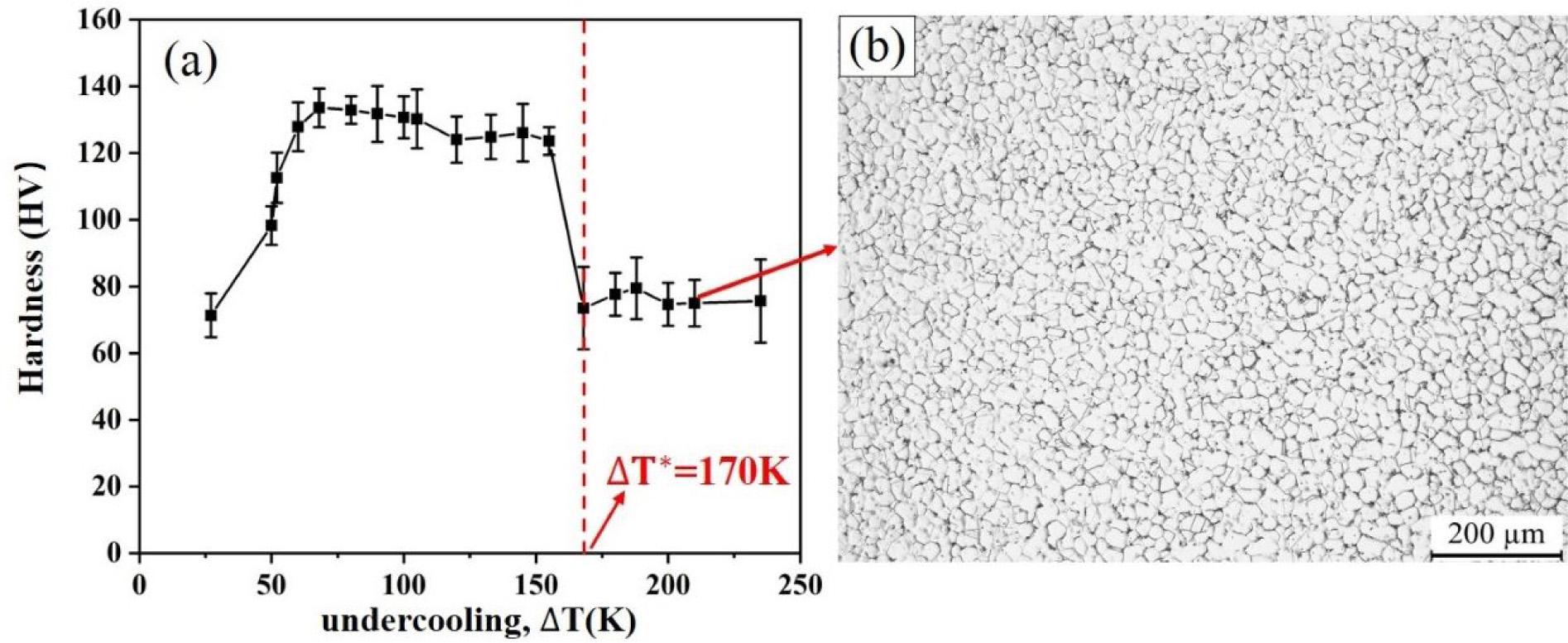

Fig. 4

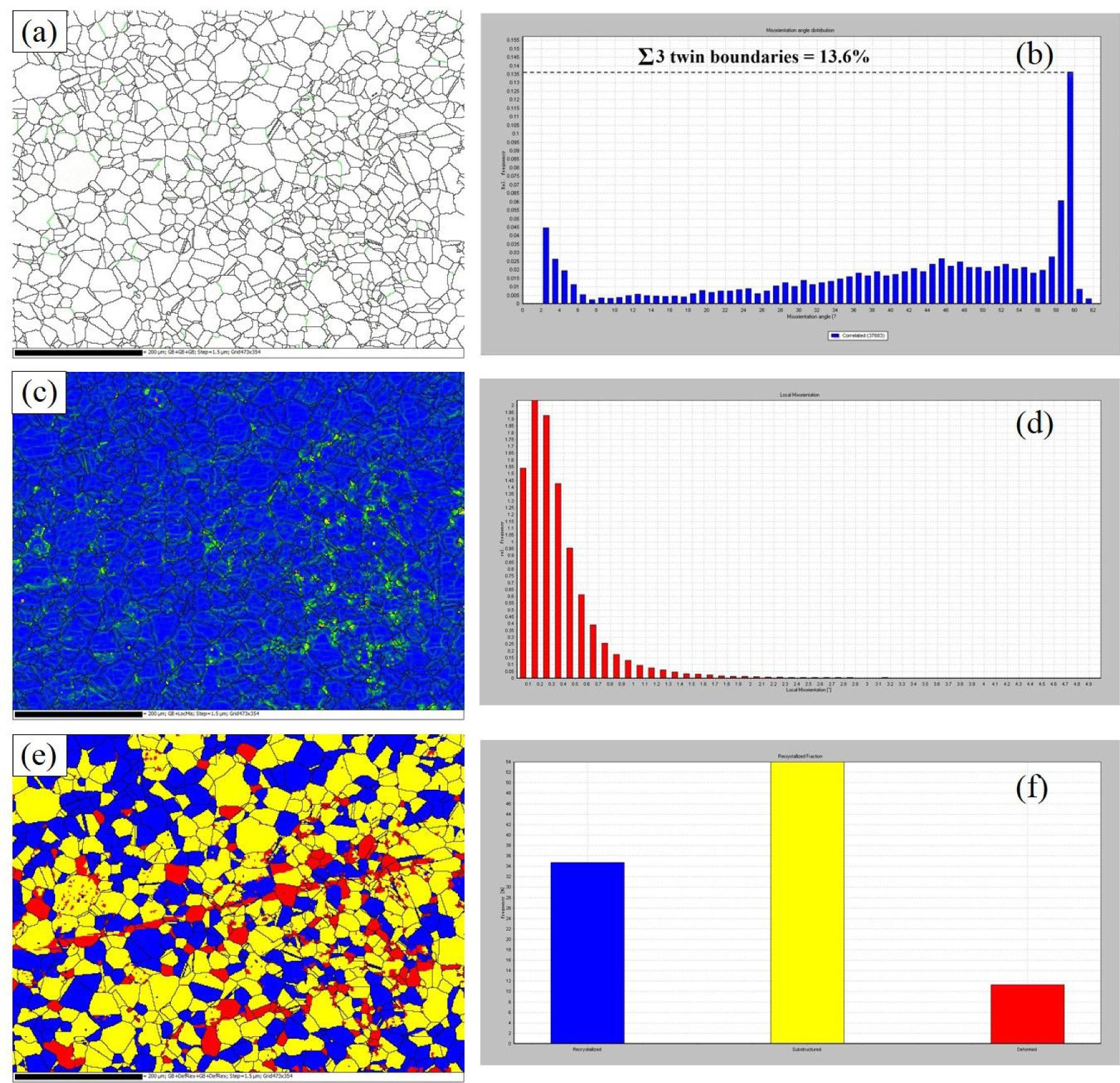

Fig. 5

Fig. 6

Fig. 7

Fig. 8

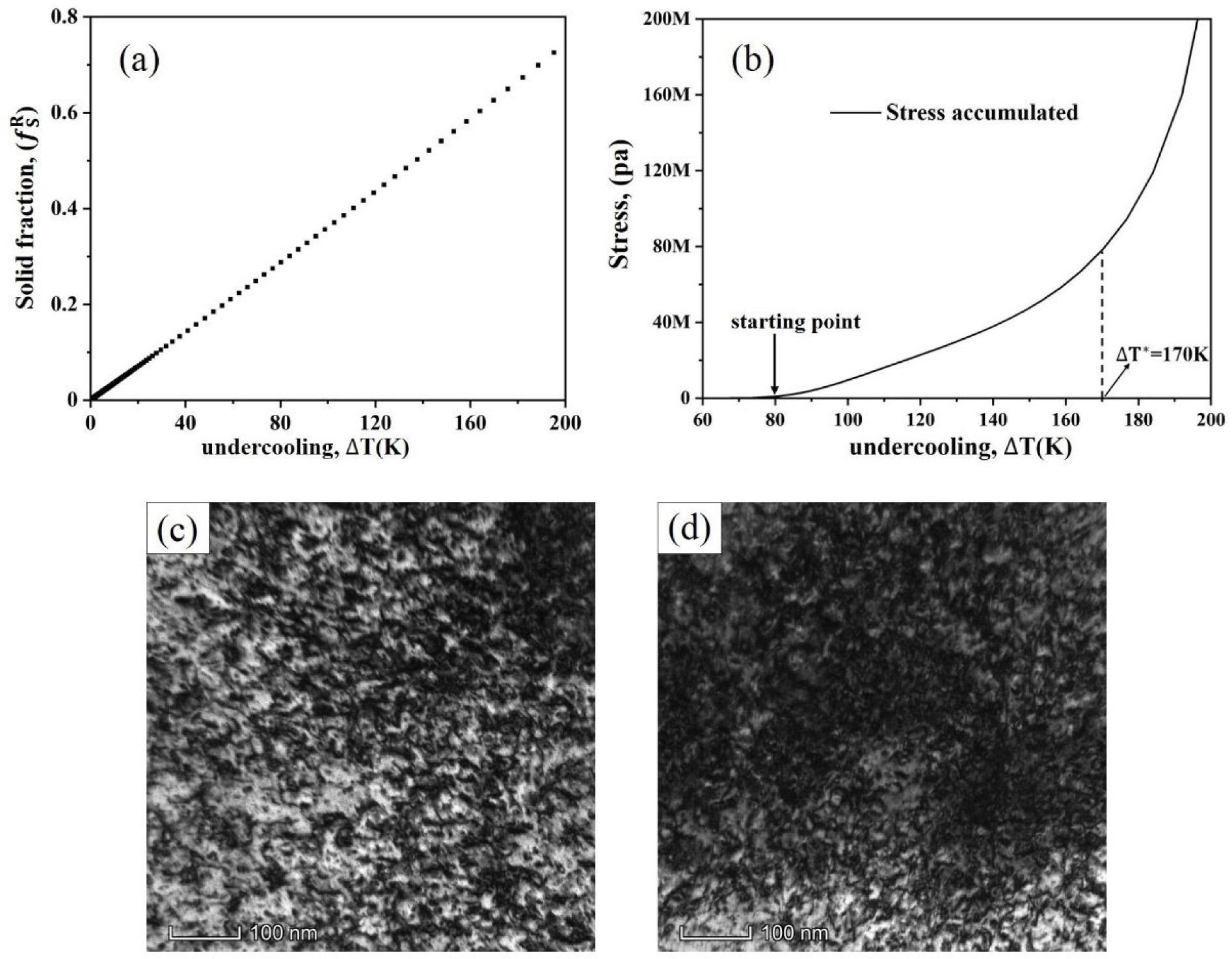

Fig. 9

Fig. 10

Fig. 11

Fig. 12

© 2021 Hongfu Wang, Cheng Tang, Hongen An, Yuhong Zhao, published by Wroclaw University of Science and Technology

This work is licensed under the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 License.