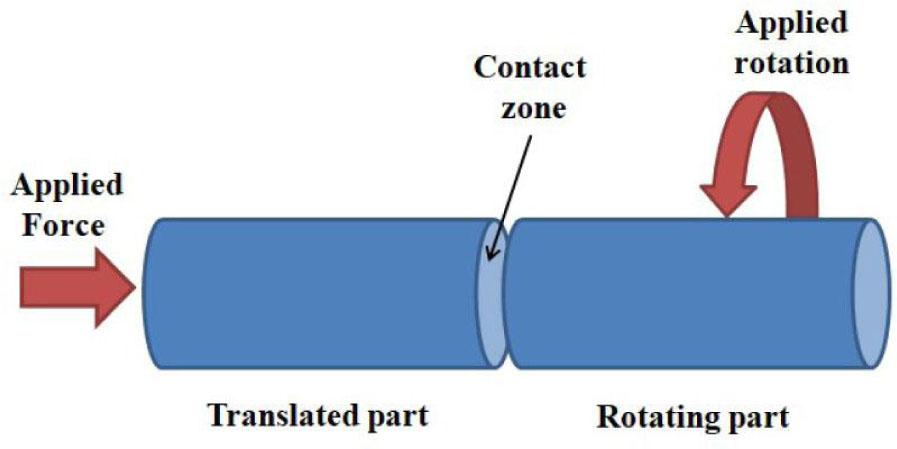

Fig. 1

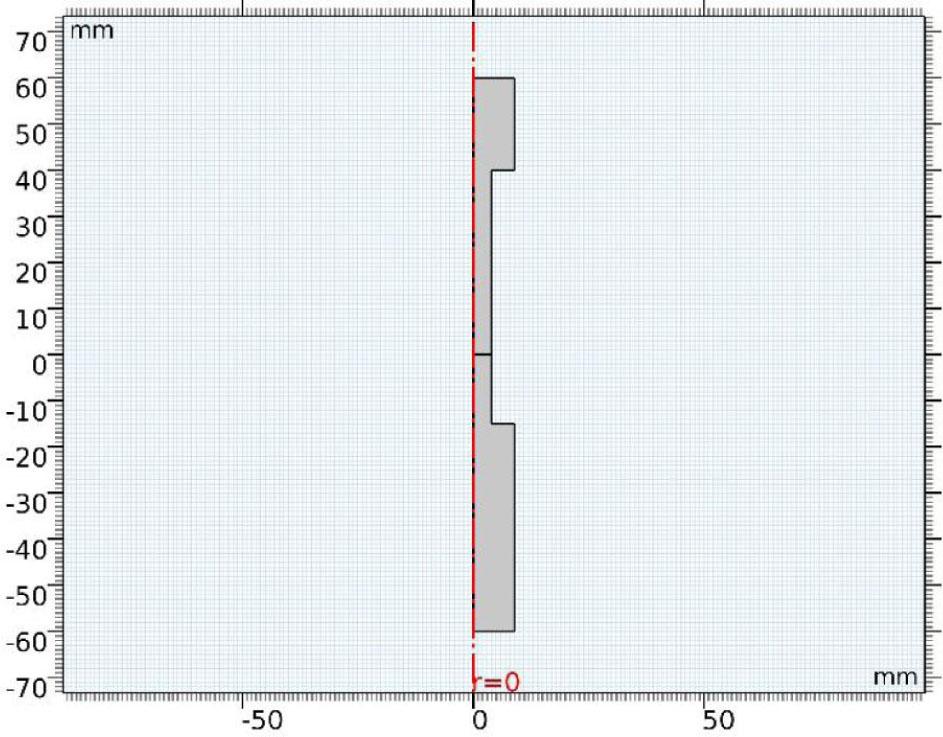

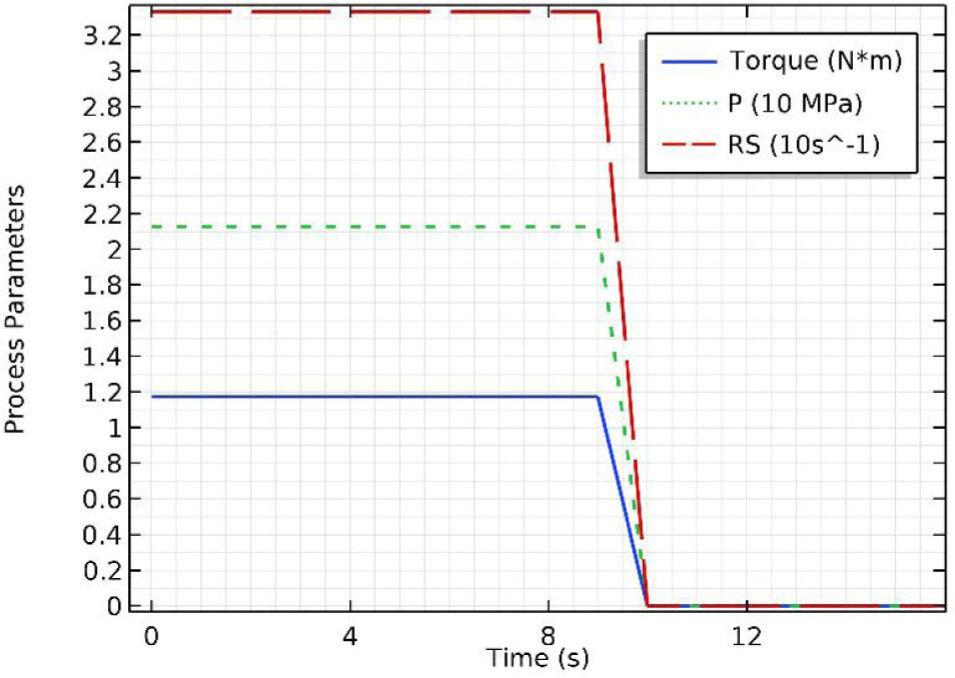

Fig. 2

![Welding parameters for CDFW. [1]](https://sciendo-parsed.s3.eu-central-1.amazonaws.com/64725239215d2f6c89dc418d/j_msp-2021-0001_fig_002.jpg?X-Amz-Algorithm=AWS4-HMAC-SHA256&X-Amz-Content-Sha256=UNSIGNED-PAYLOAD&X-Amz-Credential=AKIA6AP2G7AKOUXAVR44%2F20251204%2Feu-central-1%2Fs3%2Faws4_request&X-Amz-Date=20251204T131712Z&X-Amz-Expires=3600&X-Amz-Signature=18ea5acee0a549ee346cf17b9f140883cd8390d4d0bcf3230b79f1f6c99c4a94&X-Amz-SignedHeaders=host&x-amz-checksum-mode=ENABLED&x-id=GetObject)

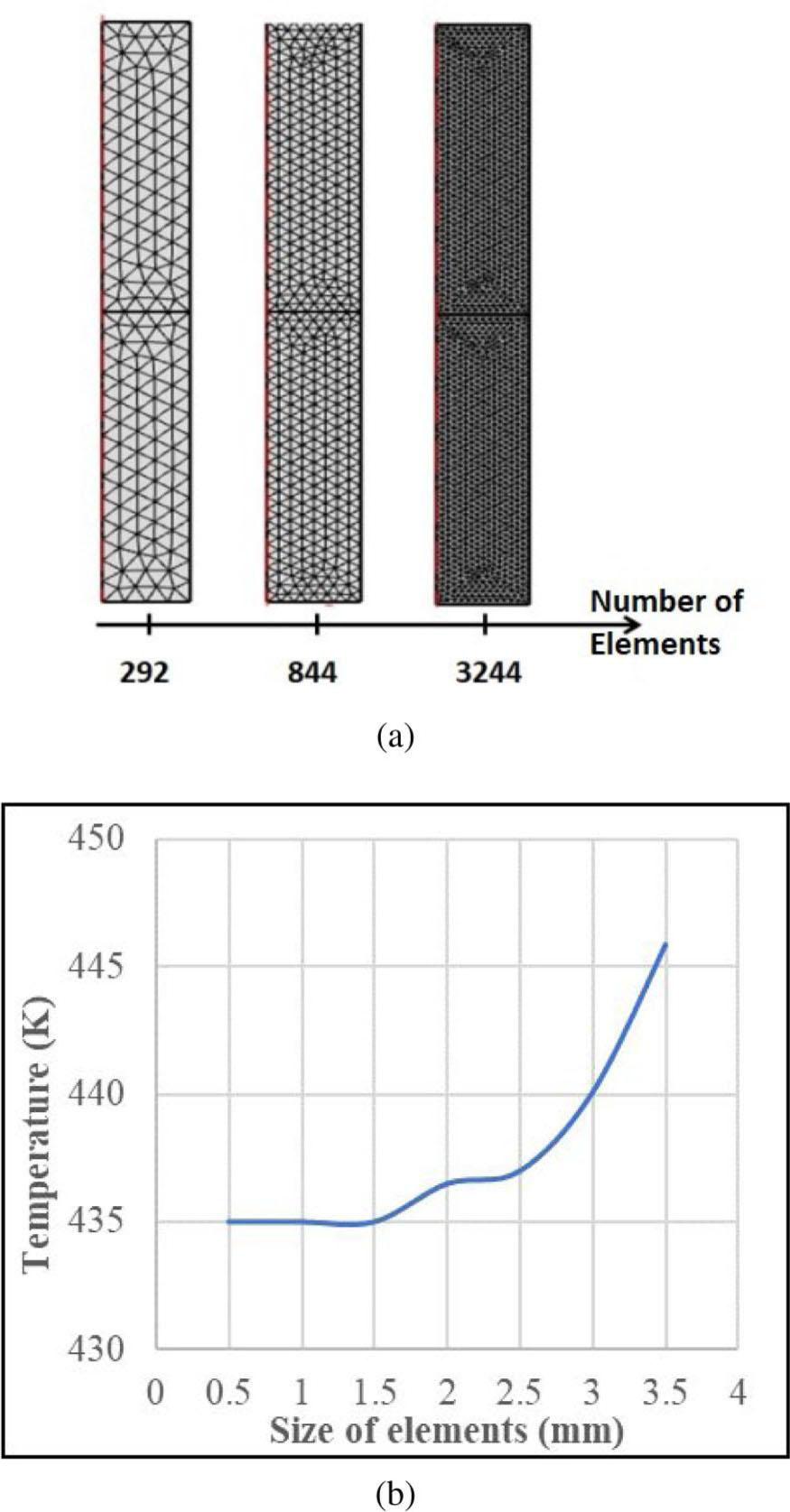

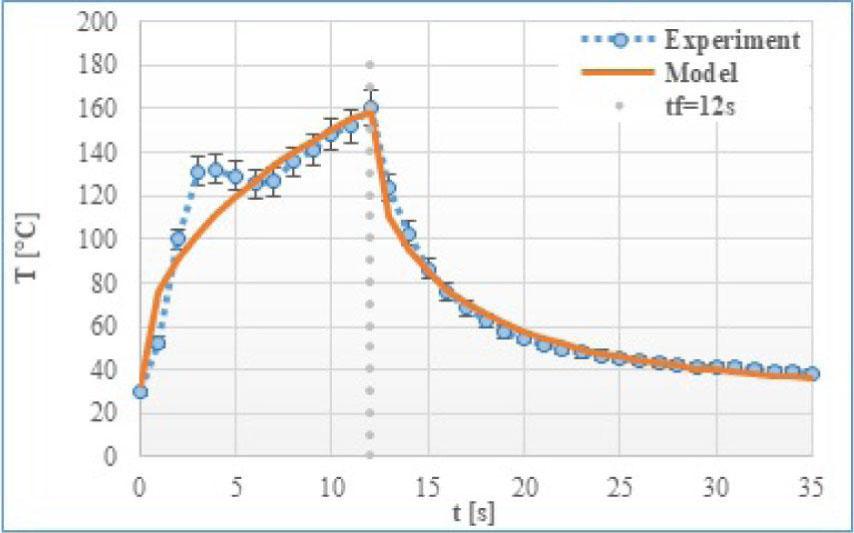

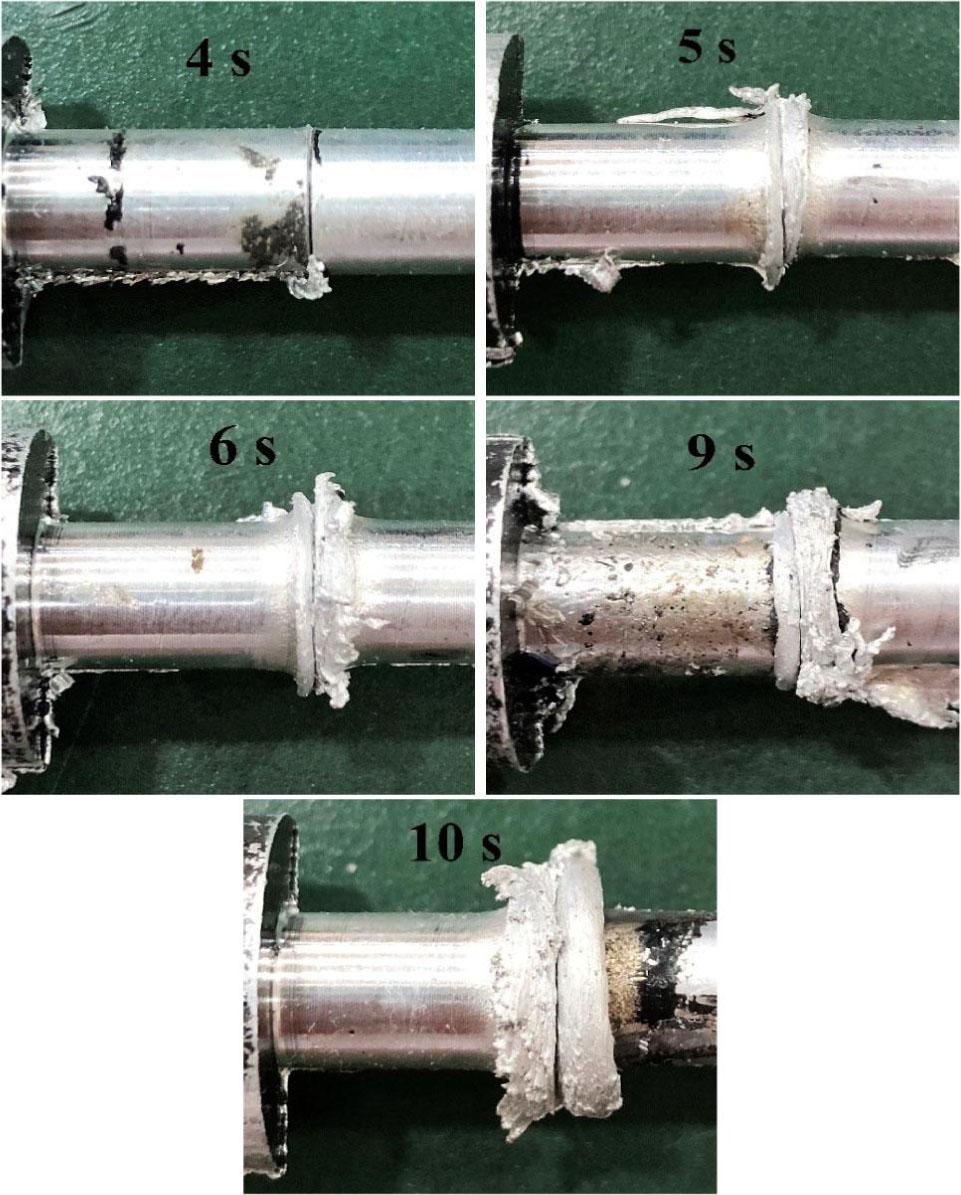

Fig. 3

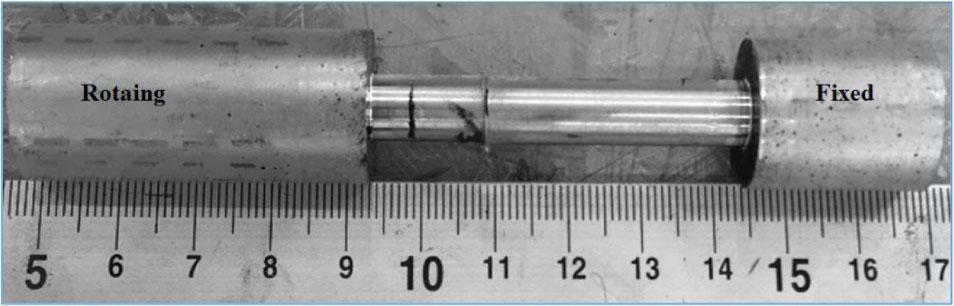

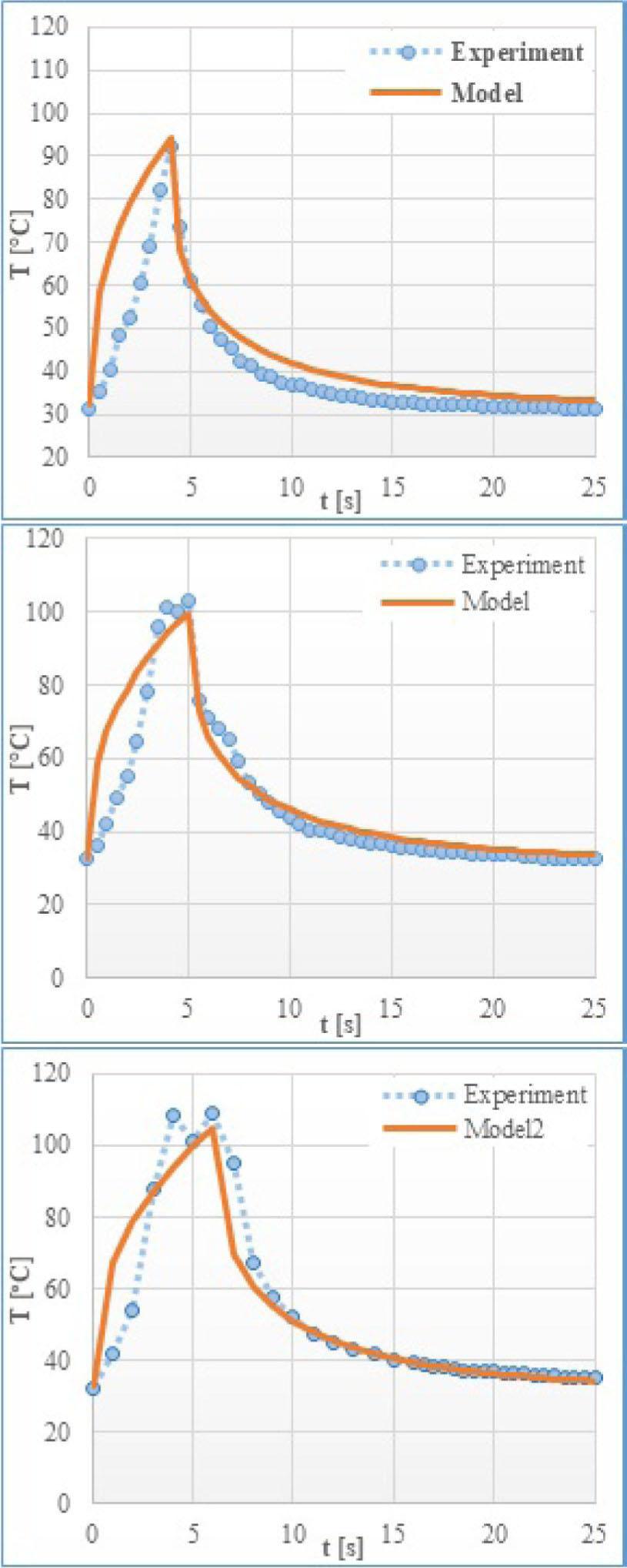

Fig. 4

Fig. 5

Fig. 6

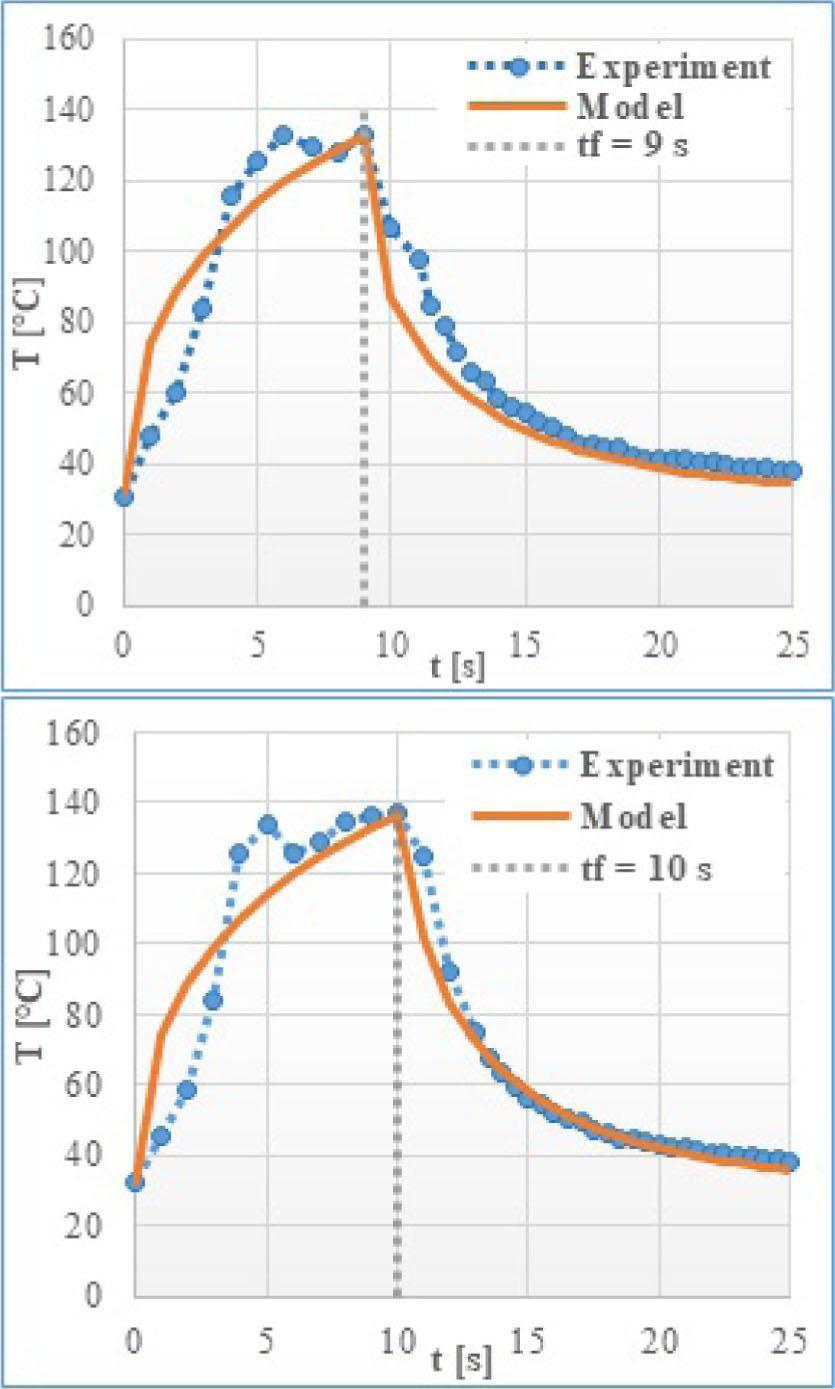

Fig. 7

Fig. 8

Fig. 9

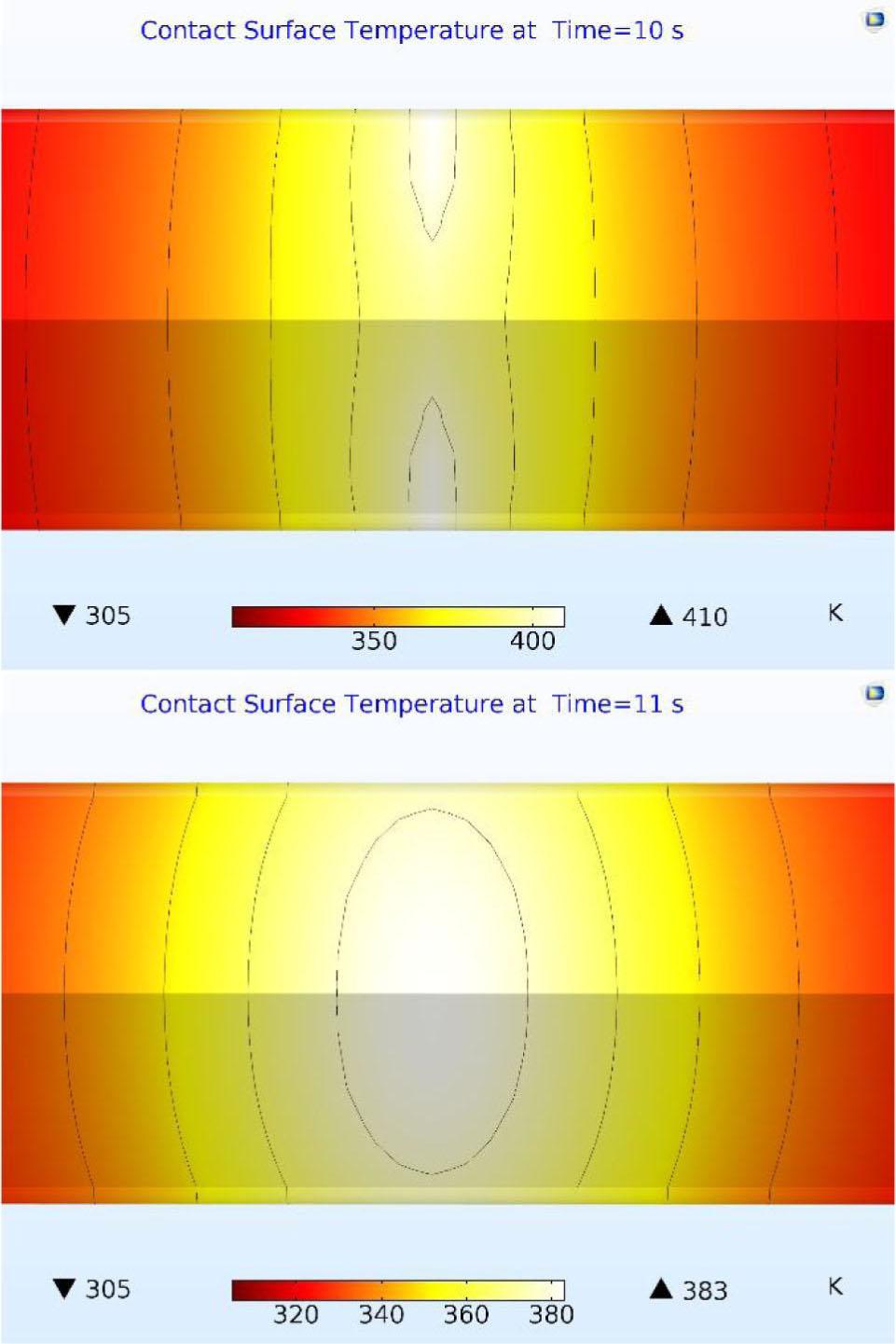

Fig. 10

Fig. 11

Fig. 12

Fig. 13

Fig. 14

Fig. 15

Fig. 16

Fig. 17

Fig. 18

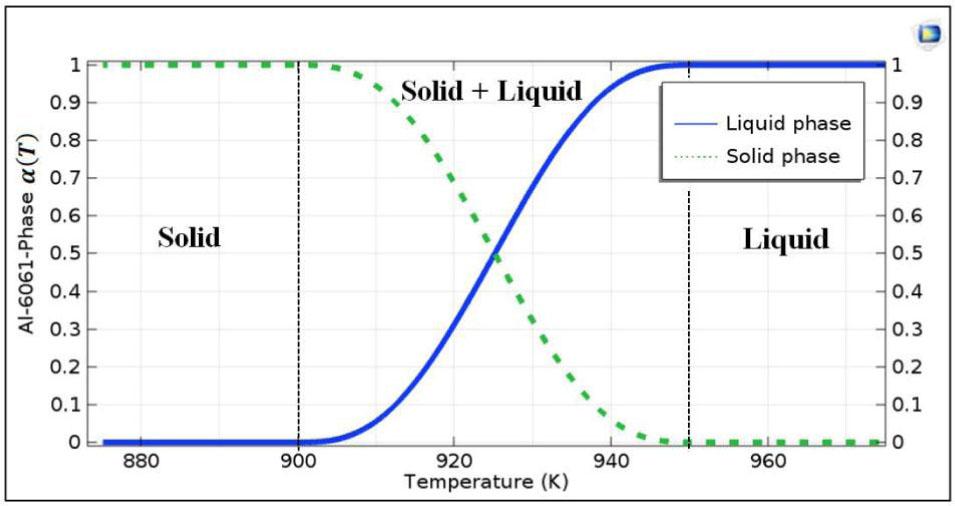

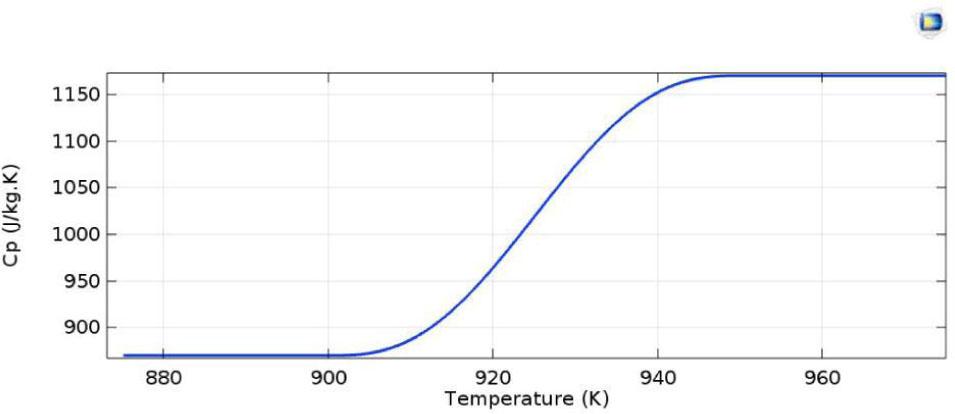

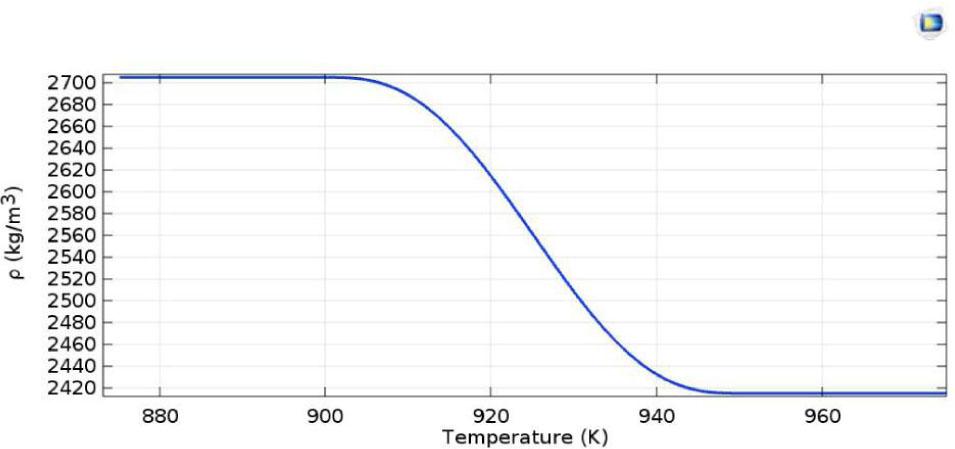

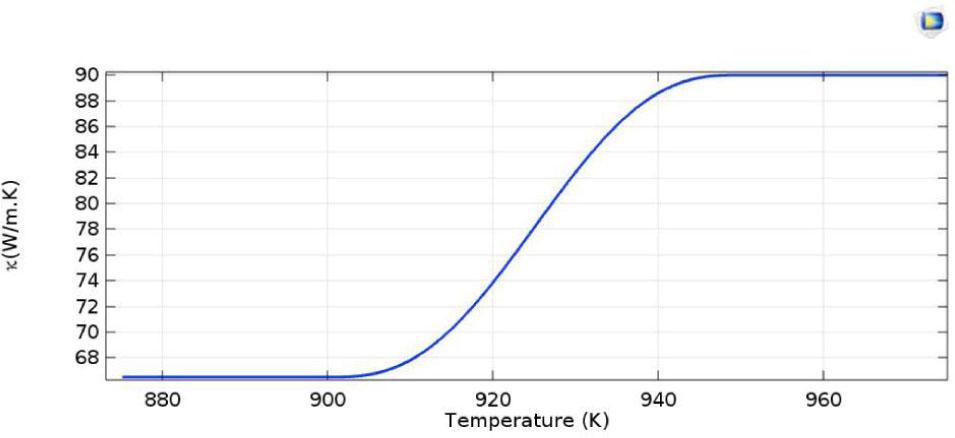

Al6061 material properties for phase-change simulation_ [16]

| Property | Value |

|---|---|

| Ttrans [K] | 925.15 |

| δT [K] | 50 |

| Δhf [kJ/kg] | 380 |

| ρsolid [kg/m3] | 2705 |

| ρliquid [kg/m3] | 2415 |

| Cp,solid [J/kg·K] | 870 |

| Cp,liquid [J/kg·K] | 1170 |

| κsolidus [W/m·K] | 66.5 |

| κliquid [W/m·K] | 90 |

CDFW process parameters_

| Process Parameter | Value / range |

|---|---|

| Rotational Speed (rpm) | 2000 |

| Friction Pressure (MPa) | 21 |

| Friction time (s) | 4, 5, 6, 9, 10, 12 |

FEM boundary conditions_

| Model | Feature | Boundary Condition |

|---|---|---|

| Solid Mechanics | The central axis of the parts | Axial Symmetry |

| The outer surfaces of the parts | Free to deform | |

| The Entire model | Zero initial displacement | |

| The rotating part | Rigid motion suppression | |

| The end of the fixed part | Axial load | |

| Heat Transfer | T = 305 K | Initial temperature |

| The central axis of the parts | Axial symmetry | |

| The outer surfaces of the parts | Heat flux according to q0 = h · (Text − T) | |

| Welding Parameters | Rotation | 0 s to tf = rotation speed, otherwise zero |

| Pressure | 0 s to tf = applied pressure, otherwise zero | |

Chemical composition in weight percent of Al6061_

| Element | Si | Fe | Cu | Mn | Mg | Zn | Cr | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| Wt% | 0.75 | 0.5 | 0.5 | 0.15 | 0.9 | 0.03 | 0.03 | 0.05 | Rest |