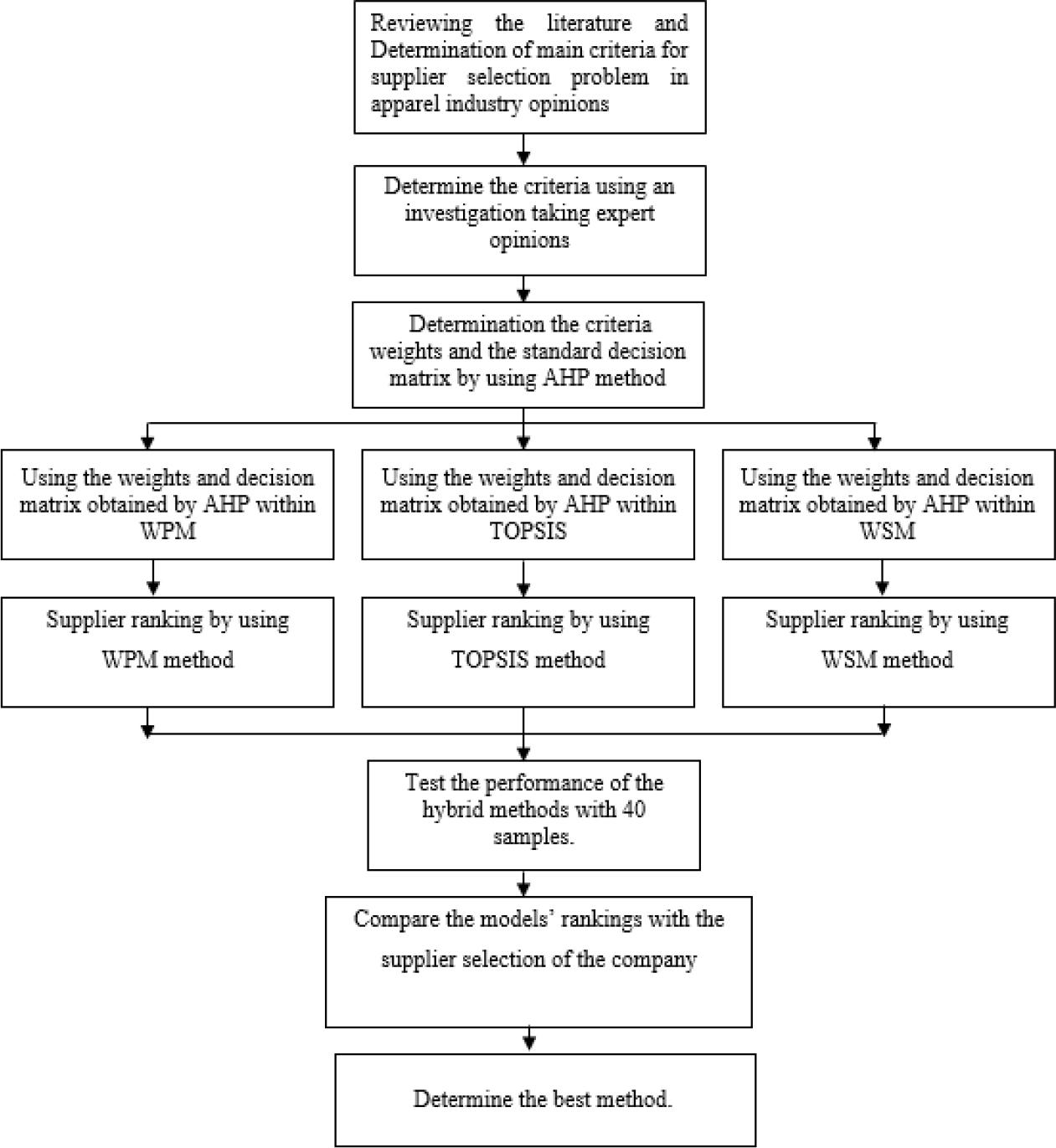

Fig. 1

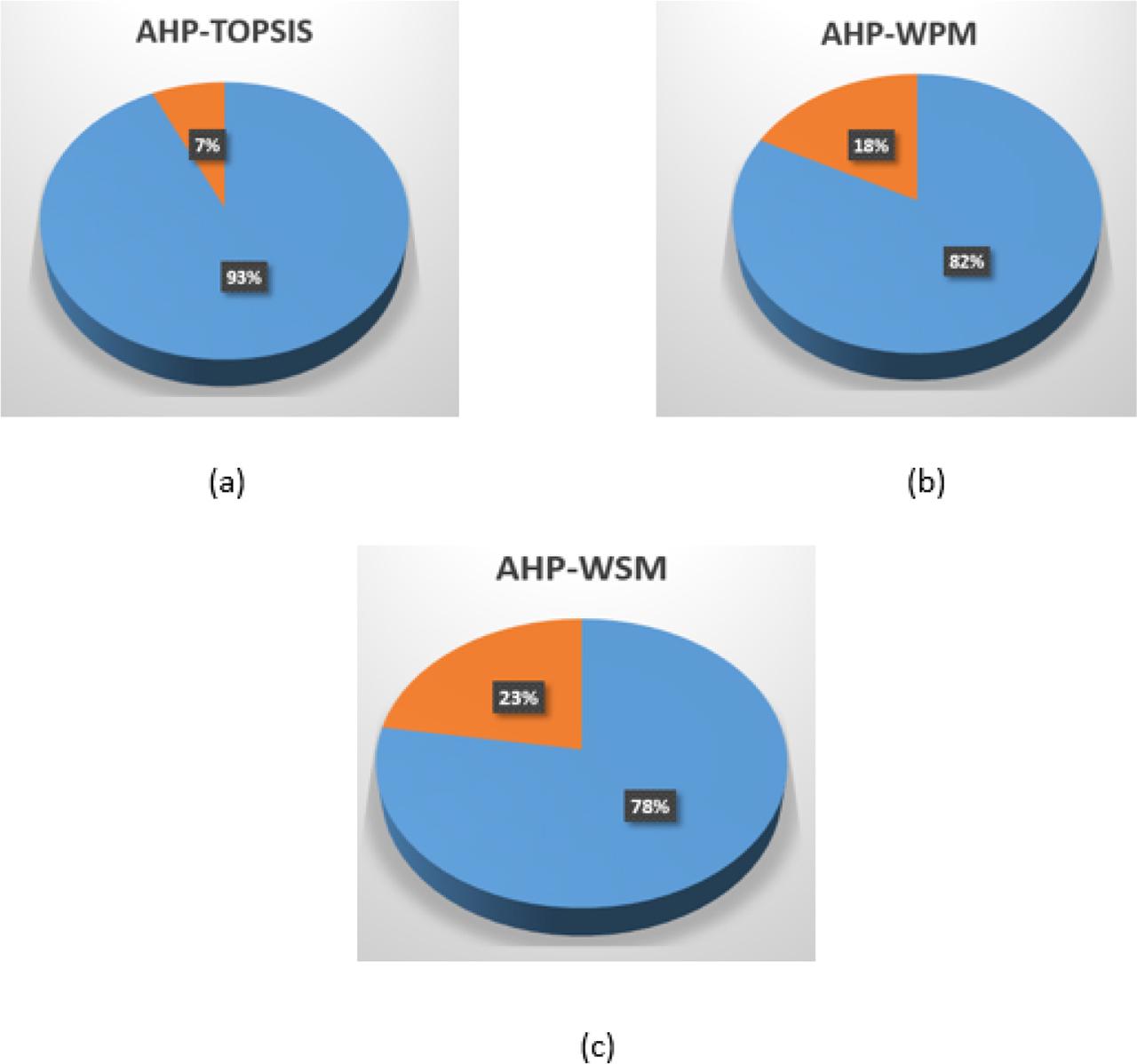

Fig. 2

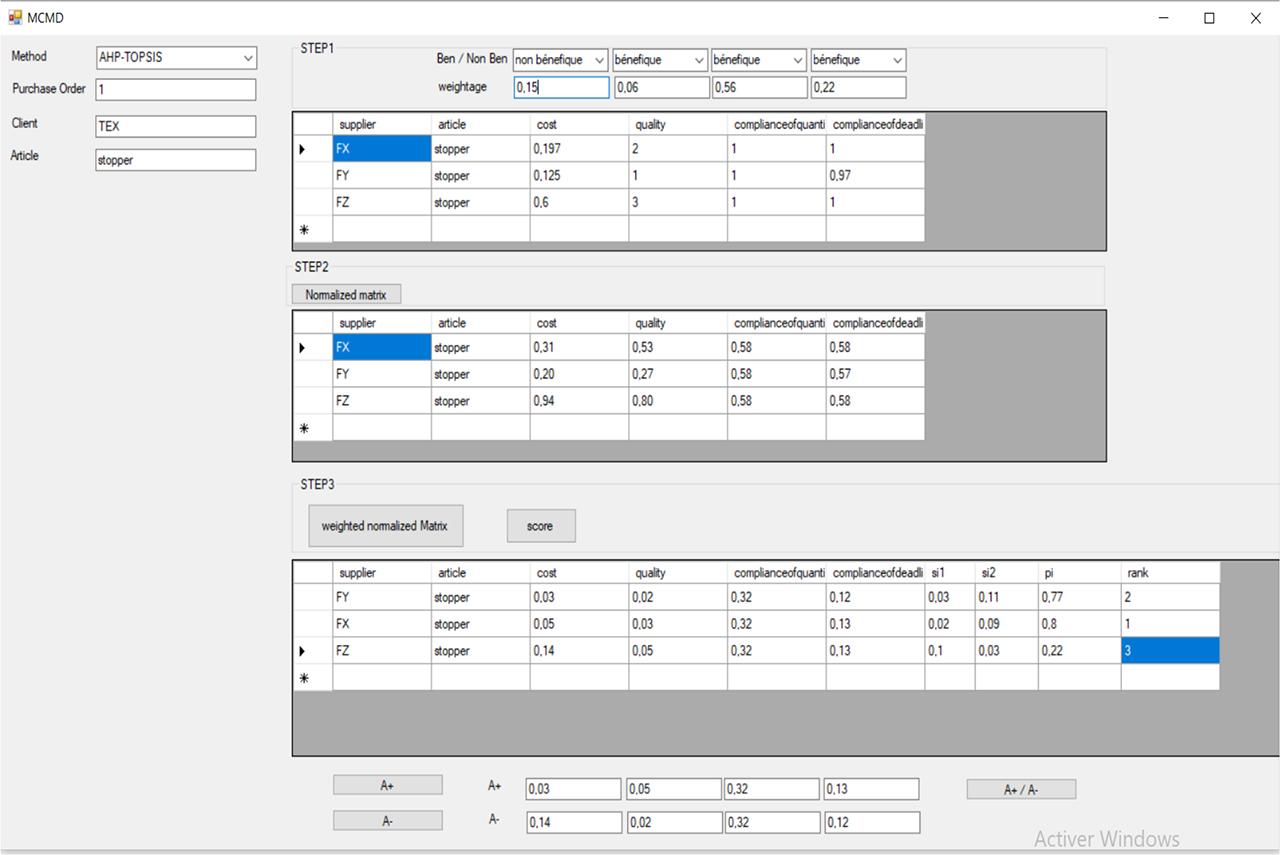

Fig. 3

Fig. 4

Fig. 5

Normalised matrix

| C1 | C2 | C3 | …. | Cm | |

|---|---|---|---|---|---|

| A1 | Y11 | Y12 | Y13 | … | Y1m |

| A2 | Y11 | Y22 | Y23 | … | Y2m |

| A3 | Y31 | Y32 | Y33 | … | Y3m |

| .. | … | … | … | … | … |

| An | Yn1 | Yn2 | Yn3 | … | Ynm |

Investigation results for the 10 experts

| Investigation | First 4 criteria | Weight | Investigation | First 4 criteria | Weight |

|---|---|---|---|---|---|

| Expert 1 | Quality | 0.06 | Expert 6 | Compliance to deadlines | 0.06 |

| Cost | 0.10 | Cost | 0.11 | ||

| Compliance to deadlines | 0.32 | Quality | 0.29 | ||

| Compliance to quantity | 0.53 | Compliance to quantity | 0.54 | ||

| Expert 2 | Cost | 0.50 | Expert 7 | Ease of production | 0.07 |

| Guarantee | 0.17 | Social relationship | 0.12 | ||

| Ease of production | 0.05 | Quantity | 0.26 | ||

| Compliance to deadlines | 0.27 | Management and organisation | 0.56 | ||

| Expert 3 | Compliance to quantity | 0.07 | Expert 8 | Ease of production | 0.06 |

| Quality | 0.15 | Financial situation | 0.10 | ||

| Cost | 0.29 | Compliance to quantity | 0.32 | ||

| Compliance to deadlines | 0.49 | Quality | 0.53 | ||

| Expert 4 | Development | 0.55 | Expert 9 | Quality | 0.55 |

| Geographical location | 0.26 | Compliance to quantity | 0.26 | ||

| Cost | 0.14 | Compliance to deadlines | 0.14 | ||

| Quality | 0.05 | Guarantee | 0.05 | ||

| Expert 5 | Guarantee | 0.06 | Expert 10 | Environment | 0.06 |

| Financial situation | 0.10 | Financial situation | 0.10 | ||

| Cost | 0.32 | Compliance to quantity | 0.32 | ||

| Quality | 0.53 | Compliance to de+adlines | 0.53 |

ANOVA for the three MCDM methods

| Source of variation | SS | Df | MS | F | P-value | F crit |

|---|---|---|---|---|---|---|

| Between groups | 0.143 | 2 | 0.071 | 15.131 | 1.431E-06 | 3.073 |

| Within groups | 0.555 | 117 | 0.004 | |||

| Total | 0.699 | 119 |

Pair-wise comparison matrix of criterion

| Criteria | C1 | C2 | C3 | …. | Cn |

|---|---|---|---|---|---|

| C1 | 1 | W1/W2 | W1/W3 | …. | W1/Wn |

| C2 | W2/W1 | 1 | W2/W3 | …. | W2/Wn |

| C3 | W3/W1 | W3/W2 | 1 | …. | W3/Wn |

| .. | … | …. | … | 1 | … |

| Cn | Wn/W1 | Wn/W2 | Wn/W3 | Wn/W.. | 1 |

Separation measures

| Cost | Quality | Compliance to quantity | Compliance to deadlines | Si+ | Si− | |

|---|---|---|---|---|---|---|

| S1 | 0.02 | 0.10 | 0.13 | 0.33 | 0.01 | 0.05 |

| S2 | 0.07 | 0.10 | 0.13 | 0.33 | 0.05 | 0.03 |

| S3 | 0.01 | 0.06 | 0.13 | 0.32 | 0.03 | 0.05 |

Normalisation Matrix

| Criteria | C1 | C2 | C3 | …. | Cn |

|---|---|---|---|---|---|

| C1 | X11 | X12 | X13 | … | X1n |

| C2 | X11 | X22 | X23 | … | X2n |

| C3 | X31 | X32 | X33 | … | X3n |

| .. | … | … | … | … | … |

| Cn | Xn1 | Xn2 | Xn3 | … | Xnn |

Pair-wise comparison matrix

| Criteria | Cost piece | Quality | Compliance to quantity | Compliance to deadlines |

|---|---|---|---|---|

| Cost/piece | 1 | 0.33 | 0.2 | 0.14 |

| Quality | 3 | 1 | 0.5 | 0.33 |

| Compliance to quantity | 5 | 2 | 1 | 0.2 |

| Compliance to deadlines | 7 | 3 | 5 | 1 |

Weighted normalised decision matrix

| C1 | C2 | C3 | …. | Cm | |

|---|---|---|---|---|---|

| A1 | Y11 ^W1 | Y12^W2 | Y13^W3 | … | Y1m^Wm |

| A2 | Y11^W1 | Y22^W2 | Y23^W3 | … | Y2m^Wm |

| A3 | Y31^W1 | Y32^W2 | Y33^W3 | … | Y3m^Wm |

| .. | … | … | … | … | … |

| An | Yn1^W1 | Yn2^W2 | Yn3^W3 | … | Ynm^Wm |

Normalisation matrix

| Cost | Quality | Compliance to quantity | Compliance to deadlines | |

|---|---|---|---|---|

| S1 | 0.31 | 0.64 | 0.58 | 0.58 |

| S2 | 0.93 | 0.64 | 0.58 | 0.58 |

| S3 | 0.19 | 0.43 | 0.58 | 0.57 |

Relative closeness and rank of suppliers

| Si+ | Si− | Ri | Rank | |

|---|---|---|---|---|

| S1 | 0.01 | 0.05 | 0.87 | 1 |

| S2 | 0.05 | 0.03 | 0.39 | 3 |

| S3 | 0.03 | 0.05 | 0.61 | 2 |

AHP-WSM Normalised matrix

| Cost | Quality | Compliance to quantity | Compliance to deadlines | |

|---|---|---|---|---|

| S1 | 0.63 | 1.00 | 1 | 1.00 |

| S2 | 0.21 | 1.00 | 1 | 1.00 |

| S3 | 1.00 | 0.67 | 1 | 0.98 |

Decision matrix

| Cost | Quality | Compliance to quantity | Compliance to deadlines | |

|---|---|---|---|---|

| S1 | 0.197 | 3 | 1 | 0.96 |

| S2 | 0.6 | 3 | 1 | 0.96 |

| S3 | 0.125 | 2 | 1 | 0,94 |

AHP-WPM suppliers rank

| Score | Suppliers rank | |

|---|---|---|

| S1 | 0.97 | 1 |

| S2 | 0.94 | 2 |

| S3 | 0.93 | 3 |

Normalization Matrix

| Criteria | Cost / piece | Quality | Compliance to quantity | Compliance to deadlines | Average vector: W |

|---|---|---|---|---|---|

| Cost/piece | 0.06 | 0.05 | 0.03 | 0.09 | 0.07 |

| Quality | 0.19 | 0.16 | 0.07 | 0.20 | 0.15 |

| Compliance to quantity | 0.31 | 0.32 | 0.15 | 0.12 | 0.22 |

| Compliance to deadlines | 0.44 | 0.47 | 0.75 | 0.60 | 0.56 |

Decision Matrix

| C1 | C2 | C3 | …. | Cm | |

|---|---|---|---|---|---|

| A1 | X11 | X12 | X13 | … | X1n |

| A2 | X11 | X22 | X23 | … | X2n |

| A3 | X31 | X32 | X33 | … | X3n |

| .. | … | … | … | … | … |

| An | Xn1 | Xn2 | Xn3 | … | Xnn |

AHP-WSM Weighted normalised matrix

| Cost | Quality | Compliance to quantity | Compliance to deadlines | |

|---|---|---|---|---|

| S1 | 0.63 | 1.00 | 1 | 1.00 |

| S2 | 0.21 | 1.00 | 1 | 1.00 |

| S3 | 1.00 | 0.67 | 1 | 0.98 |

List of criteria

| N° | Criteria | N° | Criteria |

|---|---|---|---|

| 1 | Cost | 11 | Ease of production |

| 2 | Quality | 12 | Environment |

| 3 | Compliance to quantity | 13 | Free sampling |

| 4 | Compliance to deadlines | 14 | Minimum production capacity |

| 5 | Social relationship | 15 | Technical capacity |

| 6 | Guarantee | 16 | Purchase volume in the past |

| 7 | Financial situation | 17 | Process conformity |

| 8 | Development | 18 | Certification |

| 9 | Geographical location | 19 | Control of operations |

| 10 | Management and organisation | 20 | Training and support |

Saaty’s 1–9 scale for pair-wise comparisons

| Numerical rate | Verbal judgment of preference |

|---|---|

| 1 | Equal importance |

| 3 | Weak importance of one over another |

| 5 | Essential or strong importance |

| 7 | Demonstrated importance |

| 9 | Absolute importance |

| 2, 4, 6, 8 | Intermediate values between the two adjacent judgments |

Positive ideal and negative ideal solution

| Cost | Quality | Compliance to quantity | Compliance to deadlines | |

|---|---|---|---|---|

| S1 | 0.02 | 0.10 | 0.13 | 0.33 |

| S2 | 0.07 | 0.10 | 0.13 | 0.33 |

| S3 | 0.01 | 0.06 | 0.13 | 0.32 |

| V+ | 0.01 | 0.10 | 0.13 | 0.33 |

| V− | 0.07 | 0.06 | 0.13 | 0.32 |

Statistical study of each method pair

| Method pair | σ xy | σ x | σ y | R xy | standard deviation |

|---|---|---|---|---|---|

| AHP-TOPSIS and AHP-WSM | 0.0015 | 0.11 | 0.05 | 0.29 | 0.089 |

| AHP-TOPSIS and AHP-WPM | 0.00094 | 0.1 | 0.018 | 0.47 | 0.08 |

| AHP-WSM and AHP-WPM | 0.00014 | 0.048 | 0..018 | 0.16 | 0.03 |

AHP-WSM Suppliers rank

| Score | Supplier’s rank | |

|---|---|---|

| S1 | 0.97 | 1 |

| S2 | 0.94 | 2 |

| S3 | 0.93 | 3 |

AHP-WPM weighted normalised matrix

| Cost | Quality | Compliance to quantity | Compliance to deadlines | |

|---|---|---|---|---|

| S1 | 0.63 | 1.00 | 1 | 1.00 |

| S2 | 0.21 | 1.00 | 1 | 1,00 |

| S3 | 1.00 | 0.67 | 1 | 0.98 |

Weighted normalised matrix

| Cost | Quality | Compliance to quantity | Compliance to deadlines | |

|---|---|---|---|---|

| S1 | 0.02 | 0.10 | 0.13 | 0.33 |

| S2 | 0.07 | 0.10 | 0.13 | 0.33 |

| S3 | 0.01 | 0.06 | 0.13 | 0.32 |

Test evaluation (part 1)

| Purchase order number | Item | Supplier selected by company | Supplier selected by AHP-TOPSIS | Rank of supplier | Supplier selected by AHP-WSM | Rank of supplier | Supplier selected by AHP-WPM | Rank of supplier |

|---|---|---|---|---|---|---|---|---|

| 1 | Stopper | FX | FX | 1 | FY | 2 | FY | 2 |

| 2 | Label kontakt | AY | AY | 1 | AB | 4 | AB | 4 |

| 3 | Label brice | FS | FS | 1 | FR | 3 | FR | 2 |

| 4 | Fringe | XA | XA | 1 | XR | 2 | XA | 1 |

| 5 | Yarn 100% cotton | ZD | ZA | 2 | ZD | 1 | ZA | 2 |

| 6 | Elastic | CA | CA | 1 | CX | 2 | CA | 1 |

| 7 | Zipper L18 cm | DZ | DR | 1 | DR | 1 | DR | 1 |

| 8 | Button 2 HOLE 25 | IL | IJ | 2 | IL | 1 | IJ | 2 |

| 9 | Ribbon | WK | WK | 1 | WK | 1 | WK | 1 |

| 10 | Buckle | HI | HX | 3 | HX | 2 | HX | 2 |

| 11 | Hangtag –vms | X1 | X1 | 1 | X1 | 1 | X1 | 1 |

| 12 | Rivet 84061 | B1 | B1 | 1 | B2 | 2 | B2 | 2 |

| 13 | Rivet 84425 | C1 | C1 | 1 | C1 | 1 | C1 | 1 |

| 14 | Button 11631 | CF | CF | 1 | CR | 2 | CF | 1 |

| 15 | Scotch | Y1 | Y1 | 1 | Y1 | 1 | Y1 | 1 |

| 16 | Button 4 Hole 28″ | A1 | A1 | 1 | A1 | 1 | A1 | 1 |

| 17 | Zip 14.5cm | G1 | G1 | 1 | G1 | 1 | G1 | 1 |

| 18 | Buckle 1cm | G1 | G1 | 1 | G1 | 1 | G1 | 1 |

| 19 | Confection sticker - | H1 | H1 | 1 | H1 | 1 | H1 | 1 |

| 20 | Bias Tape 100 % | W1 | W1 | 1 | W1 | 1 | W1 | 1 |

| 21 | Leather10895 | U1 | U1 | 1 | U1 | 1 | U1 | 1 |

| 22 | Zip L16.5cm | G1 | G1 | 1 | G1 | 1 | G1 | 1 |

| 23 | Yarn Tex 60 Dual Duty 5000mts-fil | T1 | T1 | 1 | T1 | 1 | T1 | 1 |

| 24 | Sangle nastro spinato 30/2 PXT mm.60 | R1 | R1 | 1 | O1 | 2 | R1 | 1 |

| 25 | Sticker dim 100*150 | BR | BR | 1 | BR | 1 | BR | 1 |

| 26 | Plastic cover | FR | FR | 1 | V | 1 | FR | 1 |

| 27 | Hang Tag Retro | BG | BG | 1 | BG | 1 | BG | 1 |

| 28 | Ribbon polyamide | FH | FH | 1 | FH | 1 | FH | 1 |

| 29 | Button tack metal | FT | FT | 1 | FT | 1 | FT | 1 |

| 30 | Button jeans 20mm | XS | XS | 1 | XS | 1 | XS | 1 |

| 31 | Rivet laiton de 2 cm | XS | XS | 1 | XS | 1 | V | 1 |

| 32 | Leather belt | GH | GH | 1 | GH | 1 | GH | 1 |

| 33 | Yarn col 439 Super Twist N°20 20gr/fil | XR | XR | 1 | XR | 1 | XR | 1 |

| 34 | Strap ecru | XY | XY | 1 | XY | 1 | XY | 1 |

| 35 | Buckle overalls | BJ | BJ | 1 | BJ | 1 | BJ | 1 |

| 36 | Zip L43cm RGKB | BN | BN | 1 | BN | 1 | BN | 1 |

| 37 | Confection sticker-Care Label | VH | VH | 1 | VH | 1 | VH | 1 |

| 38 | Finishing sticker -VMS | VY | VY | 1 | VY | 1 | VY | 1 |

| 39 | Finishing sticker women | SML | SML | 1 | SML | 1 | SML | 1 |

| 40 | Metal overalls buckle accessory Internal diameter 3.8 cm White | SF | SF | 1 | SF | 1 | SF | 1 |