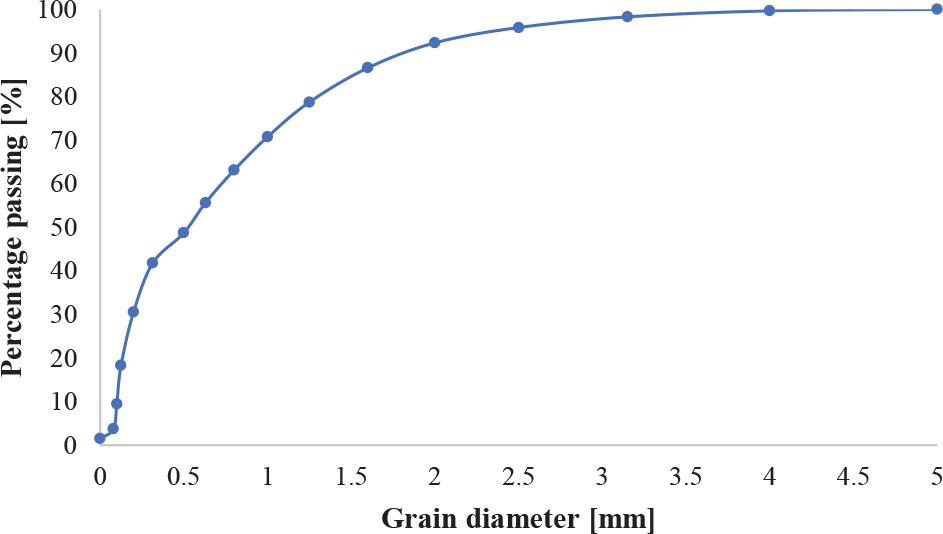

FIGURE 1.

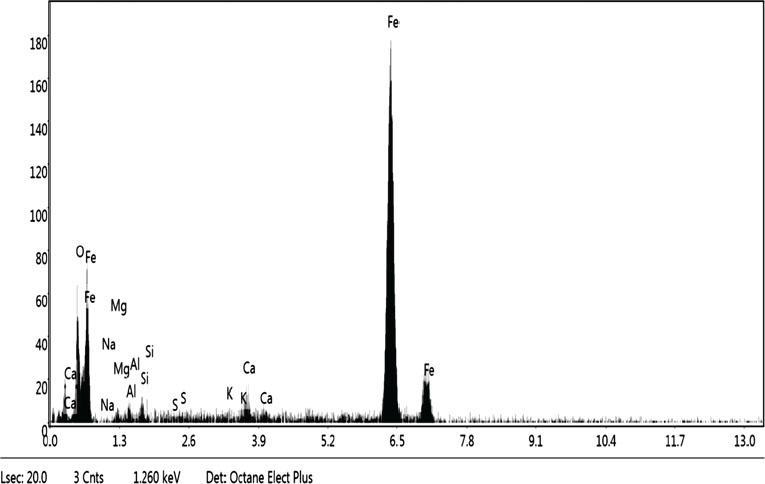

FIGURE 2.

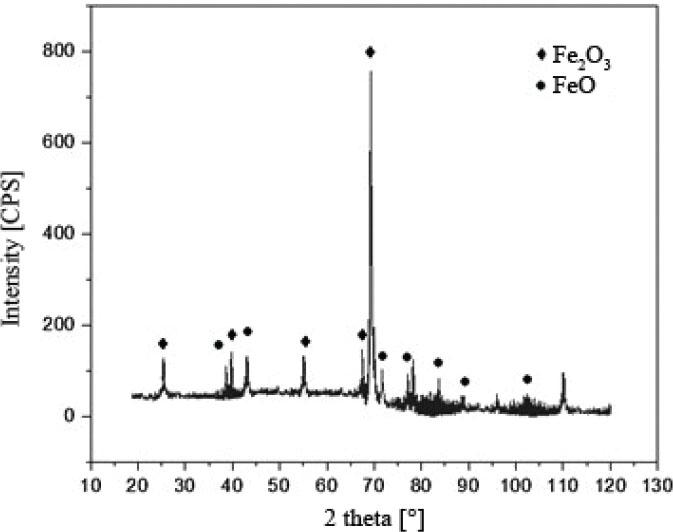

FIGURE 3.

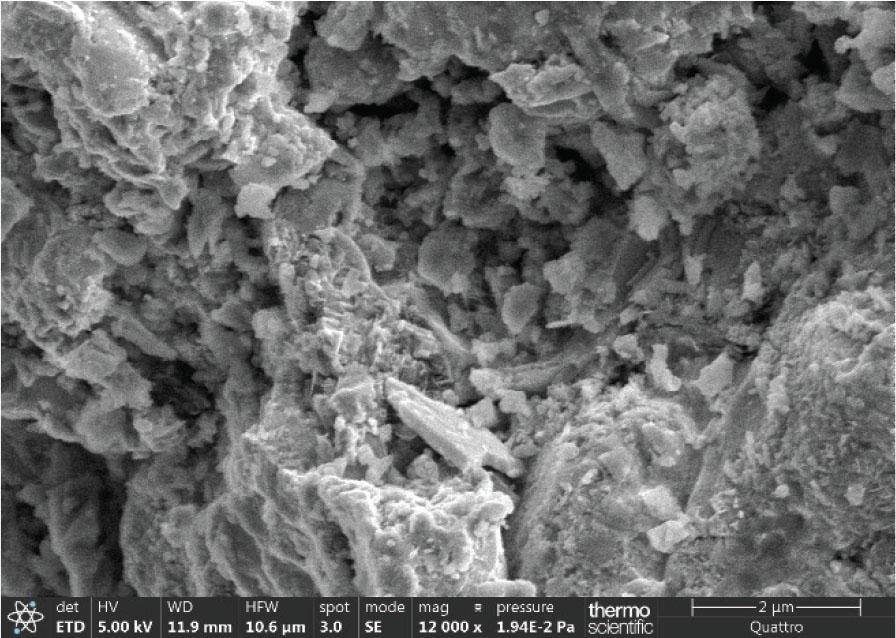

FIGURE 4.

FIGURE 5.

FIGURE 6.

FIGURE 7.

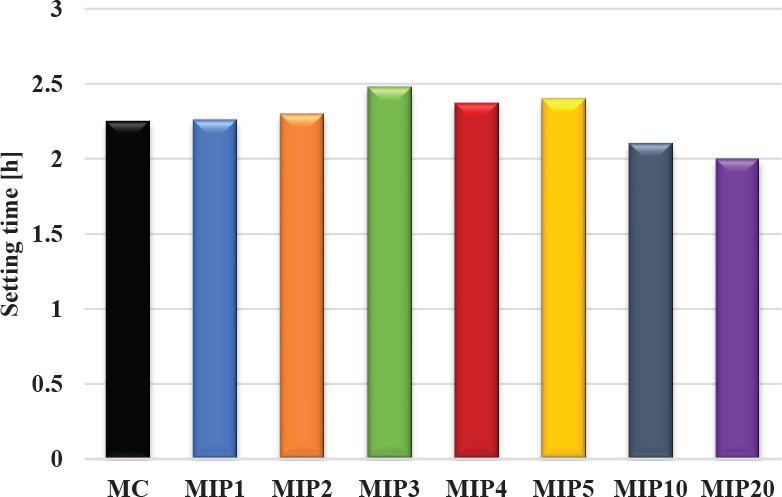

FIGURE 8.

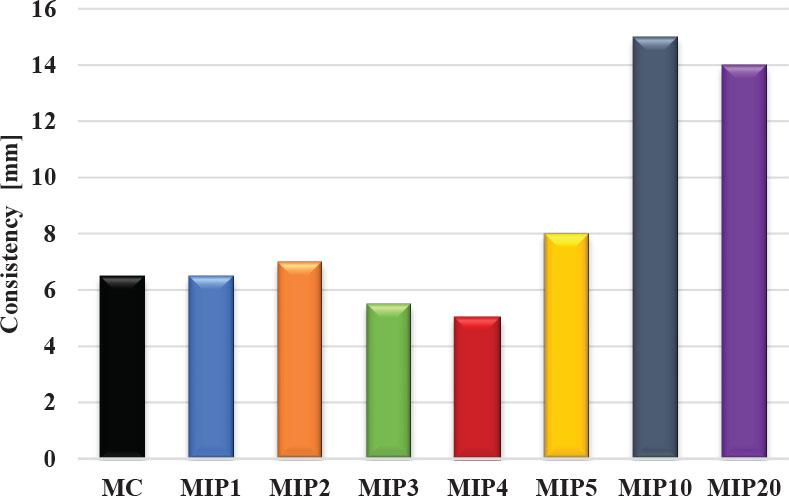

FIGURE 9.

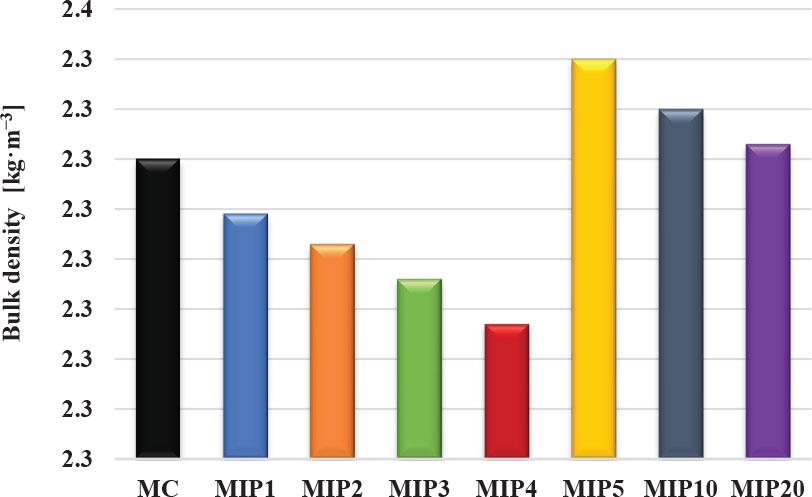

FIGURE 10.

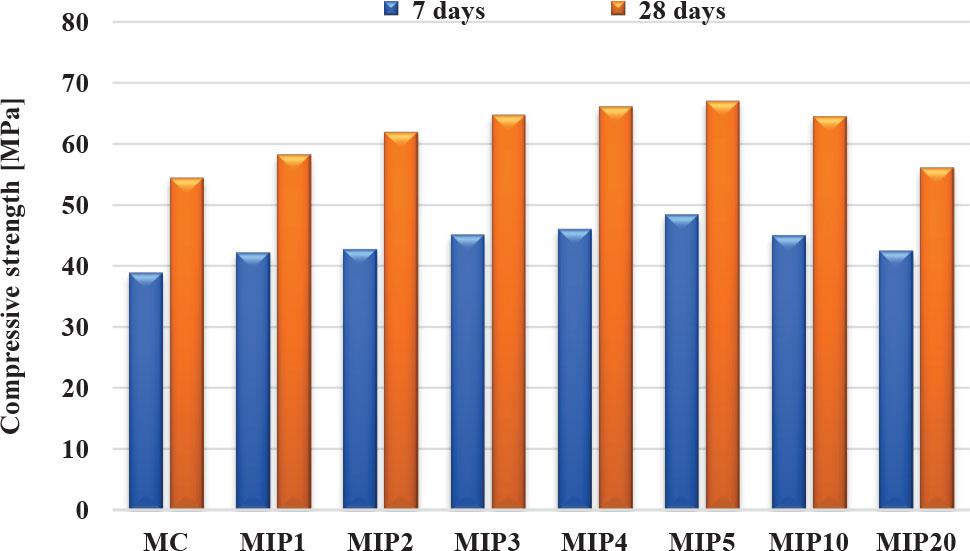

FIGURE 11.

Compositions of mortars

| Designation | Crushed sand content [g] | Cement content [g] | Iron powder content [g] | Water content [g] |

|---|---|---|---|---|

| MC0 | 1 350.0 | 450.0 | 0 | 225.0 |

| MIP1 | 1 350.0 | 445.5 | 4.5 | 225.0 |

| MIP2 | 1 350.0 | 441.0 | 9.0 | 225.0 |

| MIP3 | 1 350.0 | 436.5 | 13.5 | 225.0 |

| MIP4 | 1 350.0 | 432.0 | 18.0 | 225.0 |

| MIP5 | 1 350.0 | 427.5 | 22.5 | 225.0 |

| MIP10 | 1 350.0 | 405.0 | 45.0 | 225.0 |

| MIP20 | 1 350.0 | 360.0 | 90.0 | 225.0 |

Chemical and physical characteristics of portland cement CEM I/42_5R

| Specification | Chemical composition | |||||||

|---|---|---|---|---|---|---|---|---|

| Content [%] | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O | TiO2 | Na2O |

| 20.14 | 5.53 | 3.54 | 61.60 | 0.19 | 0.03 | 0.008 | 0.06 | |

| Mineralogical composition | ||||||||

| Content [%] | C3S | C2S | C3A | C4AF | ||||

| 55.43 | 15.53 | 8.67 | 10.76 | |||||

| Physical properties | ||||||||

| Specific density [kg·m−3] | 3 100.0 | |||||||

| Fineness [cm2·g−1] | 3 500.0 | |||||||

| Initial setting time [min] | 170.0 | |||||||

| Final setting time [min] | 255.0 | |||||||

Chemical and physical properties of iron powder

| Specification | Chemical properties | |||||||

|---|---|---|---|---|---|---|---|---|

| Content [%] | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O | FeO | P2O5 |

| 4.80 | 1.13 | 64.75 | 0.85 | 0.07 | – | 1.00 | 0.05 | |

| Physical properties | ||||||||

| Specific density [kg·m−3] | 2,250.0 | |||||||

| Apparent density [kg·m−3] | 1,220.0 | |||||||

Chemical properties of crushed sands

| Specification | Chemical composition | |||||||

|---|---|---|---|---|---|---|---|---|

| Content [%] | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O | TiO2 | Na2O |

| 0.05 | 0.03 | 0.02 | 56.03 | 0.19 | 0.03 | 0.008 | 0.06 | |

| Physical properties | ||||||||

| Specific density [kg·m−3] | 2,750.0 | |||||||

| Apparent density [kg·m−3] | 1,460.0 | |||||||

| Fineness [cm2·g−1] | 3,700.0 | |||||||

| Sand equivalent [%] | 69.0 | |||||||

| Absorption coefficient [%] | 1.1 | |||||||