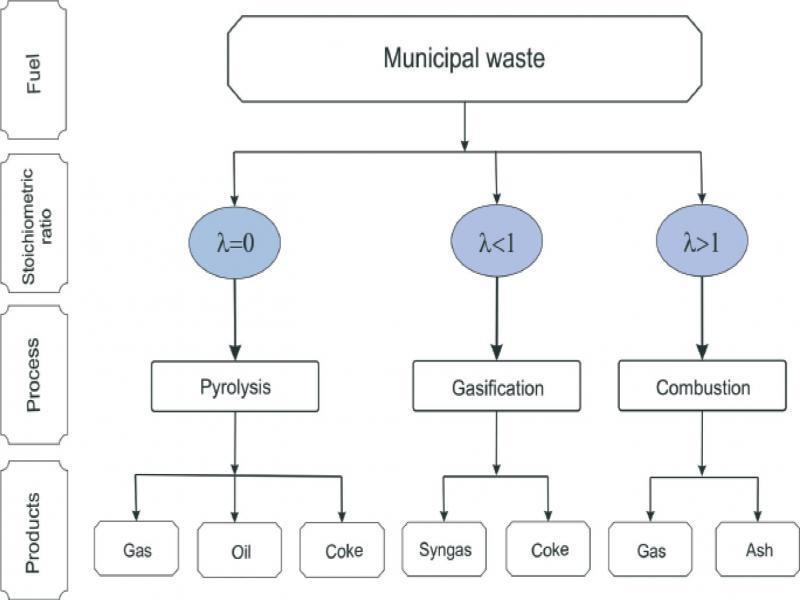

Figure 1.

![Directions of municipal waste management in Poland [4–6]](https://sciendo-parsed.s3.eu-central-1.amazonaws.com/64706f7083f1392090d6979d/j_acee-2019-042_fig_001.jpg?X-Amz-Algorithm=AWS4-HMAC-SHA256&X-Amz-Content-Sha256=UNSIGNED-PAYLOAD&X-Amz-Credential=AKIA6AP2G7AKOUXAVR44%2F20251206%2Feu-central-1%2Fs3%2Faws4_request&X-Amz-Date=20251206T210240Z&X-Amz-Expires=3600&X-Amz-Signature=02cec29cba64bada07b9875bc6ff99ae401b2c08192ed17562cc783ff1dda2d7&X-Amz-SignedHeaders=host&x-amz-checksum-mode=ENABLED&x-id=GetObject)

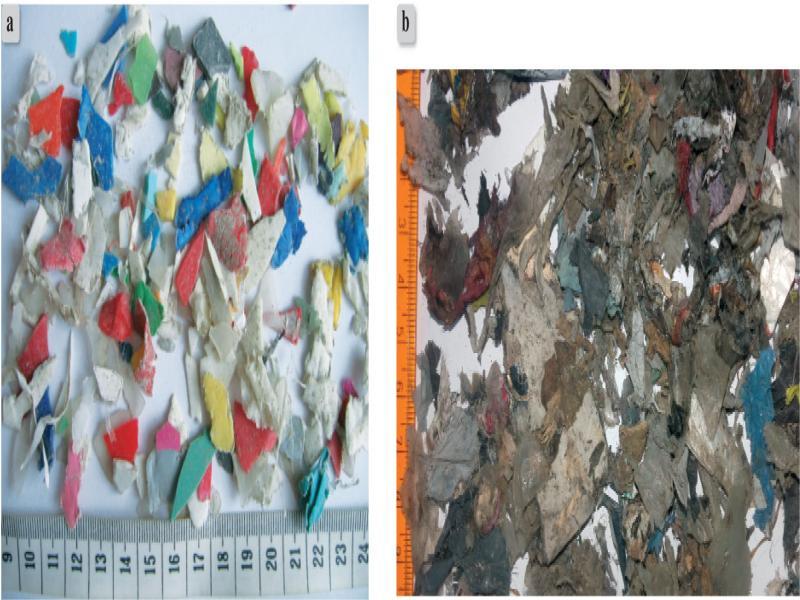

Figure 2.

Figure 3.

![Flowchart of the plant for gasification of waste [22]](https://sciendo-parsed.s3.eu-central-1.amazonaws.com/64706f7083f1392090d6979d/j_acee-2019-042_fig_003.jpg?X-Amz-Algorithm=AWS4-HMAC-SHA256&X-Amz-Content-Sha256=UNSIGNED-PAYLOAD&X-Amz-Credential=AKIA6AP2G7AKOUXAVR44%2F20251206%2Feu-central-1%2Fs3%2Faws4_request&X-Amz-Date=20251206T210240Z&X-Amz-Expires=3600&X-Amz-Signature=f9d05ff89425858c68077411066acd615475bbbc290e68e29e8da7101f891d36&X-Amz-SignedHeaders=host&x-amz-checksum-mode=ENABLED&x-id=GetObject)

Figure 4.

Technical parameters of the plant for gasification of waste [22]

| The type of deposit | Circulating fluidized bed |

| Process temperature, °C | 1200 |

| Working pressure, MPa | 1.0–1.5 |

| Reactor operating pressure, MPa | 2.0 |

| Gasification agent | steam/ O2/ CO2 |

Standards for the physicochemical analysis

| Title | Unit | Symbol | Standard |

| Determination of moisture content | % | MT | PN-Z-15008-02:1993 |

| Determining combustion heat and calculating the calorific value | MJ/kg | GCV, NCV | PN-Z-15008-04:1993 |

| Determination of ash content | % | A | PN-EN 15403:2011 |

| Determination of fly ash by weighting | % | V | PN-EN 15402:2011 |

| Determination of carbon and hydrogen | % | C, H | PN-Z-15008-05:1993 |

| Determination of nitrogen with the Kjeldahl method | % | N | PN-G-04523:1992 |

| Determination of sulfur with the Eschka method | % | S | PN-ISO 334:1997 |

| Determination of chloride using the Eschka mixture | % | Cl | PN-ISO 587:2000 |

The composition of synthesis gas from the process for WP

| Components | Symbol | Unit | The composition of synthesis gas for WP |

| Hydrogen | H2 | vol % | 51.64 |

| Carbon monoxide | CO | 46.10 | |

| Nitrogen | N2 | 0.44 | |

| Steam | H2O | 0.78 | |

| Carbon dioxide | CO2 | 0.27 | |

| Argon | Ar | 0.67 | |

| Sulfur dioxide | SO2 | 0.00 | |

| Hydrogen sulfide | H2S | ppm | 429 |

| Ammonia | NH3 | ppm | 20 |

| Hydrogen chloride | HCl | ppm | 349 |

| Gross calorific value | GCV | MJ/kg | 19.03 |

| Net calorific value | NCV | MJ/kg | 17.44 |

The composition of synthesis gas from the process for MW

| Components | Symbol | Unit | The composition of synthesis gas for WP |

| Hydrogen | H2 | vol % | 43.98 |

| Carbon monoxide | CO | 46.74 | |

| Nitrogen | N2 | 0.59 | |

| Steam | H2O | 5.81 | |

| Carbon dioxide | CO2 | 2.43 | |

| Sulfur dioxide | SO2 | 0.00 | |

| Hydrogen sulfide | H2S | ppm | 2500 |

| Ammonia | NH3 | ppm | 23 |

| Hydrogen chloride | HCl | ppm | 988 |

| Gross calorific value | GCV | MJ/kg | 15.85 |

| Net calorific value | NCV | MJ/kg | 14.49 |

Technical analysis of tested raw materials for the gasification process

| Parameter | Symbol | Unit | WP | MW |

| Total moisture content | MT | % | 0.03 | 22.47 |

| Combustible substances, Air Dried | Xd | % | 99.10 | 92.44 |

| Combustible substances, As Received | Xar | % | 99.07 | 71.67 |

| Ash, Air Dried | Ad | % | 0.86 | 7.56 |

| Ash, As Received | Aar | % | 0.86 | 5.86 |

| Volatile matter, Air Dried | Vd | % | 99.13 | 79.06 |

| Gross calorific value, Air Dried | GCVd | MJ/kg | 47.52 | 23.66 |

| Gross calorific value, As Received | GCVar | 47.50 | 18.29 | |

| Net calorific value, Air Dried | NCVd | MJ/kg | 44.38 | 22.62 |

| Net calorific value, As Received | NCVar | 44.36 | 16.97 |

Elemental composition of selected waste

| Parameter | Symbol | Unit | WP | MW | ||

| As | Air | As | Air | |||

| Carbon | C | % | 85.28 | 85.31 | 34.63 | 43.29 |

| Hydrogen | H | % | 13.95 | 13.96 | 3.42 | 4.27 |

| Sulphur | S | % | 0.22 | 0.22 | 0.47 | 0.59 |

| Nitrogen | N | % | 0.29 | 0.29 | 0.88 | 1.10 |

| Chlorine | Cl | % | 0.19 | 0.19 | 0.41 | 0.51 |

| Oxygen | O | % | 0.00 | 0.00 | 31.86 | 39.64 |