1. Introduction

The building stock has a critical role in clean energy transition as it generates around 40% of overall emissions worldwide (UNEP 2020). Reducing emissions from the housing stock requires a dramatic improvement in the efficiency of existing dwellings (Historic England 2019) to meet national targets on greenhouse gas emissions and alleviate fuel poverty. Traditional buildings constitute a large proportion of the building stock in many countries worldwide. The UK has the oldest housing stock in Europe, where traditionally constructed dwellings account for around 40% of its stock (Pickles et al. 2017). This category includes nearly all buildings constructed before 1919, as well as a significant proportion of those built before 1945. They usually consist of solid brick or stone external walls, or pre-1919 timber-framed external walls (Rickaby 2019), and generally have poor thermal performance. As of 2019, only 11% of UK solid-walled dwellings had insulation installed, highlighting the potential of solid-wall insulation as a retrofit measure (MHCLG 2020). The retrofit of traditional buildings is, therefore, essential. It is one of the UK’s five priorities for government action as identified by the Committee on Climate Change (Holmes et al. 2019) and the focus of international initiatives such as the International Energy Agency’s (IEA) Annex 76/Task 59 programme (Herrera-Avellanosa et al. 2019) for the renovation of historic buildings towards zero energy by means of conservation-compatible energy retrofit approaches (Buda et al. 2021).

The retrofit of traditional buildings entails more challenges and risks than modern buildings due to conservation requirements, the limited availability of reliable information on the building fabric, the wider variety of materials used, and its complex heat and moisture behaviour (Akkurt et al. 2020). There is increasing evidence that the inappropriate retrofit of traditional buildings has led to unintended consequences, ranging from summer overheating (Shrubsole et al. 2014) to the risks (English Heritage 2014) and failures of solid-wall retrofit programmes associated with an excess of moisture accumulation (BRE 2016). Also, there is evidence of the lack of performance data and knowledge development for solid-wall insulation (Hansford 2015), which would improve the standards of specification and installation of solid-wall insulation. National (King & Weeks 2016; Lu et al. 2021; Pickles et al. 2017; STBA 2014) and international (De Place Hansen et al. 2020; Marincioni et al. 2021) efforts have been made to guide the retrofit process for improving the performance of traditional solid walls.

Frameworks for holistic sustainable renovation processes have been developed internationally. For example, that developed by the Swedish Sustainable Integrated Renovation (SIRen) network (Olander et al. 2019) aimed at the integration of several disciplines in the process, associating roles and actors to the different building stages. Efforts in the UK have also focused on developing holistic retrofit approaches that can account for the complexity of the energy-efficient retrofit of traditional buildings, such as the ‘whole-building approach’ (May & Griffiths 2015). However, the fragmented nature of the UK’s construction industry and the lack of prescription on the responsibilities in the project team (RIBA 2020) pose challenges for a holistic approach to retrofit (Killip et al. 2020) and a direct replication of existing frameworks.

There is evidence that retrofit interventions in the UK are rarely evaluated on a whole-building and medium-term basis and that ‘proper “design” is frequently absent entirely’ (Hansford 2015: 21), leading to damp, mould and poor building performance to name a few. Excess moisture accumulation has an important role in this context because it is often associated with building damage and poor thermal performance. Understanding the building construction and its hygrothermal conditions before the retrofit is crucial for the long-term quality of an energy-efficient retrofit. However, pre-retrofit assessment is often overlooked since a proper investigation is time-consuming (especially for small, medium and micro-enterprises) and requires expert knowledge (Farsäter et al. 2019). Oversimplified assessment methods that do not rely on continuous knowledge development are often employed instead (McLeod & Hopfe 2013), potentially resulting in a high number of unintended consequences and leading to scepticism about the uptake of energy-efficient retrofit. Moreover, there is no incentive (e.g. due to lack of regulation and clarity on responsibilities) for assessing and understanding whether a retrofit strategy is performing as intended in operation, a practice that could support a safe scaling-up of installation of innovative retrofit measures.

This paper presents the development of a method for moisture risk management, which is then embedded into a framework for integrated energy and moisture performance retrofit of traditional buildings. The systematic approach proposed harmonises the principles needed to support organisations in delivering a robust holistic retrofit of traditional buildings and requires the integration of pre- and post-retrofit building assessment in the process. While previous work has addressed energy and moisture management separately, this is the first effort to the authors’ knowledge that integrates the two aspects into a framework for risk management.

2. Existing retrofit standards

Standards for improving the energy performance (or the energy efficiency) of traditional buildings have been recently developed, providing a dedicated approach for the retrofit of such buildings.

The European Standard EN 16883:2017 on the Conservation of Cultural Heritage—Guidelines for Improving the Energy Performance of Historic Buildings (CEN 2017) provides guidelines for the sustainable improvement of energy performance in historic buildings, also accounting for contextual factors such as heritage significance and impact on the outdoor environment. The standard’s main contribution is the development of a normative working procedure for the selection of retrofit measures, guiding the process from the development of the project brief to the decision-making. Although the European Standard (also published in the UK) provides a non-prescriptive framework, efforts have been made internationally to implement the standard’s guidelines into practical advice.

In the UK, a series of retrofit standards have been introduced in recent years as a response to issues associated with poor quality and practices encountered in the retrofit industry (Bonfield 2016). The overarching standard for the retrofit of existing dwellings is the PAS 2035:2019 on Retrofitting Dwellings for Improved Energy Efficiency—Specification and Guidance, which provides a specification and best-practice guidance for the energy retrofit of domestic buildings (Rickaby 2019). The document defines three grades of risk, which outline the specific compliance ‘paths’ to be followed and the requirements to be applied in each case. For example, for traditional construction, the standard prescribes an assessment of its significance, construction materials and hygrothermal performance, and installed building services (to name a few) for the evaluation of the suitability of the dwelling for improvement. A similar standard for non-domestic buildings is currently under development.

Both EN 16883:2017 and PAS 2035:2019 advocate for a whole-building approach, where retrofit measures must not be considered in isolation. To some degree, they also consider risk management, which is the process for ‘managing risks, making decisions, setting and achieving objectives and improving performance’ (ISO 2018: v). Specifically, EN 16883:2017 suggests using a five-level risk assessment scale to allow for an interdisciplinary assessment of each retrofit measure. PAS 2035, on the other hand, requires an assessment of the risks associated with a retrofit process.

Additionally, a White Paper published by the British Standard Institution (BSI) on Moisture in Buildings: An Integrated Approach to Risk Assessment and Guidance (May & Sanders 2017) has outlined a framework to integrate moisture management within the construction process, acknowledging that moisture has a considerable impact within the:

increasingly important fields of retrofit and the renovation of existing buildings, especially older, solid-wall buildings, where issues of moisture movement and risk are of a different nature from those found in new cavity construction.

The White Paper advocates for a principles-based assessment of moisture risk defining four principles (the 4 C’s) for moisture risk management (Table 1).

Table 1

The four principles (4 C’s) and subprinciples for moisture management in the British Standard Institution’s (BSI) White Paper.

| PRINCIPLE | SUBPRINCIPLE |

|---|---|

| 1. Compatibility with the context | Geography |

| Built form | |

| Materials and construction method | |

| Condition | |

| Use | |

| 2. Coherence | Coherence of moisture approach |

| Thermal coherence | |

| Airtightness | |

| Weathering/waterproofing | |

| Ventilation, heating and insulation | |

| 3. Capacity | Design |

| Process | |

| 4. Caution | Usability |

| Maintenance | |

| Monitoring | |

| Feedback |

[i] Source: May & Sanders (2017).

3. The development of an energy and moisture risk-management framework

As stated in the international standard for risk management, ISO 31000 (ISO 2018), an effective risk management is the one integrated throughout all organisational activities and which makes use of the knowledge of various stakeholders. It is supported by the best available information provided at the time, which continuously evolves, anticipating and responding to changes in context and risks (ISO 2018).

Developing a risk-management framework for the construction industry entails integrating risk management across all their internal practices. This can be achieved by first defining a risk-management process in collaboration with stakeholders.

The risk management process involves the systematic application of policies, procedures and practices to the activities of communicating and consulting, establishing the context and assessing, treating, monitoring, reviewing, recording and reporting risk.

The risk-management process should then be embedded within the context of the construction industry.

The purpose of the risk management framework is to assist the organization in integrating risk management into significant activities and functions.

The risk-management process and framework developed in this work was based on the 4 C’s principles of the BSI’s White Paper (May & Sanders 2017). The energy and moisture risk-management process was designed by means of an iterative process involving stakeholders. A first version was developed iteratively by the authors, capitalising on their research interest and expertise. The draft risk-management process was subsequently refined with support from stakeholders affiliated to the UK Centre for Moisture in Buildings (UKCMB), who were invited to a workshop (held in May 2018) to undertake and provide feedback for the development of a training programme on ‘Understanding and Managing Moisture Risks in Buildings’. All UKCMB members (approximately 130 at the time) were invited to participate, and 13 stakeholders agreed to attend the workshop. All participants were building professionals with expertise ranging from design, conservation, retrofit, remediation and insurance. During the workshop, the participants were given the first version of the risk-management process, and were asked to review, discuss and provide a revised version of the process based on their professional experience and the approach they follow when assessing and managing moisture risk in buildings. All responses were collated and implemented into a final version of the moisture risk-management process, presented below in section 4.1.

Subsequently, an integrated energy and moisture risk-management framework was developed. It was inspired by the Swedish Bygga F (Mjornell et al. 2012) framework for moisture safety in construction and developed for application to the UK context and construction process, in line with The Royal Institute of British Architects’ (RIBA) Plan of Work (2020). The framework (presented below in section 4.2) embeds the risk-management process within the construction process, and it applies the four principles of the BSI’s White Paper (May & Sanders 2017) to the stages of the construction process.

Although the risk-management framework was initially developed with a focus on moisture, it was deemed necessary to extend it into an integrated framework considering both energy and moisture issues, to improve the robustness of the retrofit and enhance the overall building performance. As argued in the White Paper, a moisture risk management has:

to be set in the context of other aims of the building project, such as providing energy efficiency, cost effectiveness, beauty, heritage and comfort. […] Any moisture strategy, therefore, has to be integrated into these other aims and a holistic and whole-building approach adopted in a joined-up process.

4. Risk-management process and framework

4.1. Risk-management process

The process developed for energy and moisture risk management aims to minimise moisture risk in buildings and to address the challenges associated with the energy-efficient retrofit of traditional buildings while considering its adaptability for new-build construction.

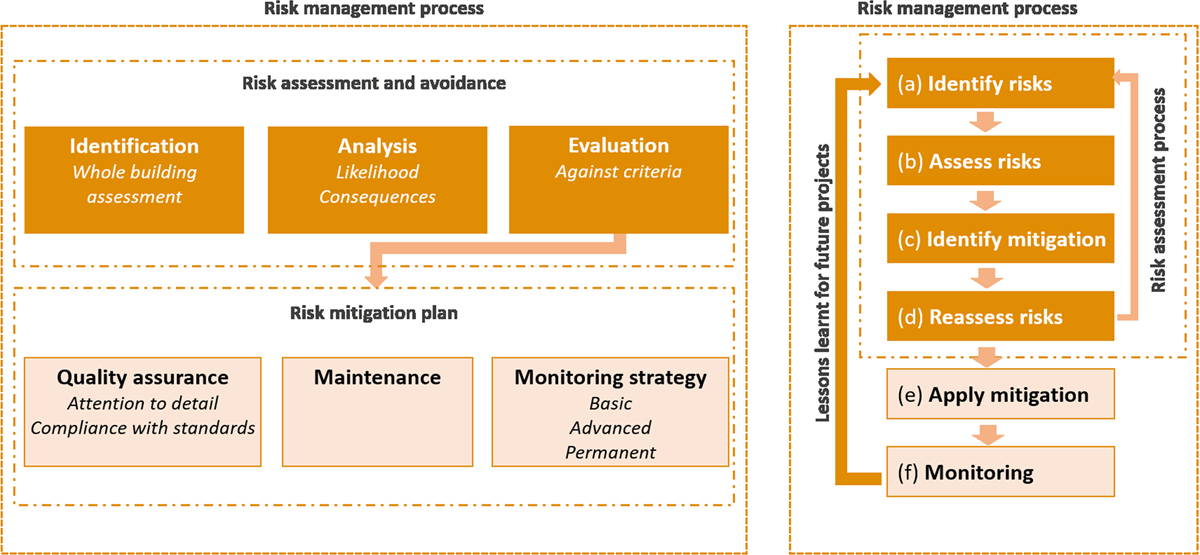

The initial version of the process (Figure 1, left) was composed of two separate parts: a first on risk assessment and avoidance—concerning risk identification, analysis and evaluation; and a second on the development of a risk-mitigation plan, based on quality assurance, maintenance and monitoring. The process entailed the use of the results of risk evaluation for the development of the risk-mitigation plan.

Figure 1

First draft (left) and final version (right) of the devised risk-management process.

During the stakeholders’ workshop, most participants suggested combining the development of a mitigation plan within the risk assessment process and stressed the importance of providing feedback from monitoring to risk identification. All responses were collated and implemented into a final version of the moisture risk-management process (Figure 1, right), which considers the assessment and management of risk within six main stages: (a) the identification and (b) assessment of risks for a proposed retrofit strategy, followed by the (c) identification of measures for mitigation of such risks, if needed, the (d) the reassessment of the risks after mitigation and the (e) decision on whether to apply such mitigation. For continual improvement of the risk management, the process ends with (f) monitoring, which must be fed back into the identification of risk for future projects. This provides the continuous generation of knowledge necessary for a sustainable and safe scaling up of retrofit measures.

4.2. Risk-management framework

The energy and moisture risk-management framework (Table 2) was developed to embed the risk-management process within the construction process in the retrofit of traditional buildings. It applies the four principles of the BSI’s White Paper (May & Sanders 2017) to the stages of the construction process. Risk management starts as soon as the project brief has been agreed with the client and the objectives of the retrofit project have been set.

Table 2

Energy and moisture risk-management framework.

| STAGE | ASSESSMENT/PLANNING | TECHNICAL DESIGN/SPECIFICATION | CONSTRUCTION/INSTALLATION | HANDOVER/USE |

|---|---|---|---|---|

| Core tasks during the stage | Assess the Context of the building(s) and devise a compatible overall approach that also meets all other design objectives | Apply a strategy for detailed design following principles of Coherence | Undertake moisture-safe construction according to the specification and principles of Coherence, Capacity and Caution | Handover documentation and operational guidance to users Implement any required measures of Caution |

| Conditions to be assessed or considered during the stage (specific to each retrofit measure) | See Table 3 as an example (solid-wall insulation) | See Table 4 as an example (solid-wall insulation) | See Table 5 as an example (solid-wall insulation) | |

| Documentation for information exchange (at the end of the stage) | Document the assessment and planning in a formal strategy List a set of suitable retrofit measures | Produce a detailed specification and instruction document with requirements for quality control | Document the actual construction process and all amendments and alterations from the specification | Document the additional interventions occurring after the retrofit (including maintenance) Store the monitoring and evaluation results |

The first stage of the framework, assessment/planning, requires the moisture risk-management process to focus on the analysis and understanding of the context of the building(s) pre-retrofit to develop an initial retrofit strategy (stages (a) and (b) in Figure 1, right). More than one strategy may be proposed during the assessment/planning stage for further assessment.

The second stage, technical design/specification, requires a focus on the principle of coherence by iteratively analysing the impact of the proposed retrofit strategies on the existing building(s) and assessing risk-mitigation options that could be applied as part of the overall retrofit strategy (stages (a) to (e) in Figure 1, right). The comparison of the assessed options would then lead to the specification of the most appropriate retrofit strategy for the building(s).

The third stage, construction/installation, concerns the installation of the specified retrofit strategy. This stage requires putting into practice the designer’s recommendations into the provision of coherence and considering caution and capacity by implementing safety factors in the process.

The last stage, handover/use, requires measures of caution for the successful performance of a retrofit strategy in use. Monitoring is central to this stage for the management of risk post-retrofit (stage (f) in Figure 1, right), as it generates new evidence and knowledge on the strategy’s performance, which is then fed back into the development of future strategies for the energy-efficient building retrofit enabling robust scaling-up.

5. Energy and moisture risk management: implications for solid wall retrofit

This section shows the practical integration of energy and moisture into the risk-management framework presented above in section 4. The risk management is illustrated across the four stages of the framework (as in Table 2) through an example for solid-wall insulation. The principles and subprinciples for moisture management stated in the BSI’s White Paper (May & Sanders 2017) (Table 1) are considered.

5.1. Assessment/planning

The assessment/planning stage requires the analysis of the building’s context, considering the following subprinciples: geography and climate, building conditions, built form, materials and construction method, and use. Table 3 illustrates the pre-retrofit conditions to be assessed at this stage. It contemplates elements such as wind-driven rain exposure and external finish conditions. It summarises key aspects to be considered, suggests appropriate assessment methods,1 and highlights relevant moisture and energy implications to be considered for each item.

Table 3

Pre-retrofit conditions to be assessed based on the principle of context to evaluate the existing risks for a solid wall.

| ASSESSMENT | CONSEQUENCES | |||

|---|---|---|---|---|

| MODE | METHOD | MOISTURE | ENERGY | |

| Geography and climate | ||||

| Assess prevalent wind direction | Desktop | Air infiltration | ||

| Assess wind-driven rain exposure | Desktop | BS 8104 (BSI 1992) | Rainwater penetration | Increased heat transfer |

| Assess the ability of the existing construction to resist driving rain | Rainwater penetration | Increased heat transfer | ||

| Conditions | ||||

| Assess the condition of vulnerable elements (e.g. rot or fungal attack for timber joists, corrosion for metal), especially if structural | Visual inspection; measurement | Moisture meters (e.g. microwave; moisture pins) | Structural damage | |

| Assess the condition of the external finish (e.g. render, pointing, mortar continuity, paints or coating) to check for cracks and damage, and assess if a repair is needed | Visual inspection; measurement | Thermography | Rainwater penetration | Localised increased heat transfer |

| Assess the quality and suitability of rainwater management (e.g. sill/verge overhangs, roof eaves, rainwater goods, drainage), and assess if a repair is needed | Visual inspection | Rainwater penetration | Localised increased heat transfer | |

| Assess the quality of seals around doors/windows | Visual inspection | Smoke pen | Water infiltration | Air infiltration; thermal comfort |

| Assess the whole-building air tightness | Measurement | Blower door test | Indoor moisture excess | Air infiltration; thermal comfort |

| Assess the existing moisture problems if any (e.g. mould, damp, condensation) on and within walls, junctions and adjacent elements (e.g. ceiling, floor), and investigate the cause(s) of the problem for possible repairs | Visual inspection; measurement | Thermography; moisture meters (e.g. microwave) | Occupants’ health; damp; structural damage | Increased heat transfer |

| Assess the whole-building thermal performance | Desktop; measurement | Annual energy usage (e.g. bills, smart meters); heat transfer coefficient (HTC) evaluation (e.g. co-heating) | Heating/cooling loads | |

| Assess the indoor environmental quality (IEQ) | Measurement | IEQ sensors (e.g. temperature and relative humidity) | Indoor moisture excess; mould growth | Thermal comfort; heating/cooling loads |

| Built form | ||||

| Assess the complexity of the built form and details to evaluate the ease and suitability of retrofit interventions | Desktop | Architectural drawings | Rainwater penetration | Potential thermal bridging |

| Materials and construction method | ||||

| Identify the existing construction method | Desktop; visual inspection | |||

| Identify the existing materials and their properties | Desktop; visual inspection; measurement | Tests: U-value; thermal conductivity; water absorption | Excess moisture | Heating/cooling loads; energy balance |

| Identify the existing rainwater protection | Visual inspection; measurement | Water absorption test | Rainwater penetration | |

| Use | ||||

| Assess the existing ventilation system and building services (e.g. heating) and whether they need upgrading | Visual inspection; measurement | Opening areas; air flow measurement in ductwork | Indoor moisture excess | Air infiltration; heating/cooling loads |

The conditions of the building pre-retrofit should be assessed both through desktop work and in-situ surveys. Desktop work enables understanding the building and its context through the analysis of existing documentation (e.g. architectural drawings, energy bills) and relevant literature (e.g. standards). In-situ surveys allow the evaluation of the actual performance and state of conservation of the building in its context; the pre-retrofit conditions are assessed by visual inspection and quantitative methods, and findings are documented. Quantitative methods may include non-destructive techniques (e.g. thermography, microwave), spot measurements (e.g. blower door and smoke test, moisture meters), laboratory testing of the hygrothermal properties of building materials (e.g. thermal conductivity or the water absorption test), and longer term measurements (e.g. to estimate the U-value of the elements and/or the heat transfer coefficient (HTC) of the building fabric to evaluate indoor environmental quality (IEQ) conditions).

The information gathered in this stage should result in recommendations about suitable retrofit measures for the assessed building(s). All the gathered information (including recommendations) should be fed into the following stage and used to support the retrofit strategy design and specification (see section 5.2 below).

5.2. Technical design/specification

The technical design/specification stage requires the analysis of the impact of the proposed retrofit measures on the existing building(s) and the assessment of options for risk mitigation that could be applied as part of the overall retrofit strategy. This stage is guided by the principle of coherence, considering the following subprinciples: coherence of moisture and thermal approach, airtightness, weathering and waterproofing, ventilation, and building services. Table 4 lists the conditions to be considered for the design and specification of retrofit measures for solid walls. It suggests appropriate assessment methods and highlights relevant moisture and energy implications. Technical design and specification can be further supported by tools such as those developed within the RIBuild project (De Place Hansen 2020) and the Sustainable Traditional Building Alliance’s (STBA) Guidance wheel (STBA 2012).

Table 4

Conditions to be considered based on the principle of coherence to evaluate the risks of retrofit strategies for solid walls.

| ASSESSMENT | CONSEQUENCES | |||

|---|---|---|---|---|

| MODE | METHOD | MOISTURE | ENERGY | |

| Coherence of the moisture and thermal approach | ||||

| Assess building performance with the retrofit measure(s) proposed | Desktop | Dynamic building performance simulations | Indoor moisture excess | Energy balance; heating/cooling loads; thermal comfort |

| Assess the extent of moisture interactions in the build up of existing walls (e.g. the presence and type of render, plaster) | Desktop; visual inspection | Hygrothermal simulations, according to EN 15026 (CEN 2007) | Excess moisture; interstitial condensation | |

| Assess the moisture risk with the retrofit measure(s) proposed to understand the influence of factors such as climate, exposure and orientation | Desktop | Hygrothermal simulations | Excess moisture; mould growth; occupants’ health | (Localised) increased heat transfer |

| Identify any standard and non-standard obstacles (e.g. fences, walls, satellite dishes, hanging baskets) that will require specific detailing to overcome thermal bridging | Desktop; visual inspection | Architectural drawings | Condensation; mould growth | Thermal bridging |

| Airtightness | ||||

| Identify any standard and non-standard obstacles that will require specific detailing to overcome air leakage | Desktop; visual inspection | Water vapour infiltration; interstitial condensation | Air infiltration; thermal comfort | |

| Assess the impact of the retrofit measure(s) on seals around doors/windows and identify if specific detailing will be required to overcome an air leakage | Desktop | Water vapour infiltration; interstitial condensation | Air infiltration; thermal comfort | |

| Assess the compatibility of the retrofit measure(s) on the whole-building air tightness (compared with pre-retrofit conditions) | Desktop | Indoor moisture excess | ||

| Weathering/waterproofing | ||||

| Identify any standard and non-standard obstacles that will require specific detailing to overcome moisture ingress (e.g. rainwater penetration) | Desktop; visual inspection | Rainwater penetration | Increased heat transfer | |

| Ventilation/building services | ||||

| Assess the compatibility of the retrofit measure(s) with existing services (e.g. services in the way) | Desktop; visual inspection | Excess moisture; mould growth | Energy balance; heating/cooling loads | |

| Assess the compatibility of the existing ventilation system with the retrofit measure(s) and whether it needs upgrading | Measurement | Opening areas; air flow measurement in ductwork | Indoor moisture excess; occupants’ health | |

The knowledge gathered in this step is used to narrow the list of suitable measures and to support the specification of the most appropriate retrofit strategy for the building(s).

5.3. Construction/installation

The construction/installation stage concerns the implementation of the specified retrofit strategy. This stage requires (1) putting into practice the designer’s recommendations regarding the provision of coherence (described above in section 5.2); and (2) considering capacity and caution to allow for the handling of unexpected problems that were not obvious before stripping out the building. Implementing quality control procedures is crucial to ensure compliance with design, and it requires interim measurements at the end of key phases of the construction. Clarity on who is to inspect construction quality is key to ensure that the building is delivered in line with the requirements set out in the design and specification stage (RIBA 2020).

Contractors should document any amendments and alterations from the specification during the construction stage. This results in improved awareness and better-informed risk management.

5.4. Handover/use

The handover/use stage requires measures of caution for the successful performance of a retrofit strategy in operation. Moreover, this stage should generate new evidence for and knowledge about the performance of the strategy implemented, which is then fed back into the development of robust and scalable retrofit strategies in the future. The subprinciples guiding this stage are usability, maintenance, monitoring and evaluation, and feedback. Table 5 lists the conditions to be assessed post-retrofit during the operational phase of the building. It suggests appropriate assessment methods and highlights relevant moisture and energy implications through an example for solid walls.

Table 5

Conditions to be assessed based on the principle of caution to evaluate the long-term risks of the retrofit strategy for solid walls.

| ASSESSMENT | CONSEQUENCE | |||

|---|---|---|---|---|

| MODE | METHOD | MOISTURE | ENERGY | |

| Usability | ||||

| Provide adequate handover (e.g. documentation on fixings for insulated walls, ventilation) | ||||

| Maintenance | ||||

| Plan maintenance of the external facade (e.g. render, pointing) | Rainwater penetration | Thermal bridges; increased heat transfer | ||

| Keep rainwater goods and drainage in good condition | Rainwater penetration | Localised increased heat transfer | ||

| Monitoring and evaluation | ||||

| Monitor the overall energy use in the building | Measurement | Utility meters | Heating/cooling loads | |

| Monitor the energy use of the individual systems | Measurement | Submeters | Heating/cooling loads | |

| Perform a Post-Occupancy Evaluation (POE) | Survey; interviews with the building’s users | Mould growth | Thermal comfort | |

| Monitor the indoor environmental quality (IEQ) (e.g. temperature, relative humidity, CO2) | Long-term measurement | IEQ sensors | Mould growth; occupants’ health | Thermal comfort; heating/cooling loads; occupants’ health |

| Measure heat losses through the insulated walls | Measurement | U-value test | Heating/cooling loads | |

| Measure heat loss through the whole building envelope | Measurement | Heat transfer coefficient (HTC) evaluation (e.g. co-heating) | Heating/cooling loads | |

| Assess the airtightness of the building envelope | Measurement | Blower door test | Water vapour infiltration | Air infiltration; thermal comfort |

| Assess the moisture content of the insulated wall | Measurement | Moisture meters (e.g. microwave) | Excess moisture; mould growth; structural damage | Increased heat transfer |

| Perform a condition survey of insulated walls and junctions | Visual inspection; measurement | Thermography | Mould growth | Thermal bridges |

| Monitor the conditions of vulnerable elements (e.g. joist ends, wall–insulation interface) | Long-term measurement | Embedded sensors (e.g. temperature, relative humidity, moisture content) | Mould growth; interstitial condensation; structural damage | |

| Feedback | ||||

| Periodically review the performance of the retrofit project and update the risk management based on the emerging knowledge | ||||

The handover/use stage should focus on the assessment of the building post-retrofit (both immediately after completion and in the longer term) to ensure the solution is performing as intended, identify the development of any risks on time, and support the learning process. The assessment of post-retrofit conditions should be carried out through interviews with building users as well as visual inspections and the monitoring of key parts of the building prone to energy and moisture risks. Long-term monitoring strategies may include the use of sensors (e.g. IEQ sensors or those embedded in the building fabric) that have to be deployed during the retrofit intervention. Therefore, the design of the monitoring strategy should be fully integrated into the design of the retrofit solution adopted (e.g. with considerations of the placement and future accessibility of sensors). With the emerging interest in smart, cloud-based sensing devices, in future the monitoring kit installed could be set up to automatically store and pre-process the data recorded, and to alert, for example, when something unexpected is recorded and further checks would be needed. This could open up new avenues for building quality assurance and performance-based financial and insurance products to support retrofit uptake.

6. Discussion and conclusions

This paper presents the development of a novel retrofit risk-management process and framework integrating energy and moisture issues. An example of the framework’s practical application was provided, with a focus on retrofit measures for solid-wall insulation. The example shows that although the risk management focused on only one measure (i.e. solid-wall insulation), more elements and systems had to be considered, suggesting the importance of a holistic approach. The example shows that energy and moisture are often interconnected, as in most cases risk-management aspects would have both energy and moisture implications.

The risk-management process and framework can be valuable tools to reduce the likelihood and impact of unintended consequences in retrofit, leading to robust and scalable retrofit measures and strategies. The example developed in this paper focused on supporting designers across the construction process, and it could be a useful reference for building surveyors and other actors involved in the retrofit process. The further development of the framework and associated guidance should target other actors, such as contractors and clients.

The fragmented nature of the UK’s construction industry, as well as the lack of prescriptive roles—and associated allocation of responsibilities within the project team—pose a challenge for integrating retrofit risk management across the construction process. However, for the domestic building stock, standards such as PAS 2035:2019 (Rickaby 2019) offer an opportunity to integrate the retrofit risk management within a wider framework for improved quality assurance. The adherence to PAS 2035 is mandatory in the UK for government-backed domestic retrofit projects (e.g. Energy Company Obligation). The PAS 2035 has also established the role of retrofit coordinators, defined as:

a specialist retrofit project manager, taking overall responsibility for overseeing the assessment of dwellings, the identification, specification and evaluation of energy efficiency measures for installation at a given dwelling as a single project, and their subsequent monitoring and evaluation.

This recently established professional figure will be able to take the responsibility of delivering a robust retrofit if equipped with the right tools such as the presented framework.

Guidelines for and training on retrofit risk management are necessary for the application of the framework and process in practice. Part of this content has been integrated into a training programme on ‘Understanding and Managing Moisture Risks in Buildings’, developed at the UKCMB and offered by two UK-based membership organisations. More should be done in future to expand the training programme for wider target audiences. Checklists based on this framework are currently being developed and included in the relevant standard on moisture in buildings, BS 5250:2021 Management of Moisture in Buildings—Code of Practice (BSI 2021).

This paper showed how risk management could integrate two disciplines, namely energy and moisture. Further integration is possible, for example, with heritage impact assessment and the assessment of wider environmental and health issues (e.g. radon, pollution). Moreover, the practical application to solid walls illustrated here could be extended to other vulnerable elements, such as suspended ground floors. Similarly, although the framework was developed for traditional buildings, it can be applied to other constructions with high moisture vulnerability (e.g. modern timber frame construction).

Notes

Acknowledgements

This paper is dedicated to the memory of the late Neil May MBE, who drove the development of this work and is a continuing source of inspiration.

The authors thank all the UK Centre for Moisture in Buildings members and Dr Peter Rickaby who contributed to the development of the moisture risk-assessment process.

Authors contribution

Concept development of paper and original draft preparation: V.M. and V.G.

Design of the work and framework development: V.M., V.G., H.A.-M.

Editing and final version approval: V.M., V.G., H.A.-M.

Competing interests

The authors have no competing interests to declare.

Funding

The authors are especially grateful for the financial support received from the Engineering and Physical Sciences Resource Council (EPSRC) Platform Grant (grant number EP/P022405/1); and the EPSRC UCL Doctoral Prize Fellowship (grant number EP/N509577/1).