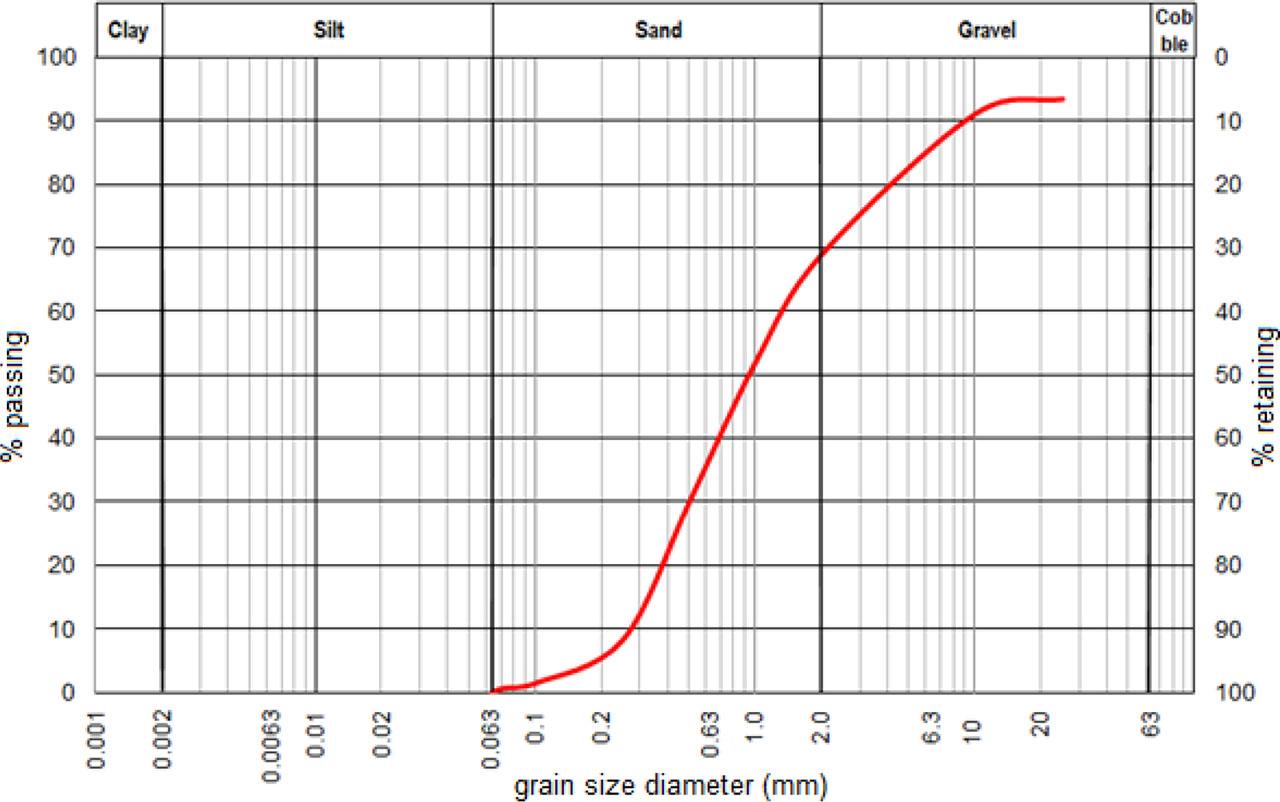

Figure 1:

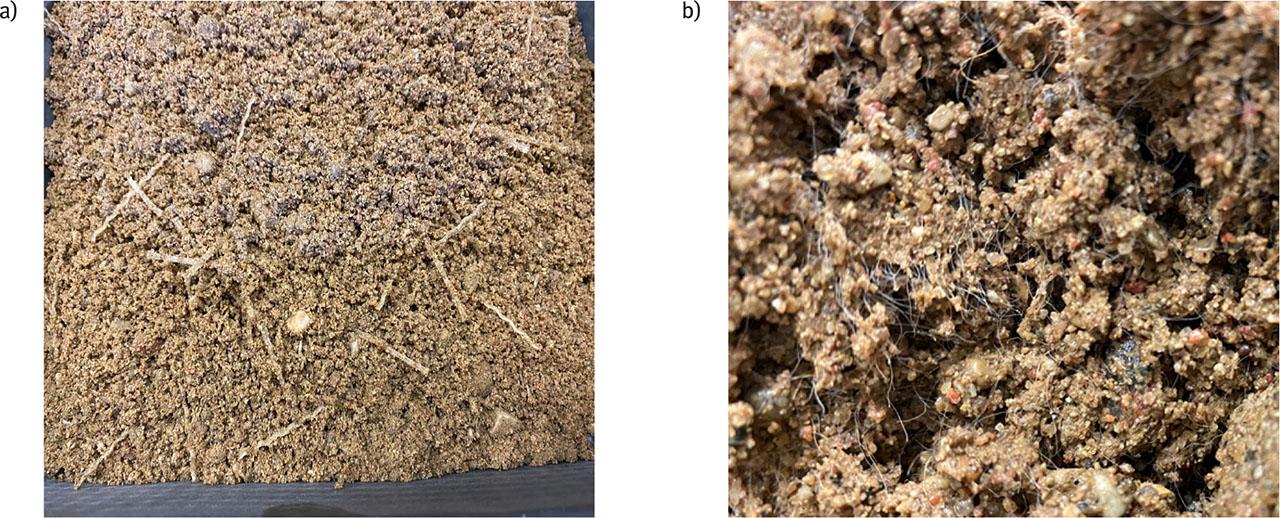

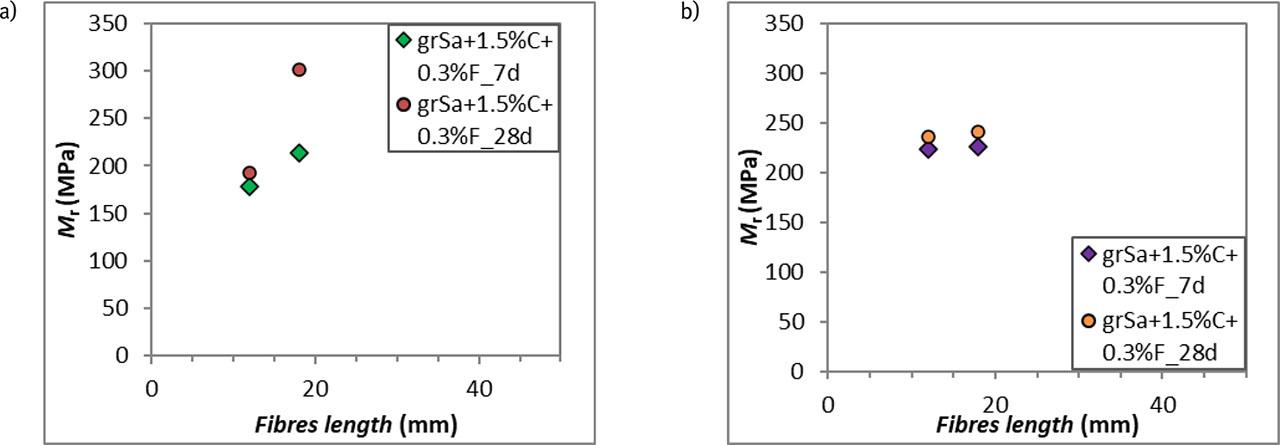

Figure 2:

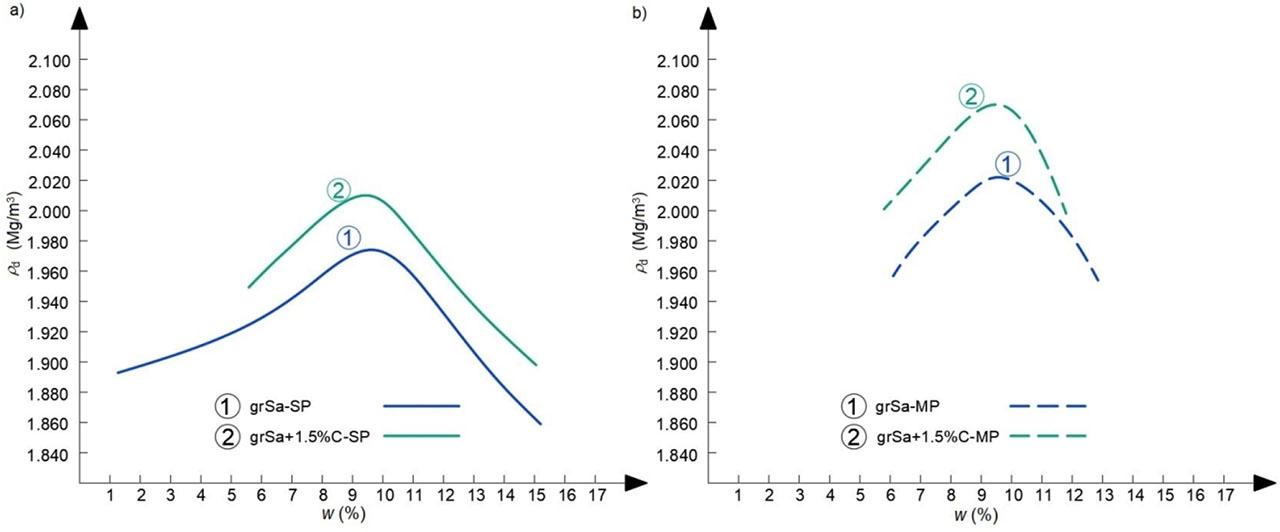

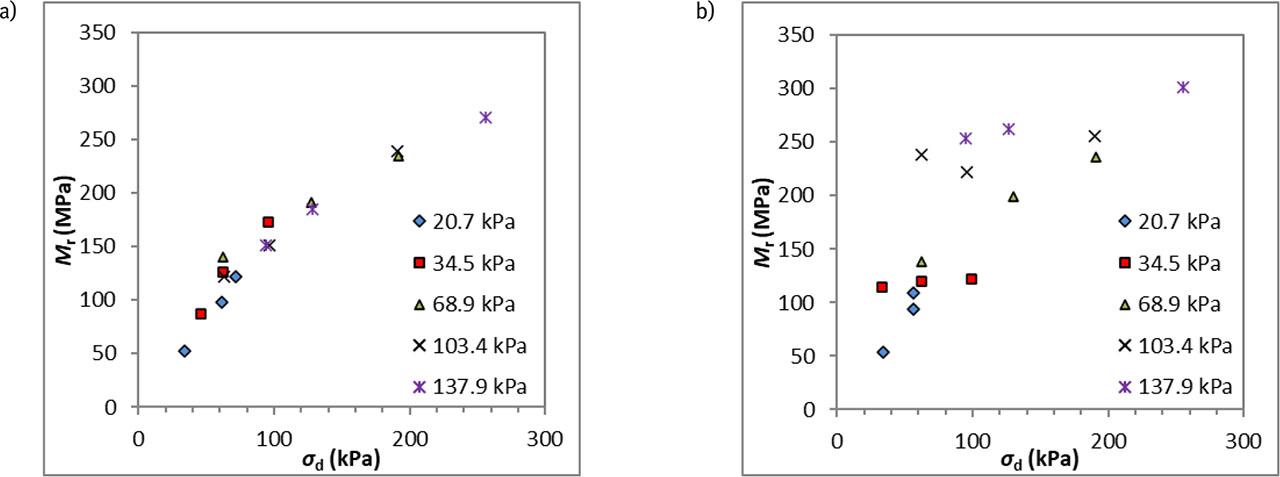

Figure 3:

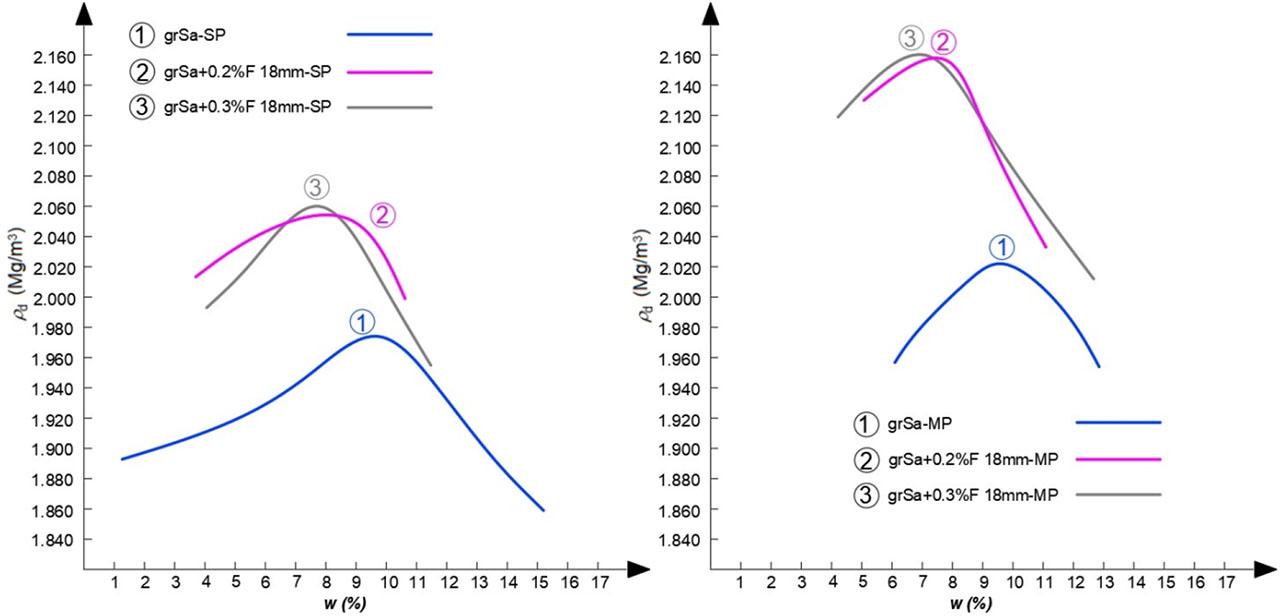

Figure 4:

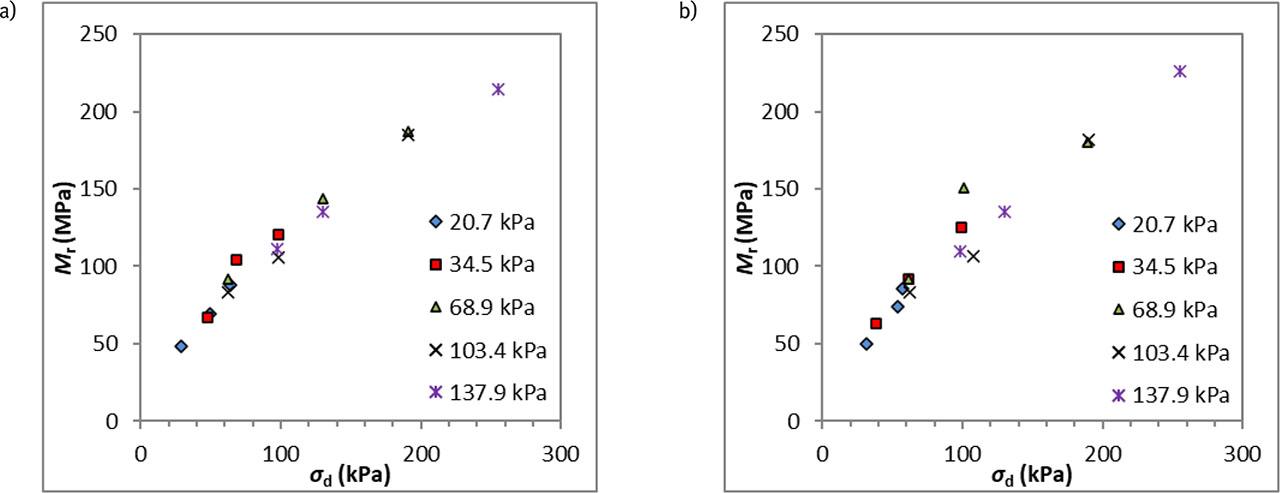

Figure 5:

Figure 6:

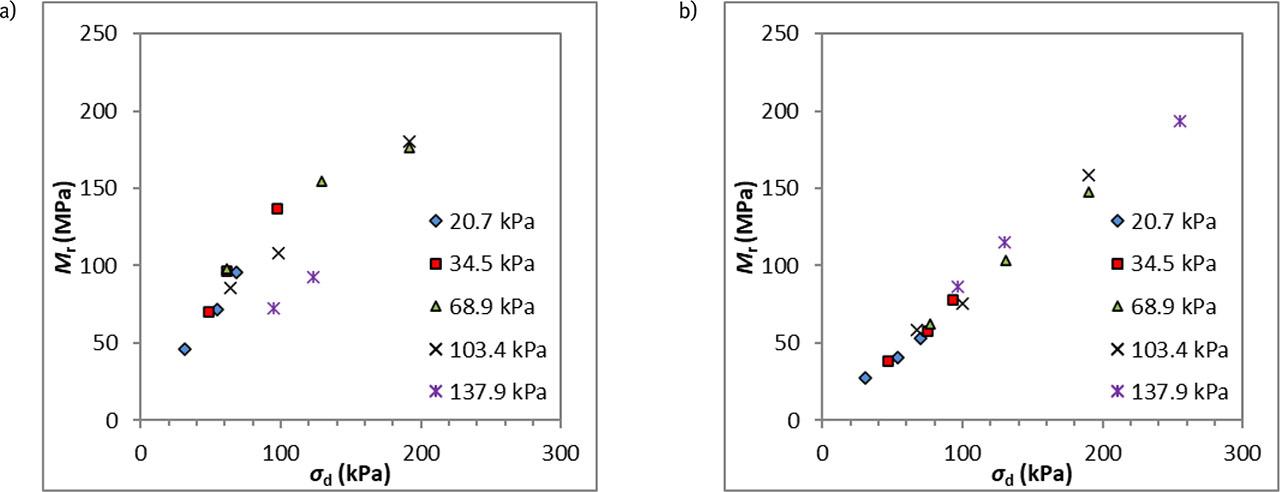

Figure 7:

Figure 8:

Figure 9:

Figure 10:

Figure 11:

Figure 12:

Figure 13:

Figure 14:

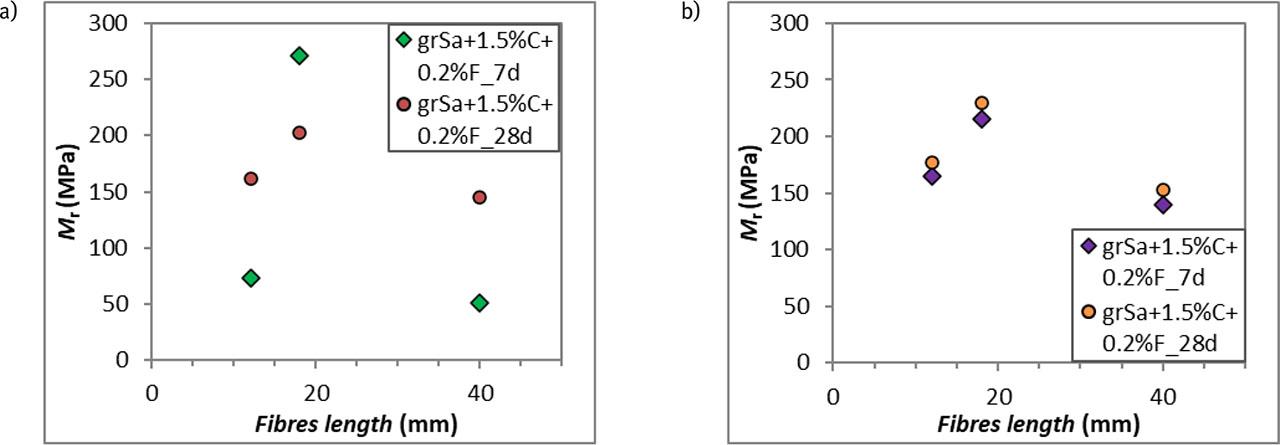

Values of Mr obtained for samples after different compaction and curing periods_

| Samples | Resilient modulus Mr (MPa) | Curing period | |

|---|---|---|---|

| SP compaction | MP compaction | (days) | |

| grSa+1.5%C | 197 | 168 | 7 |

| 272 | 353 | 28 | |

| grSa+1.5%C+0.2%F_12 mm | 73 | 165 | 7 |

| 162 | 177 | 28 | |

| grSa+1.5%C+0.3%F_12 mm | 193 | 224 | 7 |

| 178 | 236 | 28 | |

| grSa+1.5%C+0.2%F_18 mm | 271 | 215 | 7 |

| 202 | 230 | 28 | |

| grSa+1.5%C+0.3%F_18 mm | 301 | 226 | 7 |

| 214 | 241 | 28 | |

| grSa+1.5%C+0.2%F_40 mm | 51 | 140 | 7 |

| 145 | 153 | 28 | |

The specific density and compaction parameters of tested materials_

| Sample | ρs(Mg/m3) | Proctor compaction method | |||

|---|---|---|---|---|---|

| Standard | Modified | ||||

| wopt (%) | ρd max (Mg/m3) | wopt (%) | ρd max (Mg/m3) | ||

| grSa | 2.65 | 9.7 | 1.974 | 9.6 | 2.022 |

| grSa+1.5%C | 2.66 | 9.5 | 2.010 | 9.5 | 2.070 |

| grSa+1.5%C+0.2%F_12 mm | 2.66 | 9.4 | 2.075 | 7.9 | 2.150 |

| grSa+1.5%C+0.3%F_12 mm | 2.66 | 8.9 | 2.103 | 6.8 | 2.170 |

| grSa+1.5%C+0.2%F_18 mm | 2.66 | 7.9 | 2.066 | 7.0 | 2.183 |

| grSa+1.5%C+0.3%F_18 mm | 2.66 | 8.0 | 2.060 | 7.8 | 2.124 |

| grSa+1.5%C+0.2%F_40 mm | 2.66 | 8.8 | 2.108 | 7.5 | 2.144 |