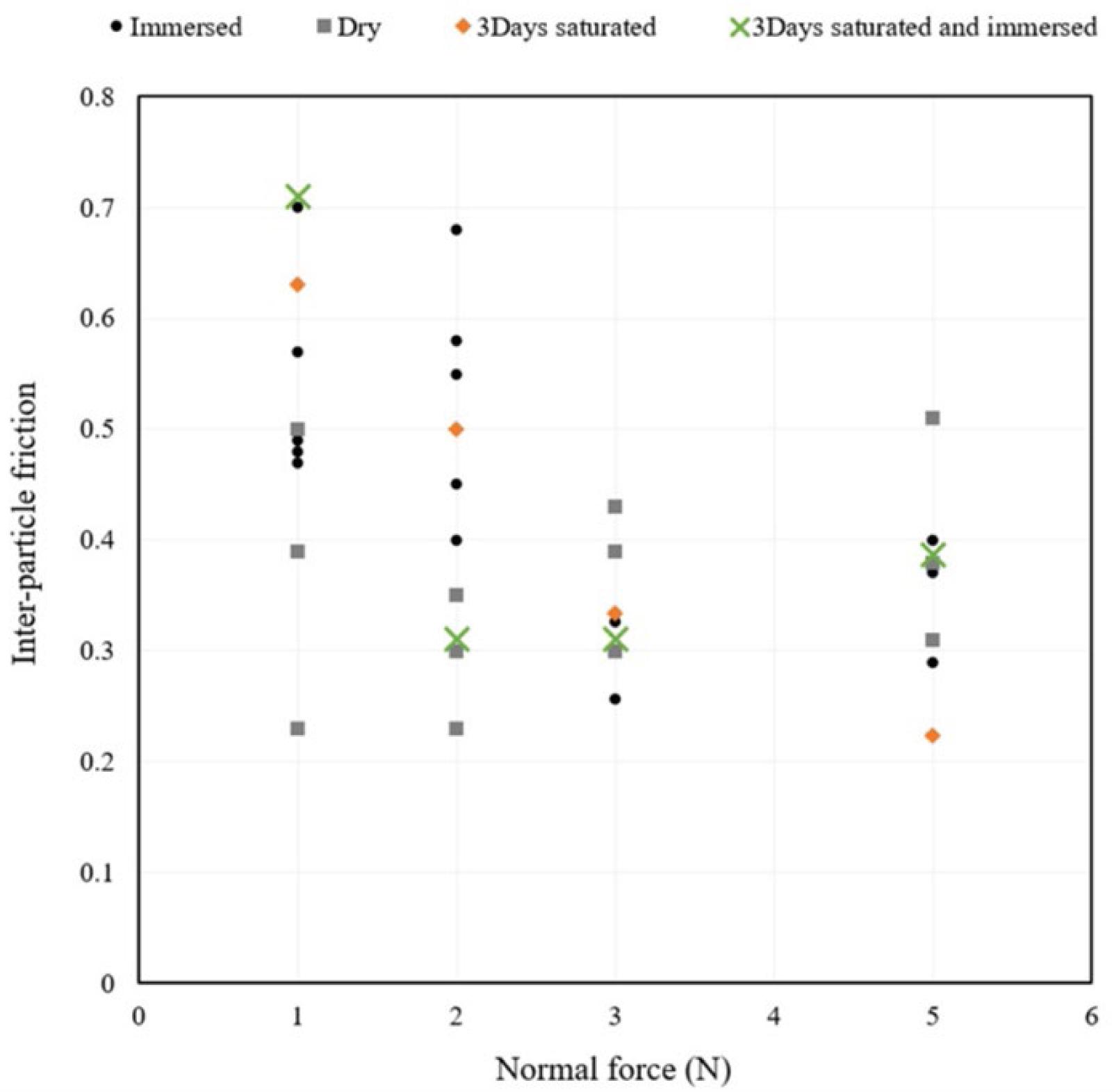

Figure 1

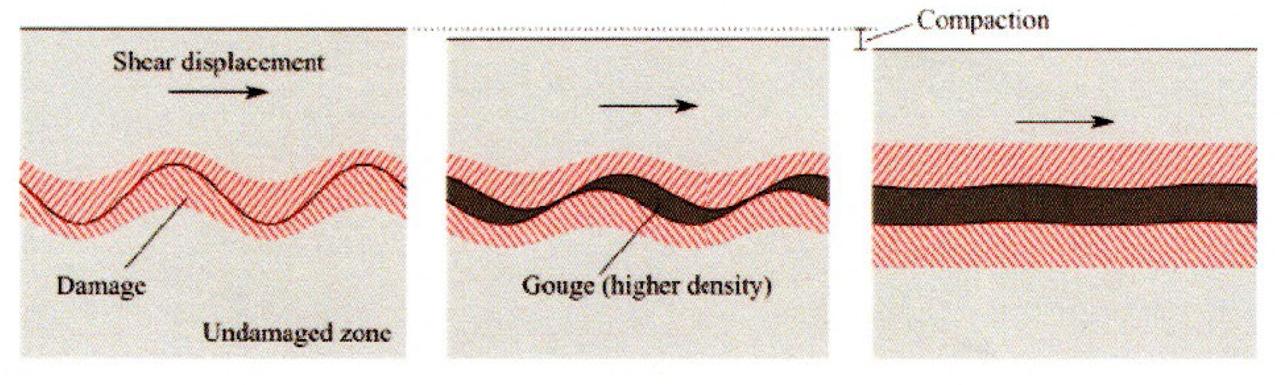

Figure 2

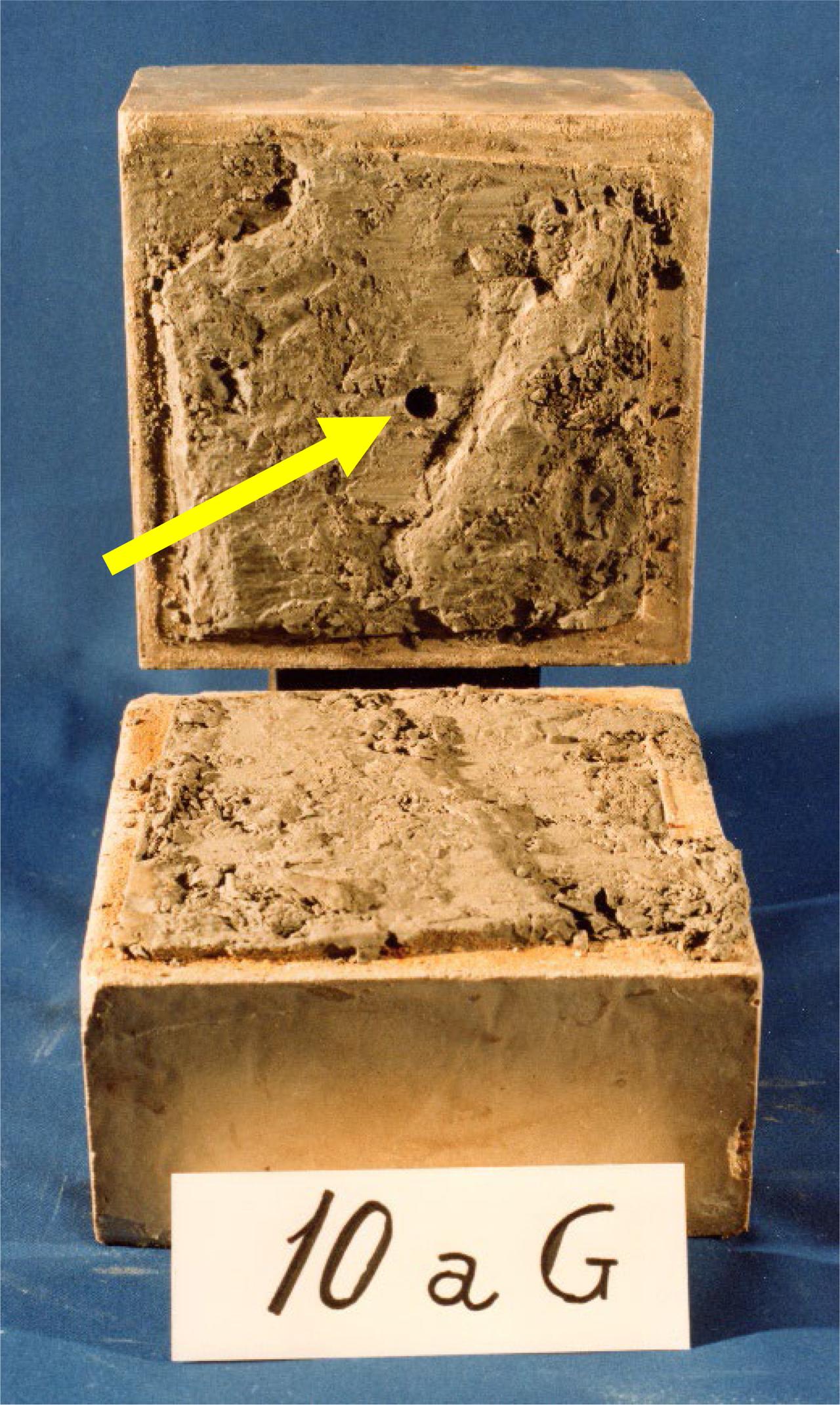

Figure 3

Figure 4

Figure 5

Figure 6

Figure 7

Figure 8

Static friction coefficient of minerals under different humidity conditions (data from Horn and Deere 1962)_

| Mineral | Oven dried | Saturated |

|---|---|---|

| Rose quartz | 0.13 | 0.45 |

| Microcline feldspar | 0.12 | 0.77 |

| Calcite | 0.14 | 0.68 |

| Muscovite | 0.43 | 0.23 |

| Chlorite | 0.53 | 0.22 |

Morphological and friction parameters for two granular soils (DNA-1A and OS) with different roughness, under both dry and wet conditions; the interparticle friction angle is assessed based only on tests carried out at 1 N normal contact force (data from Marzulli et al_ 2021)_

| Material | Particle size (for microtest), mm | Hardness, GPa | Roundness | Roughness, nm | φ′bulk low stresses range (°) | φ′bulk medium–higher stresses range (°) | φ′μ (°) |

|---|---|---|---|---|---|---|---|

| DNA-1A dry | 1.0–1.8 | 0.3 | 0.6 | 1476 | 47.9 | 40.8 | 21 |

| DNA-1A wet | 45.9 | 30 | |||||

| OS dry | 0.5–0.8 | 5.8 | 0.8 | 204 | 45.0 | 36.5 | 7.6 |

| OS wet | 40.8 | - |

Measured values of φb under different moisture conditions for granite and sandstone (data from Li et al_ 2020)_

| Rock type | Moisture condition | φb (°) |

|---|---|---|

| Granite | Dry | 33.46 |

| Wet surface | 30.59 | |

| Saturated | 30.38 | |

| Sandstone | Dry | 35.30 |

| Wet surface | 32.92 | |

| Saturated | 32.62 |

Shear strength of rock fractures under dry and wet conditions (data from Barton 1973; Alejano et al_ 2012)_

| Rock type | φb (°) | |

|---|---|---|

| Dry | Wet | |

| Mudstone | 32 | 29 |

| Siltstone | 32 | 30 |

| Limestone | 34 | 31 |

| Sandstone | 31 | 29 |

| Marble | 49 | 42 |

| Shale | 29 | 21 |

| Granite | 33 | 31 |

Values of residual friction angle of Campolattaro marls for different conditions of humidity and shearing direction (data from ISMES 1982)_

| Sample joint | Shearing direction | Number of data | Friction angle by linear regression (°) | Average friction angle (°) |

|---|---|---|---|---|

| Saturated | Parallel to joint | 8 | 17.7 | 16.3 |

| Dry | Parallel to joint | 9 | 38.0 | 37.8 |

| Dry | Perpendicular to joint | 8 | 44.4 | 44.5 |