Fig. 1

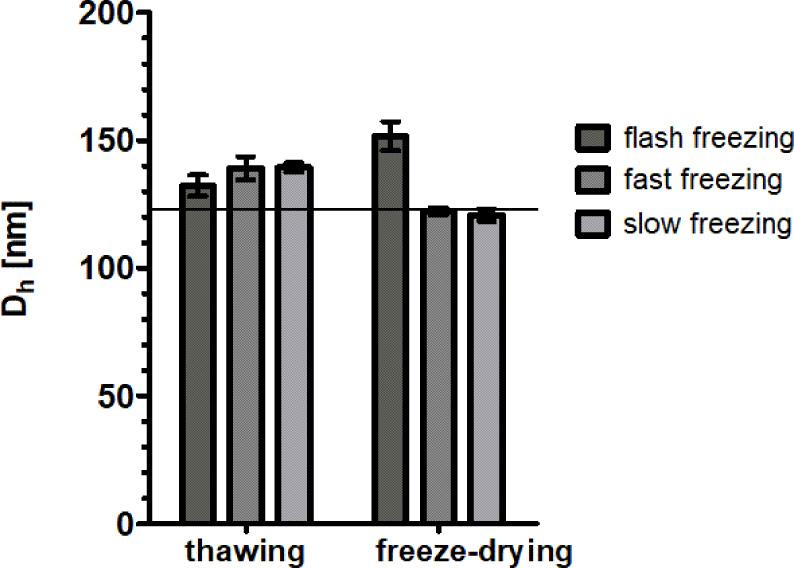

Fig. 2

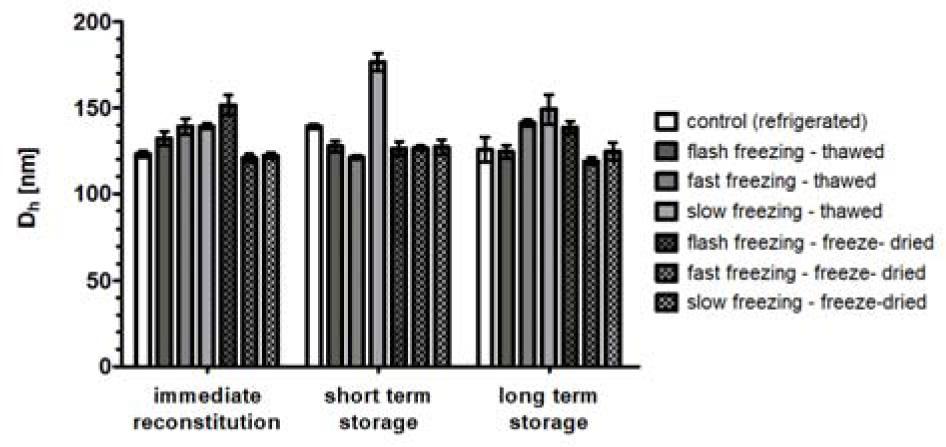

Fig. 3

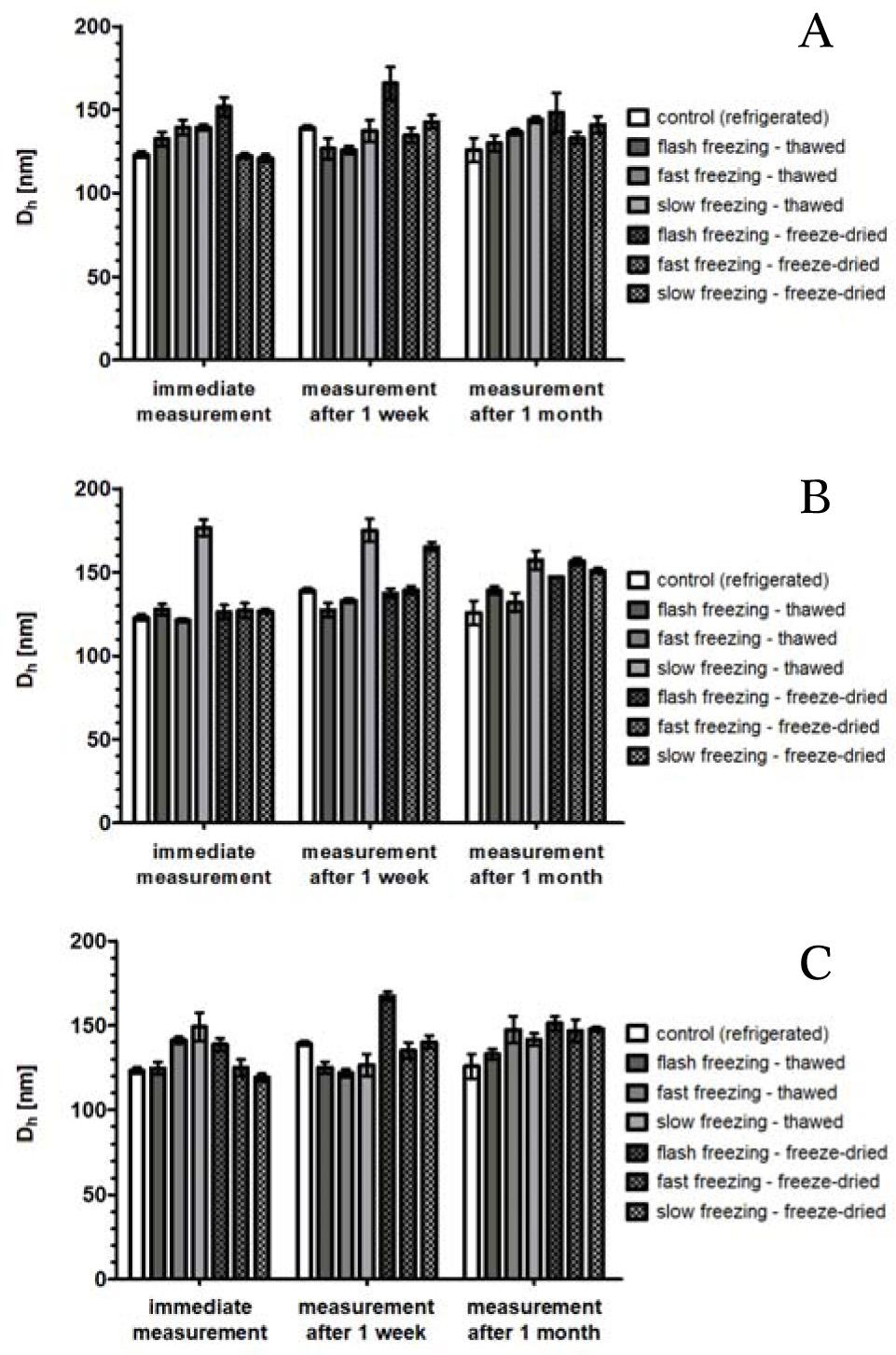

Fig. 4

Fig. 5

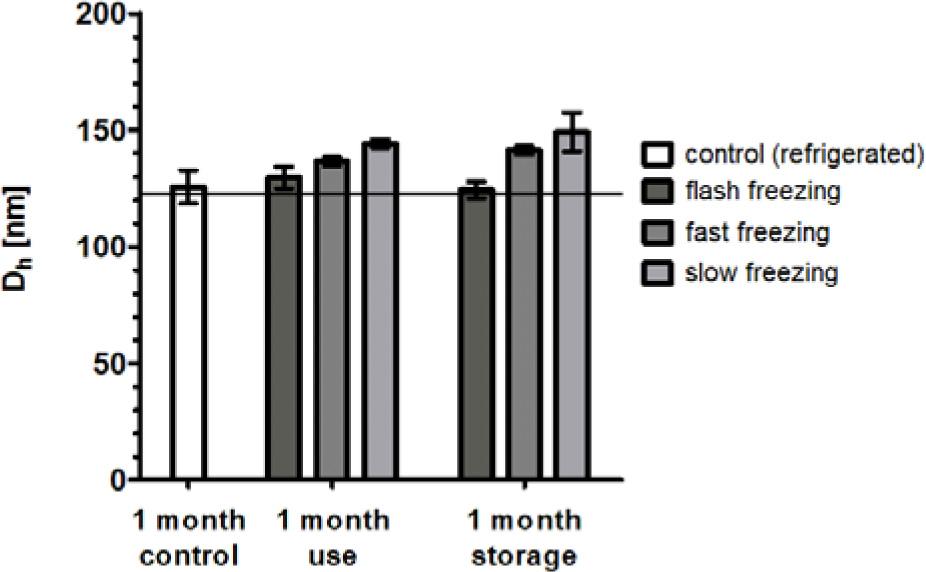

Details on the samples’ possible processing scenarios

| Processing, storage, and sample usage parameters | Options |

|---|---|

| Freezing conditions | Flash freezing (liquid nitrogen, −196°C) |

| Fast freezing (precooled freezer, −70°C) | |

| Slow freezing (precooled freezer, −22°C) | |

| Reconstitution strategy | Freeze-drying and redispersion |

| Thawing | |

| Stock storage period | Immediate reconstitution |

| 1-week storage | |

| 1-month storage | |

| Sample use period (after stock reconstitution) | Immediate measurement |

| Measurement after 1 week | |

| Measurement after 1 month |

Detailed description of various processing steps applied to the samples

| Flash freezing | Aliquoted samples were immersed in liquid nitrogen for at least 3 min, until visual inspection of samples confirmed full freeze. For prolonged storage, stock samples were moved to the precooled freezer (−70°C). |

| Fast freezing | Aliquoted samples were placed in −70°C precooled freezer for at least 12 h. For prolonged storage, stock samples were kept in the −70°C precooled freezer. |

| Slow freezing | Aliquoted samples were placed in −22°C precooled freezer for at least 12 h. For prolonged storage, stock samples were kept in −22°C precooled freezer. |

| Thawing | Reconstitution was realized by placing the stock sample at 4°C for thawing. The reconstituted sample was stored at 4°C for the whole sample use period. |

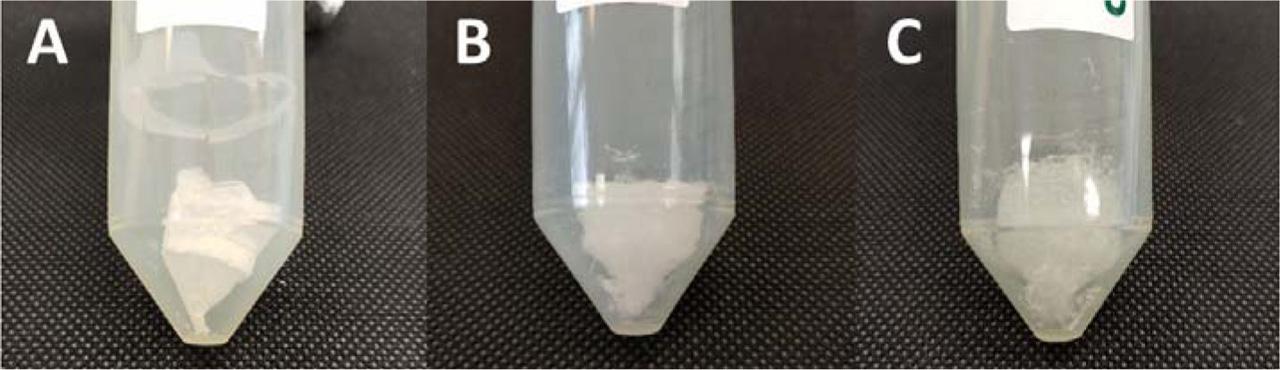

| Freeze-drying and redispersion | All stock samples, frozen in different conditions, after overnight treatment, were placed together in precooled freeze-dryer, at high vacuum, with a condenser surface temperature of −50°C, for 120 h. Stock samples in the form of freeze-dried cakes in conical tubes were vacuum-sealed and stored at 4°C until reconstitution. Redispersion was realized by adding 10 mL of ultrapure water to the cake and overnight moderate stirring at 37°C. Redispersed sample was stored at 4°C for the whole sample use period. |

| Stock storage period | Is considered to start when the processing of the particulate sample is completed, e.g., in the case of freeze-dried samples for redispersion – after completed lyophilization, and in the case of frozen samples for thawing – after samples are placed in the freezer. |