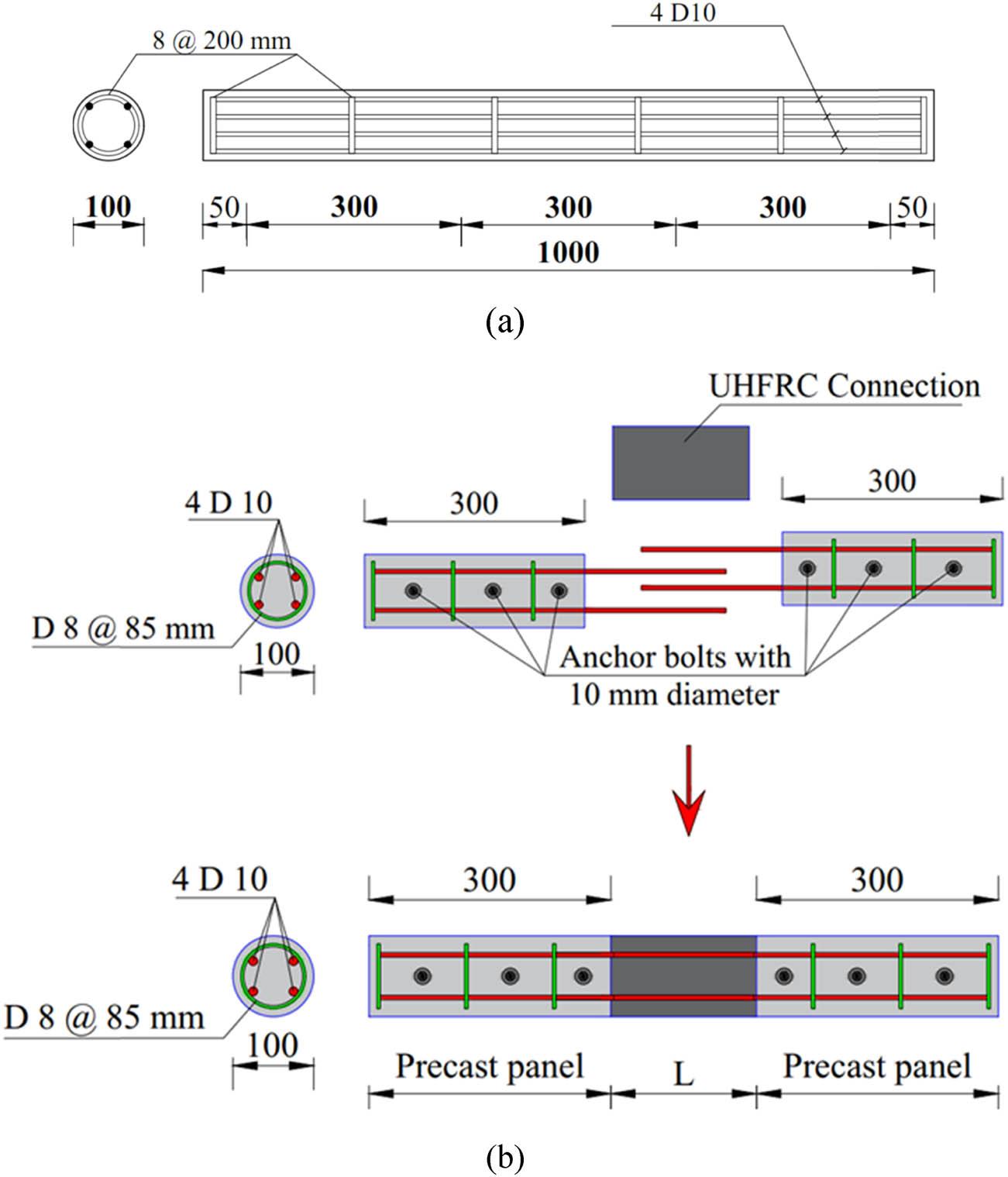

Figure 1

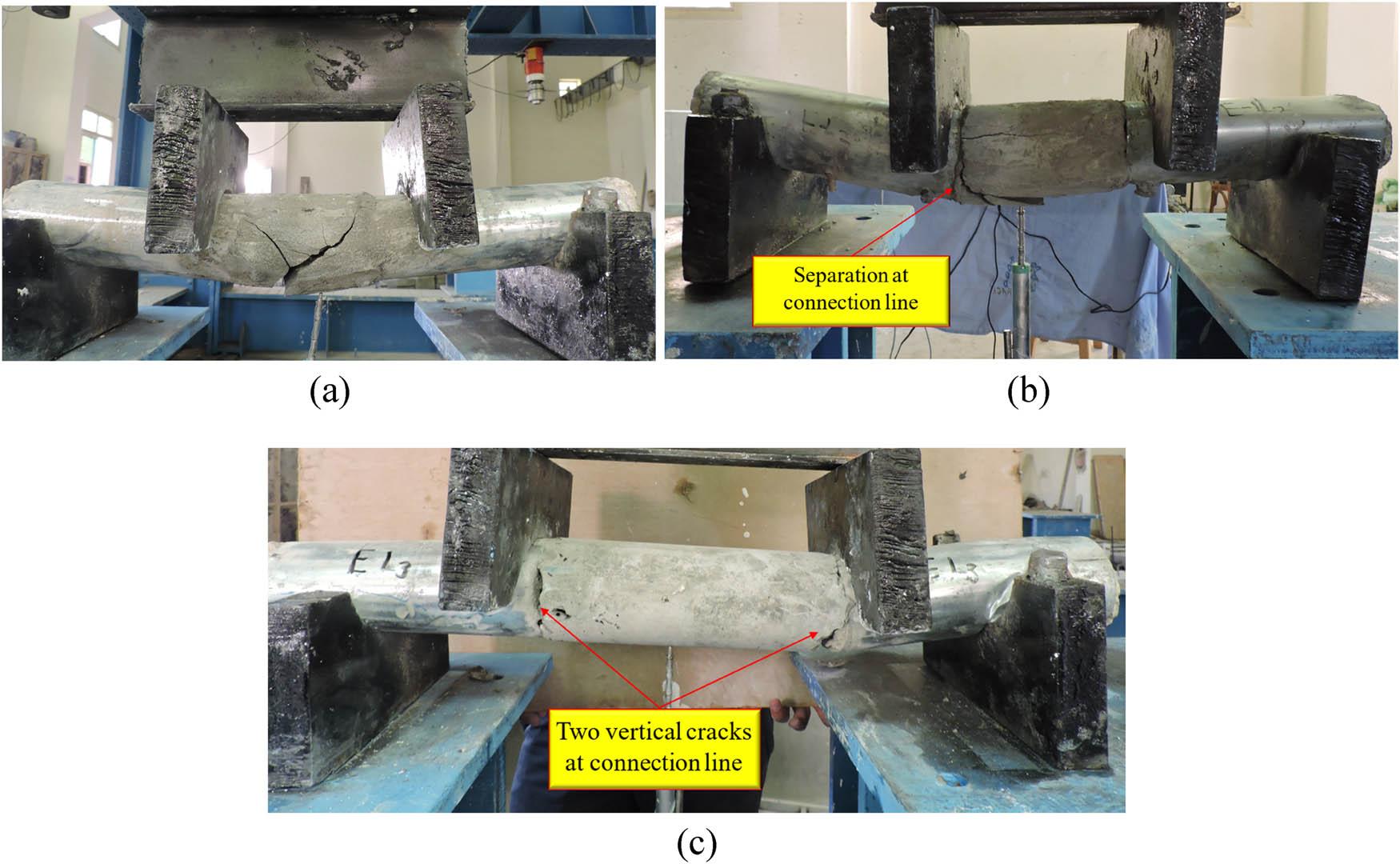

Figure 2

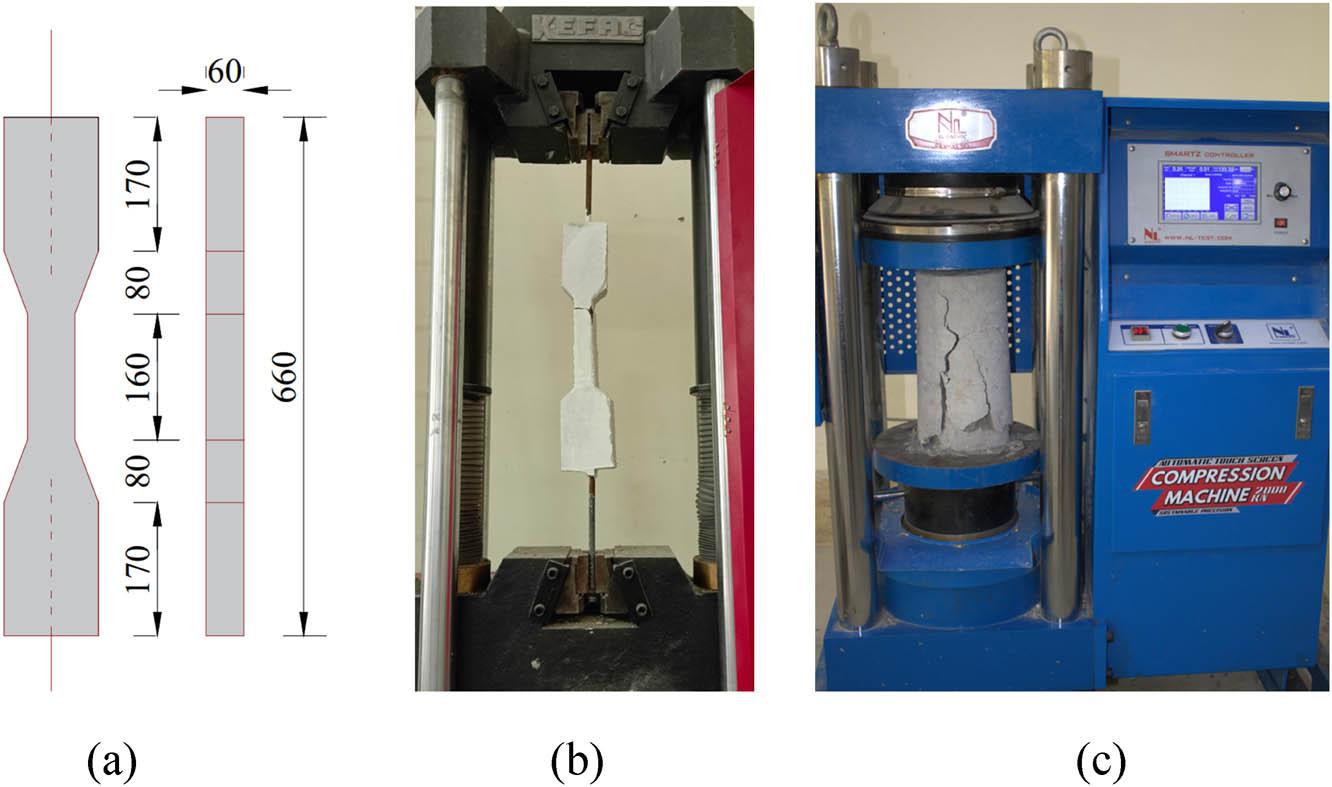

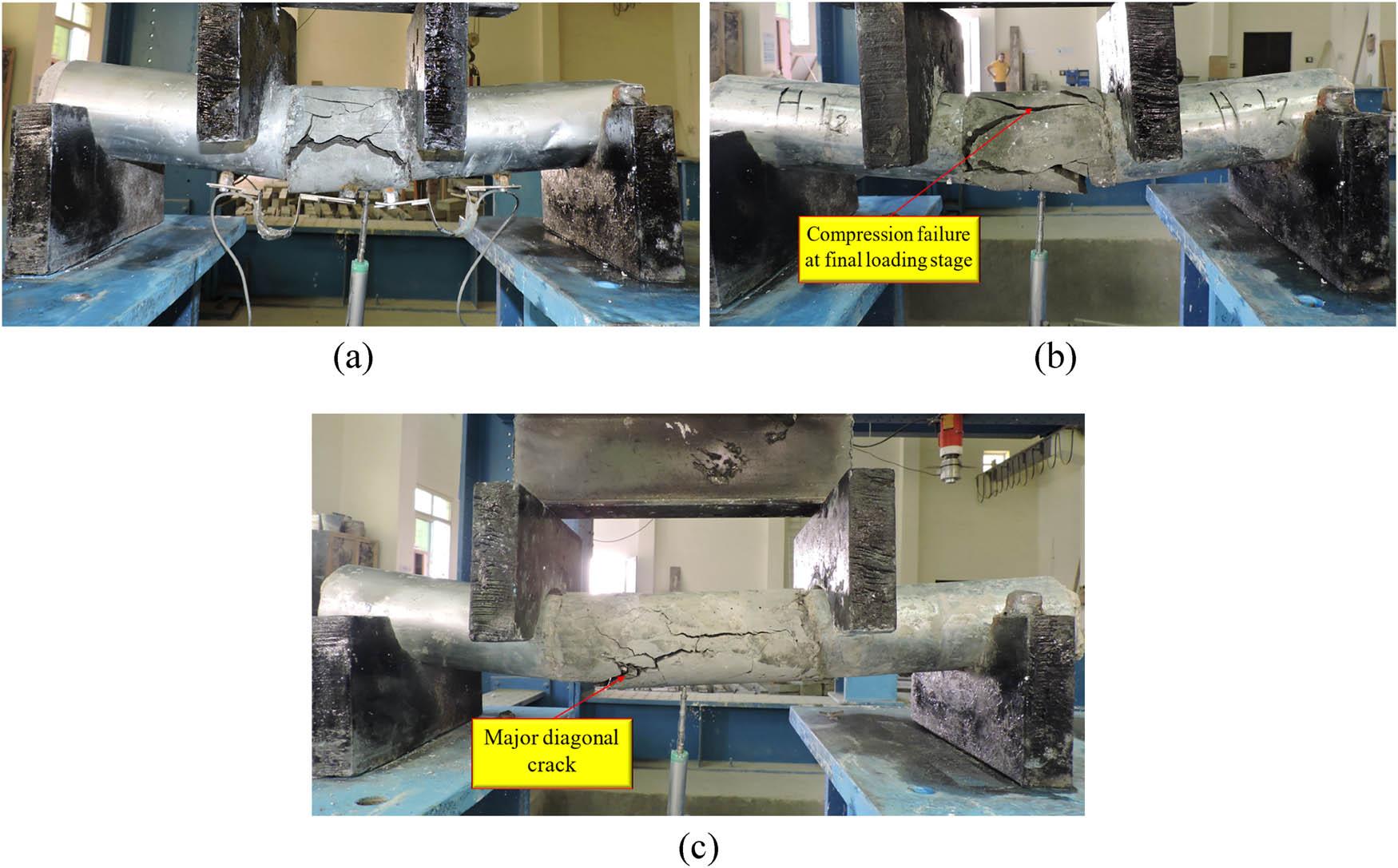

Figure 3

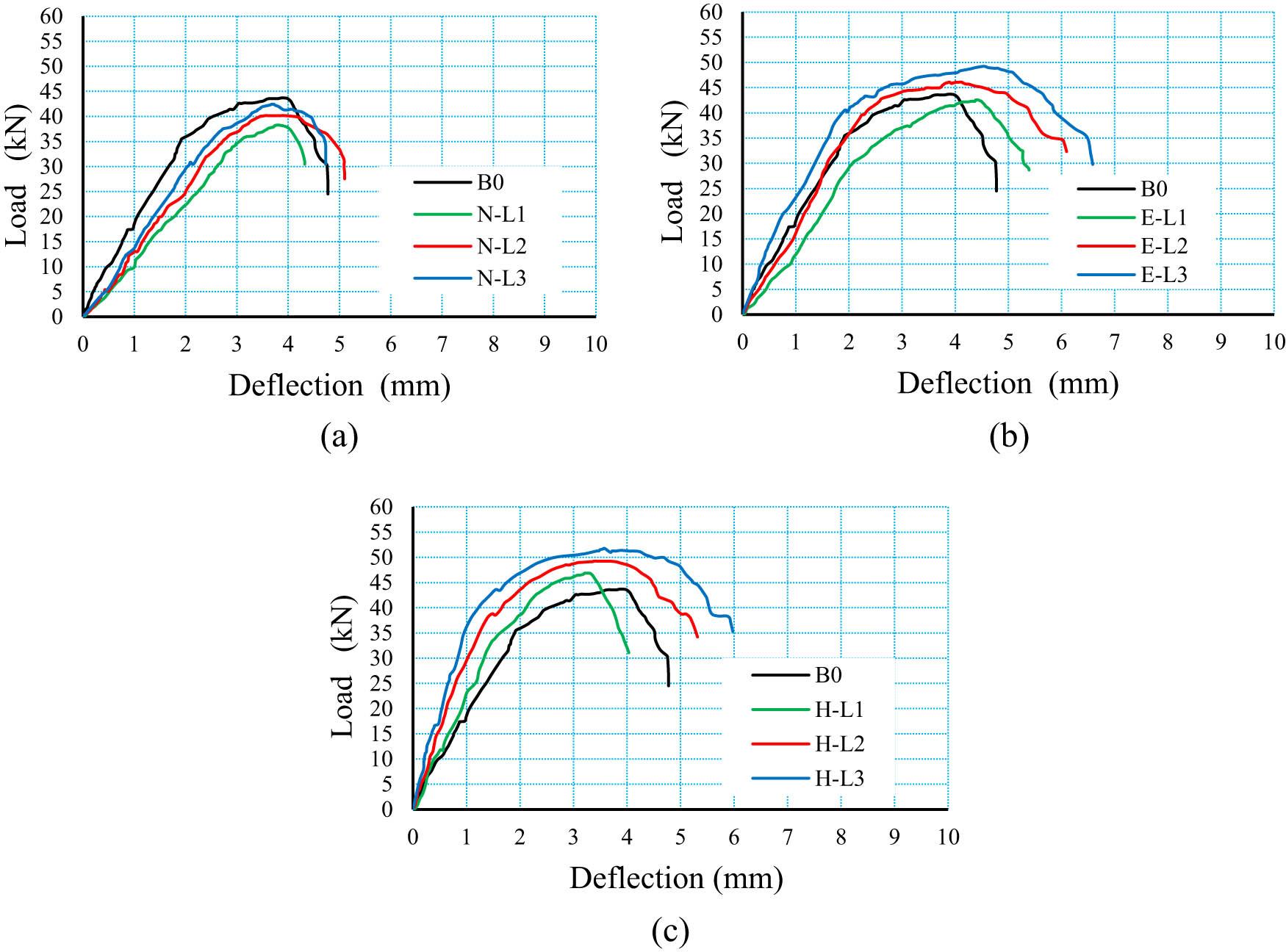

Figure 4

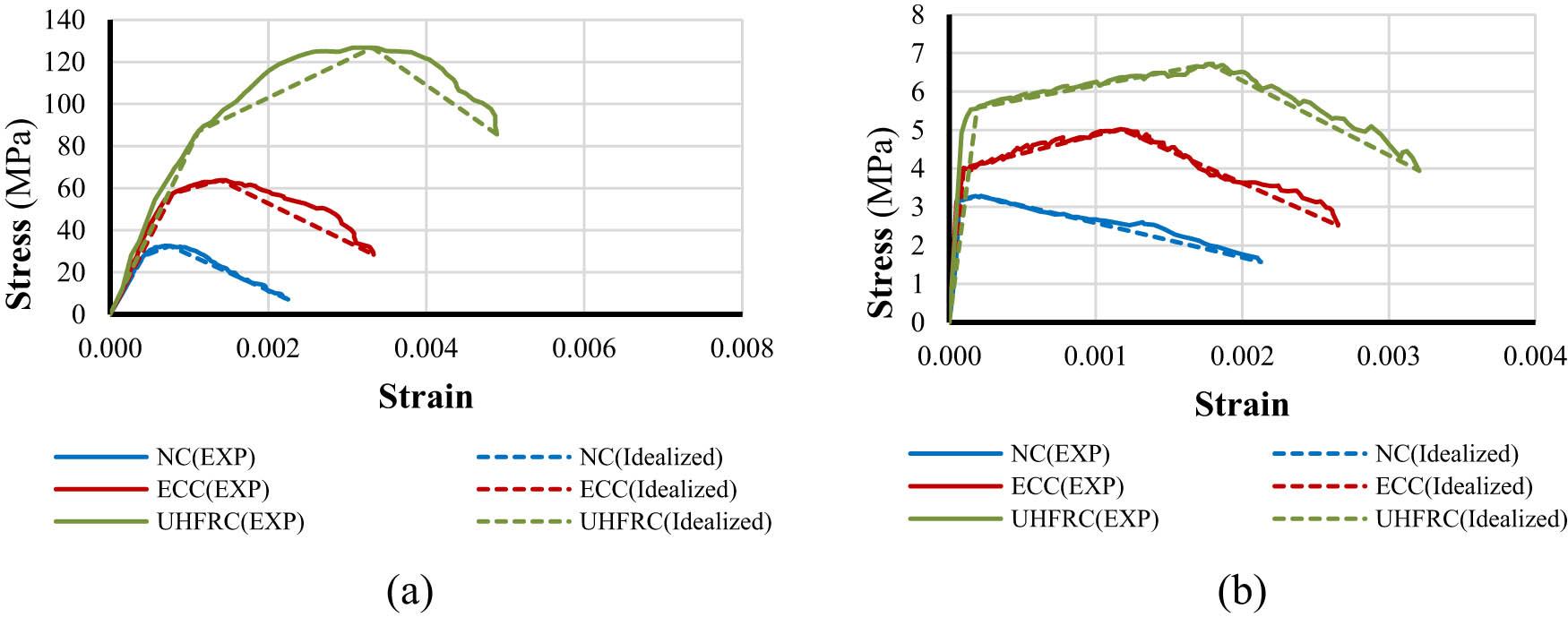

Figure 5

Figure 6

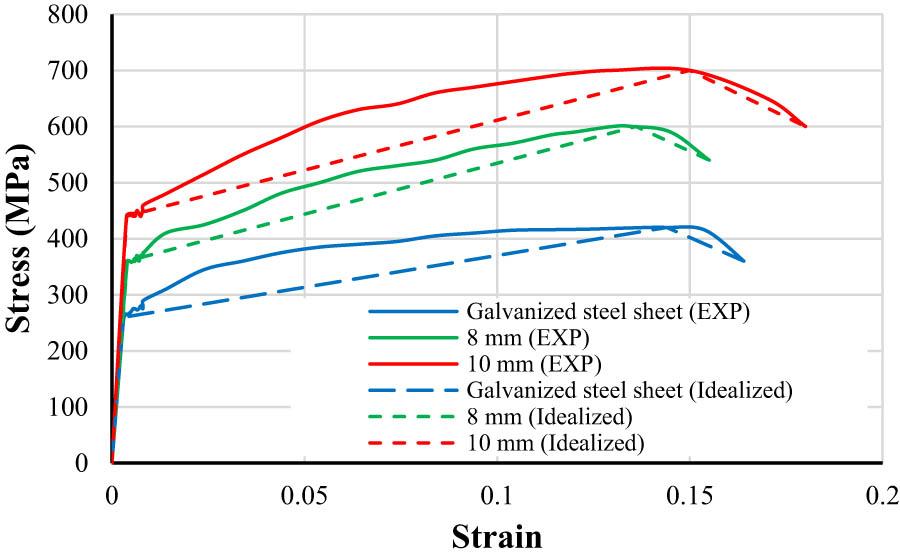

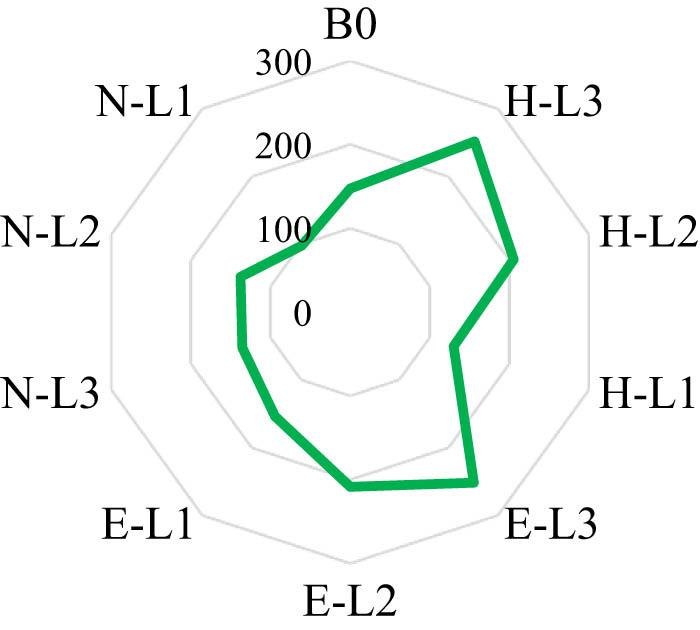

Figure 7

Figure 8

Figure 9

Figure 10

Figure 11

Figure 12

Figure 13

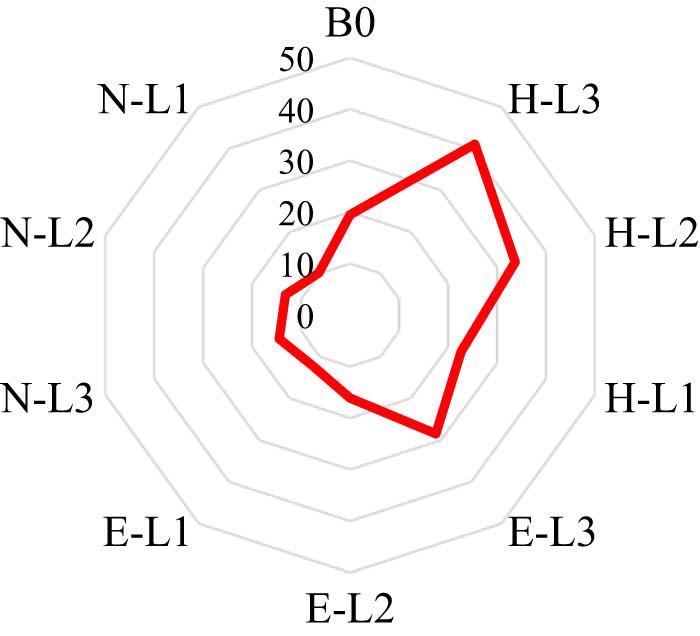

Test matrix_

| Group | Specimen’s ID | Concrete type | Connection length (L) | Objective |

|---|---|---|---|---|

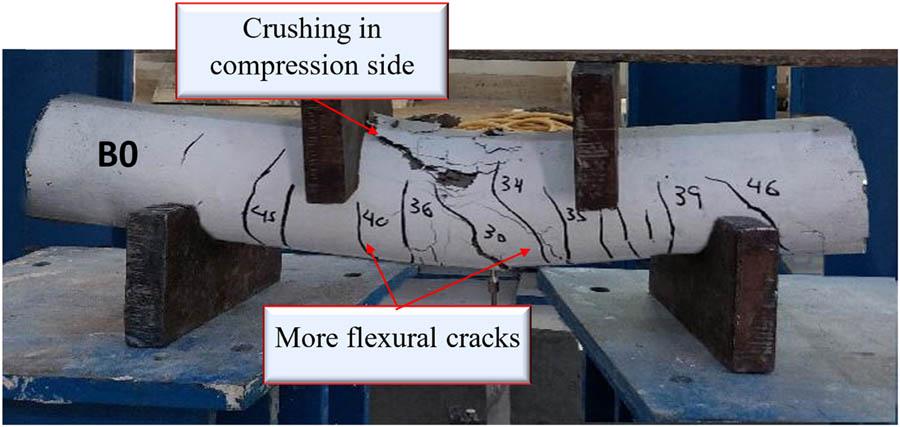

| G1 | B0 | NC | — | Control beam |

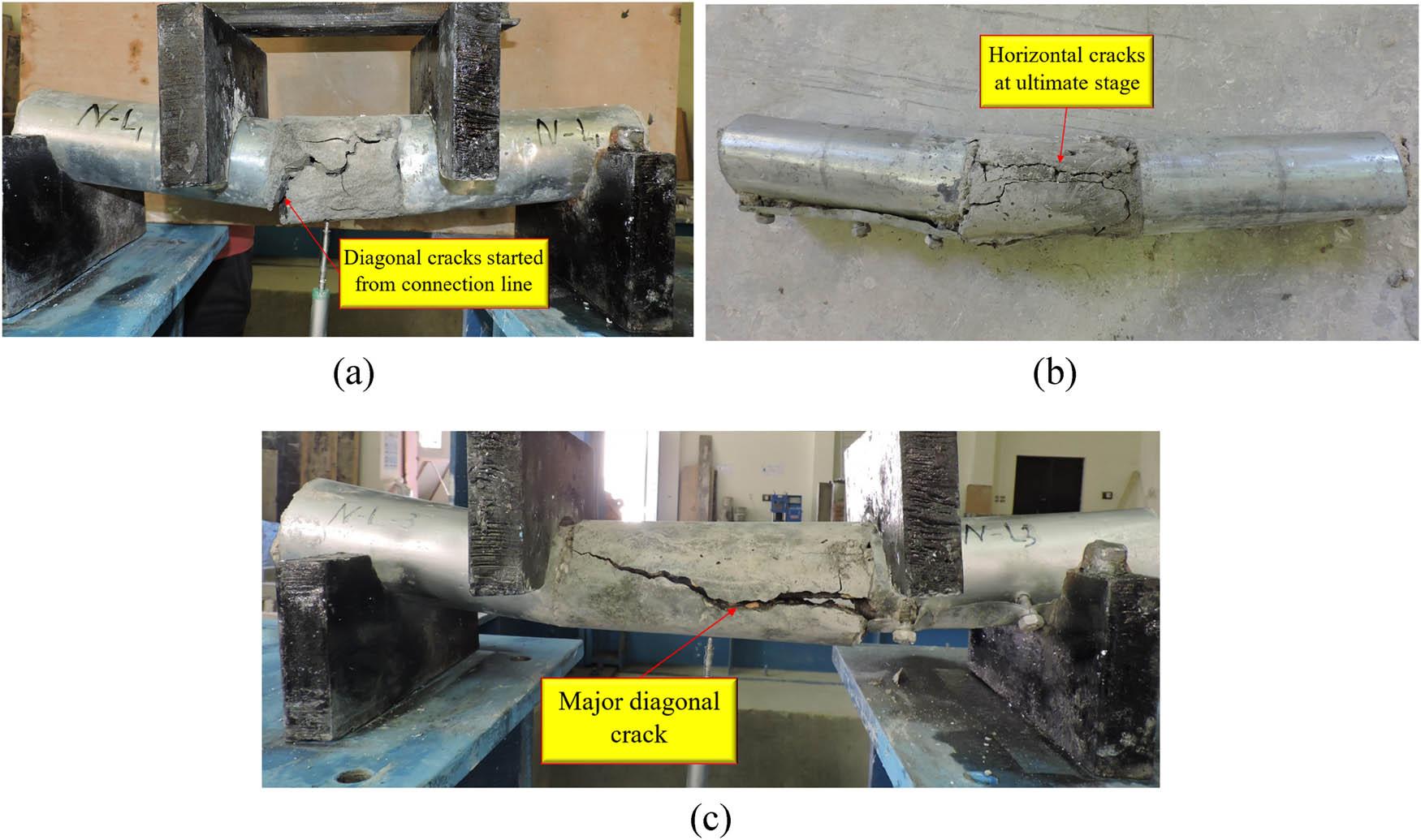

| N-L1 | 15 cm | Impact of NC connection with varied lengths in connected beams under sagging moment | ||

| N-L2 | 20 cm | |||

| N-L3 | 30 cm | |||

| G2 | B0 | NC | — | Control beam |

| E-L1 | ECC | 15 cm | Impact of ECC connection with varied lengths in connected beams under sagging moment | |

| E-L2 | 20 cm | |||

| E-L3 | 30 cm | |||

| G3 | B0 | NC | — | Control beam |

| H-L1 | UHFRC | 15 cm | Impact of UHFRC connection with varied lengths in connected beams under sagging moment | |

| H-L2 | 20 cm | |||

| H-L3 | 30 cm |

Test results of the tested connected beams_

| Specimen’s ID | Cracking stage | Ultimate stage | Elastic stiffness index (K) | K B/K B0 | Absorbed energy (E) | E B/E B0 | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| P cr (kN) | P crB/P crB0 | Δcr (mm) | P u (kN) | P uB/P uB0 | ΔPu (mm) | ||||||

| G1 | B0 | 12.95 | 1.00 | 0.66 | 44.01 | 1.00 | 3.92 | 19.62 | 1.00 | 148.35 | 1.00 |

| N-L1 | 10.21 | 0.79 | 0.99 | 38.27 | 0.87 | 3.82 | 10.31 | 0.53 | 98.81 | 0.67 | |

| N-L2 | 10.96 | 0.85 | 0.83 | 40.16 | 0.91 | 3.90 | 13.20 | 0.67 | 137.76 | 0.93 | |

| N-L3 | 11.32 | 0.87 | 0.78 | 42.43 | 0.96 | 3.74 | 14.51 | 0.74 | 135.54 | 0.91 | |

| G2 | B0 | 12.95 | 1.00 | 0.66 | 44.01 | 1.00 | 3.92 | 19.62 | 1.00 | 148.35 | 1.00 |

| E-L1 | 11.56 | 0.89 | 0.95 | 42.54 | 0.97 | 4.43 | 12.17 | 0.62 | 152.93 | 1.03 | |

| E-L2 | 12.32 | 0.95 | 0.77 | 46.08 | 1.05 | 4.11 | 16.00 | 0.82 | 208.01 | 1.40 | |

| E-L3 | 13.91 | 1.07 | 0.49 | 48.97 | 1.11 | 4.62 | 28.39 | 1.45 | 251.11 | 1.69 | |

| G3 | B0 | 12.95 | 1.00 | 0.66 | 44.01 | 1.00 | 3.92 | 19.62 | 1.00 | 148.35 | 1.00 |

| H-L1 | 13.84 | 1.07 | 0.61 | 46.85 | 1.06 | 3.21 | 22.69 | 1.16 | 130.14 | 0.88 | |

| H-L2 | 14.52 | 1.12 | 0.43 | 49.24 | 1.12 | 3.50 | 33.77 | 1.72 | 205.44 | 1.38 | |

| H-L3 | 15.26 | 1.18 | 0.37 | 51.37 | 1.17 | 3.89 | 41.24 | 2.10 | 252.77 | 1.70 | |

Mix proportion and compressive strength of the used concrete_

| Concrete | Cement (kg/m3) | Fine aggregate (kg/m3) | Coarse aggregate (kg/m3) | Fly ash (kg/m3) | Water/binder | PVA/steel fiber (%) in volume | HRWR (kg/m3) |

|

|---|---|---|---|---|---|---|---|---|

| NC | 350 | 700 | 1,150 | — | 0.43 | — | — | 32.56 |

| ECC | 580 | 450 | — | 610 | 0.22 | 2.10 | 35.3 | 63.67 |

| UHFRC | 500 | 600 | 990 | 35 | 0.24 | 2.00 | 15.6 | 126.75 |