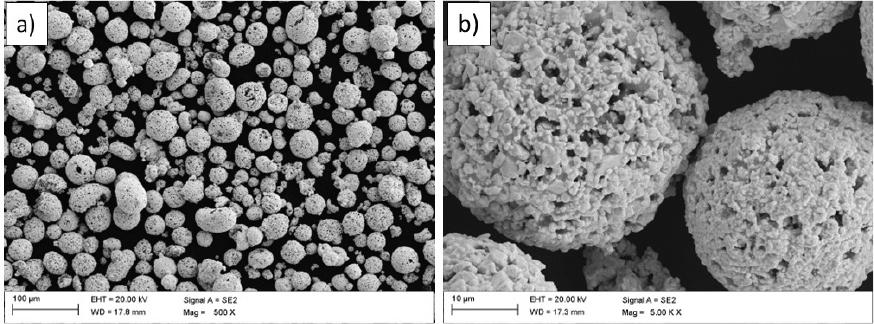

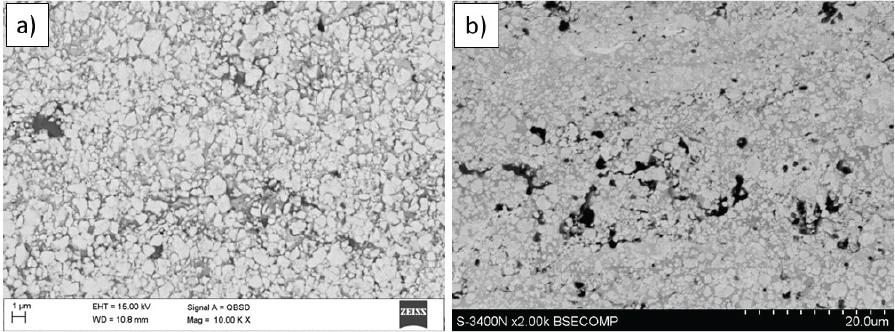

Fig. 1.

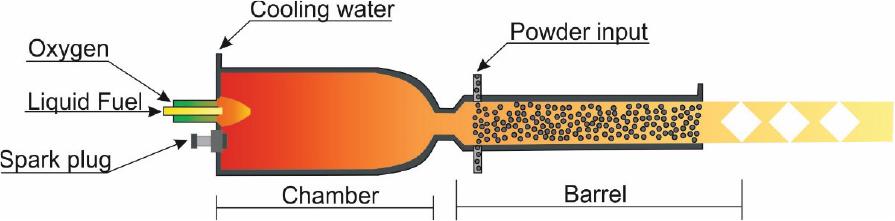

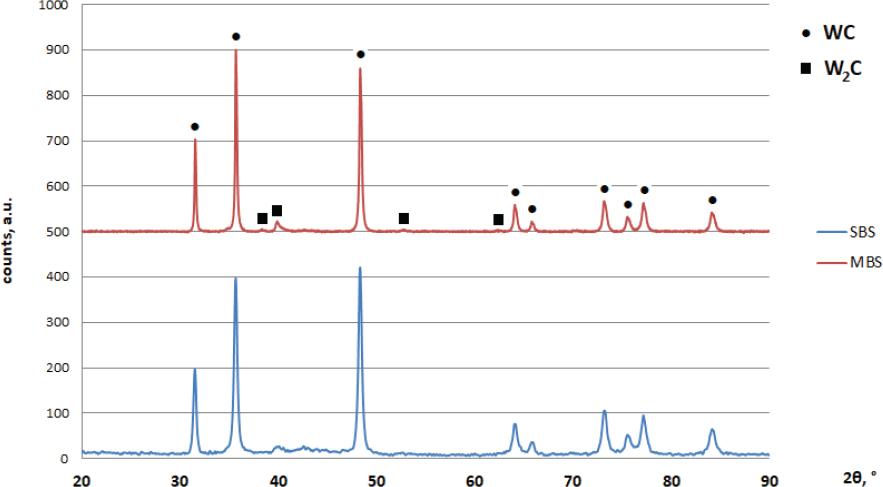

Fig. 2.

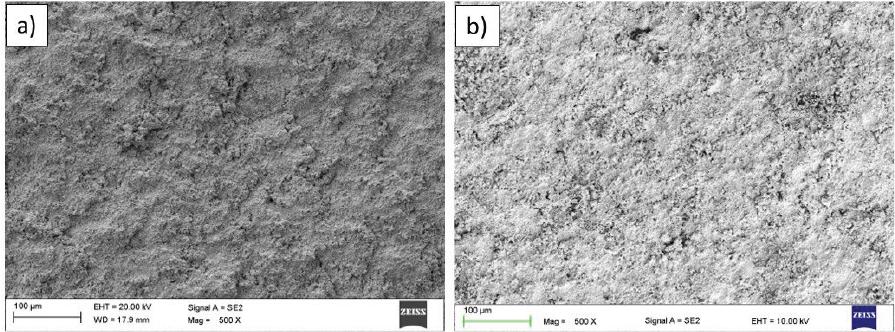

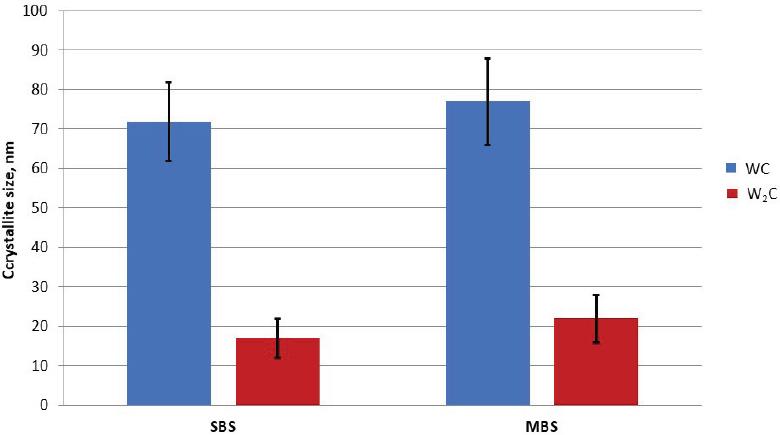

Fig. 3.

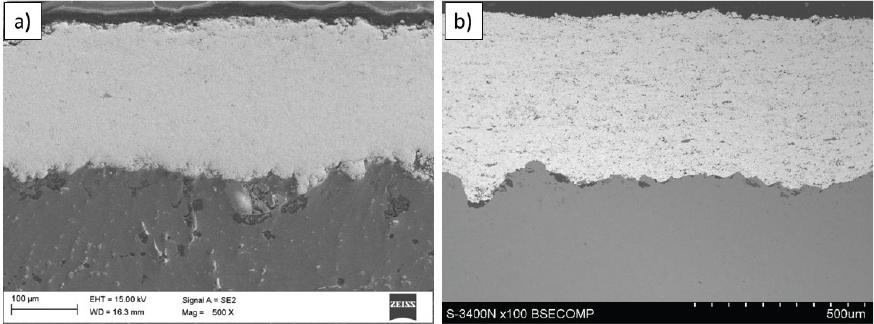

Fig. 4.

Fig. 5.

Fig. 6.

Fig. 7.

HVOF process parameters and sample code

| Sample | Medium feed rate | Spray distance mm | |||

|---|---|---|---|---|---|

| Kerosene l/min | Oxygen l/min | Nitrogen l/min | Powder g/min | ||

| SBS1 | 0.380 | 950 | 12 | 70 | 300 |

| MBS2 | 0.435 | 900 | 360 | ||

Results for surface roughness of the as-sprayed coatings

| Sample | Ra | Rp | Rv | Rz |

|---|---|---|---|---|

| SBS | 3.36 ± 0.23 | 10.20 ± 2.14 | 7.95 ± 1.48 | 18.10 ± 3.15 |

| MBS | 4.28 ± 0.24 | 11.84 ± 2.47 | 9.92 ± 1.83 | 21.77 ± 3.51 |

Results for CRI calculations

| Sample | CRI value |

|---|---|

| SBS | 0.915 |

| MBS | 0.928 |

The IIT results for carbide particles and metallic matrix in sprayed coatings

| Sample | HIT (WC) GPa | EIT (WC) GPa | HIT (Co-Cr) GPa | EIT (Co-Cr) GPa |

|---|---|---|---|---|

| SBS | 29.14 ± 1.91 | 622 ± 17 | 6.52 ± 0.47 | 192 ± 9 |

| MBS | 28.65 ± 1.94 | 624 ± 18 | 6.46 ± 0.42 | 193 ± 8 |