Fig. 1.

![The morphology and the XRD test results of the CoCrFeNiSiB4 powder: (a) SEM image, (b) XRD test result [42]](https://sciendo-parsed.s3.eu-central-1.amazonaws.com/65fc326bae8e39178ba3604d/j_msp-2023-0040_fig_001.jpg?X-Amz-Algorithm=AWS4-HMAC-SHA256&X-Amz-Content-Sha256=UNSIGNED-PAYLOAD&X-Amz-Credential=AKIA6AP2G7AKOUXAVR44%2F20251204%2Feu-central-1%2Fs3%2Faws4_request&X-Amz-Date=20251204T150714Z&X-Amz-Expires=3600&X-Amz-Signature=89d4b00c12638eb08e8c4c06b49b6a17cbec9cfb0e85376acad09a4db67ef02b&X-Amz-SignedHeaders=host&x-amz-checksum-mode=ENABLED&x-id=GetObject)

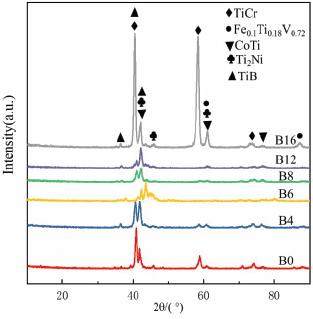

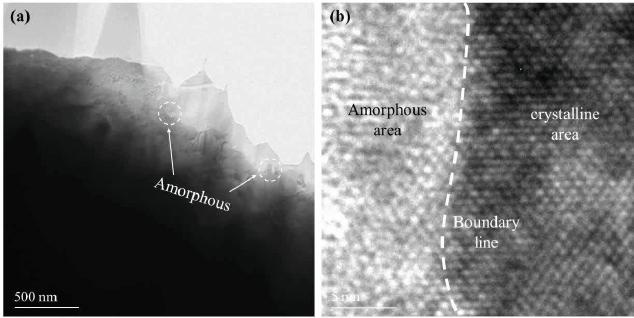

Fig. 2.

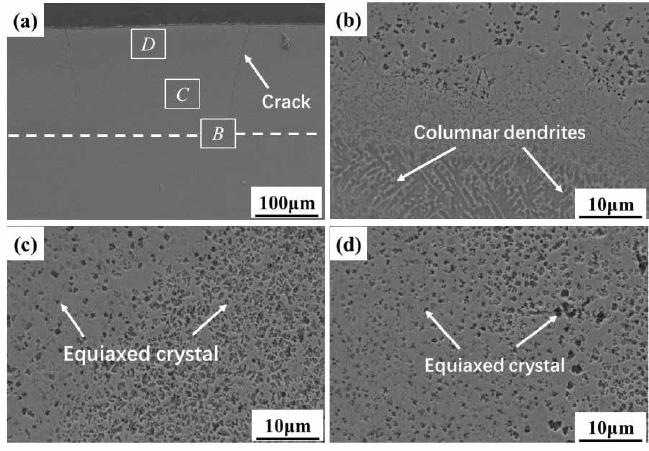

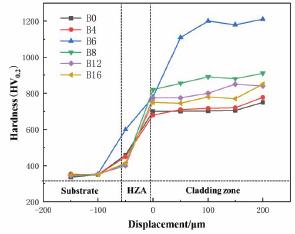

Fig. 3.

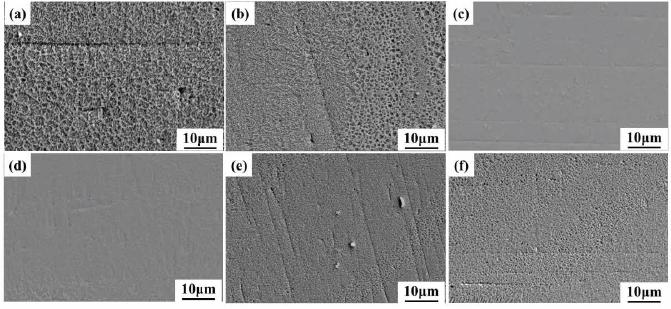

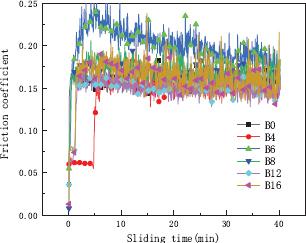

Fig. 4.

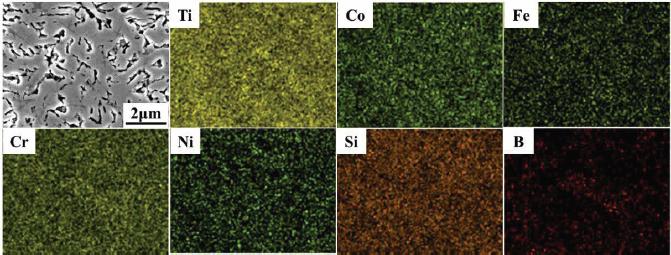

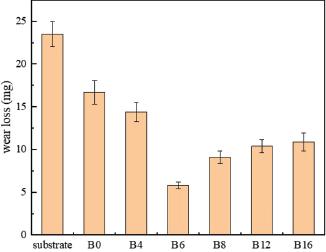

Fig. 5.

Fig. 6.

Fig. 7.

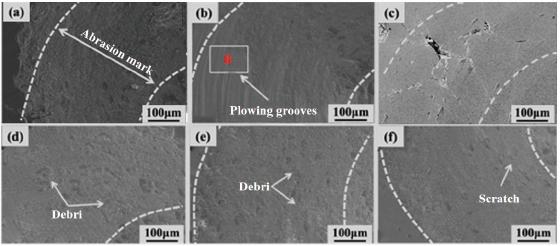

Fig. 8.

Fig. 9.

Fig. 10.

Fig. 11.

Theoretical amorphous content of specimens

| Sample | B0 | B4 | B6 | B8 | B12 | B16 |

|---|---|---|---|---|---|---|

| Content (%) | 2.46 | 35.65 | 68.86 | 22.31 | 10.55 | 0.97 |

EDS analysis in Fig_ 9 (wt%)

| Ti | Cr | Fe | Co | Ni | O | |

|---|---|---|---|---|---|---|

| A | 64.41 | 1.26 | 2.78 | 4.89 | 5.33 | 21.33 |

| B | 67.22 | 4.30 | 1.24 | 5.95 | 7.61 | 13.69 |

Chemical composition of TC4

| Element | Fe | C | N | H | O | Al | V | Si | Ti |

|---|---|---|---|---|---|---|---|---|---|

| wt% | 0.30 | 0.10 | 0.05 | 0.01 | 0.20 | 5.5–6.8 | 3.5–4.5 | 0.15 | Bal. |

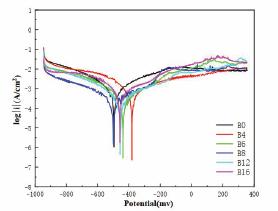

The electrochemical parameters of (Co34Fe8Cr29Ni8Si7)100–xBx alloy coatings in 3_5 wt% NaCl

| Sample | Ecorr/mV | Icorr/(A·cm–2) |

|---|---|---|

| B0 | –482.034 | 8.974×10–5 |

| B4 | –419.289 | 5.846×10–5 |

| B6 | –380.255 | 7.096×10–5 |

| B8 | –501.733 | 8.318× 10–5 |

| B12 | –449.567 | 8.851 × 10–5 |

| B16 | –436.434 | 8.337 × 10–5 |

The marked numbers and nominal components of the samples

| Sample number | Powder(wt%) |

|---|---|

| B0 | Co34Fe8Cr29Ni8Si7 |

| B4 | (Co34Fe8Cr29Ni8Si7)96B4 |

| B6 | (Co34Fe8Cr29Ni8Si7)94B6 |

| B8 | (Co34Fe8Cr29Ni8Si7)92B8 |

| B12 | (Co34Fe8Cr29Ni8Si7)88B12 |

| B16 | (Co34Fe8Cr29Ni8Si7)84B16 |