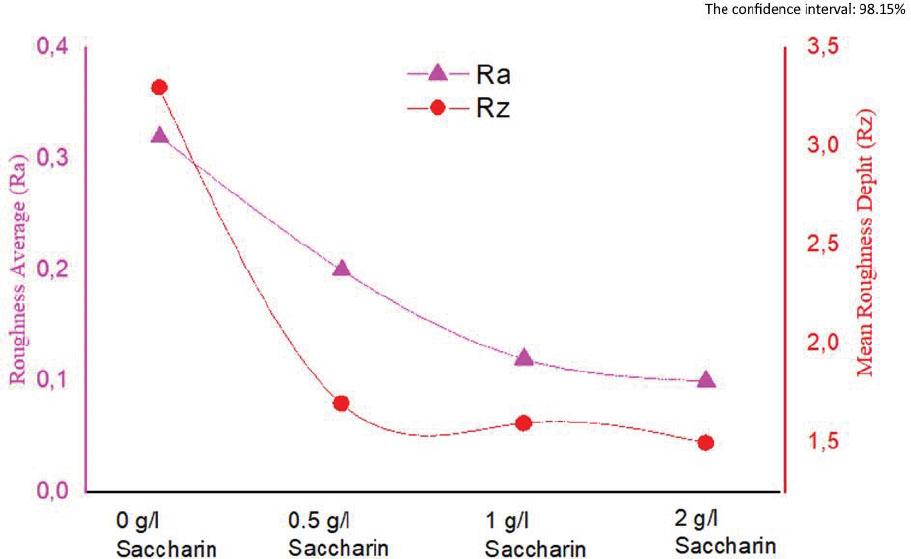

Fig. 1.

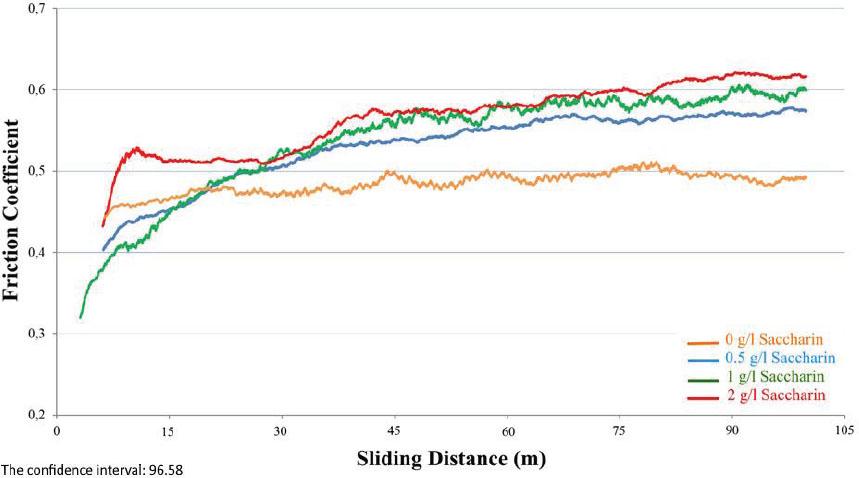

Fig. 2.

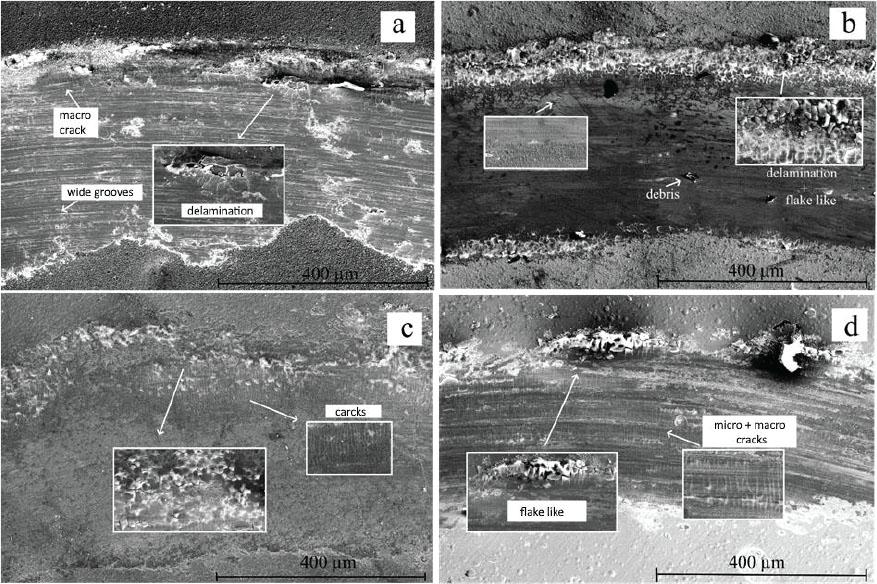

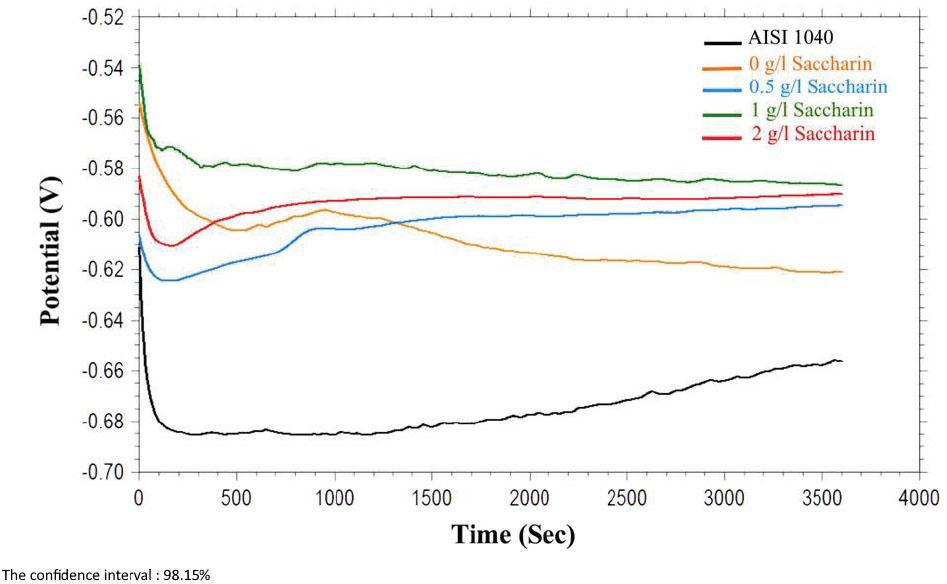

Fig. 3.

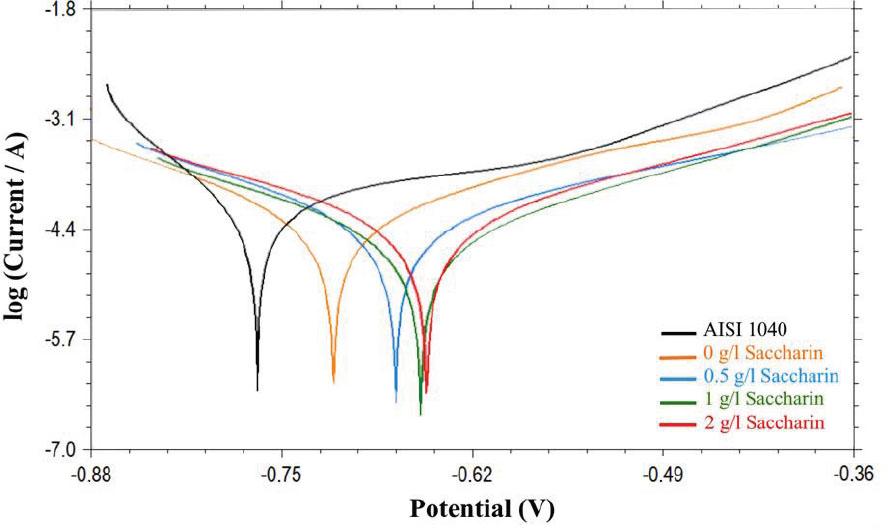

Fig. 4.

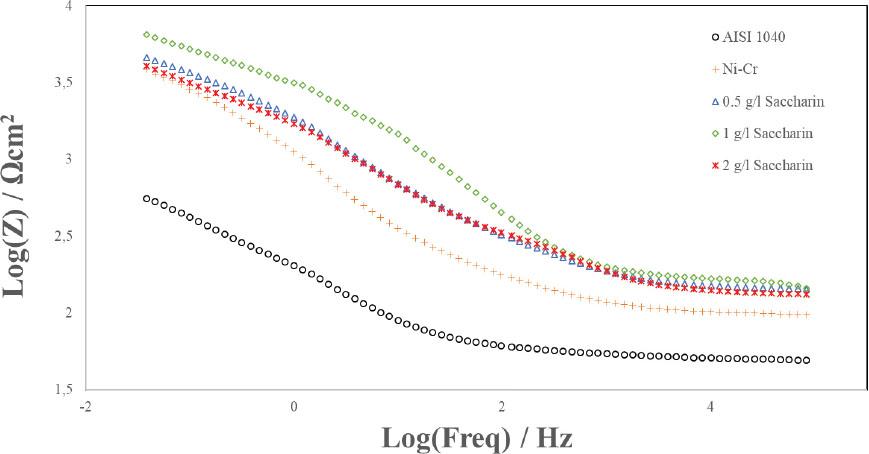

Fig. 5.

Fig. 6.

Fig. 7.

Fig. 8.

Fig. 9.

Fig. 10.

Wear rate, wear volume loss and average COF values

| Sample Name | Wear rate (mm3/Nm) (10−6) | Volume loss (mm3) (103) | Coefficient of Friction (COF) |

|---|---|---|---|

| 0 g/l saccharin | 11.24 | 5.620 | 0.483 |

| 0.5 g/l saccharin | 5.91 | 2.953 | 0.528 |

| 1 g/l saccharin | 4.93 | 3.002 | 0.535 |

| 2 g/l saccharin | 3.75 | 1.875 | 0.563 |

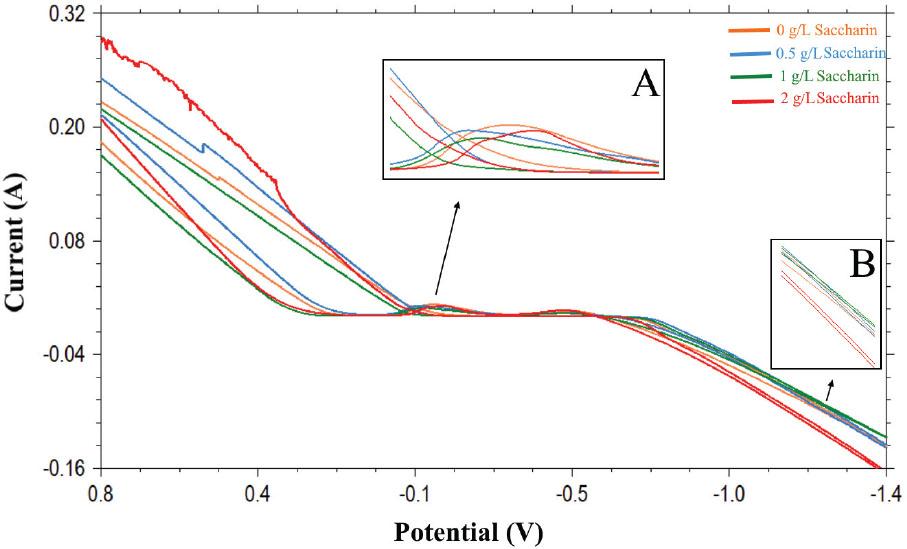

Corrosion data determined using the Tafel extrapolation method

| ECorr (mV) | Icorr (μ A/cm2) | Corrosion rate (mm/year) | |

|---|---|---|---|

| AISI 1040 | −770 | 91.73 | 1.08 |

| 0 g/l Saccharin | −719 | 65.18 | 0.77 |

| 0.5 g/l Saccharin | −678 | 58.26 | 0.68 |

| 1 g/l Saccharin | −662 | 38.18 | 0.44 |

| 2 g/l Saccharin | −658 | 56.53 | 0.66 |

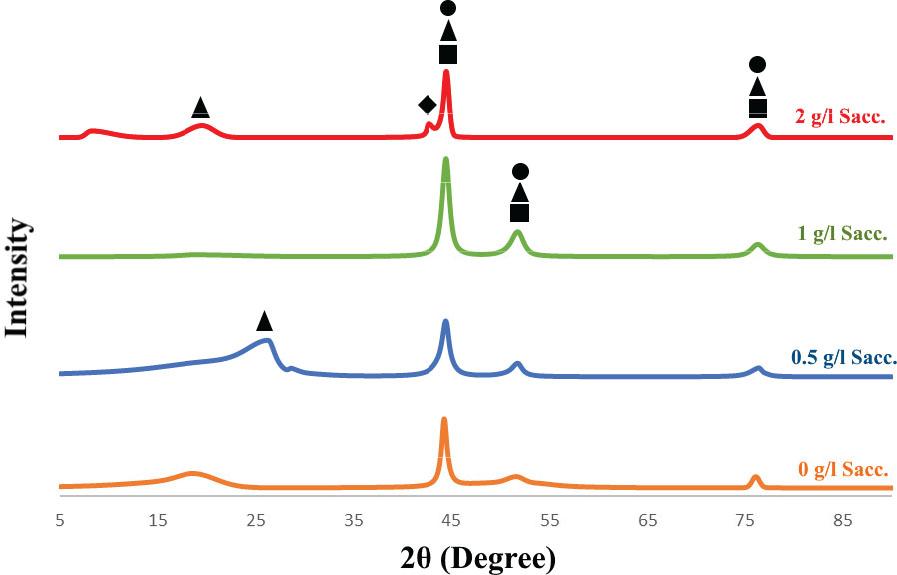

Parameters obtained from XRD models

| Sample | 2 (Degree) | Full width at half maximum (FWHM) | Grain size (D) (nm) |

|---|---|---|---|

| 0 g/l Saccharin | 44.28 | 0.650 | 32.42 |

| 0.5 g/l Saccharin | 44.44 | 0.960 | 21.87 |

| 1 g/l Saccharin | 44.46 | 0.875 | 23.99 |

| 2 g/l Saccharin | 44.47 | 0.644 | 32.58 |

Electrodeposition conditions

| Parameter | Amount |

|---|---|

| Current density | 200 mA/cm2 |

| Ultrasonic mixing | 5 min |

| Temperature | 40°C |

| Mixing speed | 100 rpm |

| pH | 2.5 |

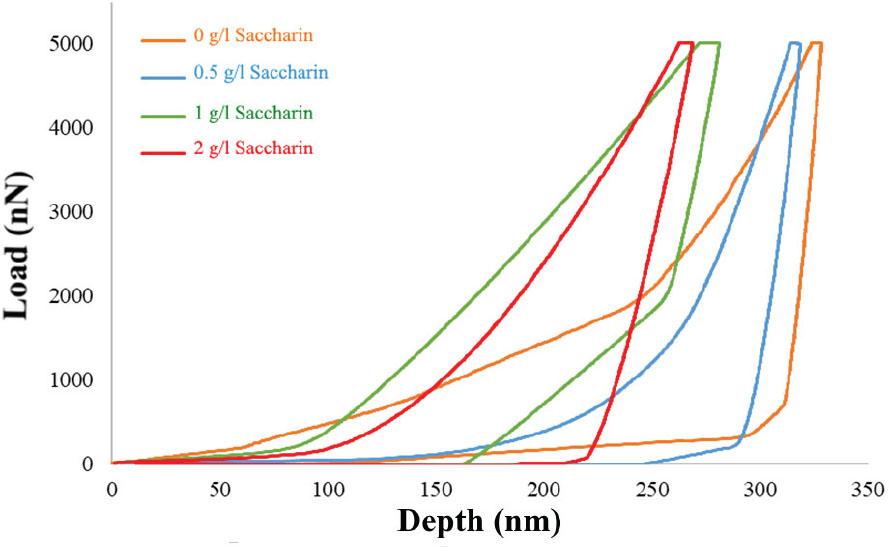

Elastic modulus, hardness and residual stress values

| hc (nm) | Pmax (μN) | S (μN/nm) | A (nm2) | Hmax (nm) | Er (GPa) | H (GPa) | Residual Stress (Gpa) | |

|---|---|---|---|---|---|---|---|---|

| 0 g/l Sacc. | 317 | 5006 | 326 | 2842233 | 329 | 171.58 | 1.76 | 0.51 |

| 0.5 g/l Sacc. | 304 | 5005 | 257 | 2632610 | 319 | 140.58 | 1.90 | 0.24 |

| 1 g/l Sacc. | 250 | 5007 | 99 | 1819289 | 281 | 65.17 | 2.75 | −0.95 |

| 2 g/l Sacc. | 242 | 5008 | 136 | 1706650 | 269 | 92.11 | 2.93 | −0.71 |

Chemical composition of steel used in experimental studies

| C | Si | Mn | Fe | Pmax | Smax |

|---|---|---|---|---|---|

| 0.419 | 0.254 | 0.751 | 98 | 0.040 | 0.050 |

Equivalent circuit parameters

| Rs (Ω.cm2) | Rp (Ω.cm2) | n | Yo(10−4) (Ω−1.cm−2.sn) | CP (μF/cm2) | |

|---|---|---|---|---|---|

| AISI 1040 | 214 | 2328 | 0.42 | 5.85 | 89.6 |

| 0 g/l Saccharin | 161 | 2615 | 0.53 | 6.08 | 91.8 |

| 0.5 g/l Saccharin | 195 | 4371 | 0.67 | 2.95 | 33.4 |

| 1 g/l Saccharin | 145 | 5520 | 0.67 | 2.70 | 32.9 |

| 2 g/l Saccharin | 166 | 5472 | 0.59 | 2.67 | 34.7 |

Bath components

| Bath solution | Amount | Function |

|---|---|---|

| NiSO4.7H2O (nickel sulphate) | 50 g/l | Ni2+ source |

| NiCl2.6H2O (nickel chloride) | 45 g/l | Ni2+ source |

| CrCl3. 6H2O (chromium chloride) | 75 g/l | Cr3+ source |

| H3BO3 (boric acid) | 50 g/l | Blocking agent |

| C6H8O7 (citric acid) | 70 g/l | Blocking agent |

| Na3C6H5O7.2H2O (sodium citrate dihydrate) | 105 g/l | Complexing agent |

| C7H4NNaO3S • 2H2O (sodium saccharin) | 0, 0.5, 1, 2 g/l | Additive material |

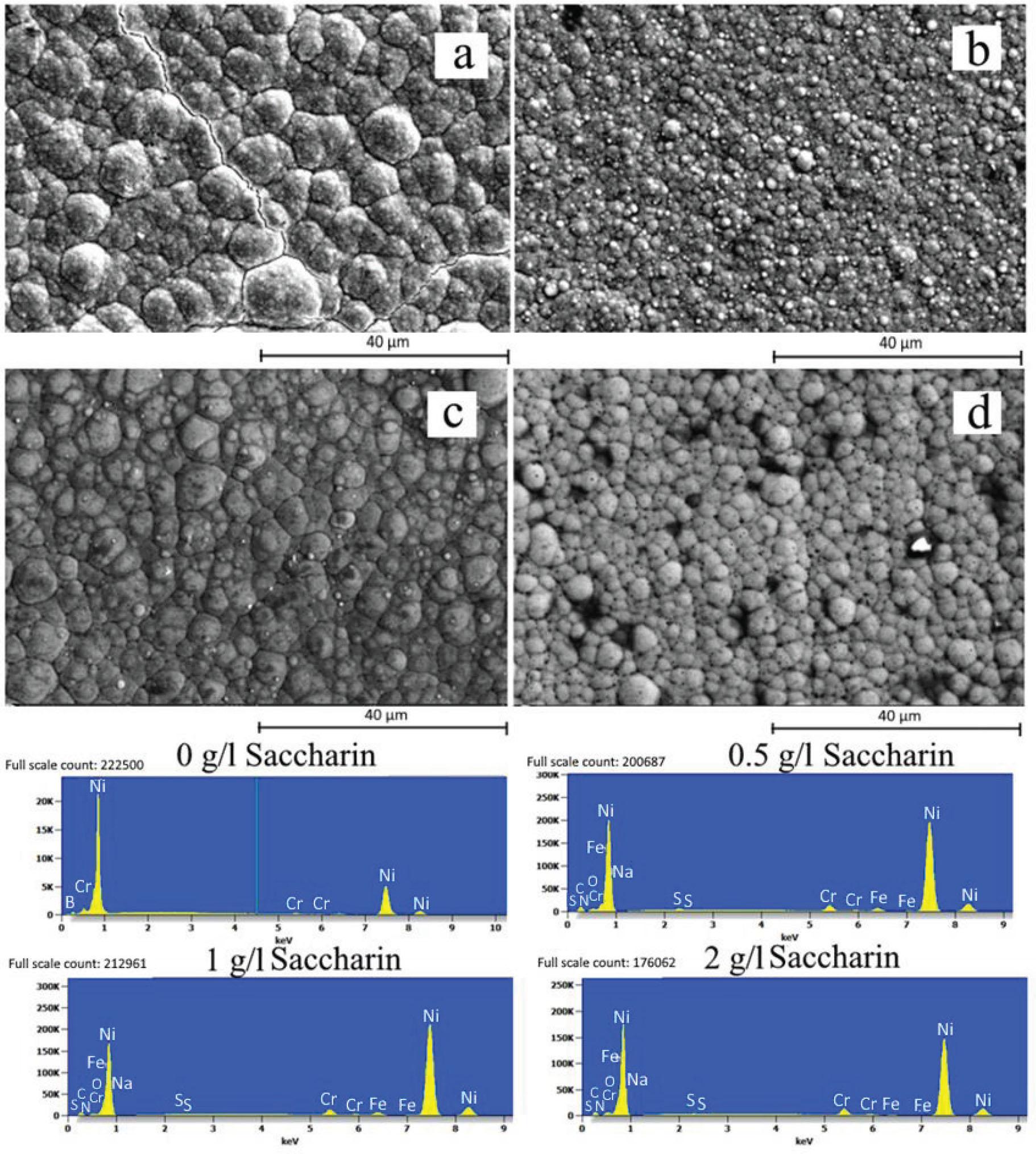

Chemical composition of coatings according to EDS analysis (wt_ %)

| C | N | O | Na | S | Cr | Ni | |

|---|---|---|---|---|---|---|---|

| 0 g/l Saccharin | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 1.18 | 98.82 |

| 0.5 g/l Saccharin | 7.83 | 2.27 | 1.77 | 0.17 | 0.17 | 2.53 | 85.27 |

| 1 g/l Saccharin | 8.64 | 2.37 | 0.00 | 0.13 | 0.19 | 2.84 | 85.83 |

| 2 g/l Saccharin | 7.87 | 1.85 | 0.29 | 0.19 | 0.22 | 3.38 | 86.21 |

Angle values and DB card numbers

| Chemical formula | 2-theta (deg) | Phase name | DB card number | Chemical formula | 2-theta (deg) | Phase name | DB card number | ||

|---|---|---|---|---|---|---|---|---|---|

| 18.7 | 100 | 44.4 | 111 | ||||||

| 26.3 | 110 | 01-089-2392 | ■ | Ni | 51.8 | 200 | 00-004-0850 | ||

| ▲ | Cr | 44.4 | 210 | 01-077-7591 | 76.3 | 220 | |||

| 51.7 | 200 | 44.4 | 111 | ||||||

| 76.3 | 220 | • | (Cr2Ni23)0.16 | 51.8 | 200 | 01-077-7616 | |||

| ♦ | Cr7Ni3 | 42.6 | 410 | 00-051-0637 | 76.3 | 220 |