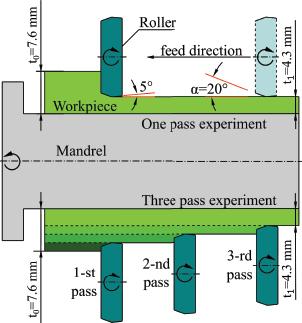

Fig. 1.

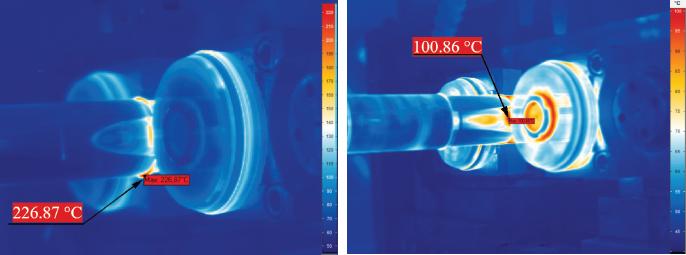

Fig. 2.

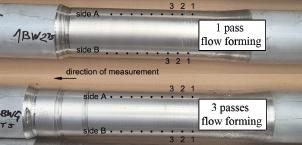

Fig. 3.

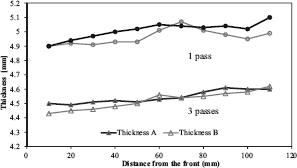

Fig. 4.

Fig. 5.

Fig. 6.

Fig. 7.

Fig. 8.

Fig. 9.

Fig. 10.

Fig. 11.

Fig. 12.

Fig. 13.

A summary of the results of the flow forming of aluminum alloy 6060

| No. | Type of experiment | t0 (mm) | t1 (mm) | Δt = t0 -11 (mm) | Average Δt (mm) | εt (%) | Average εt(%) |

|---|---|---|---|---|---|---|---|

| 1 | 1 pass | 7.55 | 4.98 | 2.57 | 2.62 | 34% | 35% |

| 2 | 1 pass | 7.7 | 4.96 | 2.74 | 36% | ||

| 3 | 1 pass | 7.6 | 5.04 | 2.56 | 34% | ||

| 4 | 3 passes | 7.55 | 4.54 | 3.01 | 3.04 | 40% | 40% |

| 5 | 3 passes | 7.65 | 4.72 | 2.93 | 38% | ||

| 6 | 3 passes | 7.55 | 4.37 | 3.18 | 42% |

The mechanical properties determined in the static tensile test

| Tensile speed [mm/min] | Rp0.2 ± URp0.2 [MPa] | Rm ± URm [MPa] | A50 mm ± UA50 mm [%] | Z ± UZ [%] |

|---|---|---|---|---|

| 0.5 | 137 ± 12 | 176 ± 12 | 20.1 ± 1.0 | 64.8 ± 2.5 |

| 5 | 137 ± 12 | 179 ± 12 | 19.4 ± 1.9 | 61.7 ± 4.4 |

| 50 | 135 ± 12 | 177 ± 12 | 20.9 ± 2.5 | 61.9 ± 6.5 |

| 500 | 141 ± 12 | 182 ± 12 | 16.6 ± 5.7 | 57.0 ± 3.7 |

Hardness properties of specimens after the flow forming

| Distance from surface (mm) | With cooling agent (HV) | Without cooling agent (HV) |

|---|---|---|

| 0.2 | 73.5 | 78.2 |

| 0.4 | 73.4 | 77.5 |

| 0.6 | 74.6 | 75.0 |

| 0.8 | 74.5 | 74.7 |

| 1.0 | 74.6 | 74.3 |

Strength properties of specimens after the forming

| Number of forming passes | Δt (mm) | Rp0,2 (MPa) | Rm (MPa) | A50 mm (%) | Z(%) | HV |

|---|---|---|---|---|---|---|

| 1 | 2.62 | 199–207 | 216–224 | 10.2–12.7 | 45.7–53.4 | 73.0 |

| 3 | 3.04 | 211–226 | 220–239 | 7.1–12.1 | 50.4–60.8 | 78.7 |

The chemical composition of the AA 6060 tested

| Element | Si | Mg | Fe | Mn | Cr | Ti | Cu | Zn |

|---|---|---|---|---|---|---|---|---|

| Wt% | 0.55 ± 0.03 | 0.381 ± 0.01 | 0.088 ± 0.02 | 0.063 ± 0.04 | 0.014 ± 0.00 | >0.010 ± 0.00 | 0.002 ± 0.00 | 0.001 ± 0.00 |