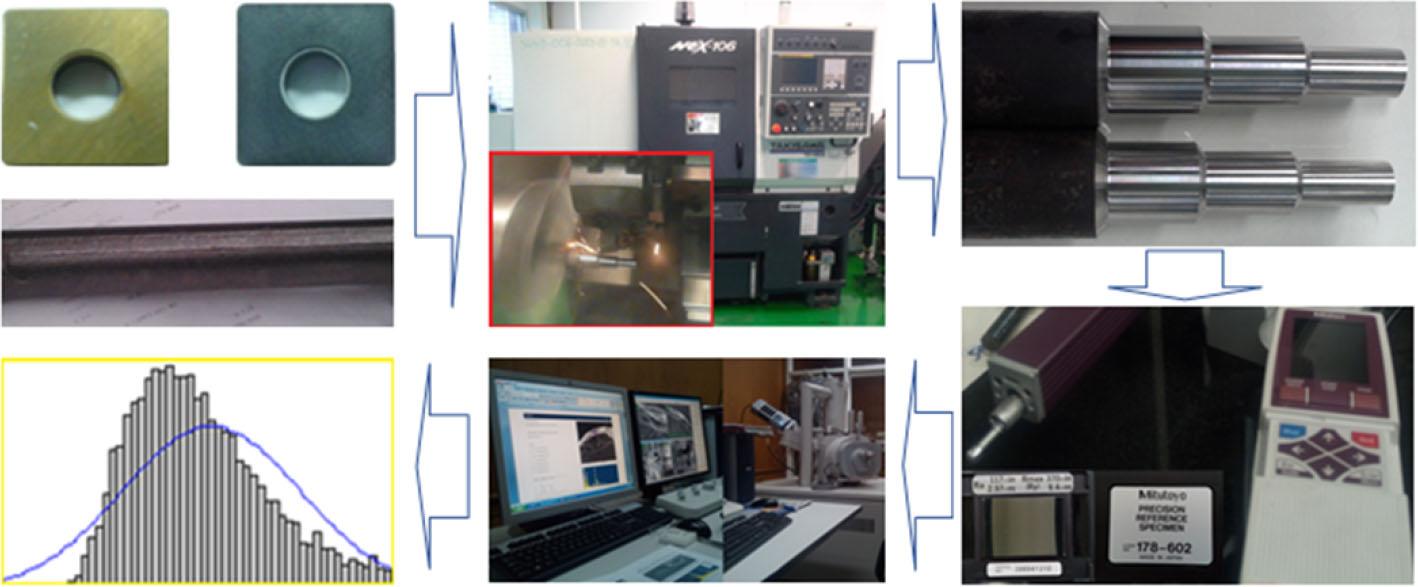

Fig. 1.

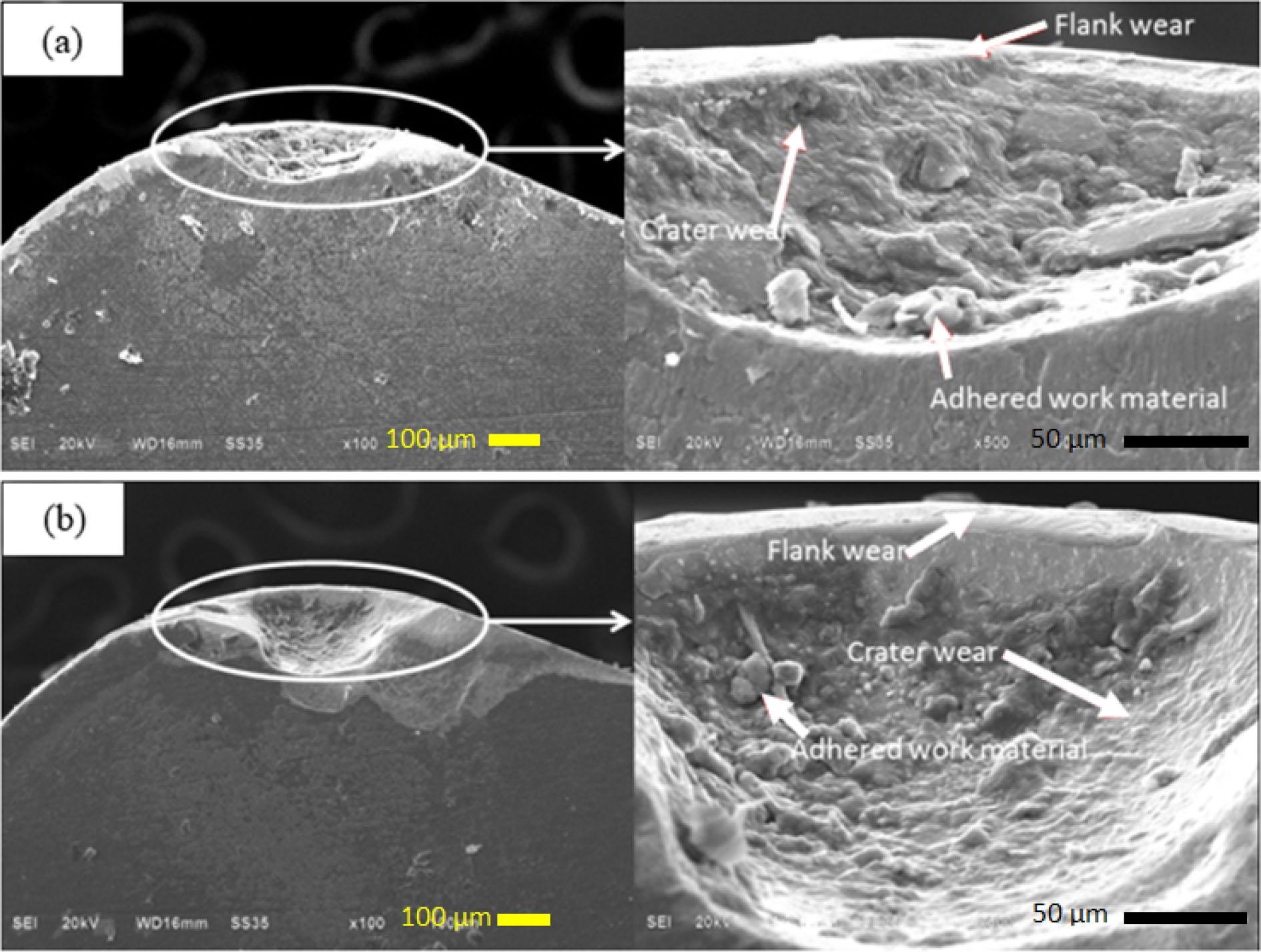

Fig. 2.

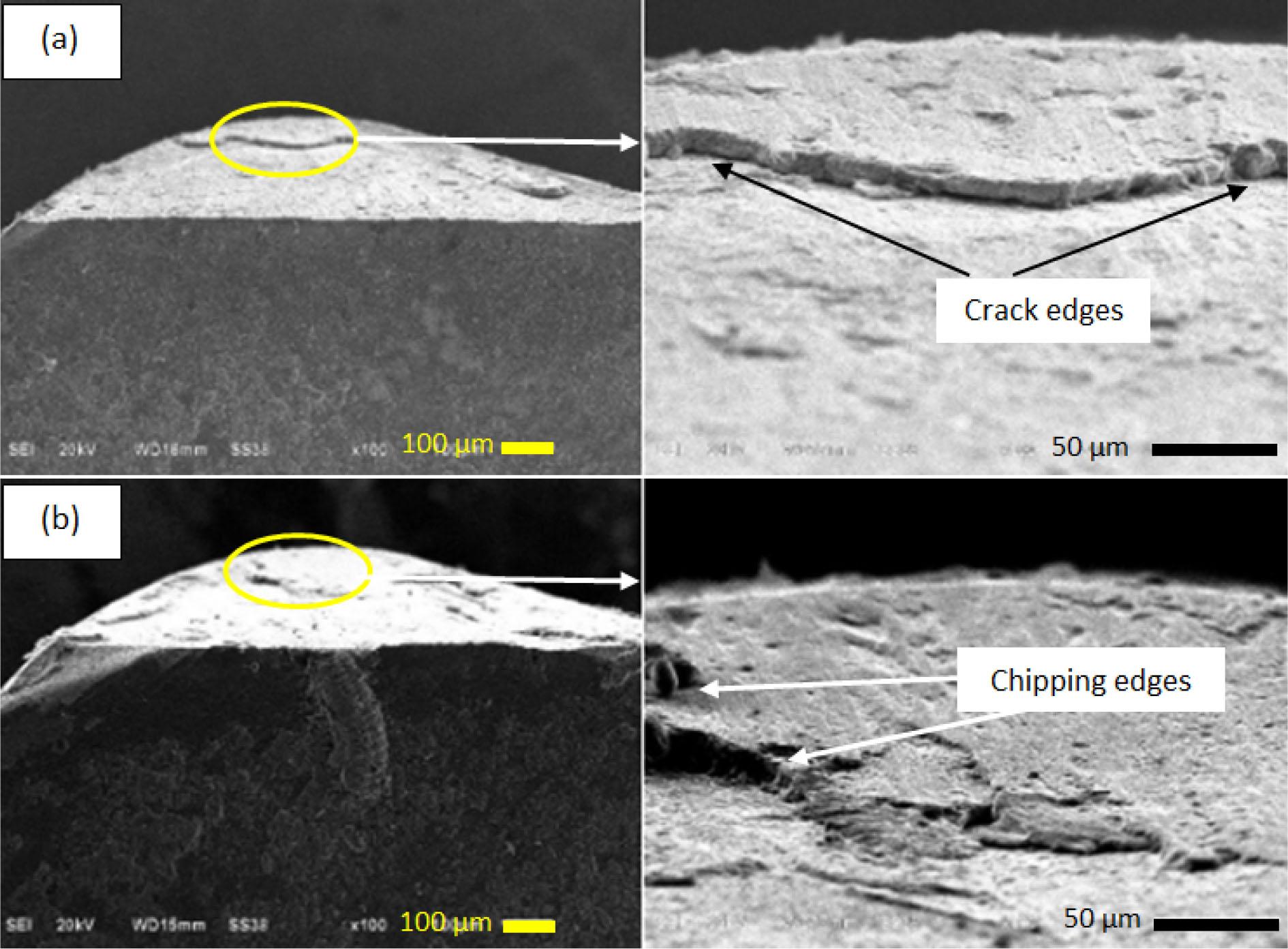

Fig. 3.

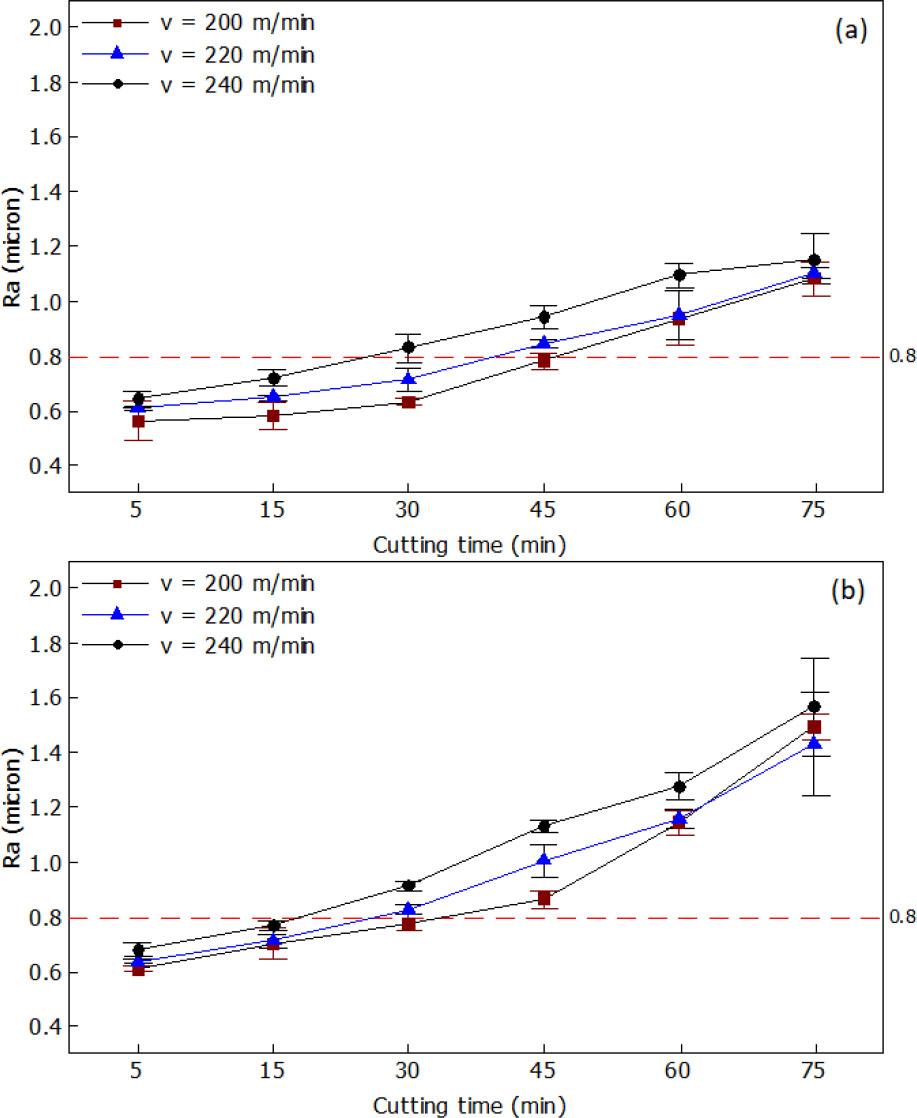

Fig. 4.

Fig. 5.

Fig. 6.

Fig. 7.

Fig. 8.

Fig. 9.

Fig. 10.

Fig. 11.

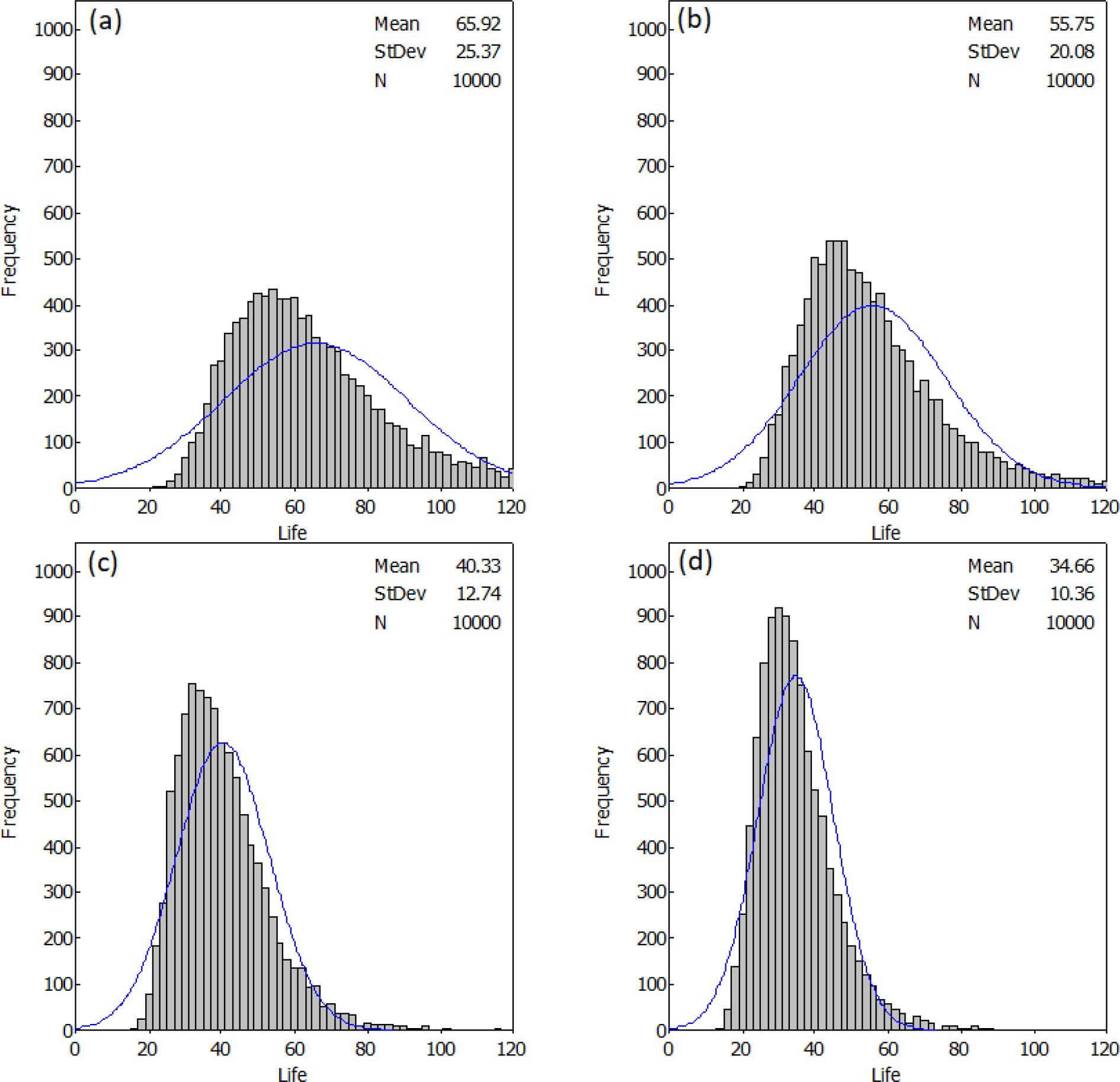

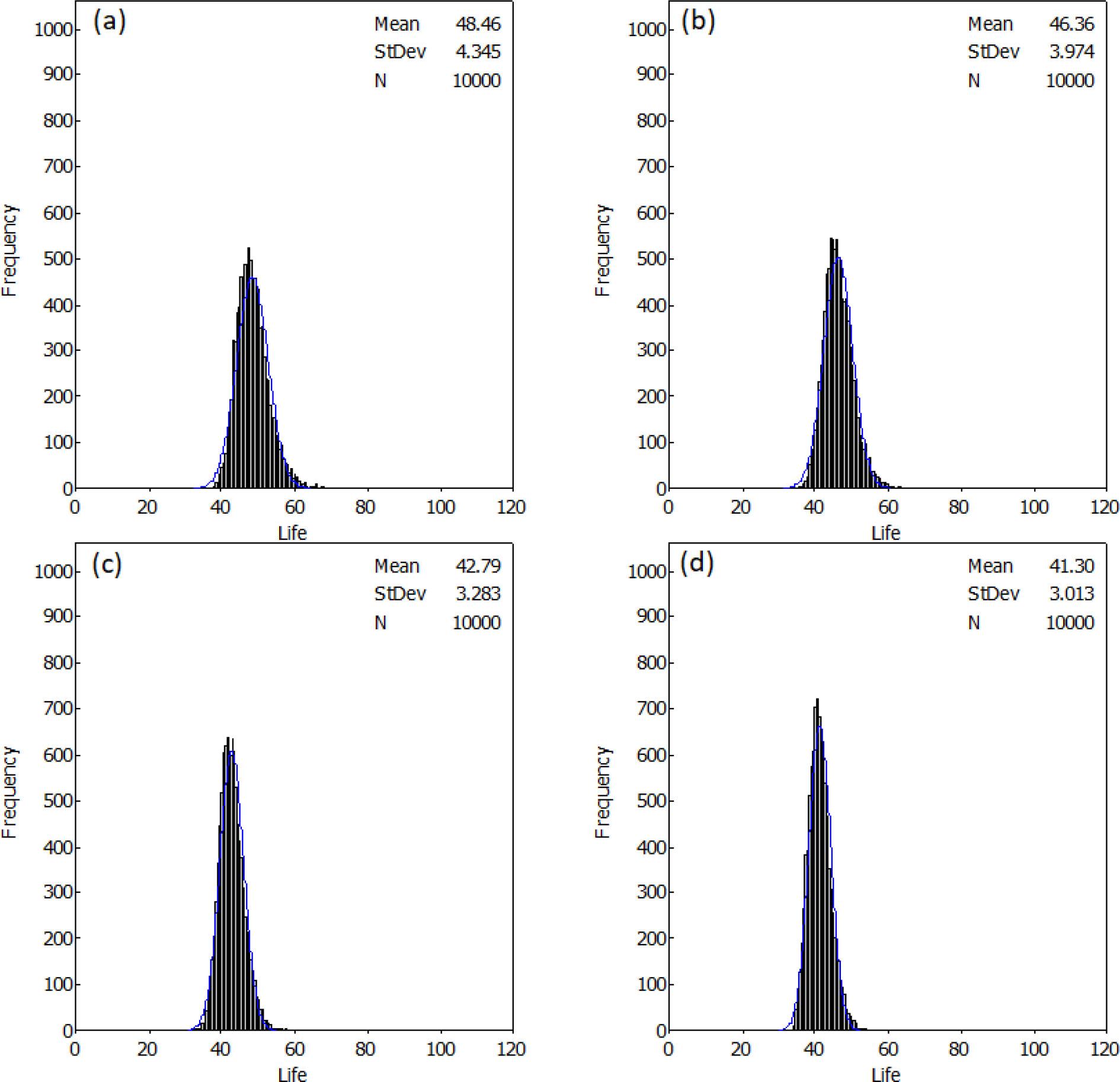

Predicted tool life values of the two tool inserts by varying cutting speeds −10%, −5%, 5%, and 10% from 220 m/min while keeping the feed rate constant at 0_06 mm/rev

| % Change | Al2O3+TiC | TiN+AlCrN | ||

|---|---|---|---|---|

| Average | S.D. | Average | S.D. | |

| −10 | 65.92 | 25.37 | 46.65 | 18.33 |

| −5 | 55.75 | 20.08 | 38.32 | 14.27 |

| 5 | 40.33 | 12.74 | 27.42 | 9.00 |

| 10 | 34.66 | 10.36 | 23.48 | 7.73 |

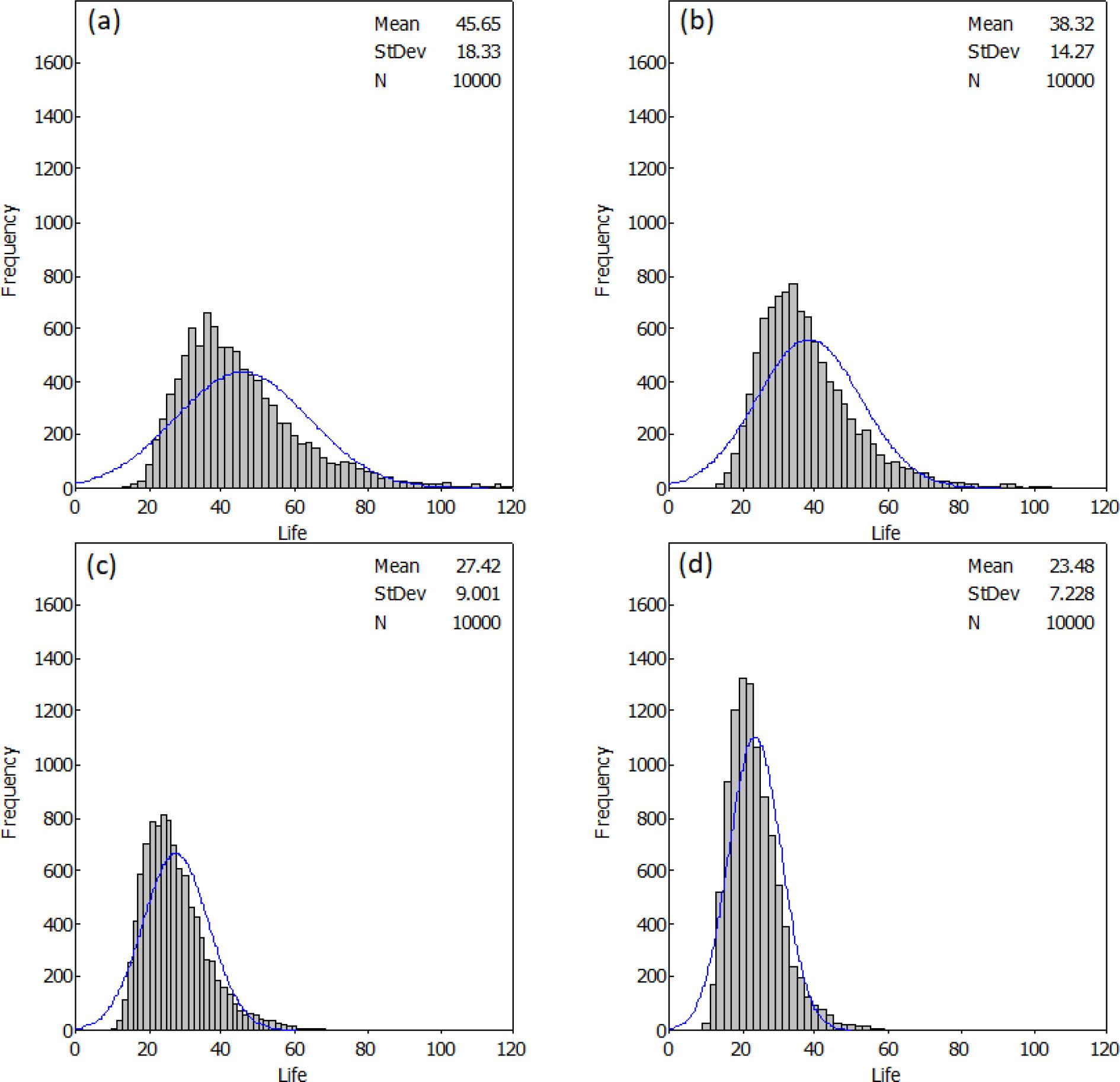

Predicted tool life values of the two tool inserts by varying feed rates −10%, −5%, 5%, and 10% from 0_06 mm/rev when keeping the cutting speed constant at 220 m/min

| % Change | Al2O3+TiC | TiN+AlCrN | ||

|---|---|---|---|---|

| Average | S.D. | Average | S.D. | |

| −10 | 48.46 | 4.35 | 33.13 | 3.22 |

| −5 | 46.36 | 3.97 | 31.65 | 2.90 |

| 5 | 42.79 | 3.28 | 29.02 | 2.41 |

| 10 | 41.30 | 3.01 | 27.91 | 2.18 |

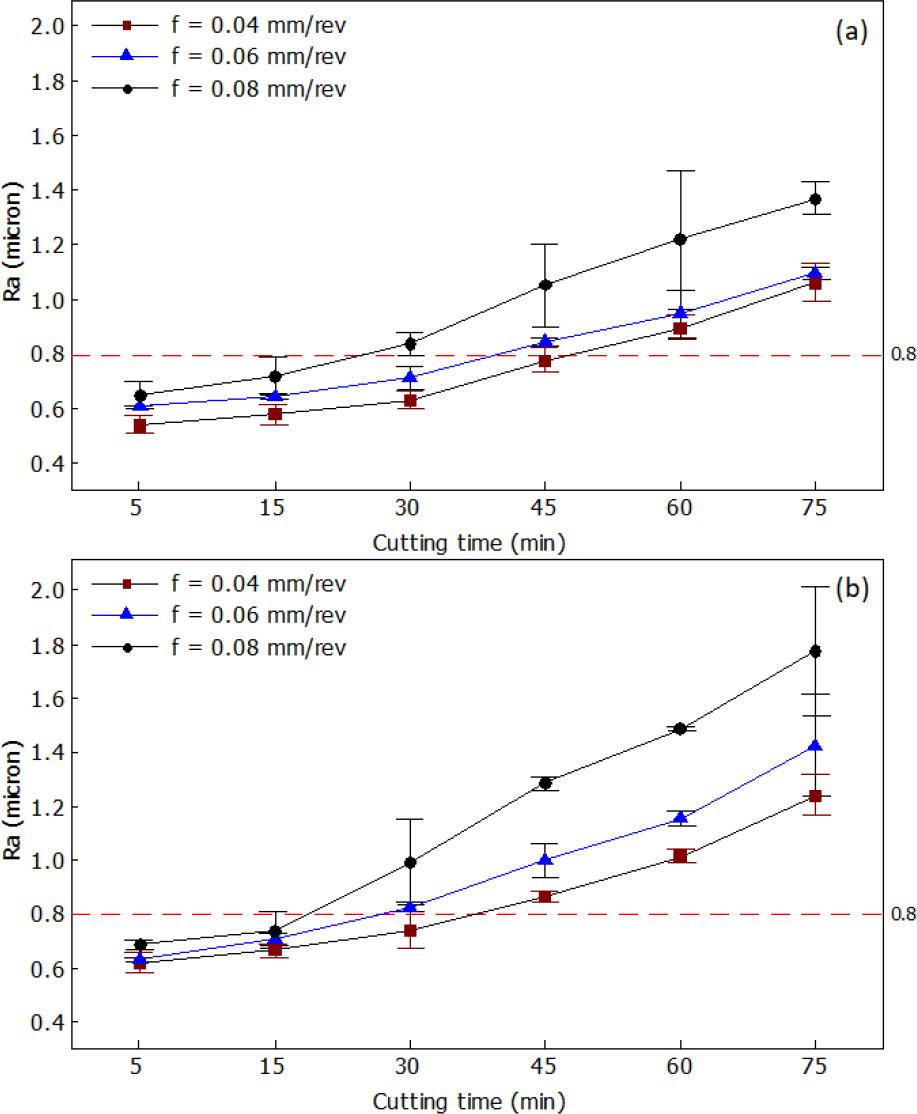

Results of Ra (in μm) values of the machined samples at different cutting times

| Cutting time (min) | Al2O3+TiC | TiN+AlCrN | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cutting speed (m/min) (Holding feed rate constant at 0.06 mm/rev) | Feed rate (mm/rev) (Holding cutting speed constant at 220 m/min) | Cutting speed (m/min) (Holding feed rate constant at 0.06 mm/rev) | Feed rate (mm/rev) (Holding cutting speed constant at 220 m/min) | |||||||||

| 200 | 220 | 240 | 0.04 | 0.06 | 0.08 | 200 | 220 | 240 | 0.04 | 0.06 | 0.08 | |

| 5 | 0.594 | 0.610 | 0.635 | 0.532 | 0.610 | 0.634 | 0.612 | 0.634 | 0.691 | 0.610 | 0.634 | 0.683 |

| 5 | 0.561 | 0.606 | 0.656 | 0.556 | 0.606 | 0.673 | 0.608 | 0.638 | 0.673 | 0.620 | 0.638 | 0.698 |

| 5 | 0.534 | 0.608 | 0.647 | 0.545 | 0.608 | 0.657 | 0.616 | 0.641 | 0.680 | 0.640 | 0.641 | 0.687 |

| 15 | 0.583 | 0.646 | 0.713 | 0.597 | 0.646 | 0.689 | 0.728 | 0.701 | 0.759 | 0.668 | 0.701 | 0.712 |

| 15 | 0.602 | 0.645 | 0.734 | 0.566 | 0.645 | 0.741 | 0.684 | 0.715 | 0.772 | 0.658 | 0.715 | 0.754 |

| 15 | 0.563 | 0.653 | 0.720 | 0.579 | 0.653 | 0.732 | 0.691 | 0.718 | 0.769 | 0.678 | 0.718 | 0.761 |

| 30 | 0.637 | 0.732 | 0.853 | 0.643 | 0.732 | 0.857 | 0.775 | 0.835 | 0.919 | 0.774 | 0.835 | 1.064 |

| 30 | 0.629 | 0.713 | 0.824 | 0.621 | 0.713 | 0.837 | 0.769 | 0.828 | 0.906 | 0.723 | 0.828 | 0.937 |

| 30 | 0.631 | 0.698 | 0.810 | 0.639 | 0.698 | 0.823 | 0.793 | 0.821 | 0.912 | 0.734 | 0.821 | 0.986 |

| 45 | 0.796 | 0.850 | 0.961 | 0.801 | 0.850 | 0.990 | 0.864 | 1.030 | 1.130 | 0.876 | 1.030 | 1.302 |

| 45 | 0.771 | 0.852 | 0.927 | 0.778 | 0.852 | 1.064 | 0.854 | 0.998 | 1.138 | 0.857 | 0.998 | 1.282 |

| 45 | 0.782 | 0.840 | 0.945 | 0.764 | 0.840 | 1.107 | 0.879 | 0.981 | 1.122 | 0.869 | 0.981 | 1.292 |

| 60 | 0.938 | 0.945 | 1.097 | 0.920 | 0.945 | 1.217 | 1.162 | 1.173 | 1.293 | 1.018 | 1.173 | 1.489 |

| 60 | 0.979 | 0.989 | 1.109 | 0.897 | 0.989 | 1.120 | 1.127 | 1.153 | 1.280 | 1.031 | 1.153 | 1.491 |

| 60 | 0.901 | 0.918 | 1.073 | 0.883 | 0.918 | 1.327 | 1.136 | 1.149 | 1.253 | 1.011 | 1.149 | 1.487 |

| 75 | 1.108 | 1.097 | 1.142 | 1.092 | 1.097 | 1.378 | 1.474 | 1.474 | 1.625 | 1.253 | 1.474 | 1.881 |

| 75 | 1.058 | 1.112 | 1.198 | 1.035 | 1.112 | 1.392 | 1.513 | 1.342 | 1.488 | 1.271 | 1.342 | 1.687 |

| 75 | 1.074 | 1.096 | 1.124 | 1.066 | 1.096 | 1.346 | 1.486 | 1.472 | 1.581 | 1.213 | 1.472 | 1.774 |