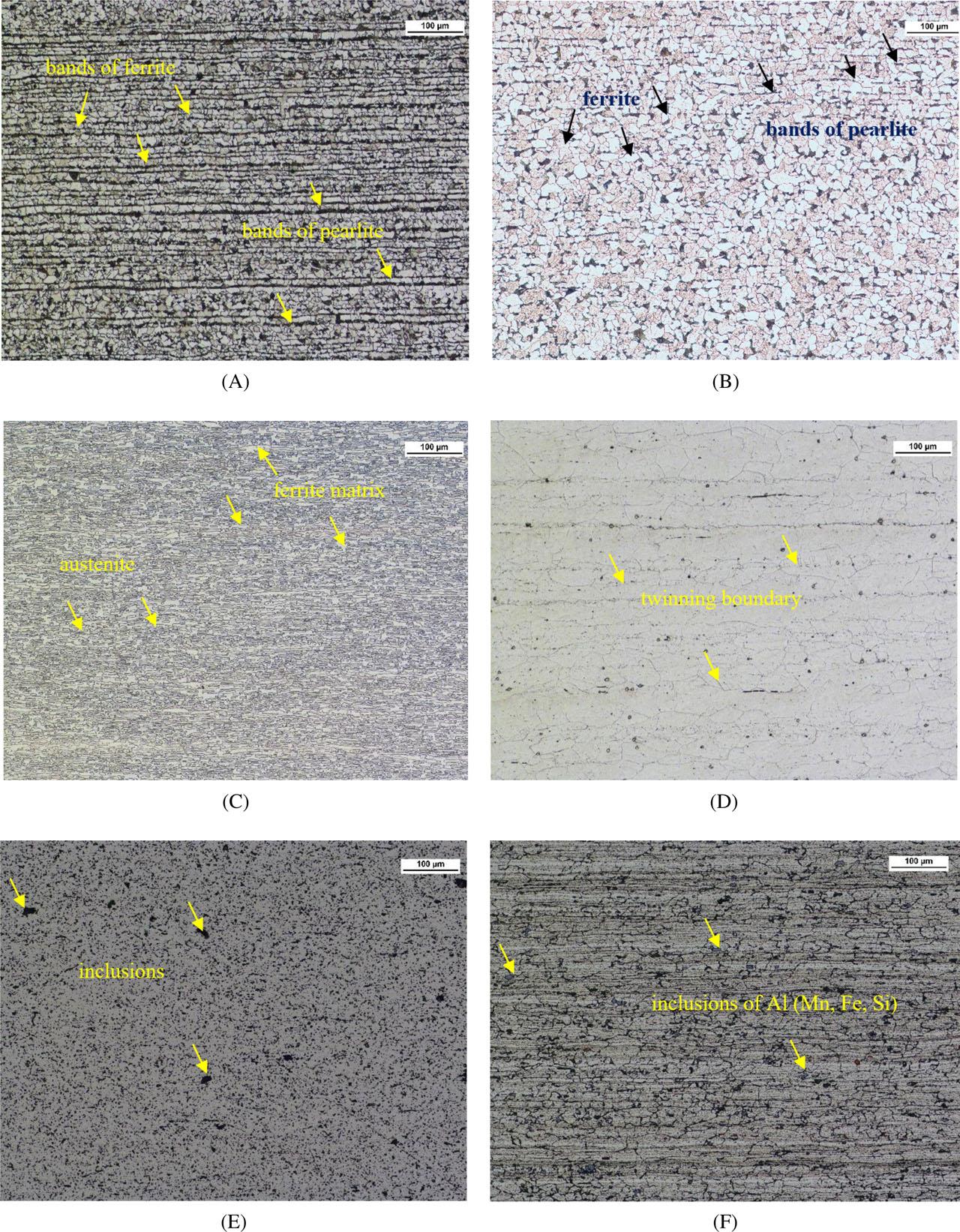

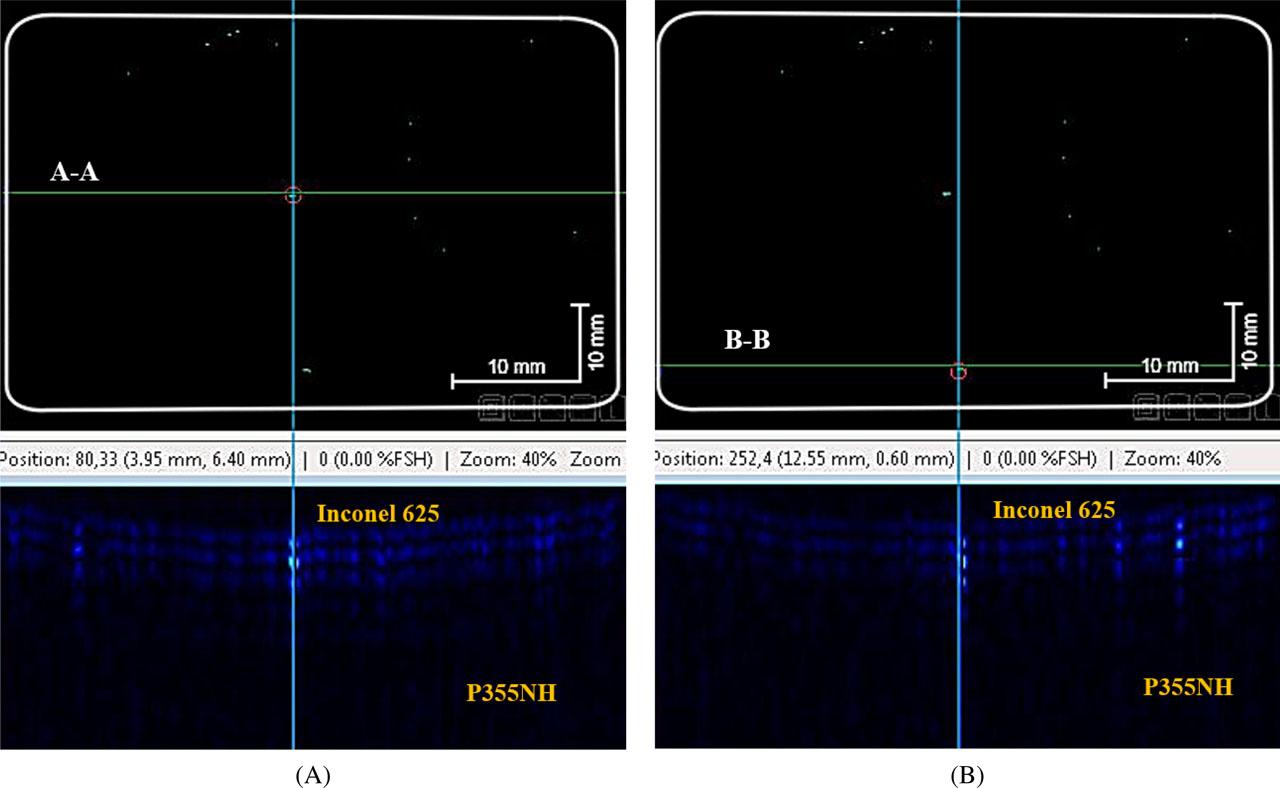

Fig. 1

Fig. 2

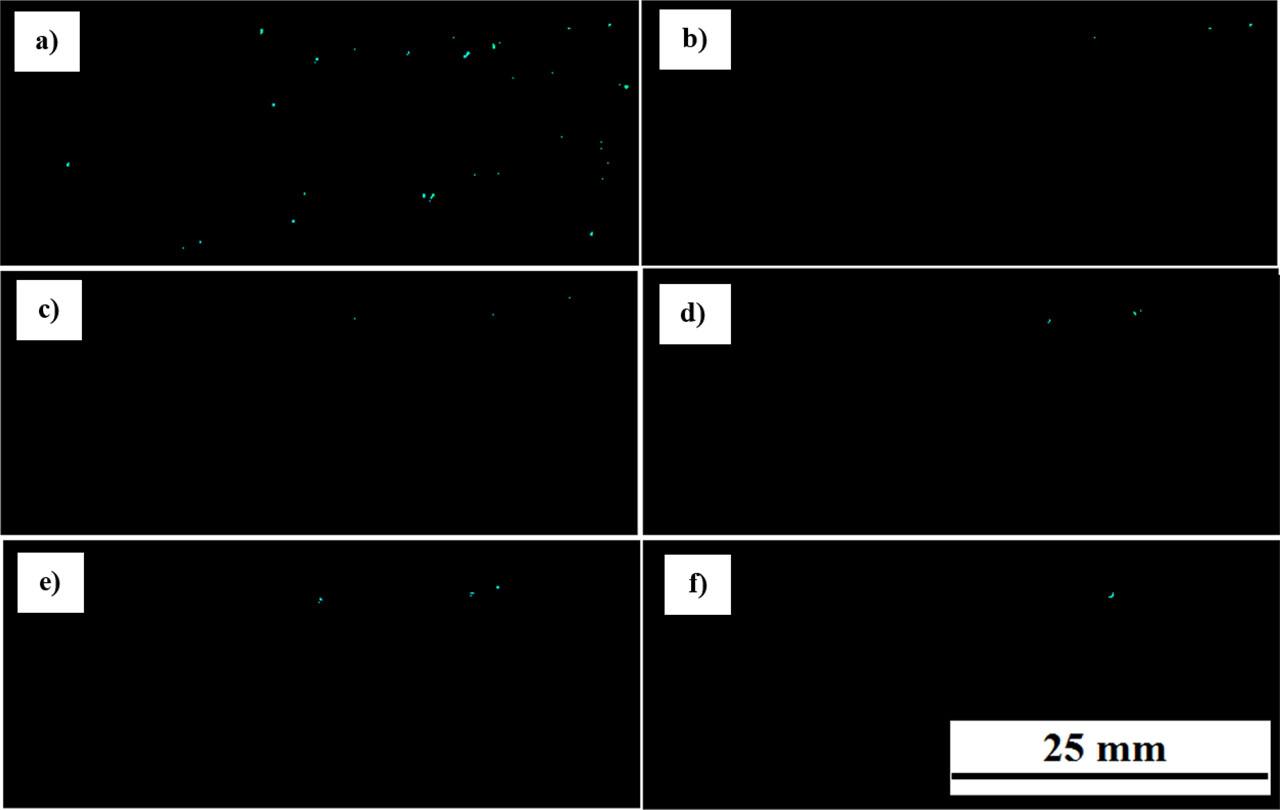

Fig. 3

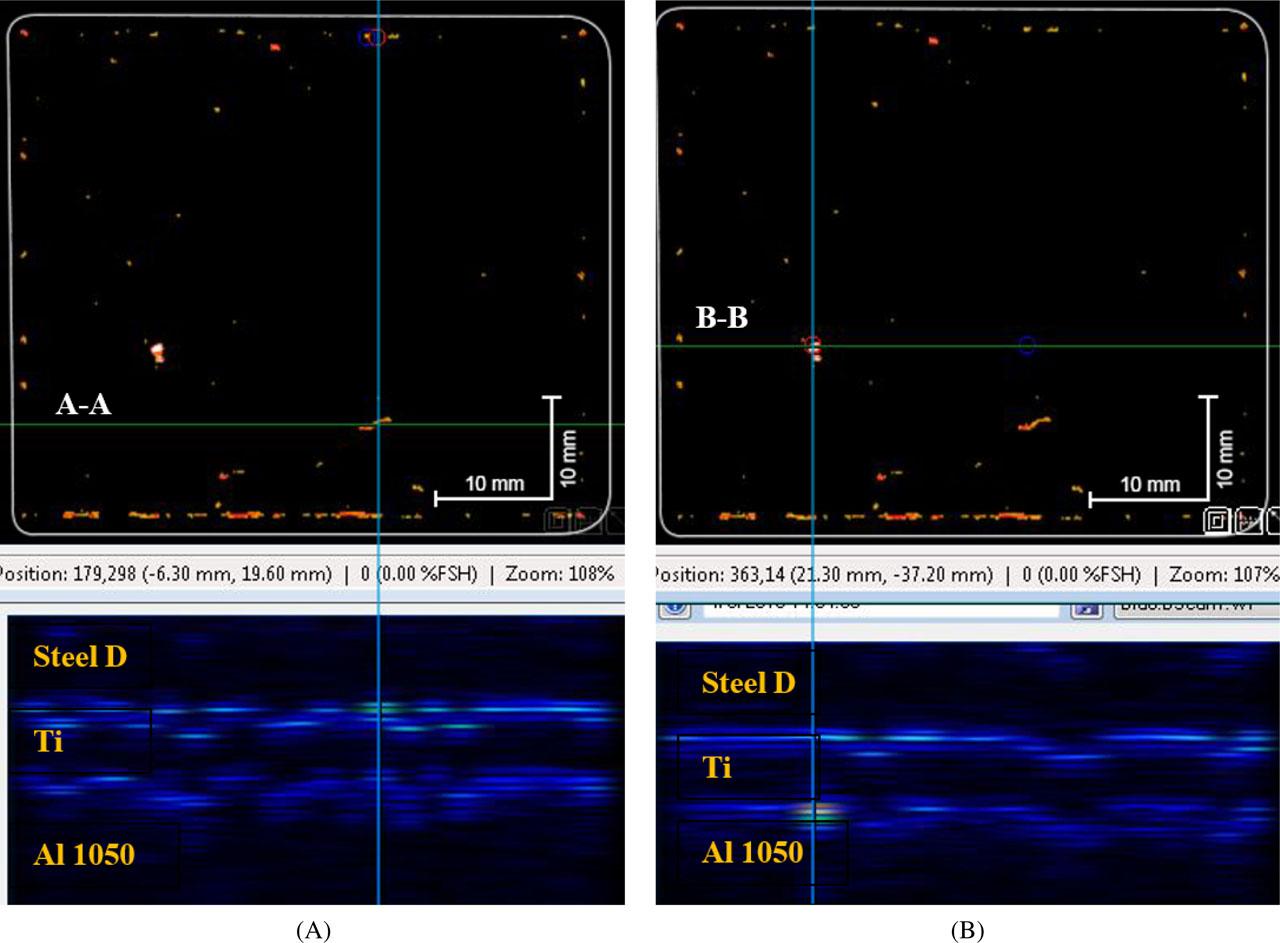

Fig. 4

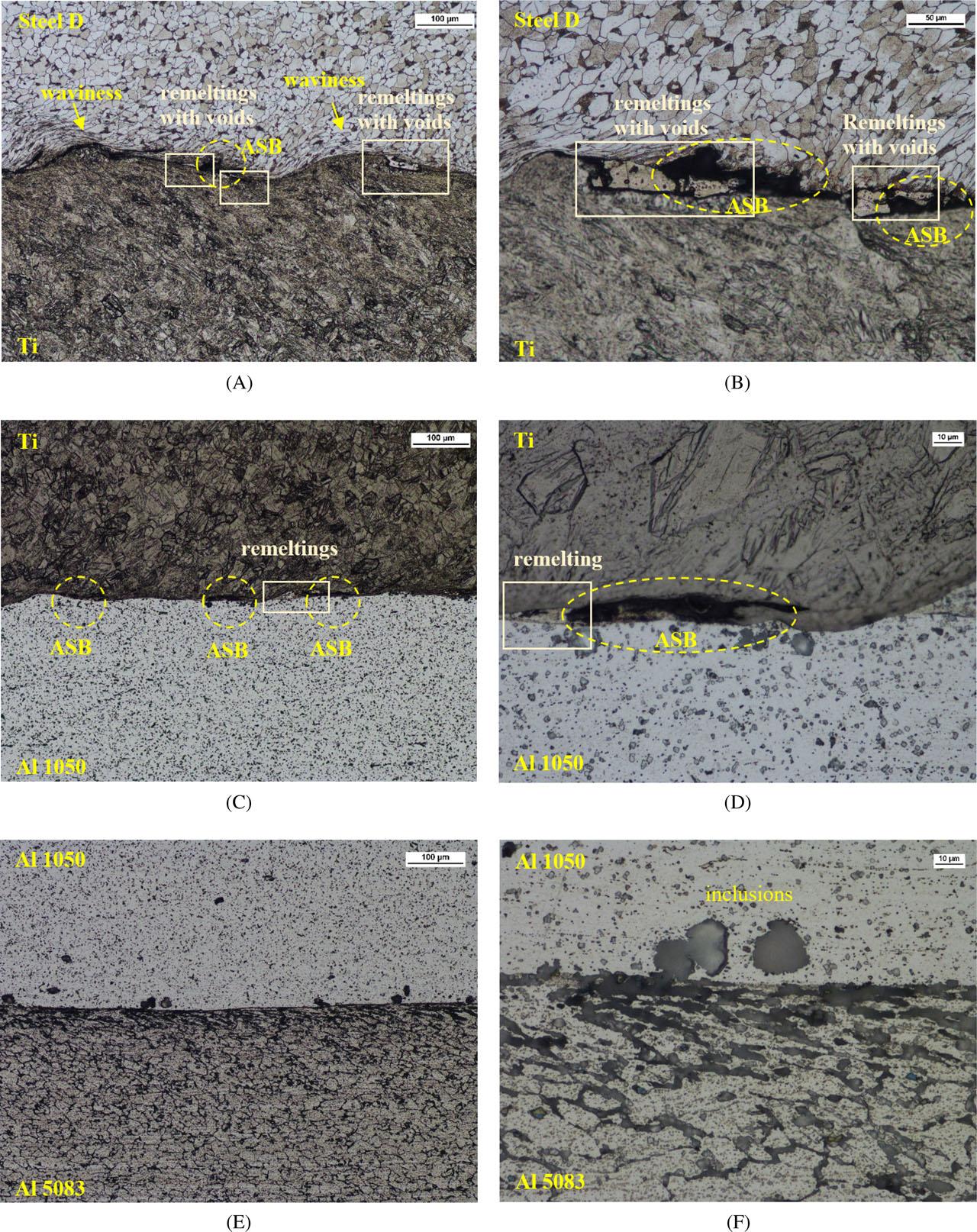

Fig. 5

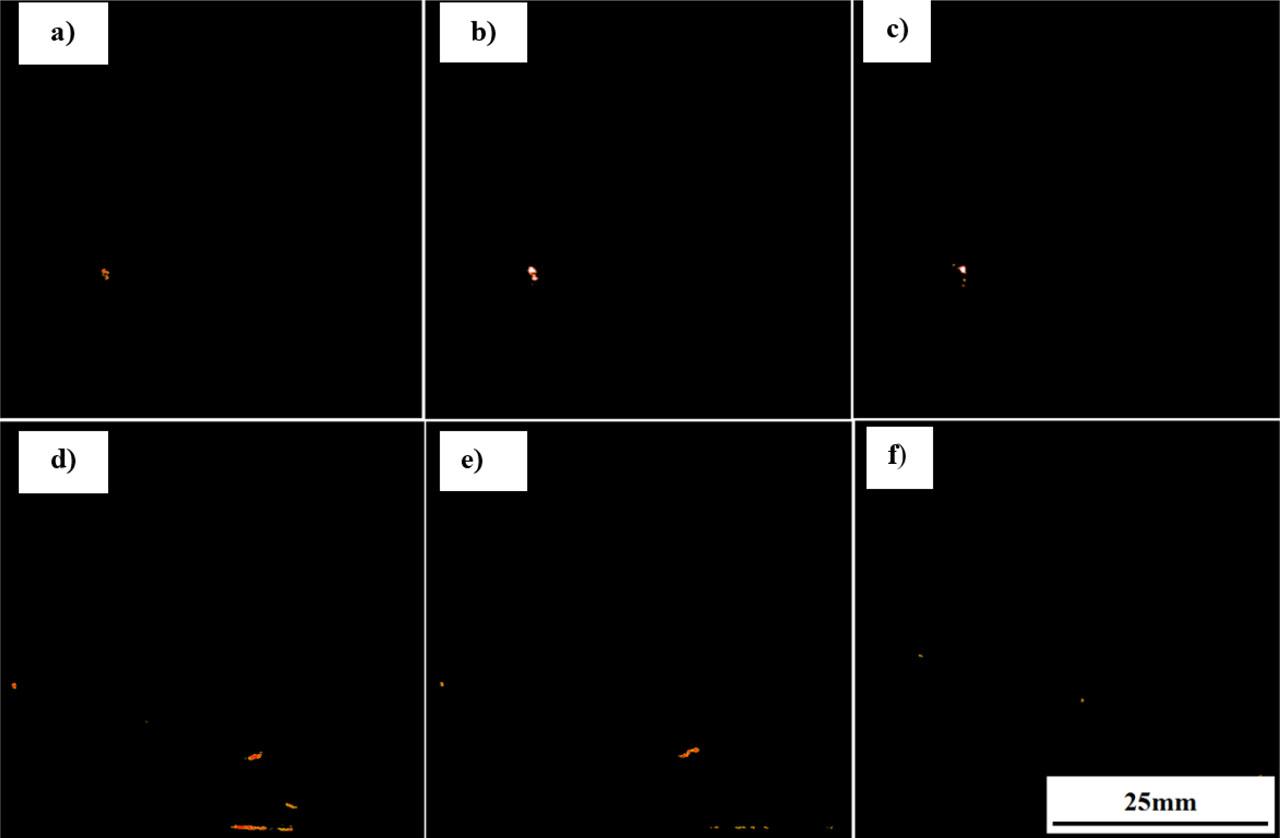

Fig. 6

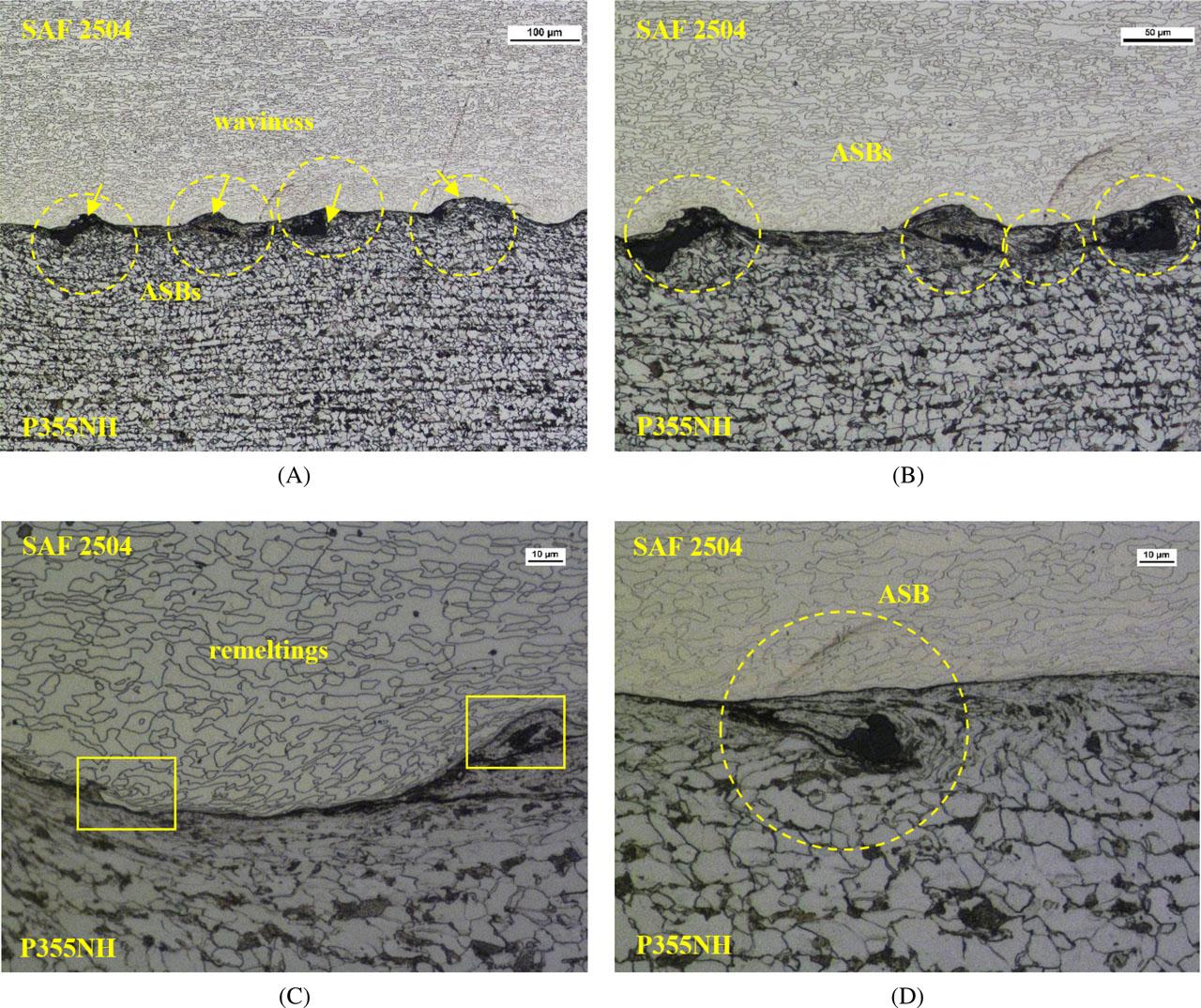

Fig. 7

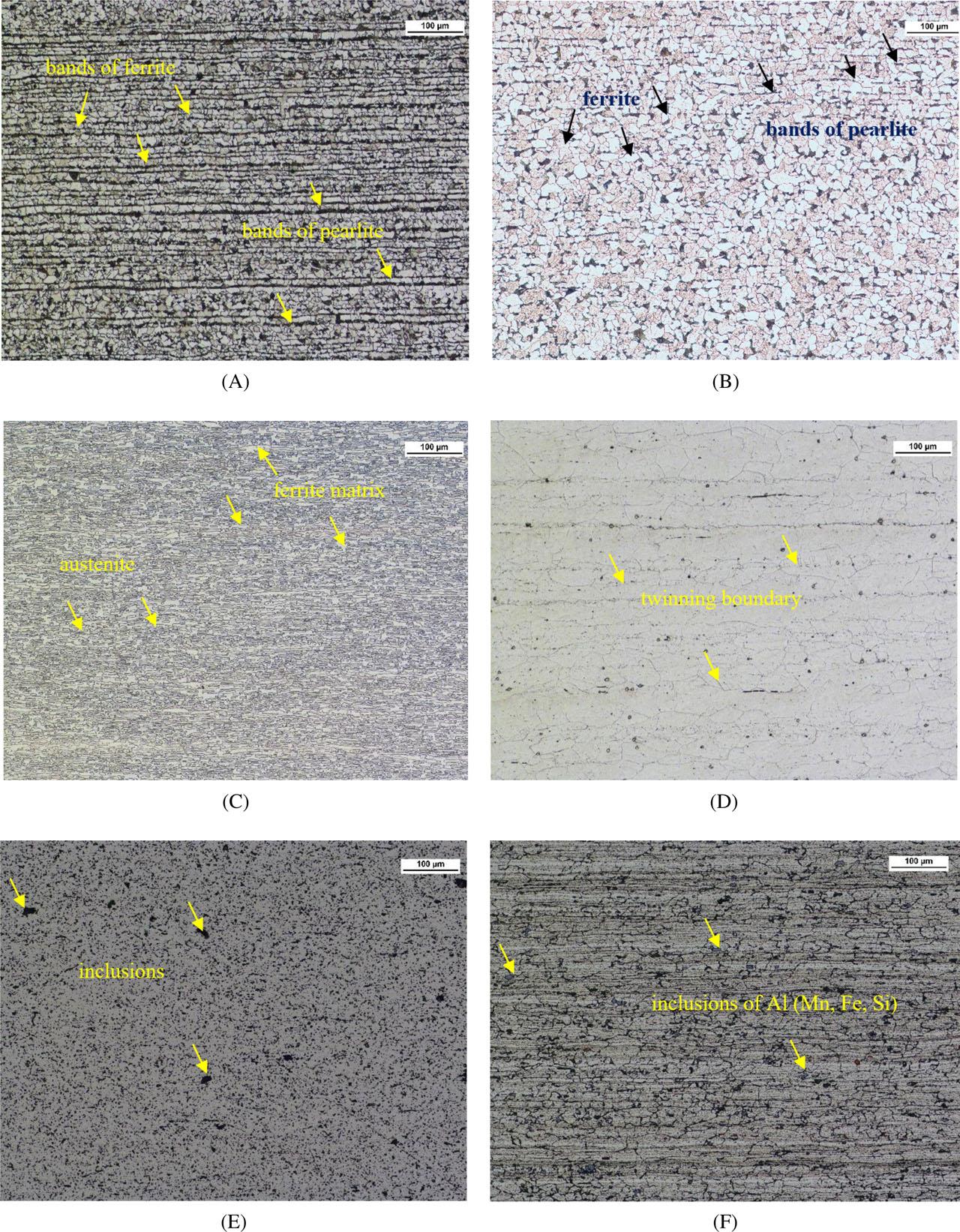

Fig. 8

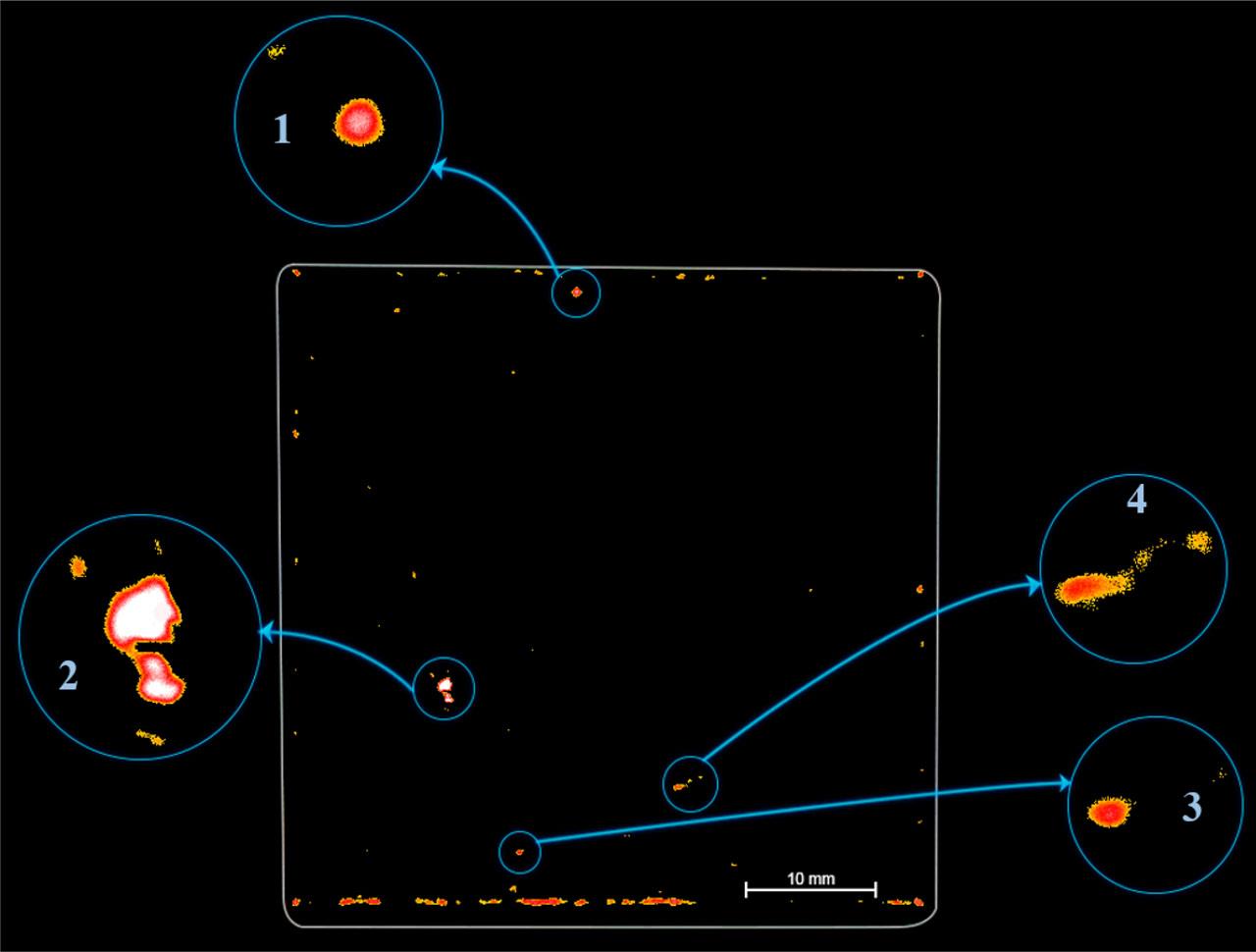

Fig. 9

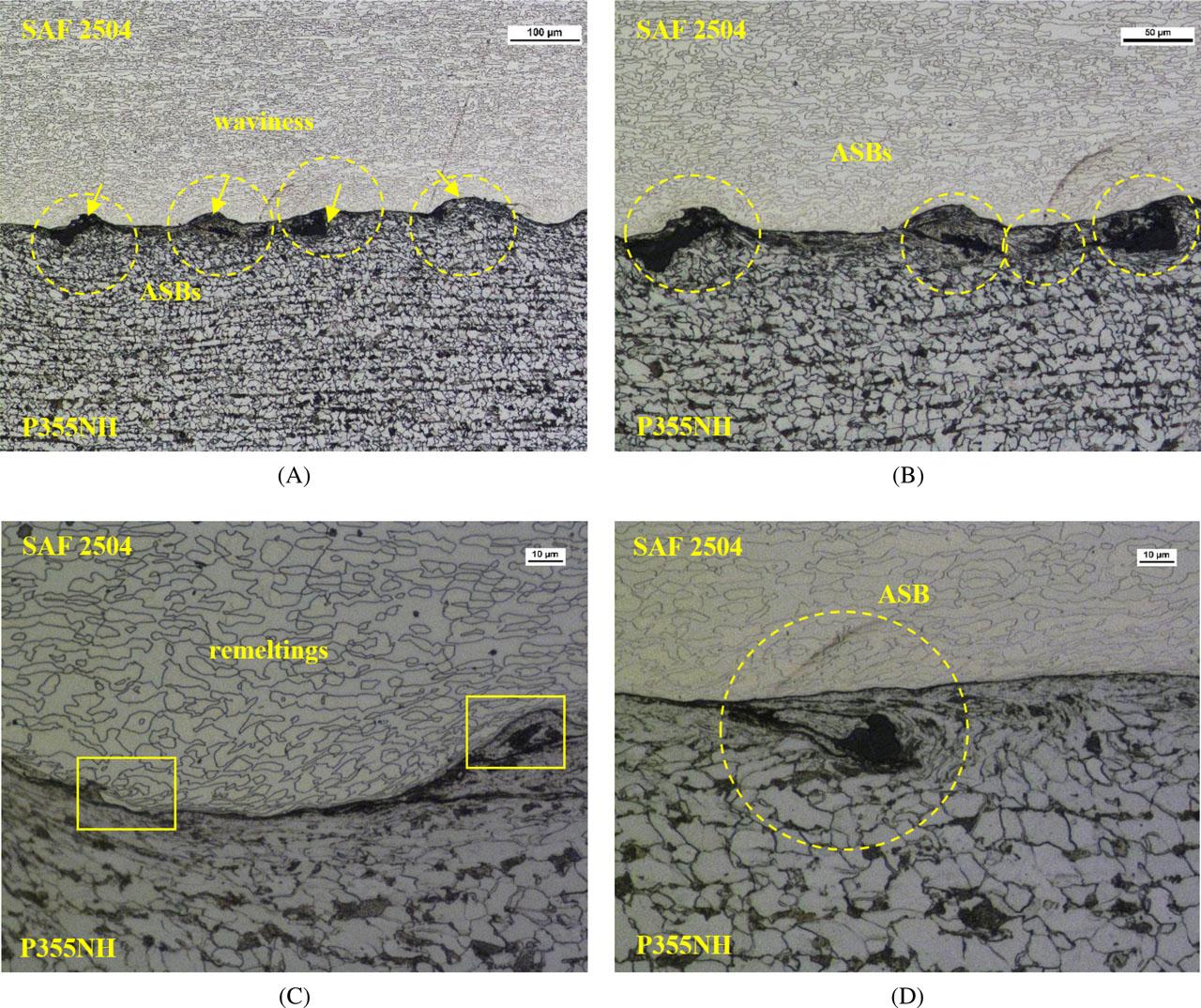

Fig. 10

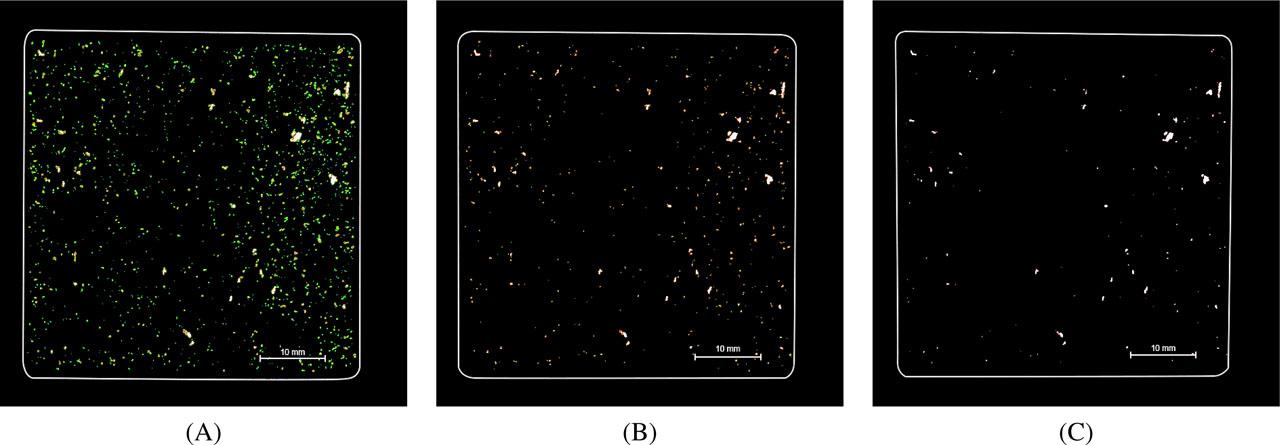

Fig. 11

Fig. 12

Fig. 13

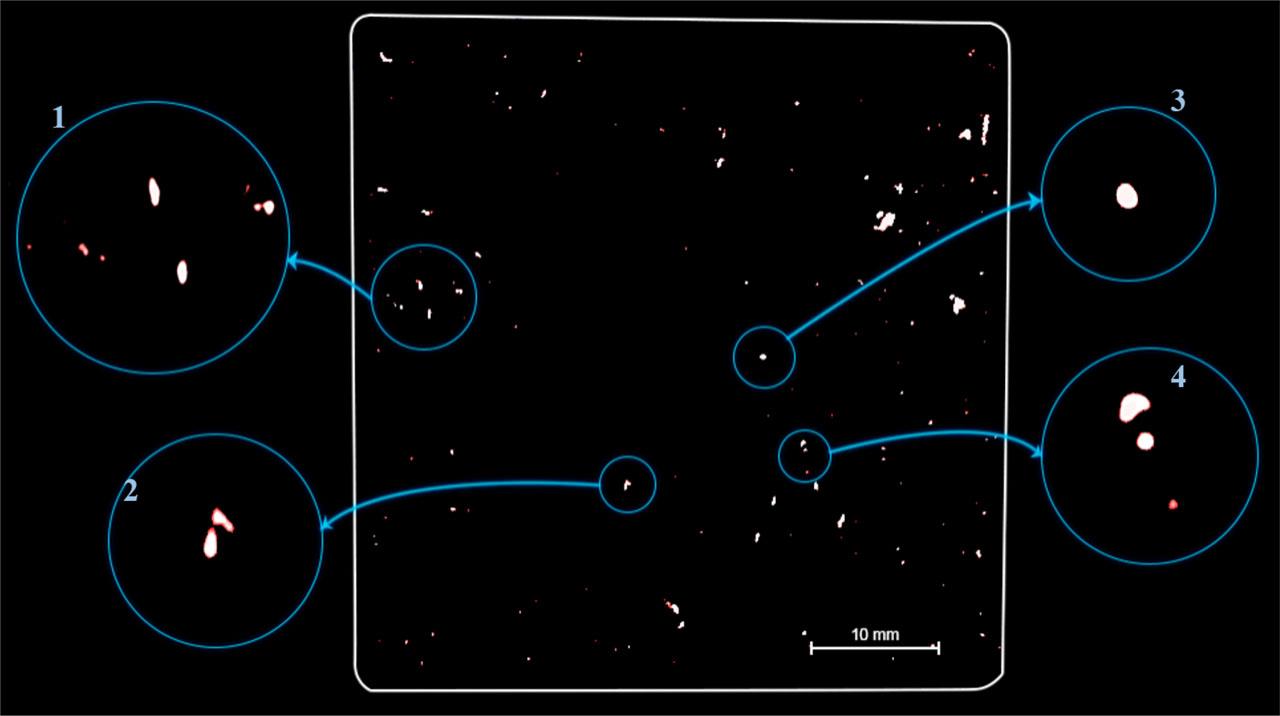

Fig. 14

© 2022 Marcin Korzeniowski, Beata Białobrzeska, Anna Lewandowska, published by Wroclaw University of Science and Technology

This work is licensed under the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 License.