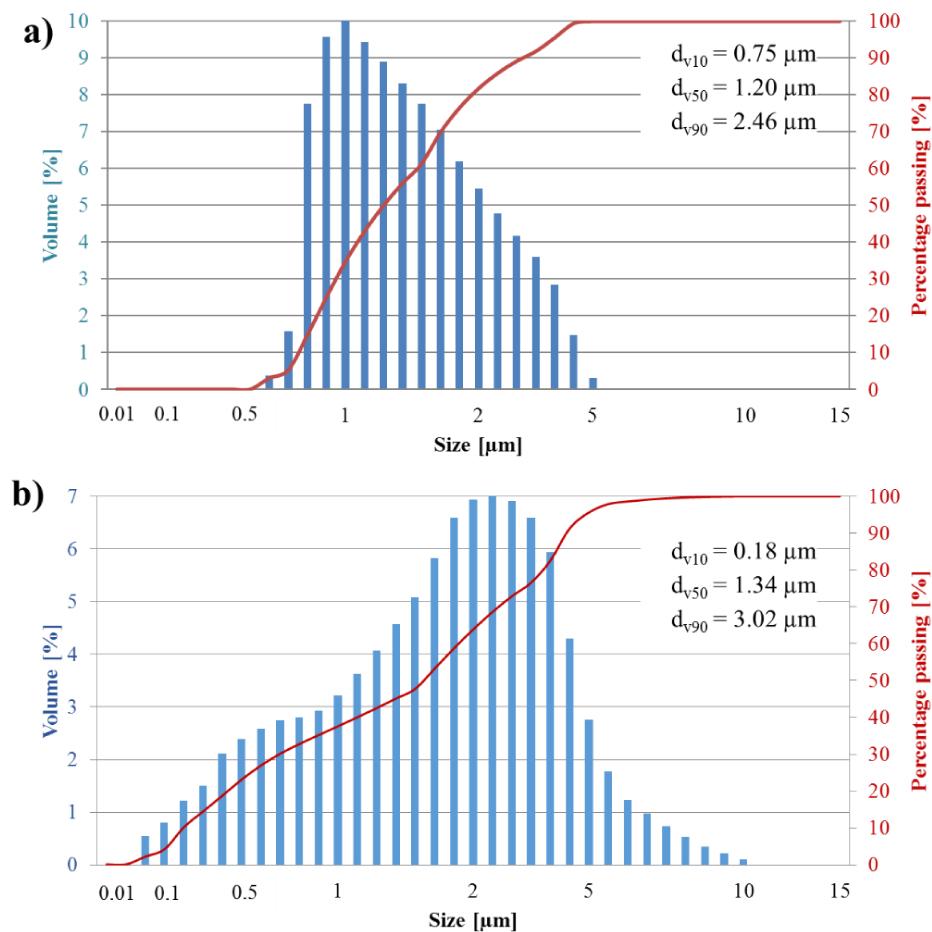

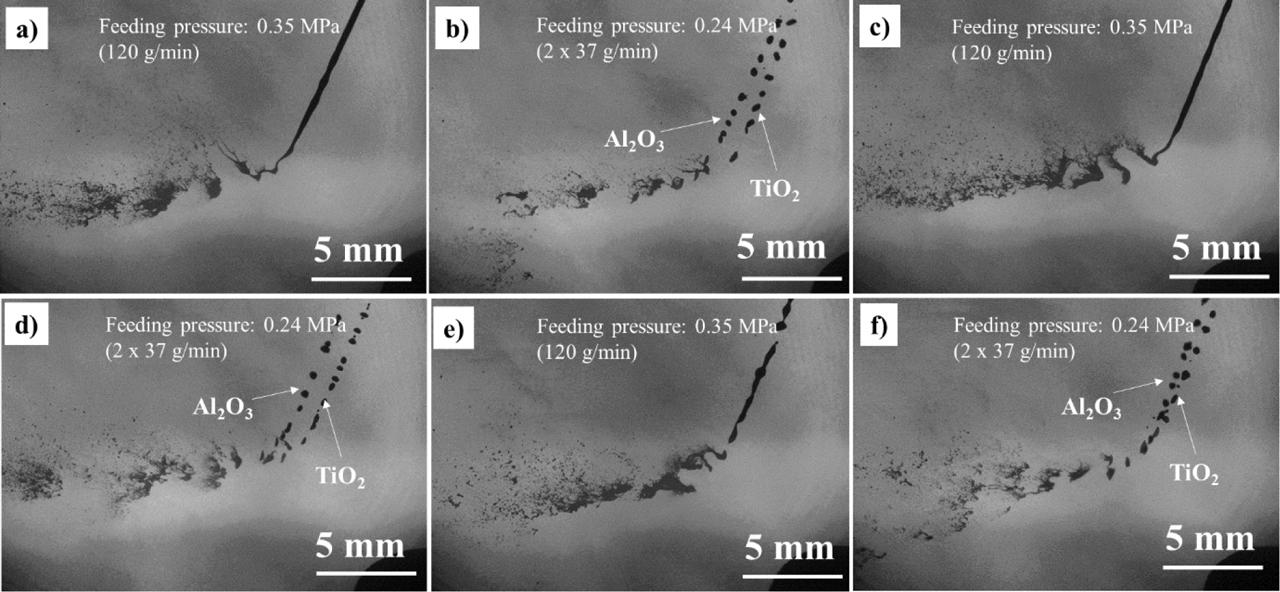

Fig. 1

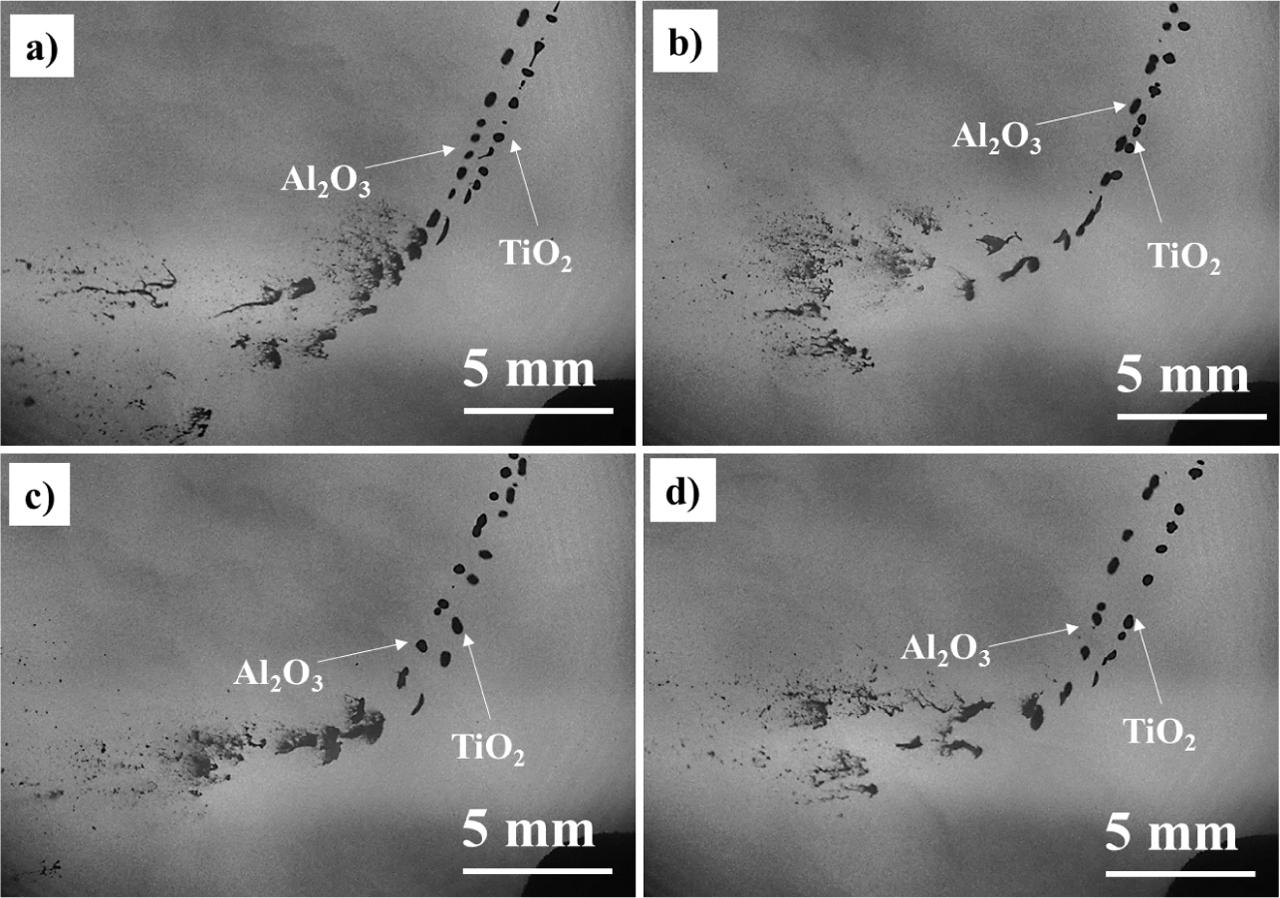

Fig. 2

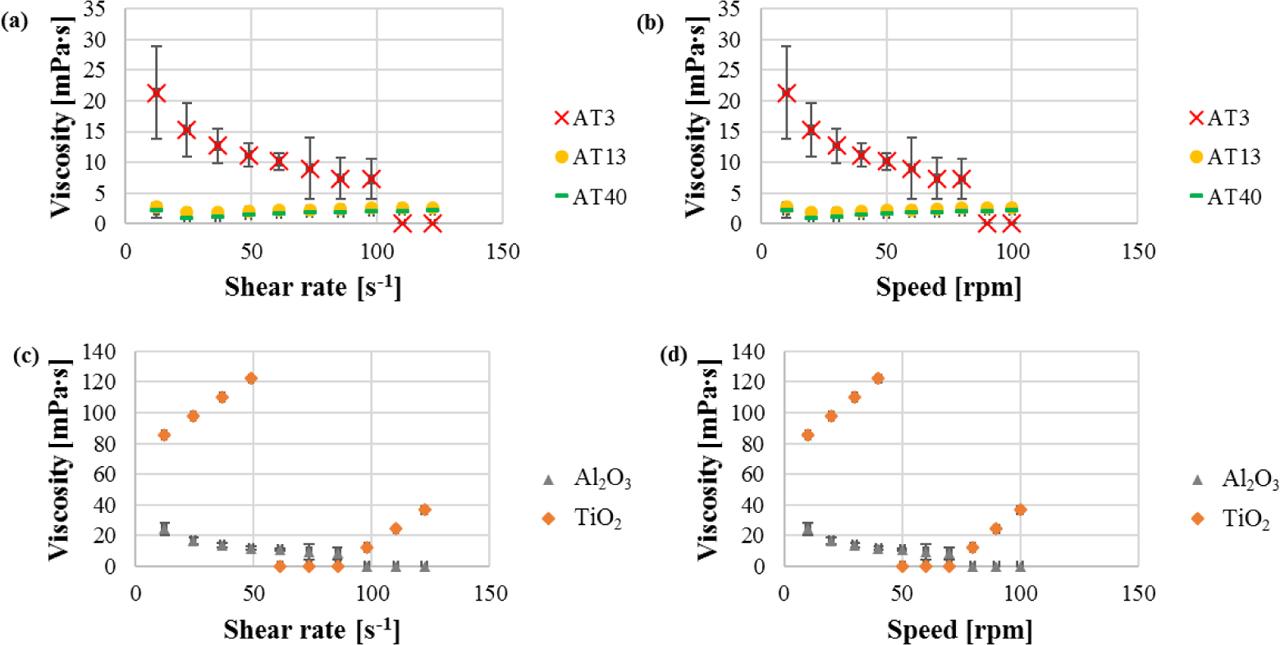

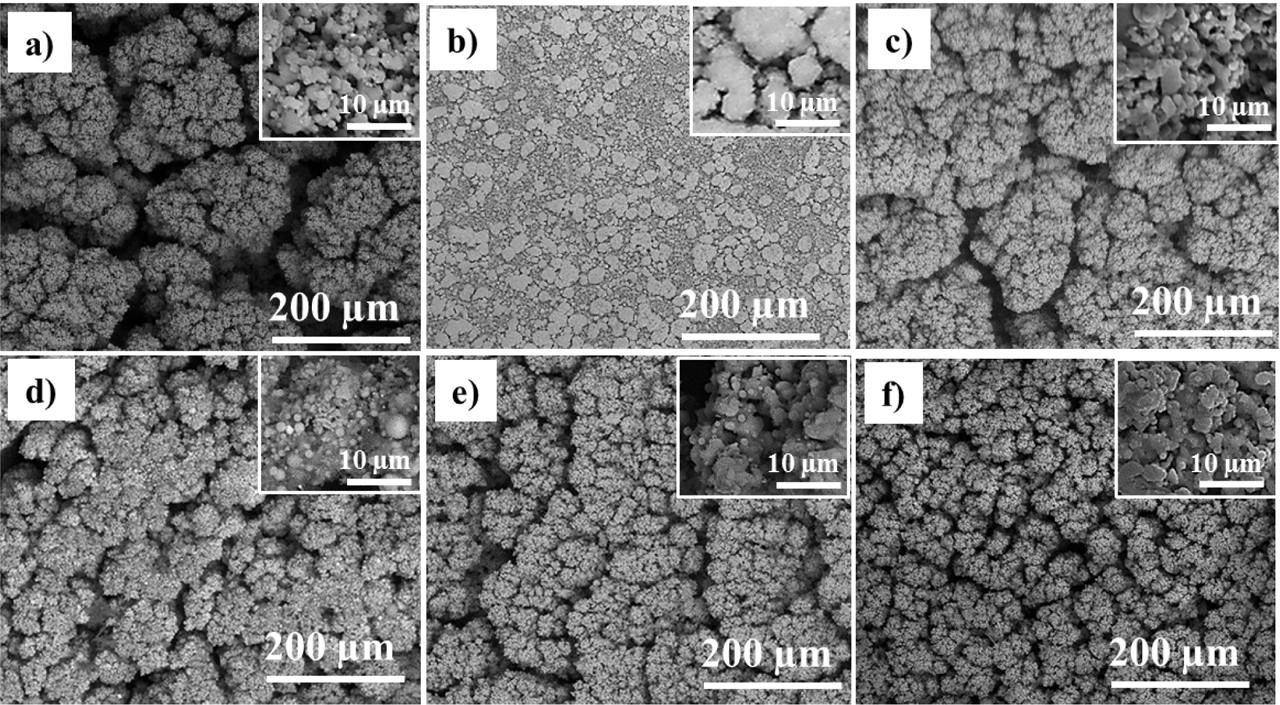

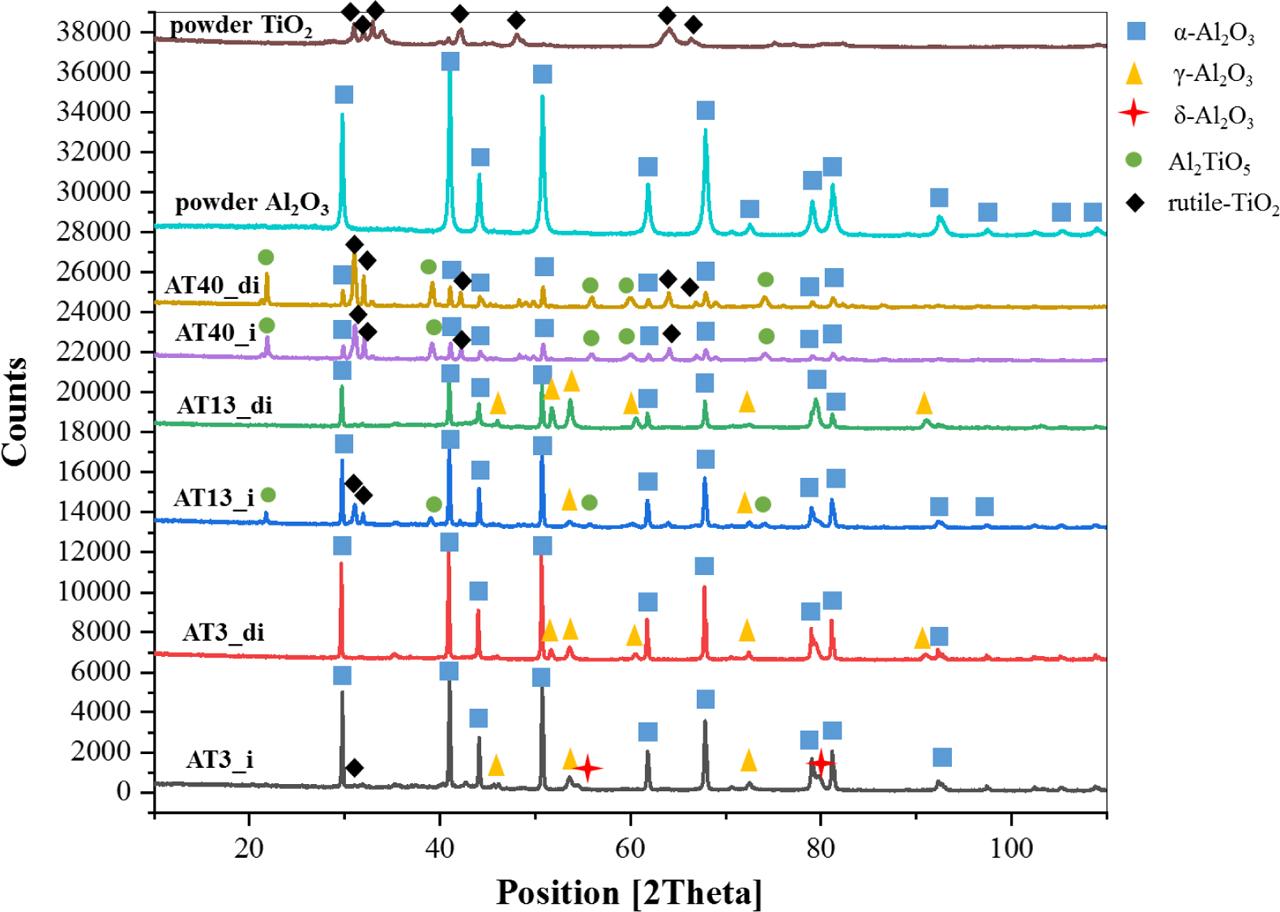

Fig. 3

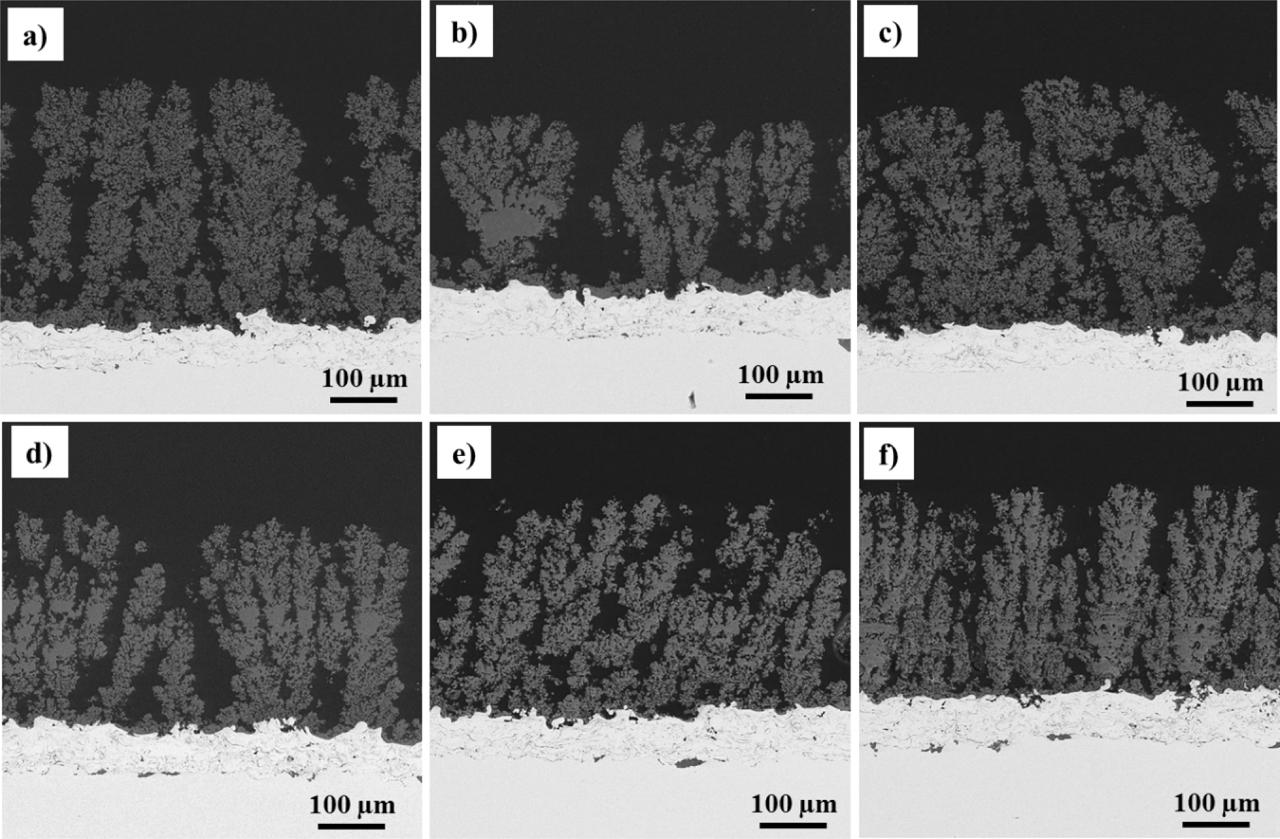

Fig. 4

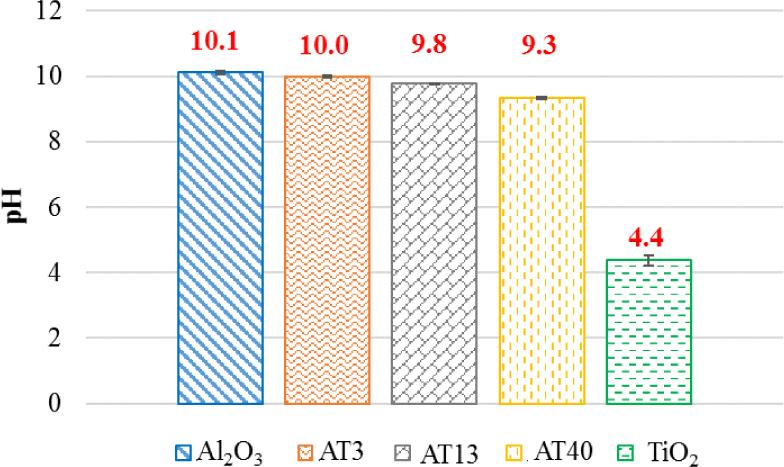

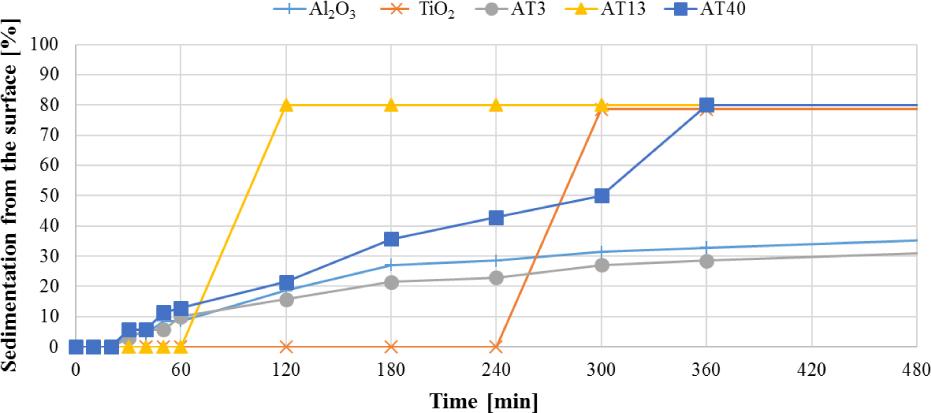

Fig. 5

Fig. 6

Fig. 7

Fig. 8

Fig. 9

Fig. 10

Fig. 11

Fig. 12

Fig. 13

Fig. 14

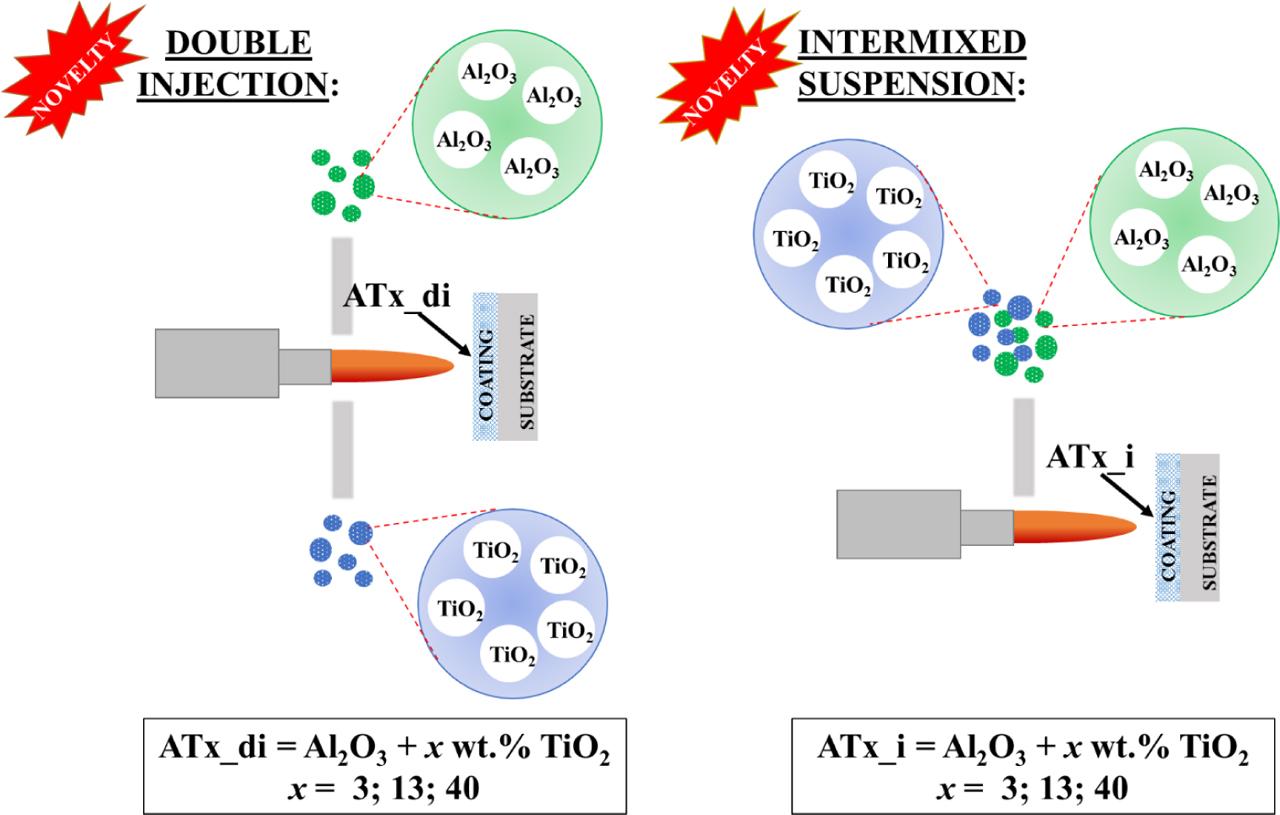

Characteristic of suspensions used for the Al2O3-TiO2 coatings deposition

| Coating code | Target composition | Used suspensions | Solvent | |

|---|---|---|---|---|

| AT3_i | Al2O3 + 3 wt.% TiO2 | intermixed Al2O3 and TiO2, to have Al2O3 + 3 wt.% TiO2 | H2O | |

| AT3_di | Al2O3 + 3 wt.% TiO2 | Al2O3 | TiO2 | H2O |

| AT13_i | Al2O3 + 13 wt.% TiO2 | intermixed Al2O3 and TiO2, to have Al2O3 + 13 wt.% TiO2 | H2O | |

| AT13_di | Al2O3 + 13 wt.% TiO2 | Al2O3 | TiO2 | H2O |

| AT40_i | Al2O3 + 40 wt.% TiO2 | intermixed Al2O3 and TiO2, to have Al2O3 + 40 wt.% TiO2 | H2O | |

| AT40_di | Al2O3 + 40 wt.% TiO2 | Al2O3 | TiO2 | H2O |

Deposition parameters of bond coat

| Substrate | austenitic stainless steel AISI 304/1.4301, 3 mm thick, diameter 25 mm; sand blasted before spraying (F36 grit, 500–600 μm mesh size) and sonicated with ethanol |

| Powder | NiCr 80-20, Amdry 4535; dried 3 h before spraying at 110°C |

| Electric power | 27 kW |

| Injection | radial, external |

| Stand-off distance | 100 mm |

| Gun | SG-100, Praxair, Indianapolis, USA |

| Feeding | 15 g/min |

| Transverse velocity | 400 mm/s |

| Plasma gases | Ar/H2: 45/5 slpm |

| Carrier gas | Ar 3.5 slpm |

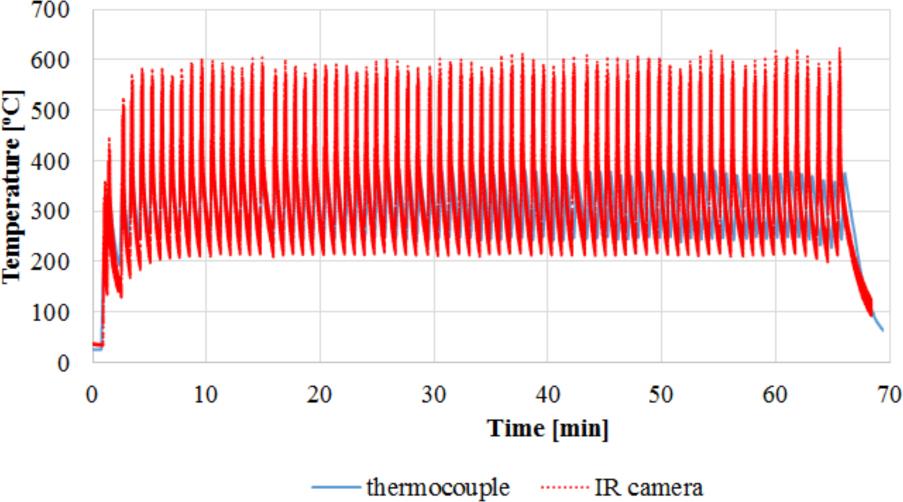

Deposition parameters and thickness of top coat

| AT3_i | AT3_di | AT13_i | AT13_di | AT40_i | AT40_di | |

|---|---|---|---|---|---|---|

| Injection angle, ° | 25 | 25 | 25 | 25 | 25 | 25 |

| Feeding distance, mm | 25 | 25 | 25 | 25 | 25 | 25 |

| Stand-off distance, mm | 100 | 100 | 100 | 100 | 100 | 100 |

| Nozzle diameter, mm | 0.35 | 2×0.2 | 0.35 | 2×0.2 | 0.35 | 2×0.2 |

| Robot speed, mm/s | 30 | 30 | 30 | 30 | 30 | 30 |

| Carousel speed, RPM | 55.5 | 55.5 | 55.5 | 55.5 | 55.5 | 55.5 |

| Torch amperage, A | 500 | 500 | 500 | 500 | 500 | 500 |

| Torch power, kW | 150 | 150 | 150 | 150 | 150 | 150 |

| Feeding liquid rate, g/min | 120 | 2×37 | 120 | 2×37 | 120 | 2×37 |

| Feeding pressure, MPa | 0.35 | 0.24 | 0.35 | 0.24 | 0.35 | 0.24 |

| Interpass substrate temperature, °C | 250 | 250 | 250 | 250 | 250 | 250 |

| Preheating | yes | yes | yes | yes | yes | yes |

| Active cooling | air | air | air | air | air | air |

| Number of deposition cycles | 40 | 140 | 40 | 120 | 40 | 100 |

| Total number of deposition passes | 120 | 420 | 120 | 360 | 120 | 300 |

| Net spraying time, min | 9.3 | 32.7 | 9.3 | 28 | 9.3 | 23.3 |

| Coating thickness, μm | 338.2±16.9 | 241.5±8.2 | 360.9±16.7 | 296.7±5.8 | 316.2±10.9 | 287.6±8.4 |

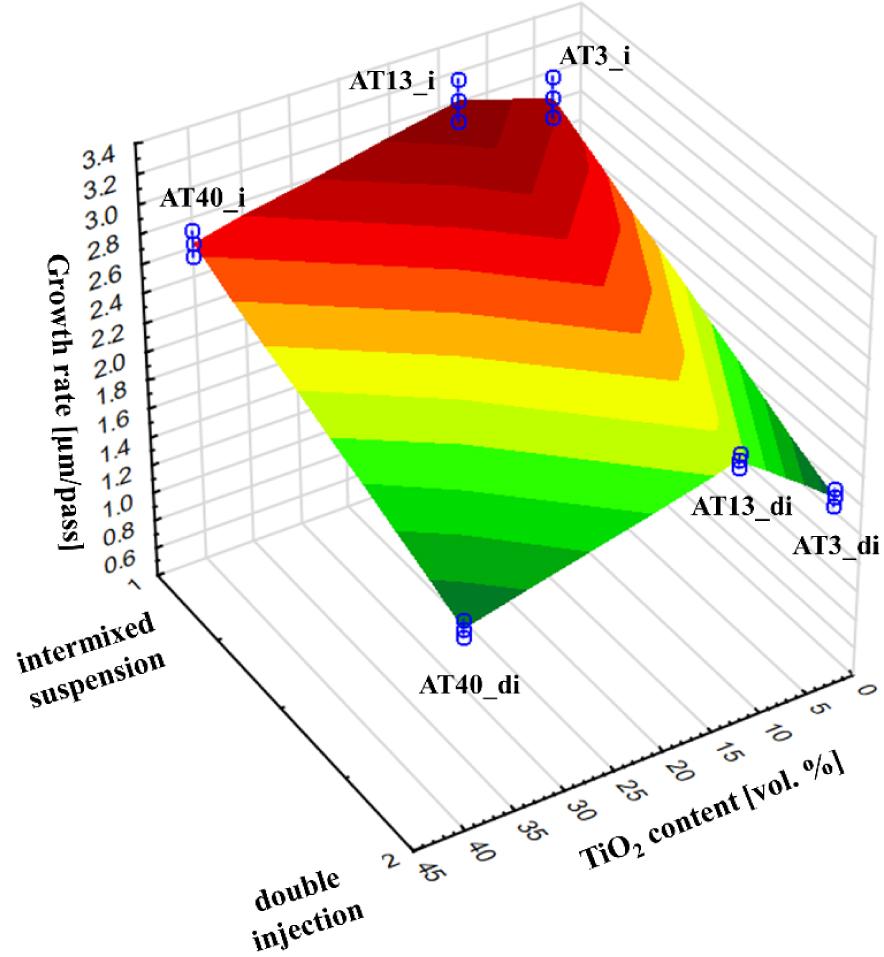

| Normalized growth rate, μm/pass | 2.82±0.14 | 1.74±0.06 | 3.01±0.14 | 2.24±0.05 | 2.63±0.09 | 1.80±0.06 |

Comparison of the double injection and intermixed spraying

| Property | Double injection | Intermixed suspension |

|---|---|---|

| feedstock stability | + easier prevention of agglomeration and sedimentation of two feedstocks separately | − stability of a mixture (suspension/suspension; suspension/powder; suspension/solution precursor) may not be easily guaranteed |

| waste | + minimized material loss – the suspension after spraying can be further stored and easily used for the next spraying | − waste remains, initial suspensions cannot be separated and used again |

| spraying comprehensiveness | + it opens up the possibility for a precise control of the particle thermal history, the microstructure and phase composition of coatings | + easier optimization of spraying parameters for the injection of a single liquid |

| tailoring of chemical composition | − difficult selection of suspension/solvent/powder/dispersing agents concentrations (especially when strong dilution is needed) | + easy tailoring of the feedstock chemical composition |

| sprayability | − spraying is difficult in the case of low constituent content – there is a need to intensively dilute the suspensions; consequently, lots of energy is consumed for solvent evaporation, leading to a low process efficiency; + feasibility of the process | + the ratio of the feedstock composition may be easily adjusted, so the disadvantages of the double injection are easily omitted |