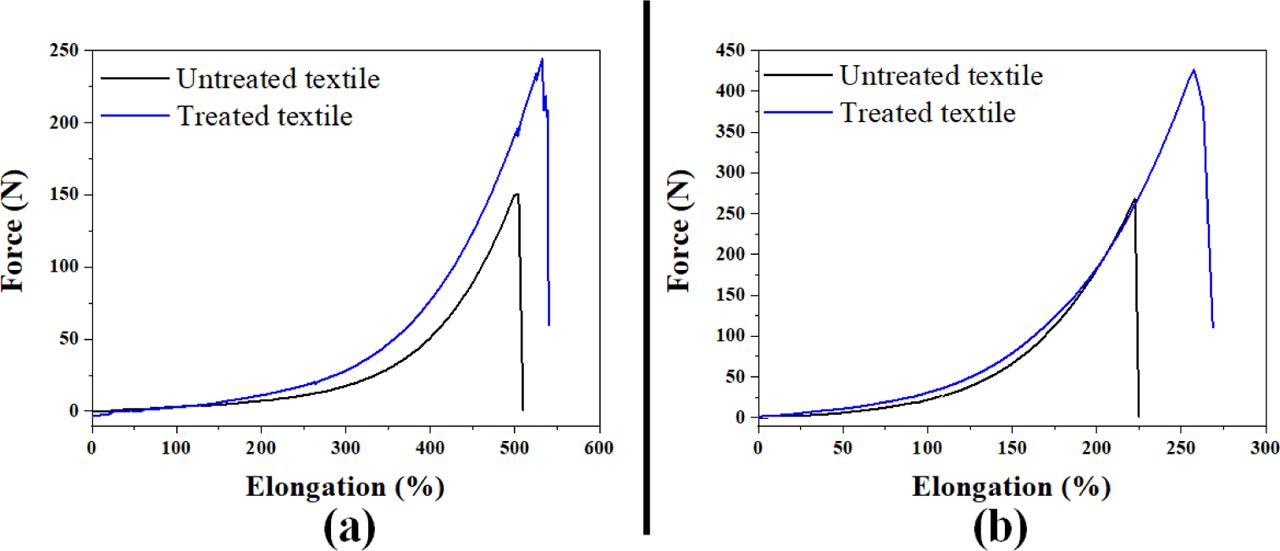

Fig. 1

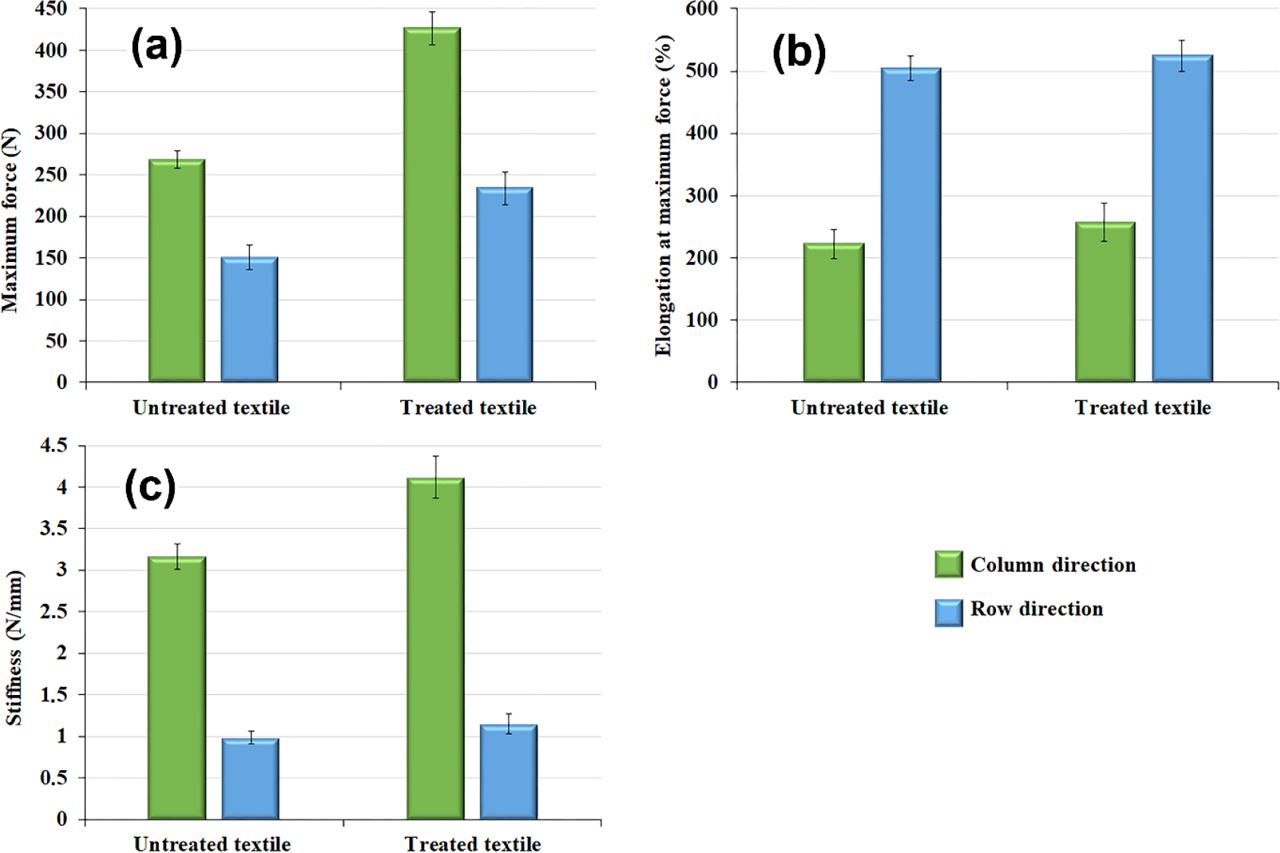

Fig. 2

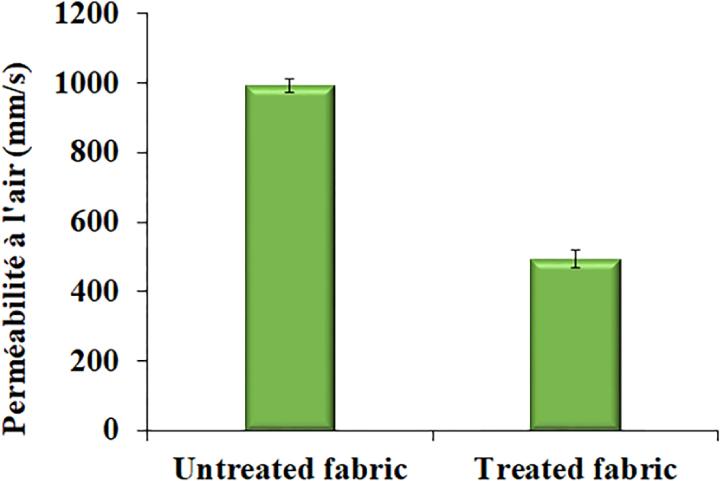

Fig. 3

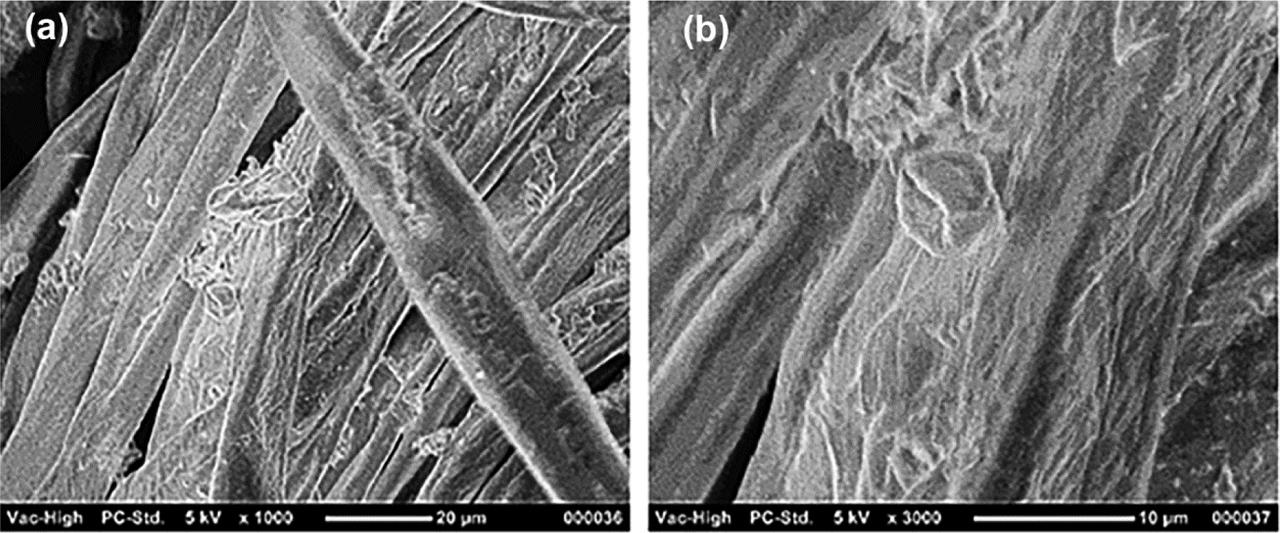

Fig. 4

Fig. 5

Fig. 6

Fig. 7

Fig. 8

Fig. 9

Fig. 10

Fig. 11

Fig. 12

ANOVA

| Source | Degrees of freedom | Sum of squares | Variance | F | p-value |

|---|---|---|---|---|---|

| Regression | 9 | 20.4000 | 2.2667 | 18.98 | 0.002 |

| Residuals | 5 | 0.5971 | 0.1194 | – | – |

| Total | 14 | 20.9971 | – | – | – |

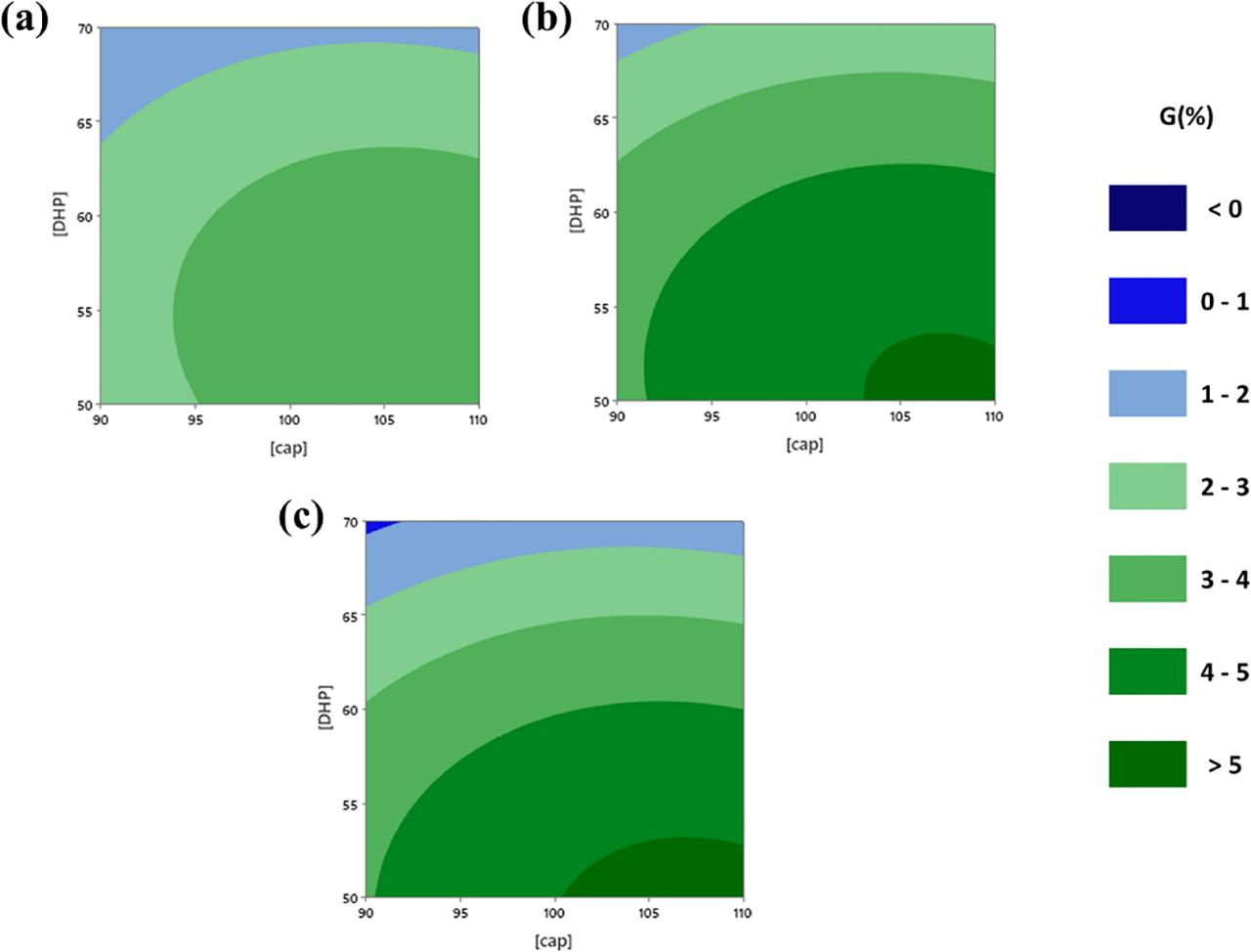

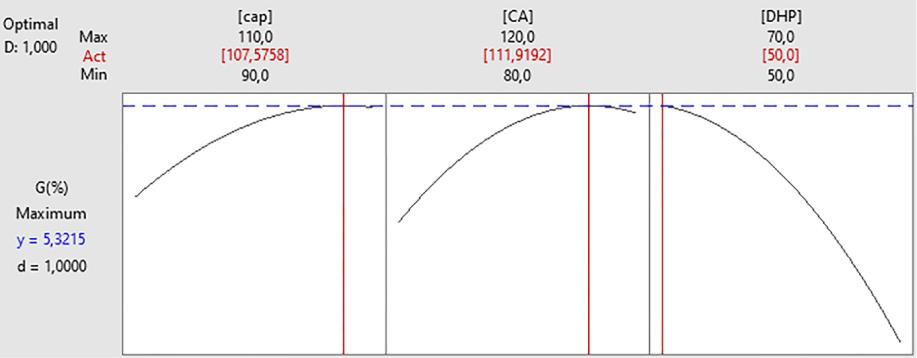

Box-Behnken design and experimental results

| Experiment N° | Coded values | Real values | Mean response | ||||

|---|---|---|---|---|---|---|---|

| X1 | X2 | X3 | U1 | U2 | U3 | G (%) (n = 3) | |

| 1 | −1 | −1 | 0 | 90 | 80 | 60 | 2.25 |

| 2 | +1 | −1 | 0 | 110 | 80 | 60 | 3.68 |

| 3 | −1 | +1 | 0 | 90 | 120 | 60 | 2.75 |

| 4 | +1 | +1 | 0 | 110 | 120 | 60 | 4.11 |

| 5 | −1 | 0 | −1 | 90 | 100 | 50 | 3.85 |

| 6 | +1 | 0 | −1 | 110 | 100 | 50 | 4.72 |

| 7 | −1 | 0 | +1 | 90 | 100 | 70 | 1.88 |

| 8 | +1 | 0 | +1 | 110 | 100 | 70 | 2.11 |

| 9 | 0 | −1 | −1 | 100 | 80 | 50 | 3.45 |

| 10 | 0 | +1 | −1 | 100 | 120 | 50 | 5.22 |

| 11 | 0 | −1 | +1 | 100 | 80 | 70 | 1.50 |

| 12 | 0 | +1 | +1 | 100 | 120 | 70 | 1.47 |

| 13 | 0 | 0 | 0 | 100 | 100 | 60 | 4.23 |

| 14 | 0 | 0 | 0 | 100 | 100 | 60 | 4.26 |

| 15 | 0 | 0 | 0 | 100 | 100 | 60 | 4.28 |

Experimental range and levels of independent process variables

| Coded variable | Natural variable | Unit | Levels | ||

|---|---|---|---|---|---|

| −1 | 0 | +1 | |||

| X1 | U1: microcapsules concentration | (g ⋅ L−1) | 90 | 100 | 110 |

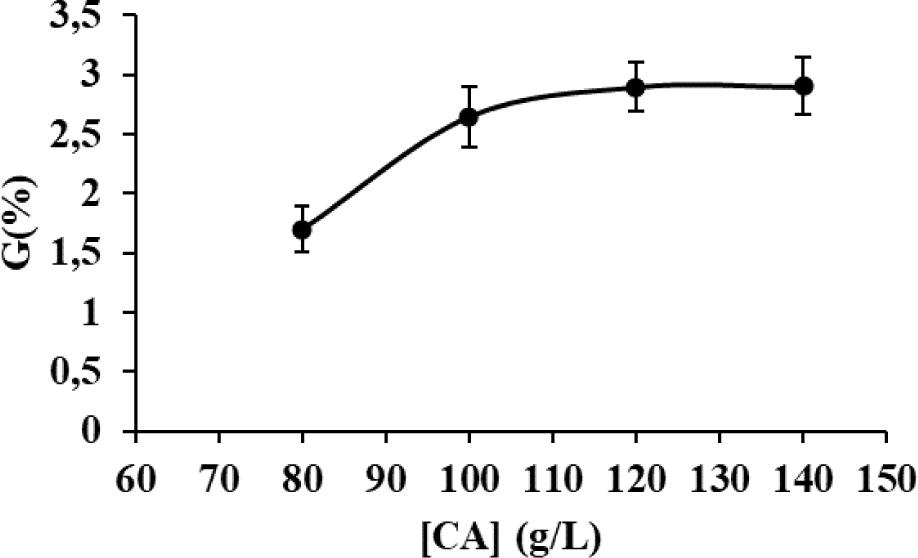

| X2 | U2: CA crosslinking agent concentration | (g ⋅ L−1) | 80 | 100 | 120 |

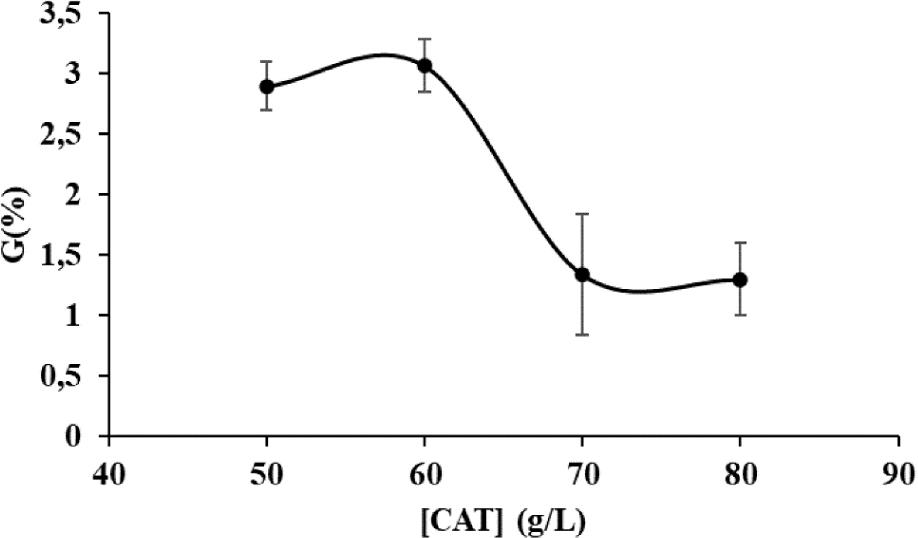

| X3 | U3: DHP CAT | (g ⋅ L−1) | 50 | 60 | 70 |