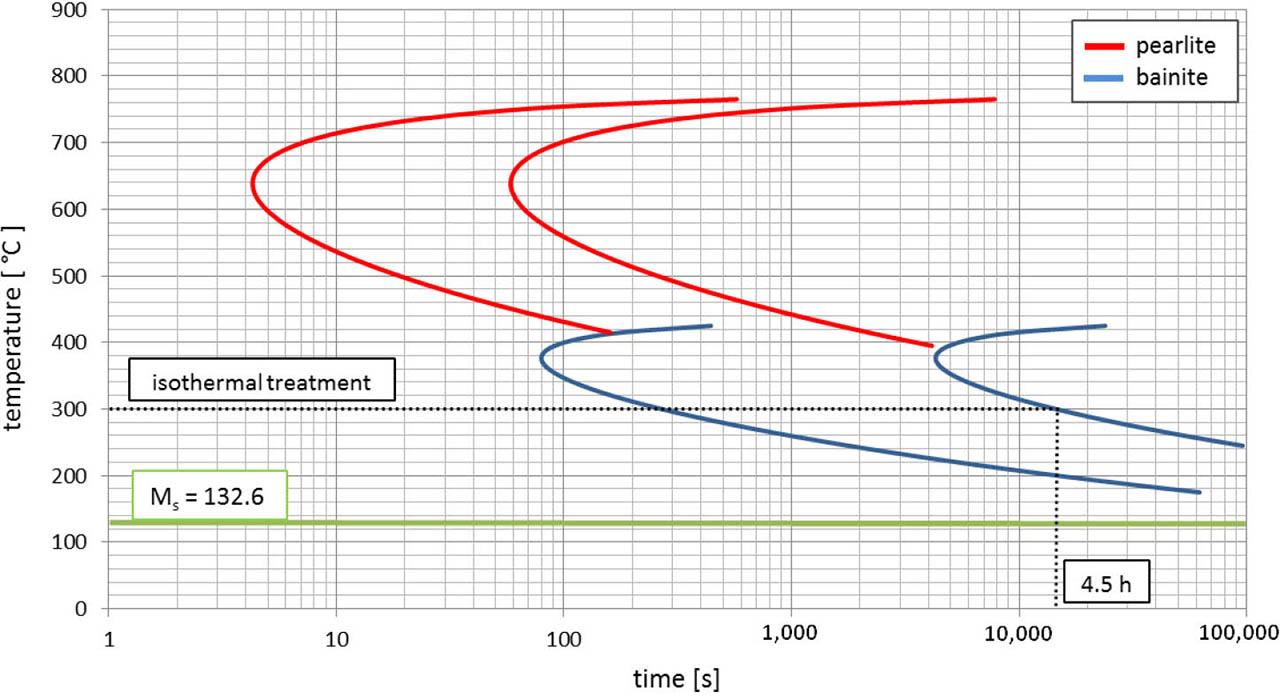

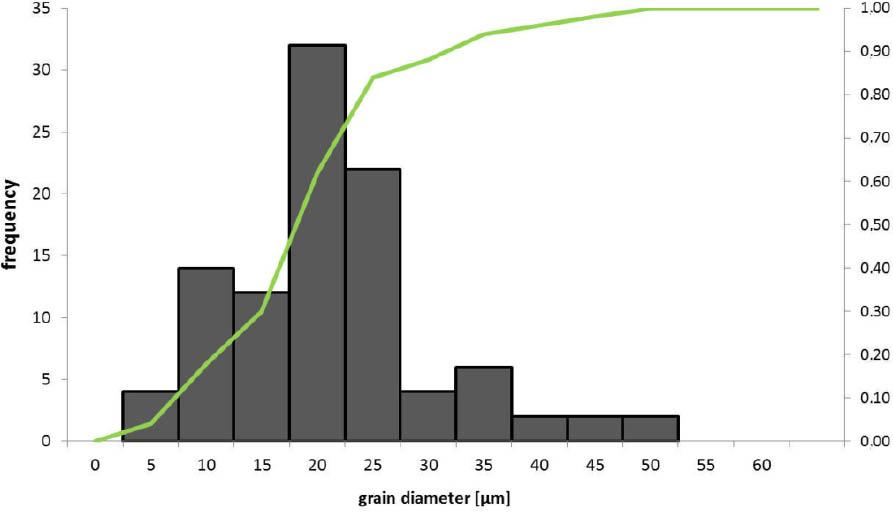

Fig. 1

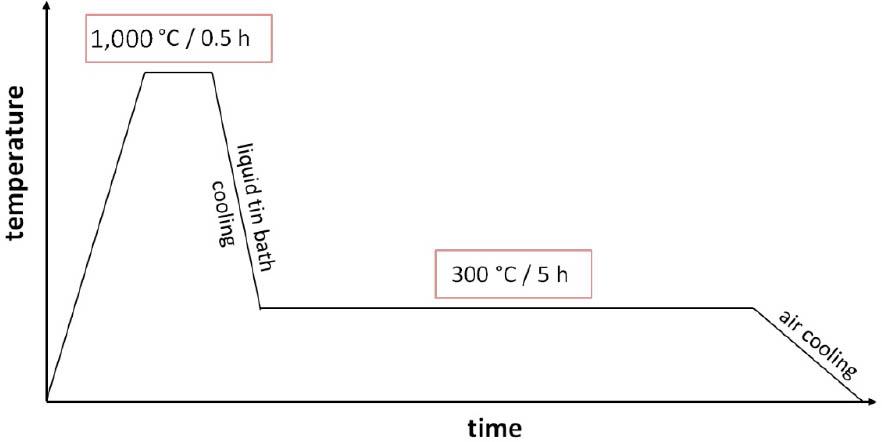

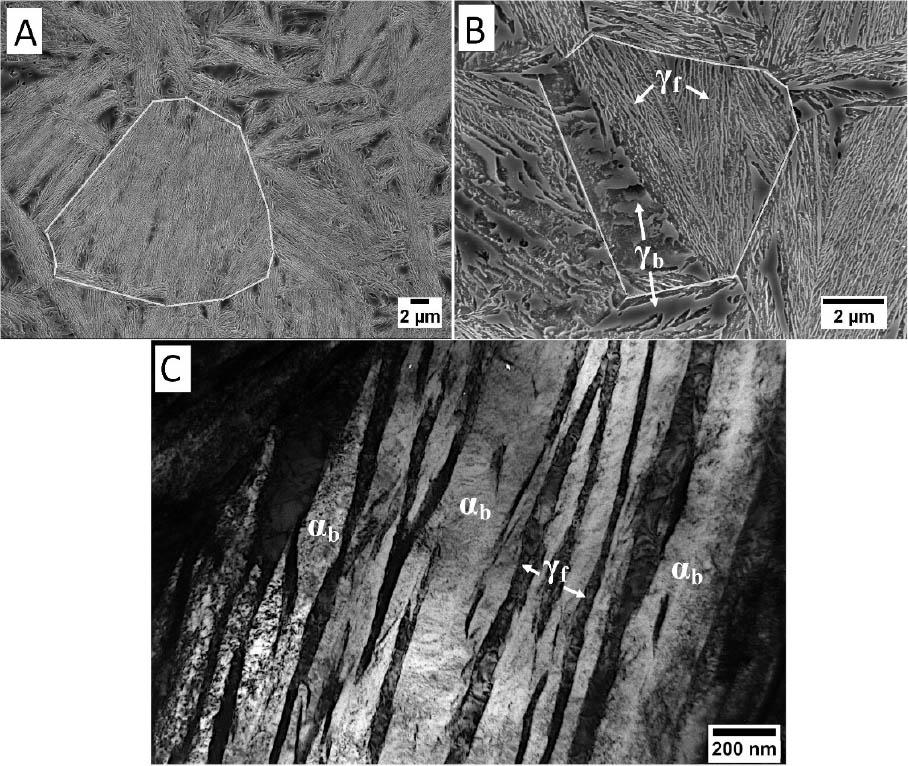

Fig. 2

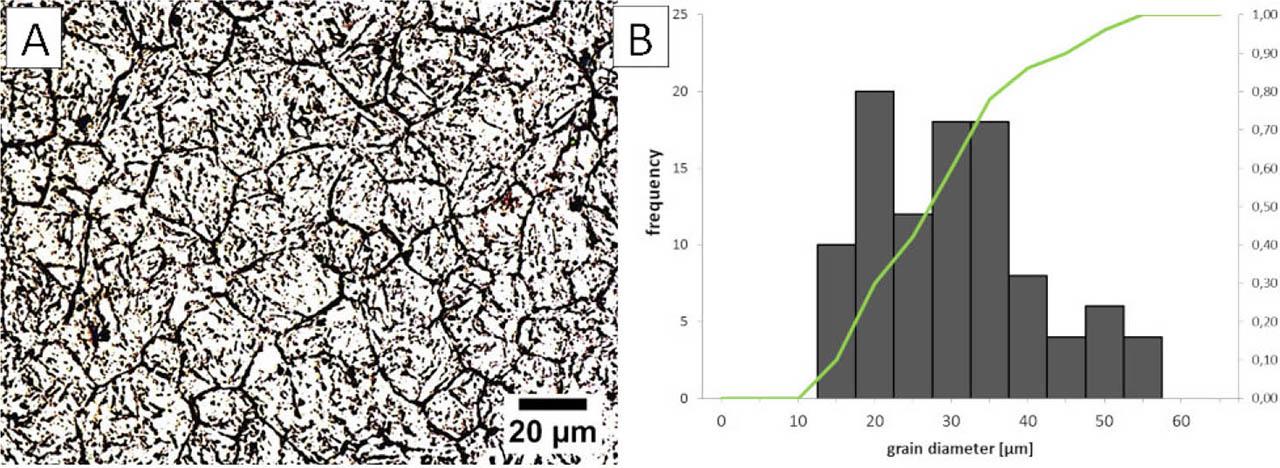

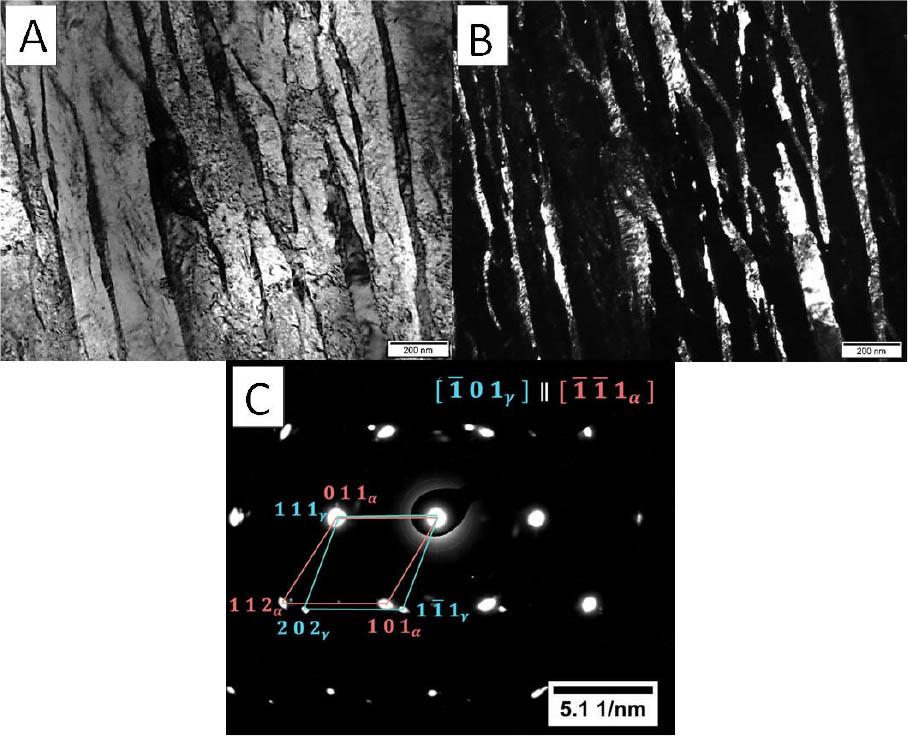

Fig. 3

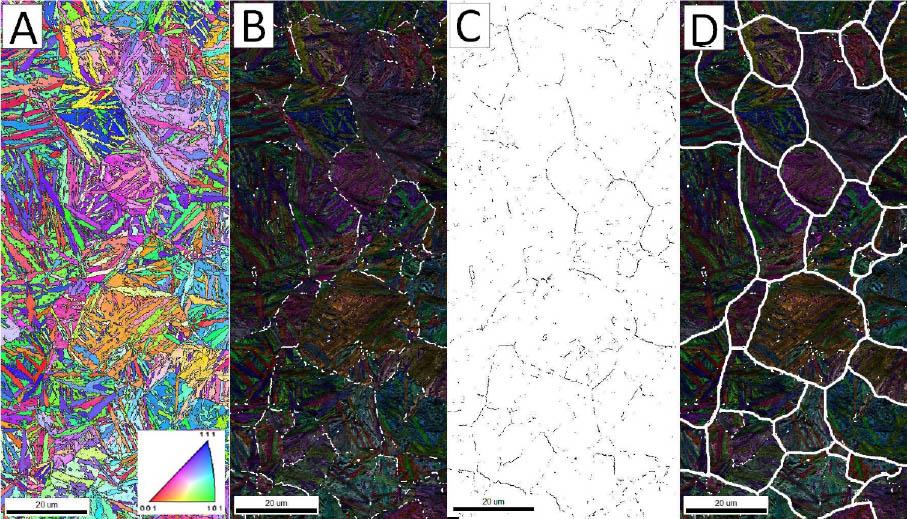

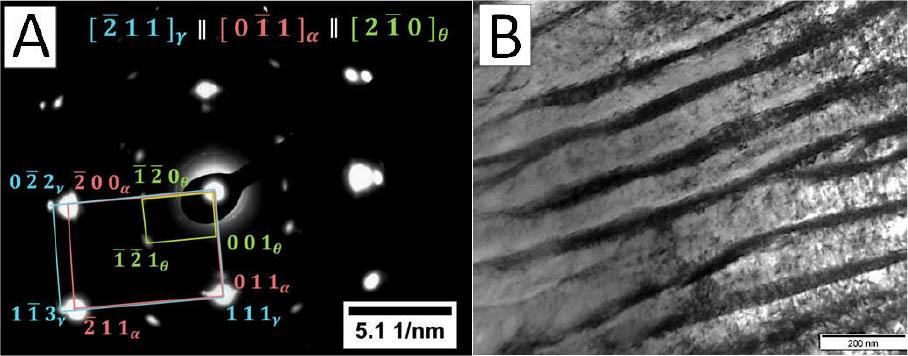

Fig. 4

Fig. 5

Fig. 6

Fig. 7

Fig. 8

Fig. 9

Fig. 10

Fig. 11

Fig. 12

Fig. 13

Fig. 14

Measurement results of retained austenite content considering its morphology_

| Method | Measurement areas | Blocky austenite (γb), % | Film-like austenite (γf), % | Total austenite (γb + γf), % | Ratio, γf/γb |

|---|---|---|---|---|---|

| SEM – graphical analysis | 3 | 20.5 ± 3.2 | 23.7 ± 4.1 | 44.2 | 1.16 |

| EBSD – phase distribution map | 3 | 22.3 ± 5.8 | – | – | – |

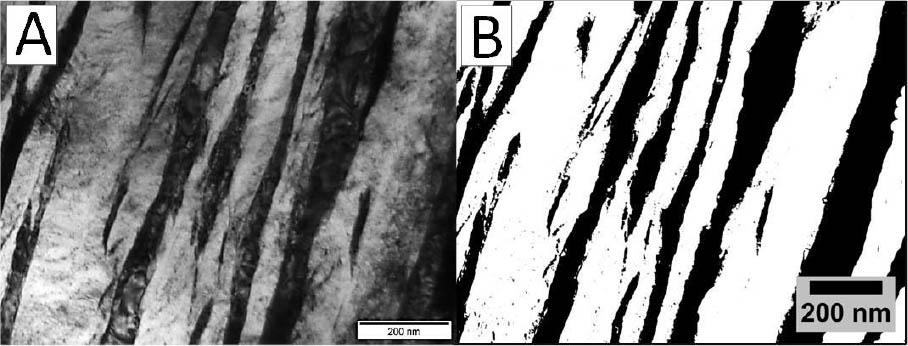

| TEM – graphical analysis | 5 | – | 24.8 ± 9.1 | – | – |

| TEM + EBSD | – | 22.3 ± 5.8 | 24.8 ± 9.1 | 47.1 | 1.11 |

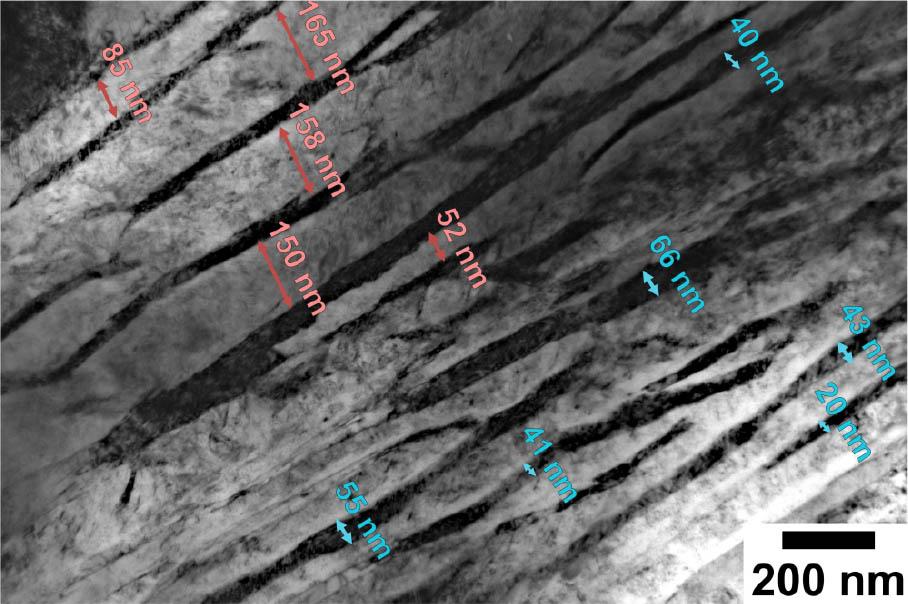

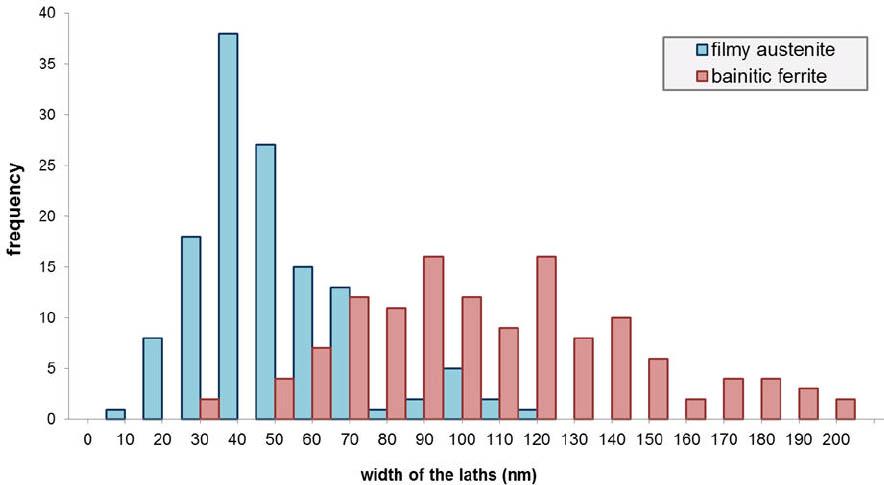

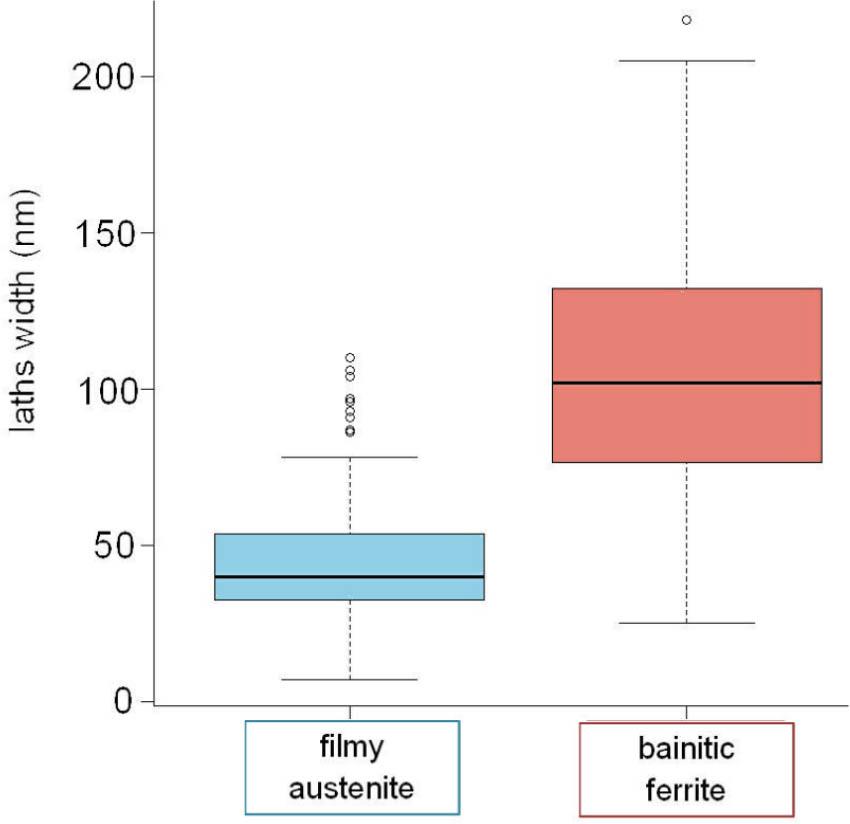

Results of measurement of the thicknesses of film-like austenite and bainitic ferrite_

| Phase | Count number | x̄, nm | SD, nm | Median, nm | Q1, nm | Q3, nm | ½IQR, nm |

|---|---|---|---|---|---|---|---|

| Filmy austenite | 131 | 44.6 | 20.3 | 40.0 | 32.5 | 53.4 | 10.4 |

| Bainitic ferrite | 131 | 106.8 | 40.7 | 102.0 | 76.3 | 131.8 | 27.7 |

The chemical composition of 9XC steel_

| Chemical composition, wt.% | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Mo | Al | Ni | P | S | V |

| 0.94 | 1.54 | 0.44 | 1.05 | 0.01 | 0.022 | 0.18 | 0.01 | 0.007 | 0.006 |

Comparison of prior-austenite grain size measurements obtained by conventional etching by picric acid solution and by the EBSD technique_

| Method | Measurement counts | x̄, mm | SD, mm | Median, mm | Q1, mm | Q3, mm | ½IQR, mm |

|---|---|---|---|---|---|---|---|

| Conventional etching by picric acid solution | 100 | 27.8 | 10.9 | 26.4 | 18.9 | 34.9 | 8.0 |

| EBSD analysis using misorientation angles (20°–40°) | 100 | 18.7 | 9.2 | 17.8 | 13.9 | 21.8 | 4.0 |