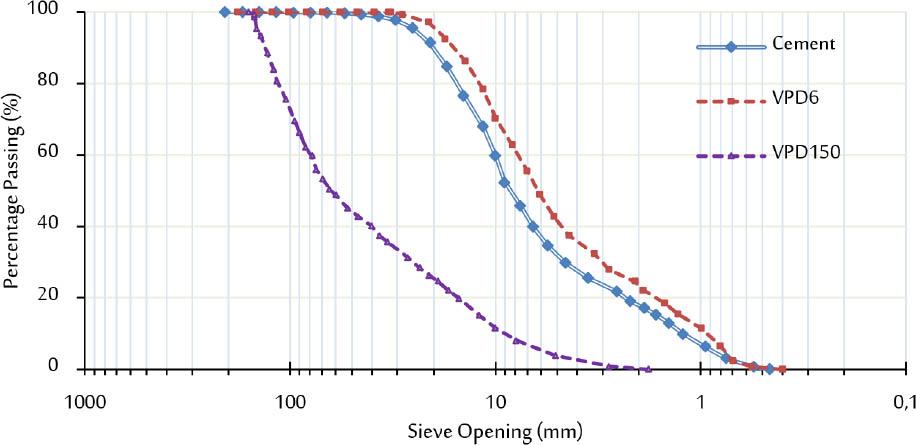

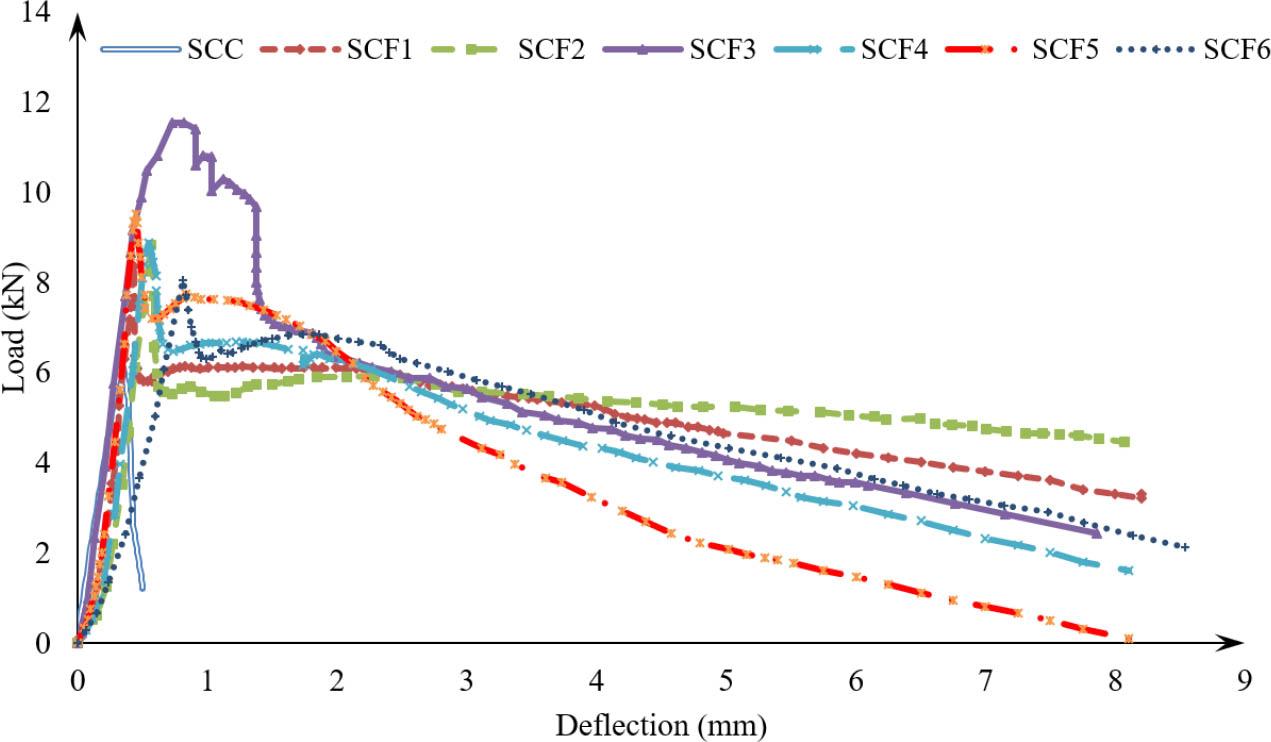

Fig. 1

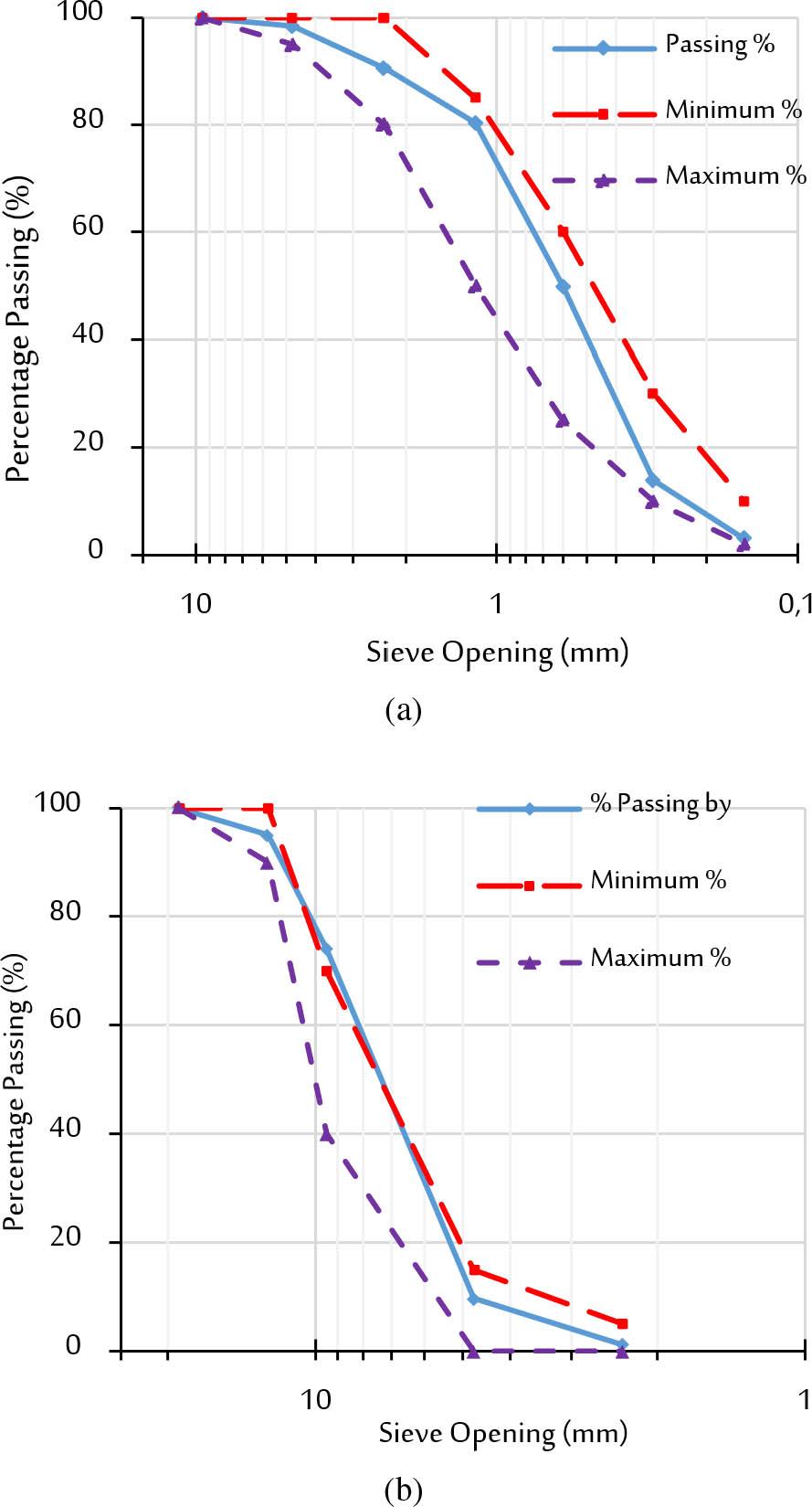

Fig. 2

Fig. 3

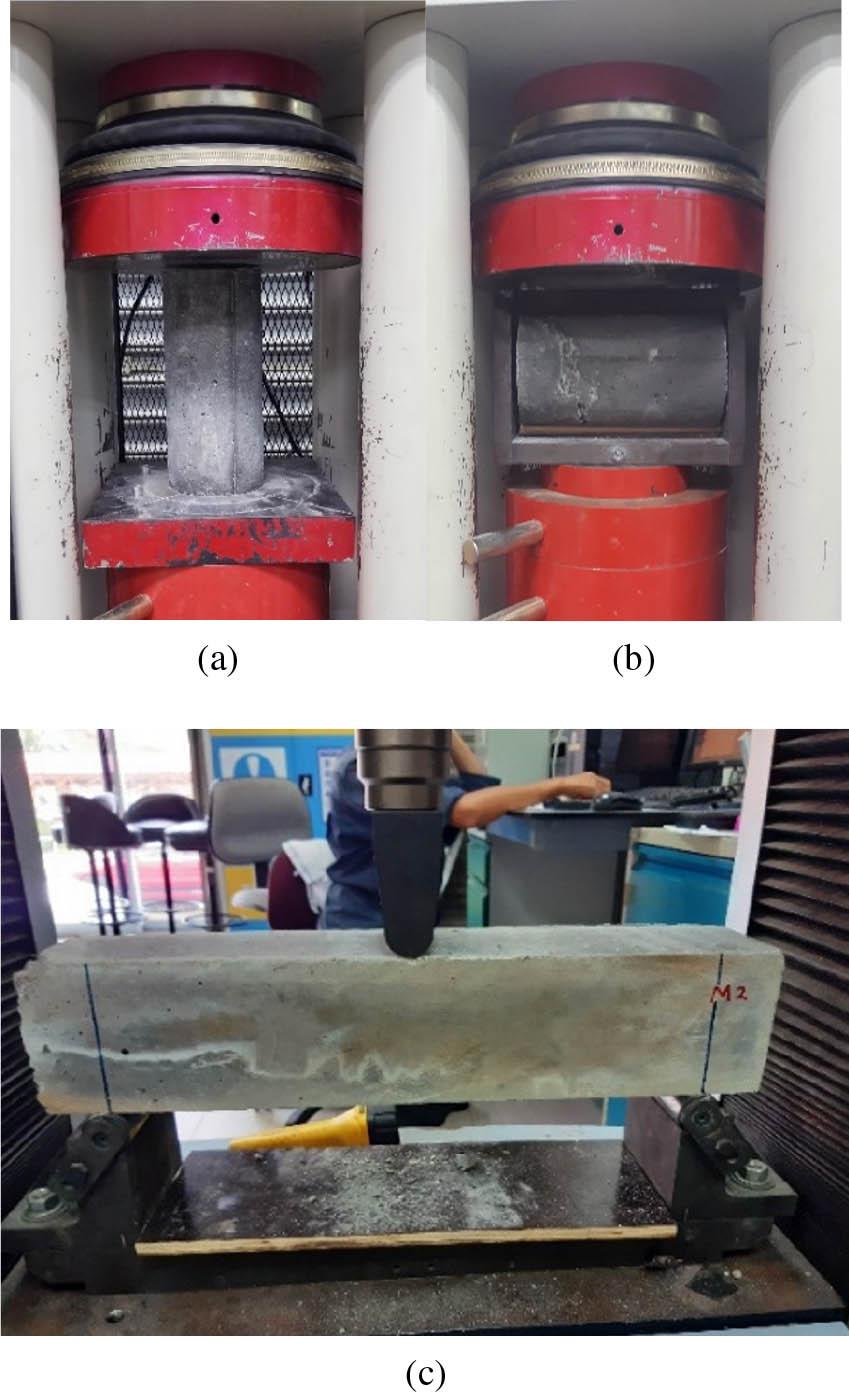

Fig. 4

Fig. 5

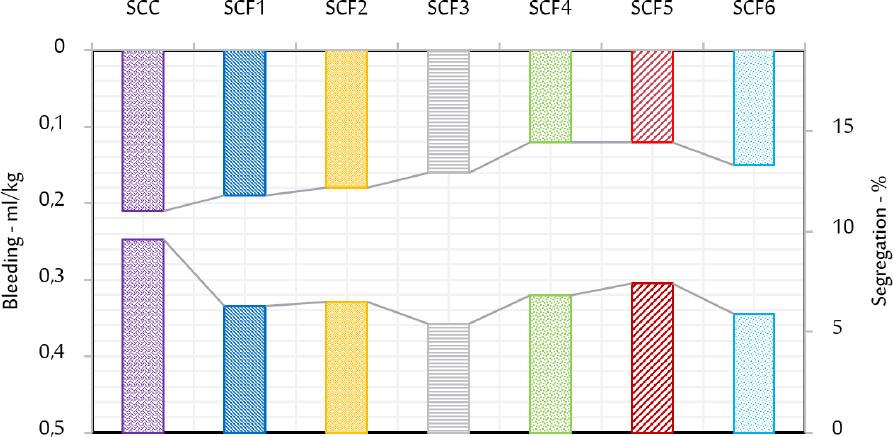

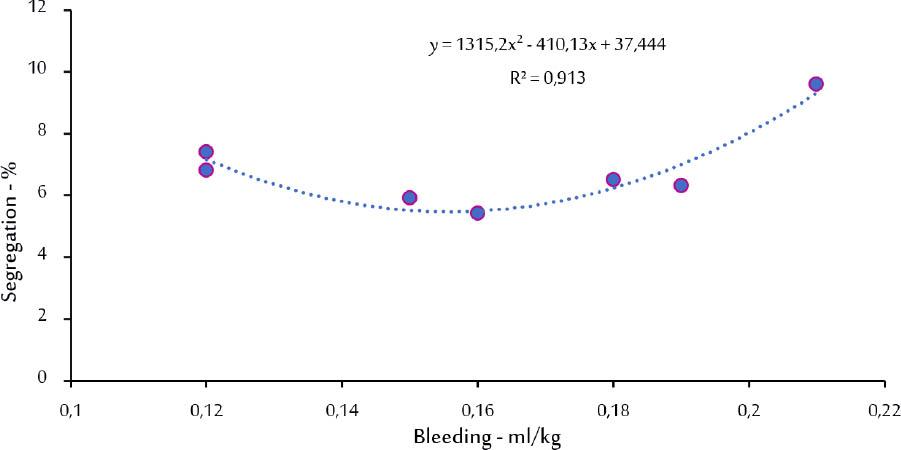

Fig. 6

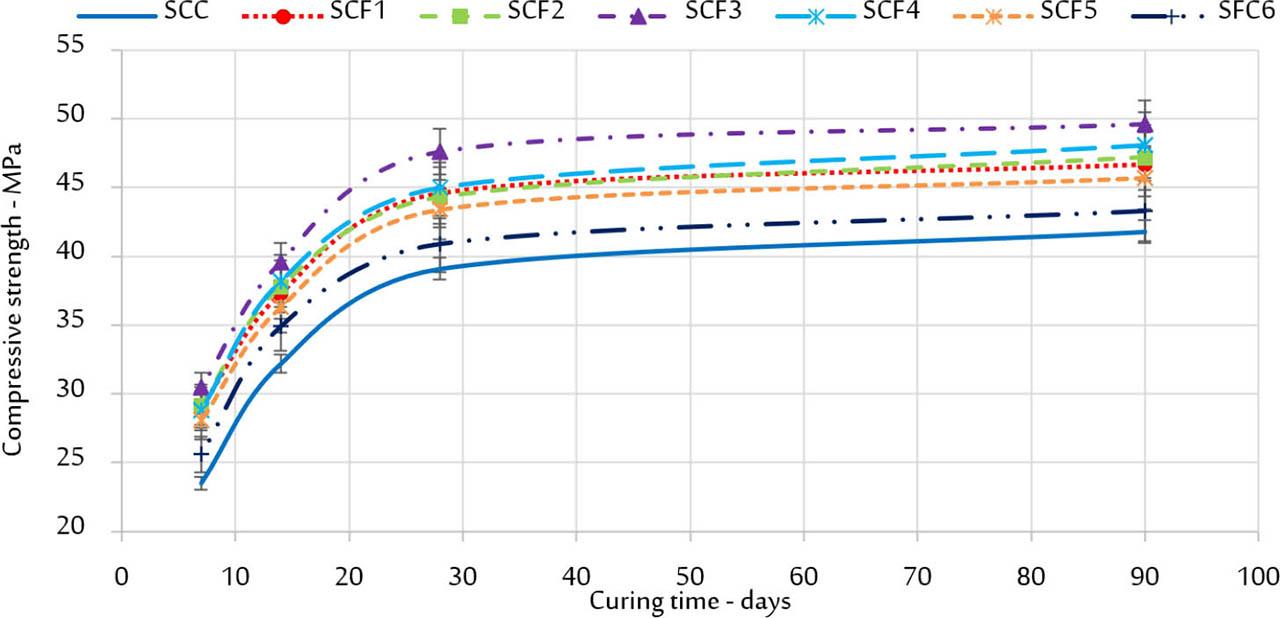

Fig. 7

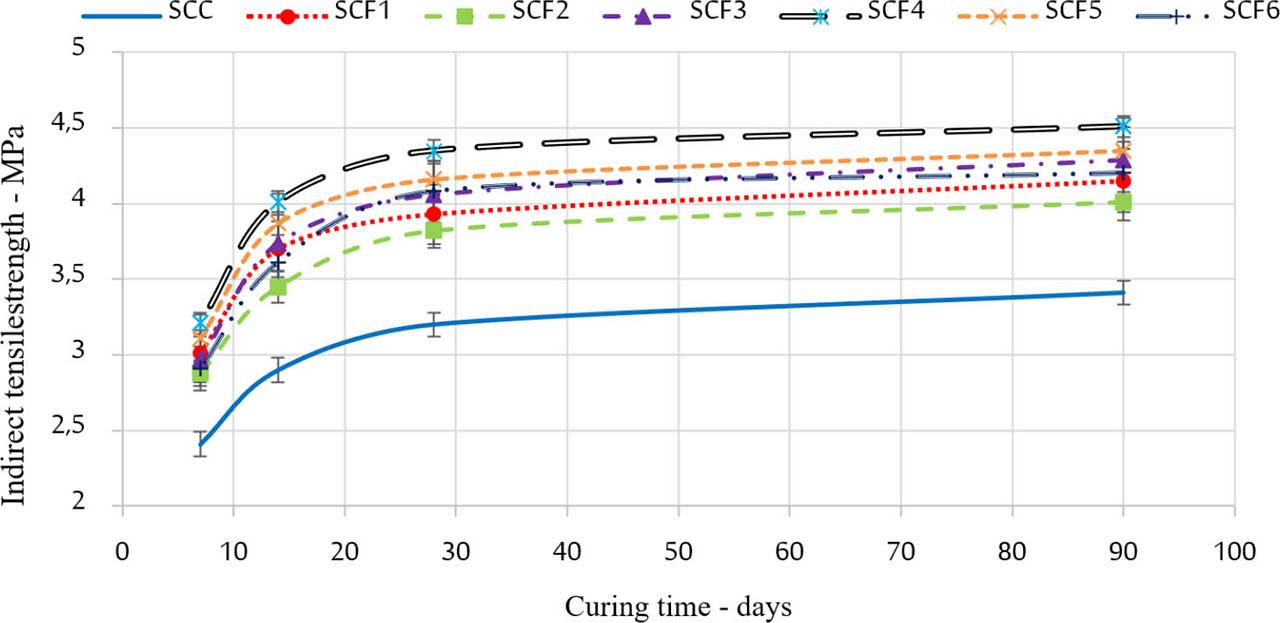

Fig. 8

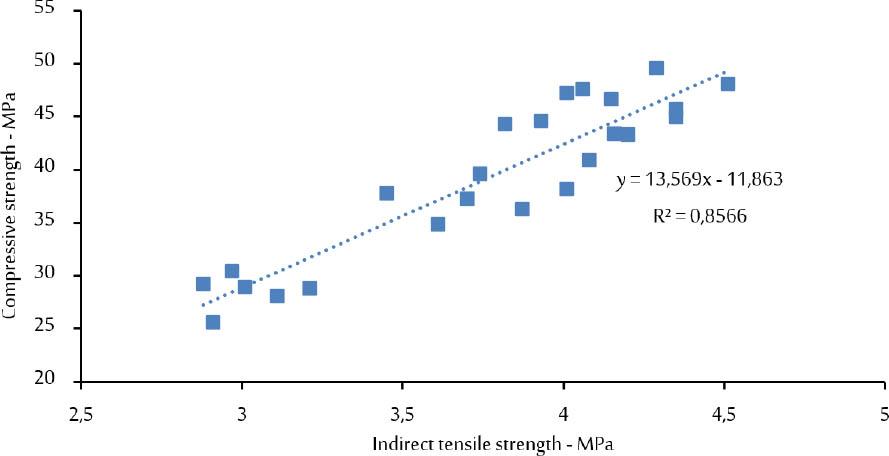

Fig. 9

Fig. 10

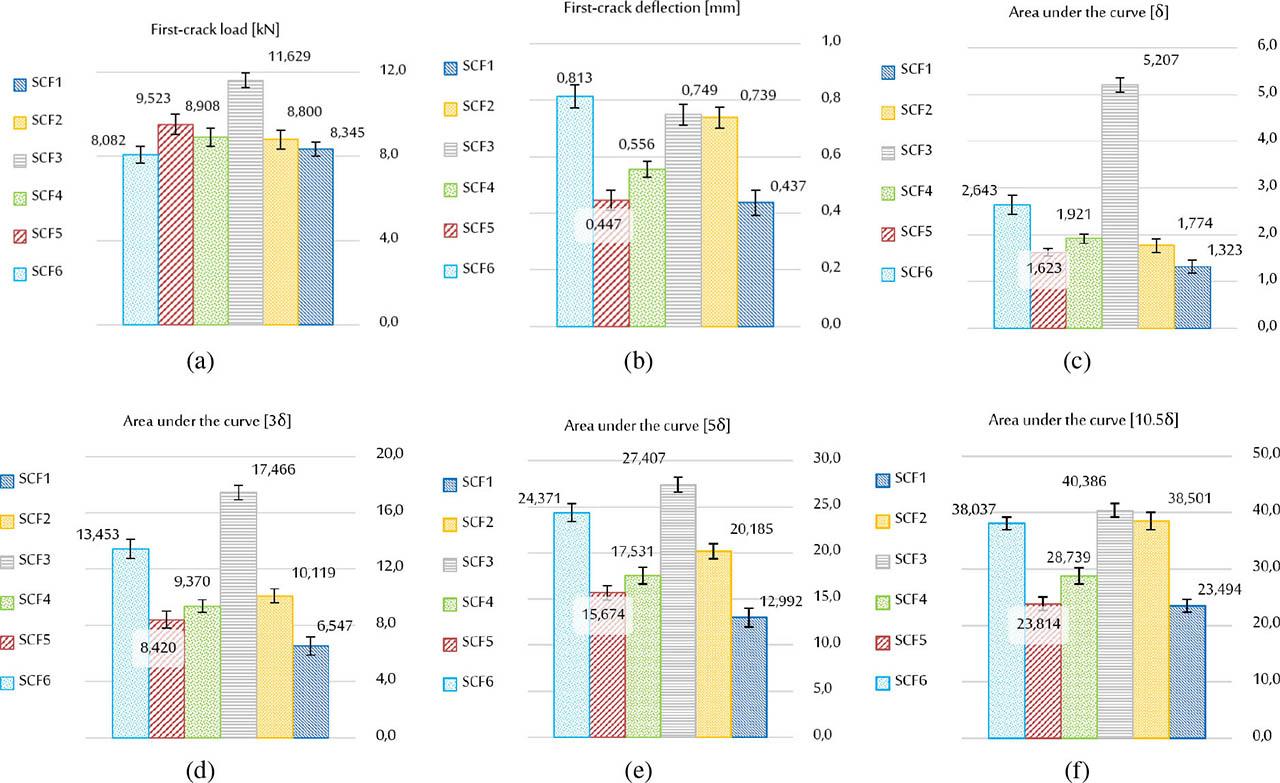

![Flexural toughness indices according to ASTM C 1018 [35].](https://sciendo-parsed.s3.eu-central-1.amazonaws.com/6472525e215d2f6c89dc41a8/j_msp-2021-0016_fig_010.jpg?X-Amz-Algorithm=AWS4-HMAC-SHA256&X-Amz-Content-Sha256=UNSIGNED-PAYLOAD&X-Amz-Credential=AKIA6AP2G7AKOUXAVR44%2F20251204%2Feu-central-1%2Fs3%2Faws4_request&X-Amz-Date=20251204T150709Z&X-Amz-Expires=3600&X-Amz-Signature=1bfcdccba39a69a1faca004dd88ed8e7a006c591f72cbc21343dc8235f9c0808&X-Amz-SignedHeaders=host&x-amz-checksum-mode=ENABLED&x-id=GetObject)

Fig. 11

Fig. 12

Fig. 13

Fig. 14

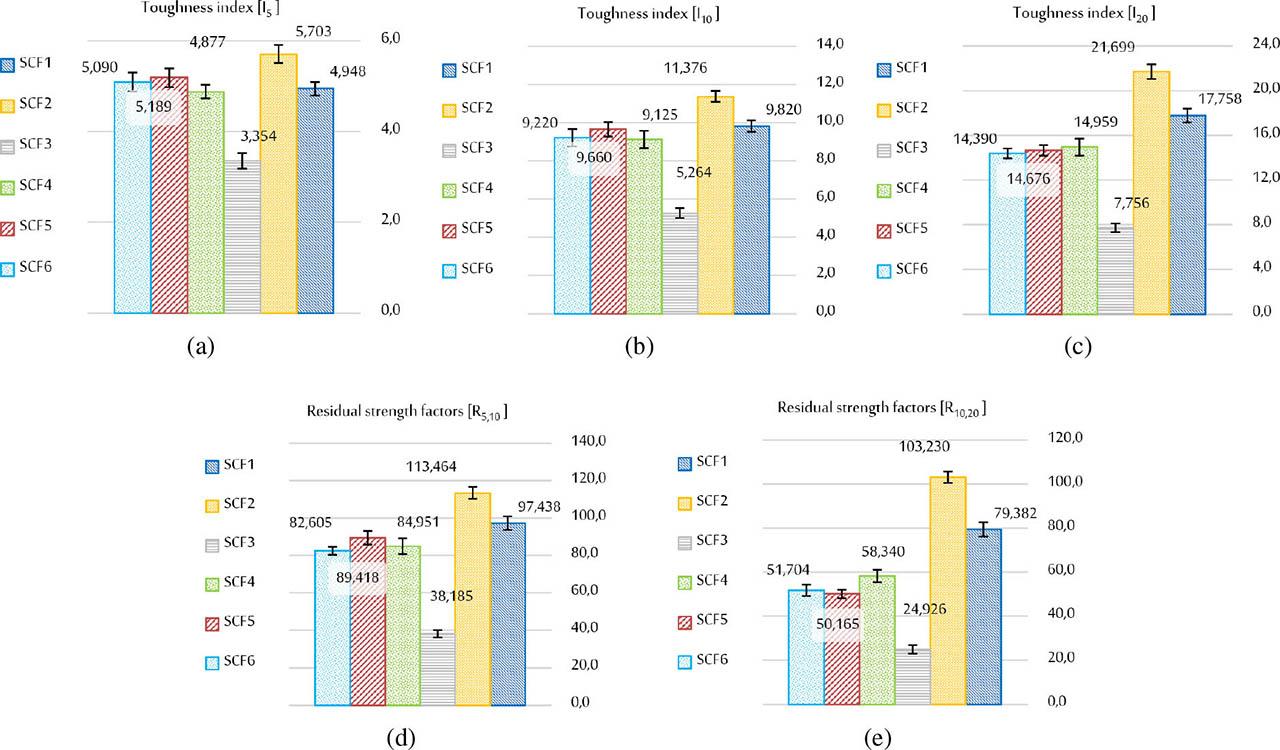

![Flexural toughness indices according to ACI 544 [45].](https://sciendo-parsed.s3.eu-central-1.amazonaws.com/6472525e215d2f6c89dc41a8/j_msp-2021-0016_fig_014.jpg?X-Amz-Algorithm=AWS4-HMAC-SHA256&X-Amz-Content-Sha256=UNSIGNED-PAYLOAD&X-Amz-Credential=AKIA6AP2G7AKOUXAVR44%2F20251204%2Feu-central-1%2Fs3%2Faws4_request&X-Amz-Date=20251204T150709Z&X-Amz-Expires=3600&X-Amz-Signature=c12126062c160b131922de5a9b1364d8ed9fb1f362f58f2d4dd74bf304dae386&X-Amz-SignedHeaders=host&x-amz-checksum-mode=ENABLED&x-id=GetObject)

Fig. 15

Physical properties of VPP and cement_

| Property | VPP | Cement |

|---|---|---|

| Relative density | 2.61 | 3.10 |

| Surface area (cm2/g) Blaine method | 3.970 | 3.530 |

| Median diameter (μm) | 6.3 | 9.2 |

Chemical composition of VPP and cement_

| Oxide | VPP % | Cement % |

|---|---|---|

| SiO2 | 46.5 | 20.05 |

| Al2O3 | 17.59 | 4.93 |

| Fe2O3 | 7.33 | 3.90 |

| CaO | 12.52 | 61.57 |

| MgO | 6.94 | 0.81 |

| Na2O | 2.58 | 0.08 |

| TiO2 | 1.41 | 0.24 |

| K2O | 1.17 | 1.33 |

| P2O5 | 0.71 | 0.08 |

| SO3 | 0.42 | 3.06 |

| MnO | 0.14 | 0.19 |

| Cl | 0.01 | – |

| LOI | 1.61 | 2.10 |

| SiO2 + Al2O3 + Fe2O3 | 76.01 | – |

The SCC mixtures fresh state characteristics_

| Mixture | L-box | Slump flow | Segregation | Bleeding | Density |

|---|---|---|---|---|---|

| Ratio | (mm) | % | (ml/cm2) | (kg/m3) | |

| SCC | 0.92 | 690 | 9.6 | 0.21 | 2,336 |

| SCF1 | Restricted | 450 | 6.3 | 0.19 | 2,269 |

| SCF2 | Restricted | 480 | 6.5 | 0.18 | 2,321 |

| SCF3 | Restricted | 520 | 5.4 | 0.16 | 2,315 |

| SCF4 | Restricted | 490 | 6.8 | 0.12 | 2,276 |

| SCF5 | Restricted | 480 | 7.4 | 0.12 | 2,304 |

| SCF6 | Restricted | 510 | 5.9 | 0.15 | 2,219 |

The absorption and porosity of SCC mixtures_

| SCC | SCF1 | SCF2 | SCF3 | SCF4 | SCF5 | SCF6 | |

|---|---|---|---|---|---|---|---|

| Porosity % | 15 | 16.10 | 16.02 | 16.90 | 16.30 | 16.74 | 18.12 |

| Absorption % | 7.33 | 7.64 | 7.42 | 7.88 | 7.71 | 7.84 | 9.03 |

Copolymer-based SP properties_

| Properties | Information |

|---|---|

| Chemical base | Modified polycarboxylate in water |

| Color | Liquid/turbid to light yellowish |

| Density | 1.070 (20°C) |

| Chloride ion content | <0.1% w/w |

| Alkaligehalte | <0.5% w/w |

Physical properties of VPD and cement_

| SF | |||||

|---|---|---|---|---|---|

| Item |

| ||||

| Hooked end SF1 | Flat end SF2 | Hooked end SF3 | Micro SF4 | Micro SF5 | |

| Specific gravity | 7.85 | 7.85 | 7.85 | 7.85 | 7.85 |

| Length (mm) | 60 | 50 | 30 | 21 | 13 |

| Diameter (deq) (mm) | 0.92 | 0.9 | 0.55 | 0.35 | 0.2 |

| Aspect ratio | 65 | 56 | 55 | 60 | 65 |

| Young’s modulus (Es) (GPa) | 210 | 210 | 210 | 200 | 200 |

| Tensile strength (ft) (MPa) | 1,160 | 1,160 | 1,160 | 1,100–1,300 | 1,100–1,300 |

Properties of concrete mixture_

| Mixture | Cement | VPP | Gravel | Sand | SF1 | SF2 | SF3 | SF4 | SF5 | Water | SP |

|---|---|---|---|---|---|---|---|---|---|---|---|

| (kg/m3) | |||||||||||

| SCC | 350 | 150 | 801 | 822 | – | – | – | – | – | 220 | 6.5 |

| SCF1 | 350 | 150 | 801 | 795 | 78.4 | – | – | – | – | 220 | 6.5 |

| SCF2 | 350 | 150 | 801 | 795 | – | 78.4 | – | – | – | 220 | 6.5 |

| SCF3 | 350 | 150 | 801 | 795 | – | – | 78.4 | – | – | 220 | 6.5 |

| SCF4 | 350 | 150 | 801 | 795 | – | – | – | 78.4 | – | 220 | 6.5 |

| SCF5 | 350 | 150 | 801 | 795 | – | – | – | – | 78.4 | 220 | 6.5 |

| SCF6 | 350 | 150 | 801 | 795 | 15.6 | 15.6 | 15.6 | 15.6 | 15.6 | 220 | 6.5 |