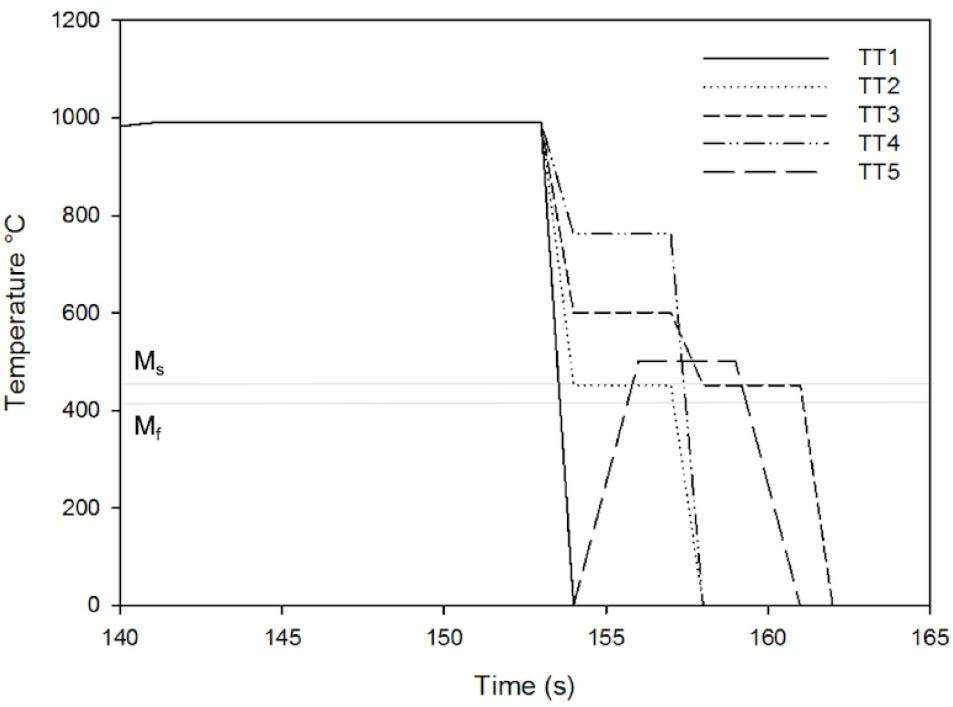

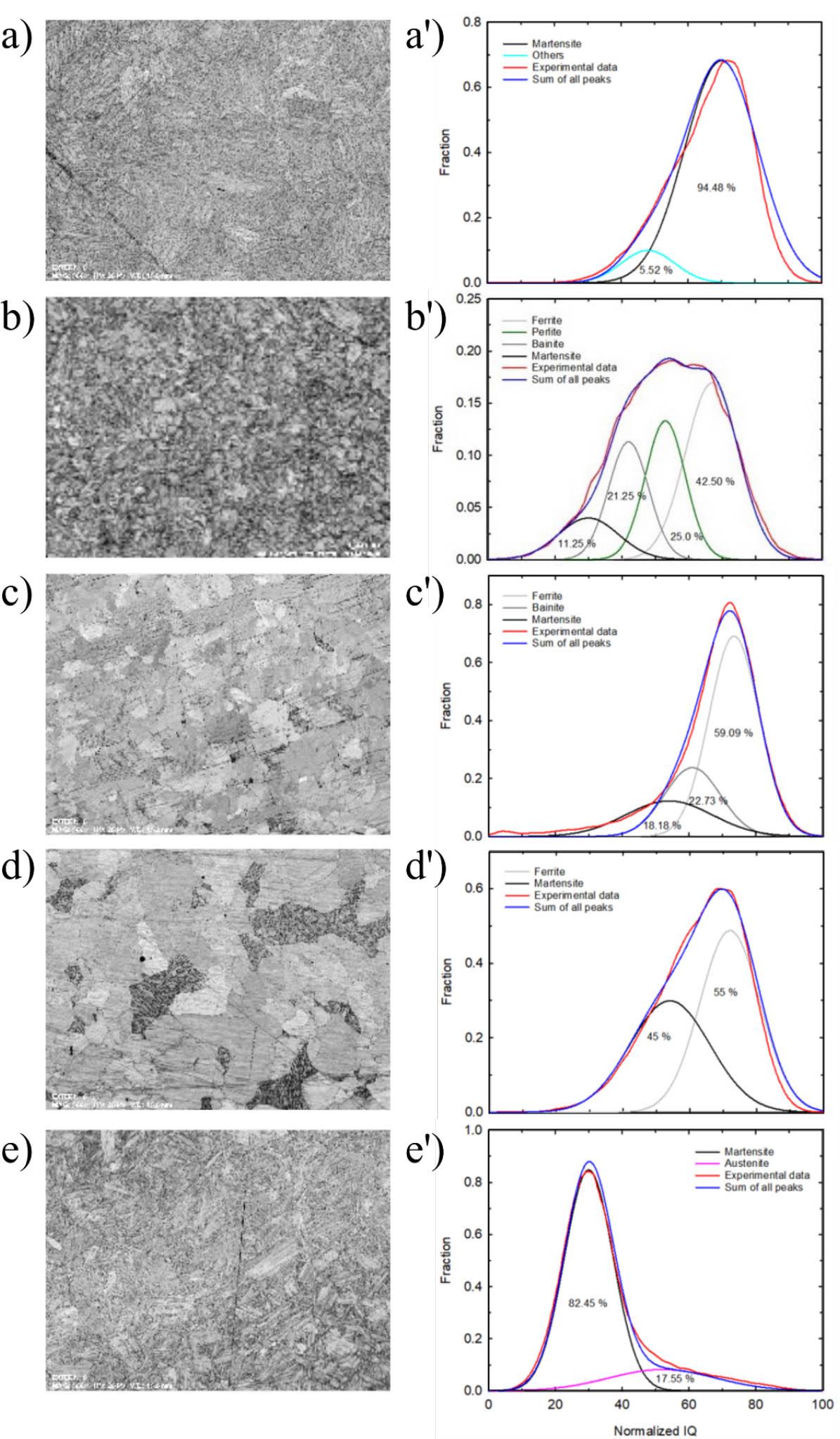

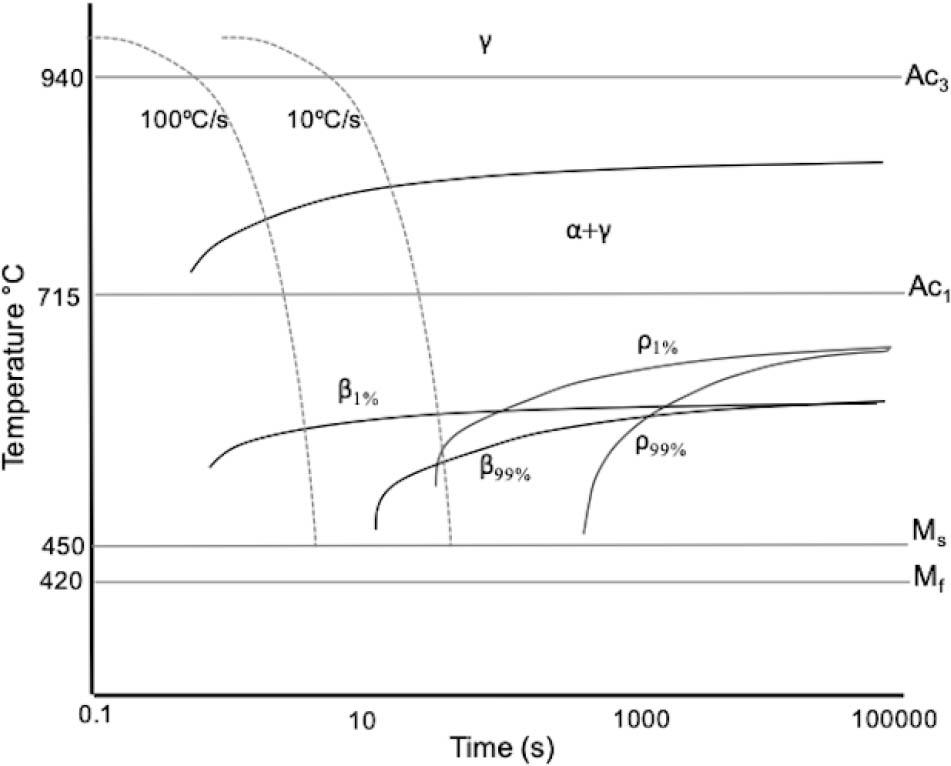

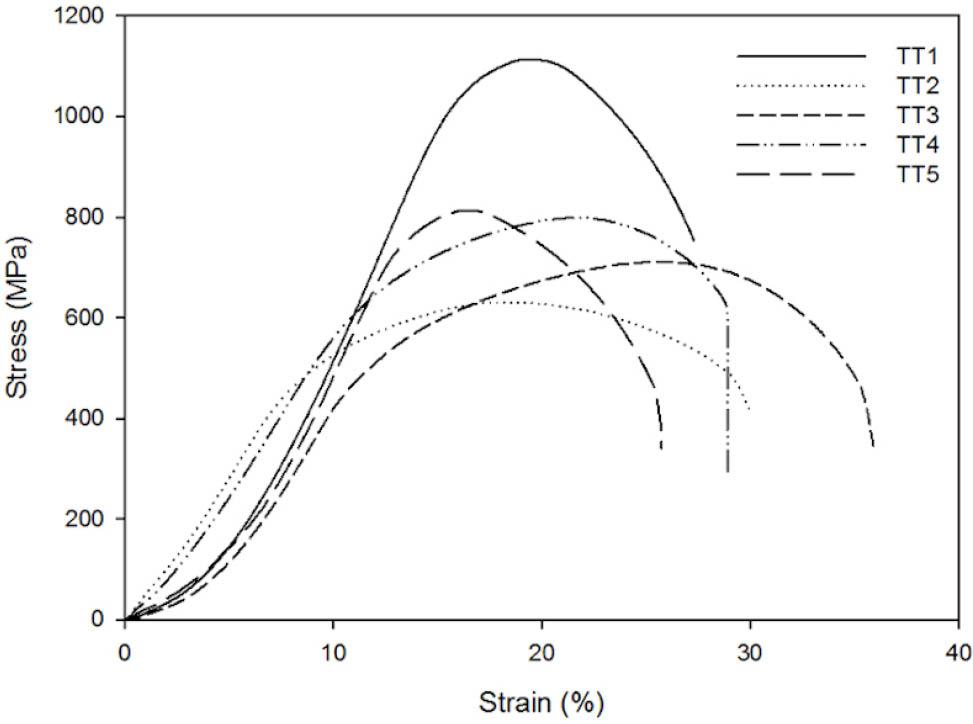

Fig. 1

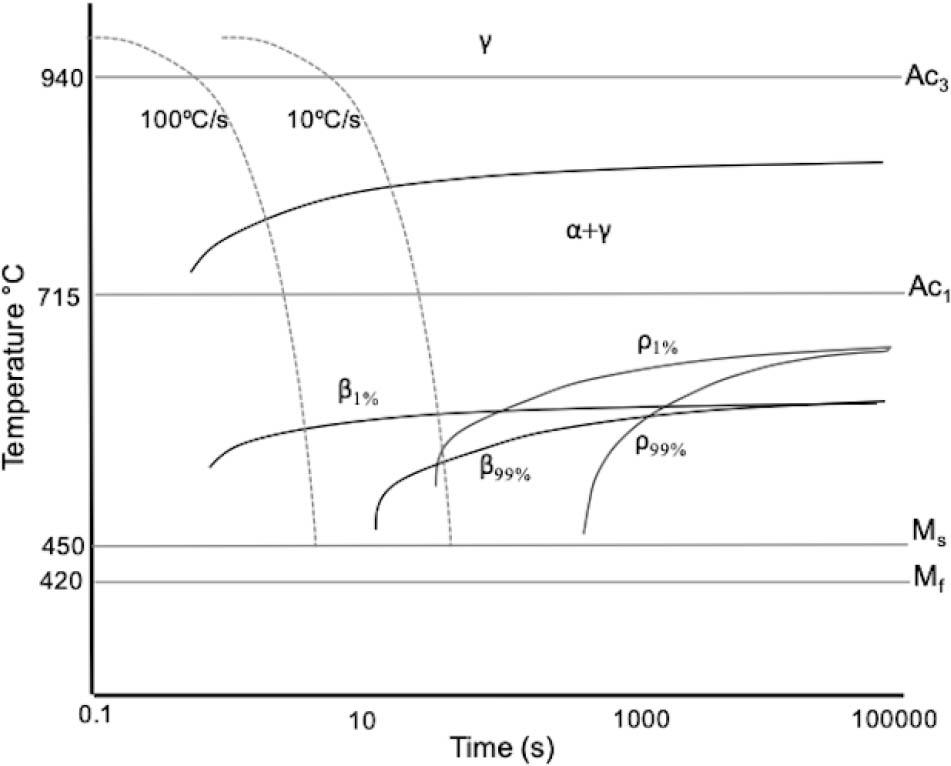

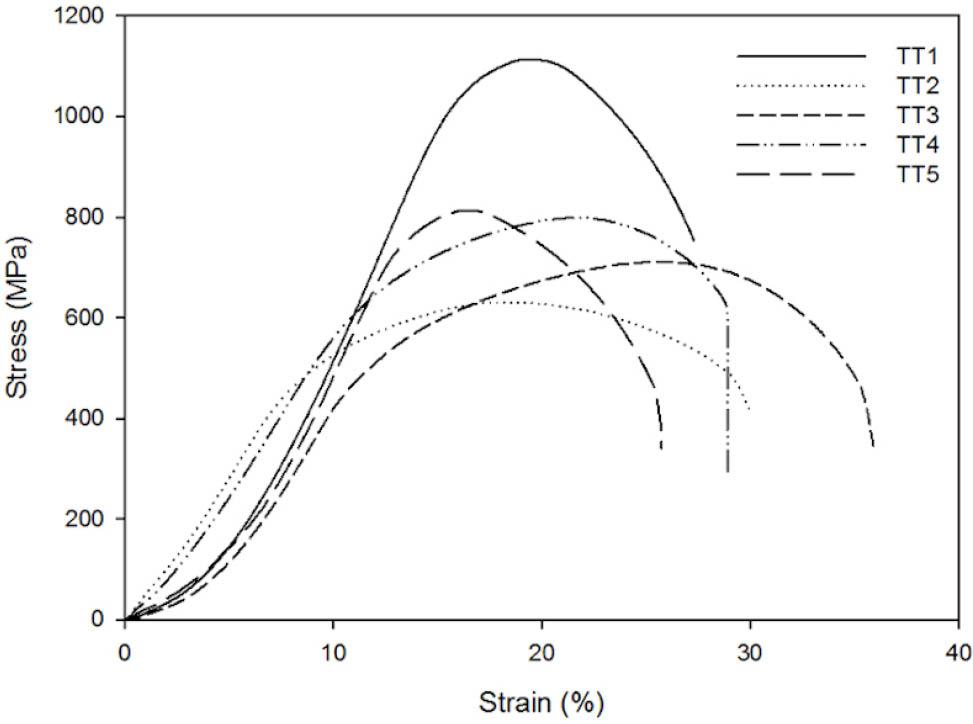

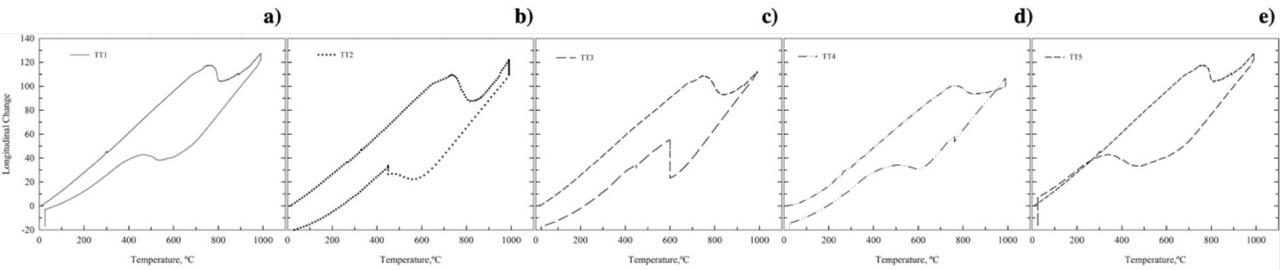

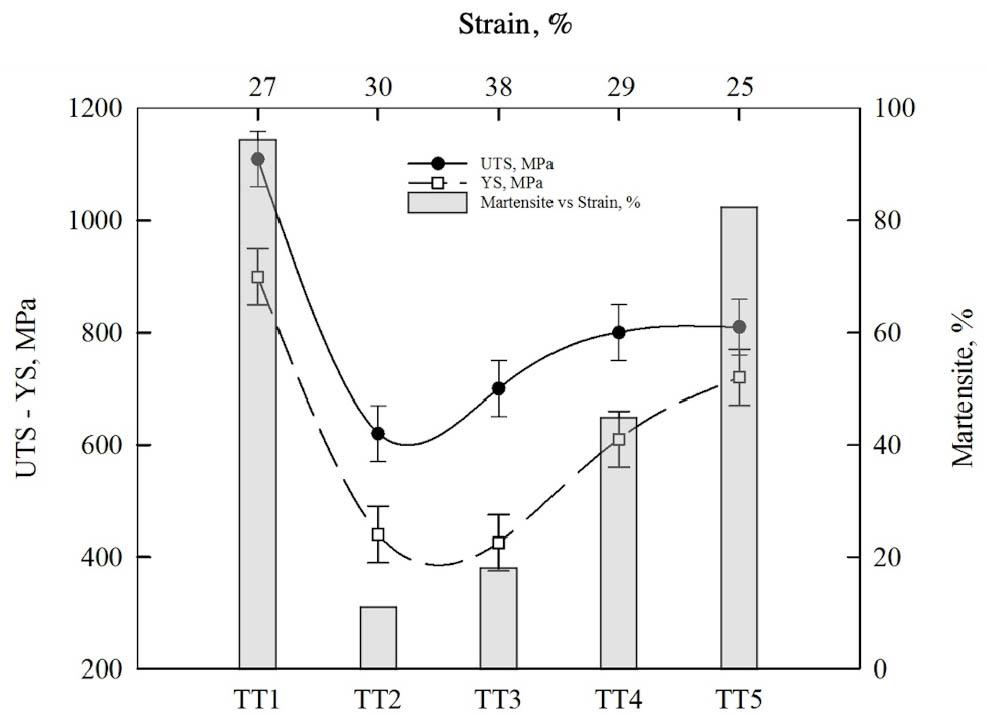

Fig. 2

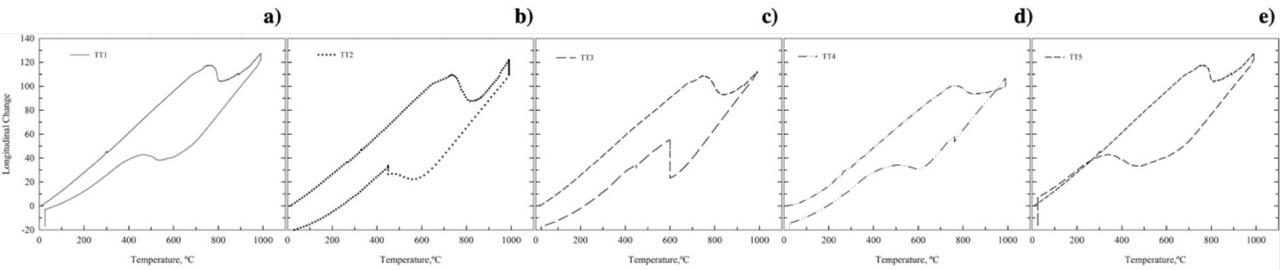

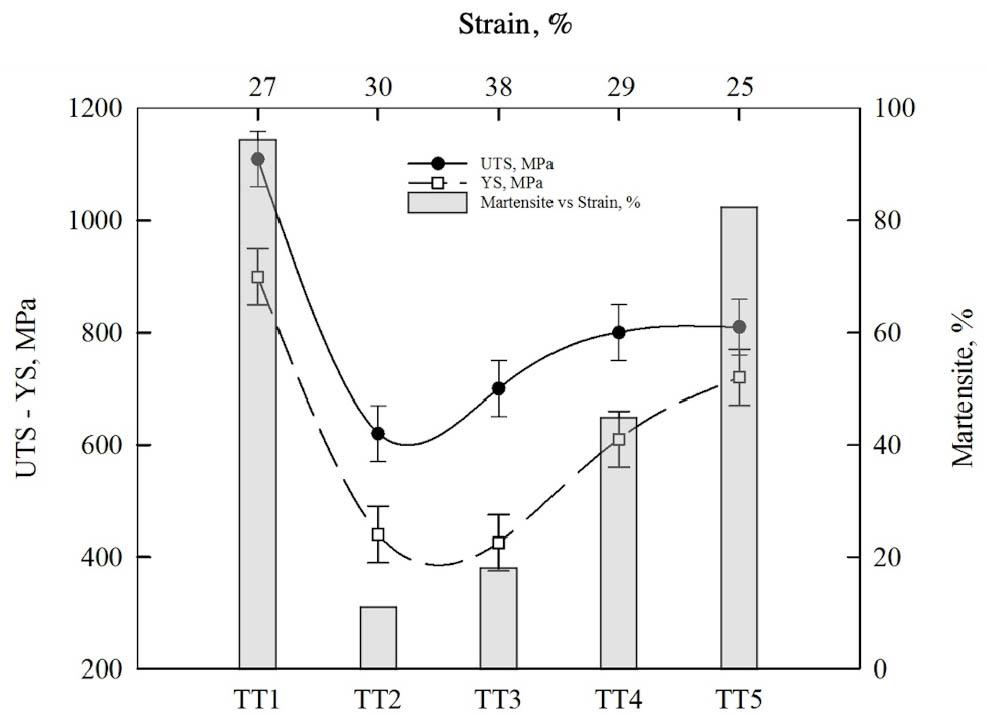

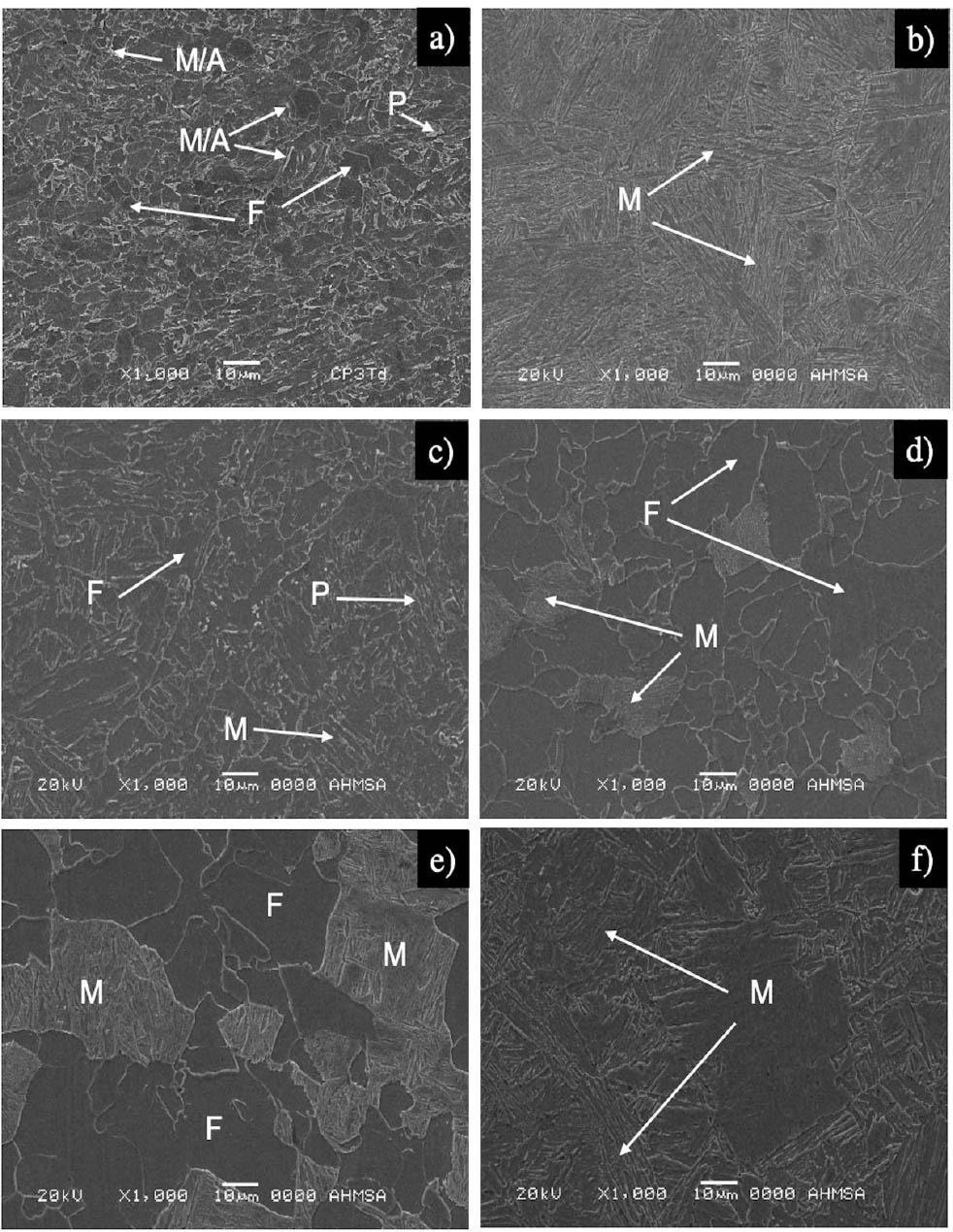

Fig. 3

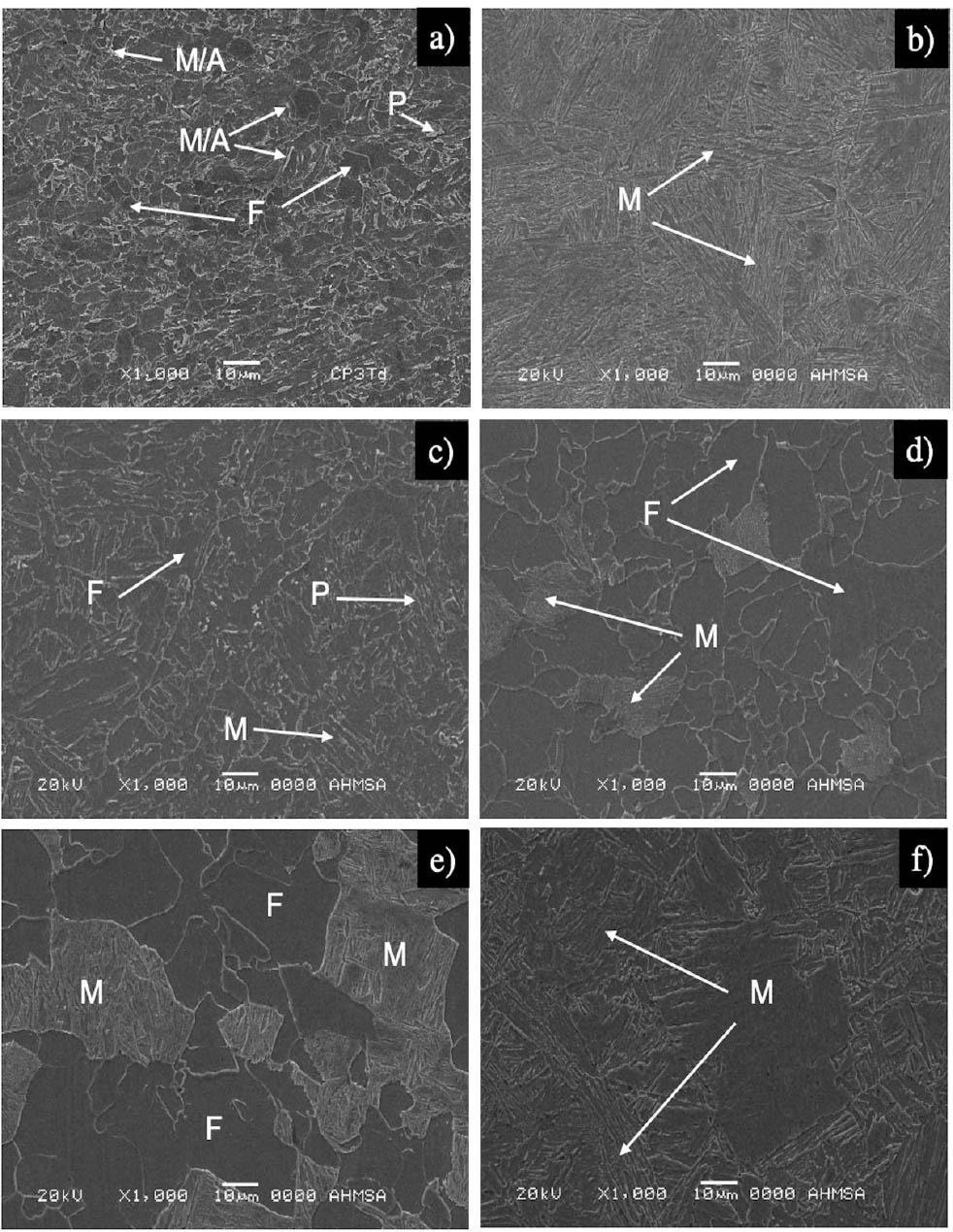

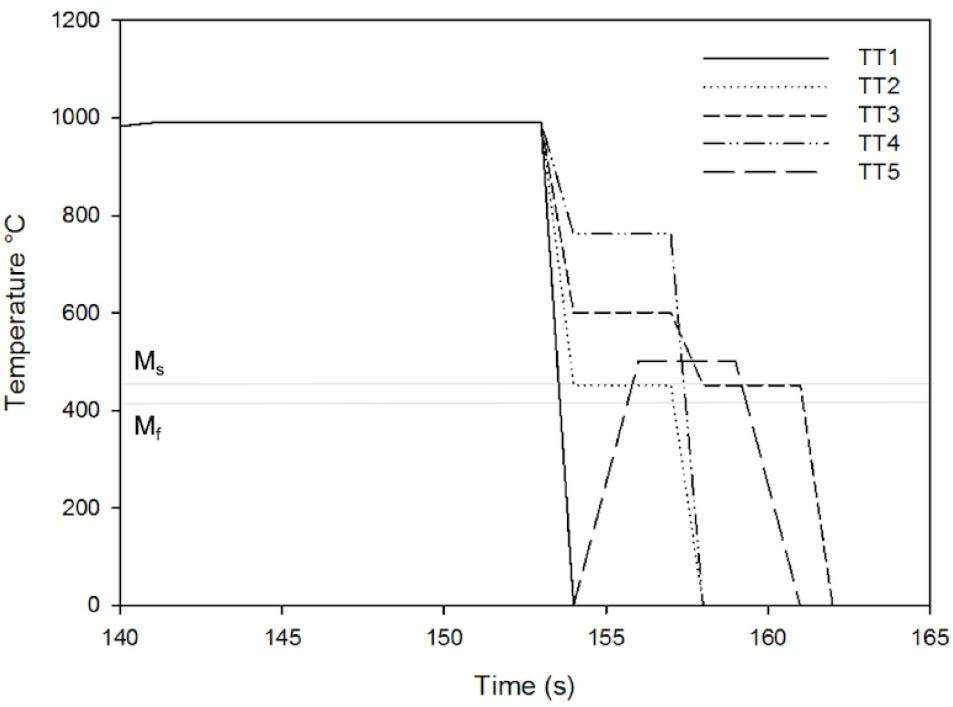

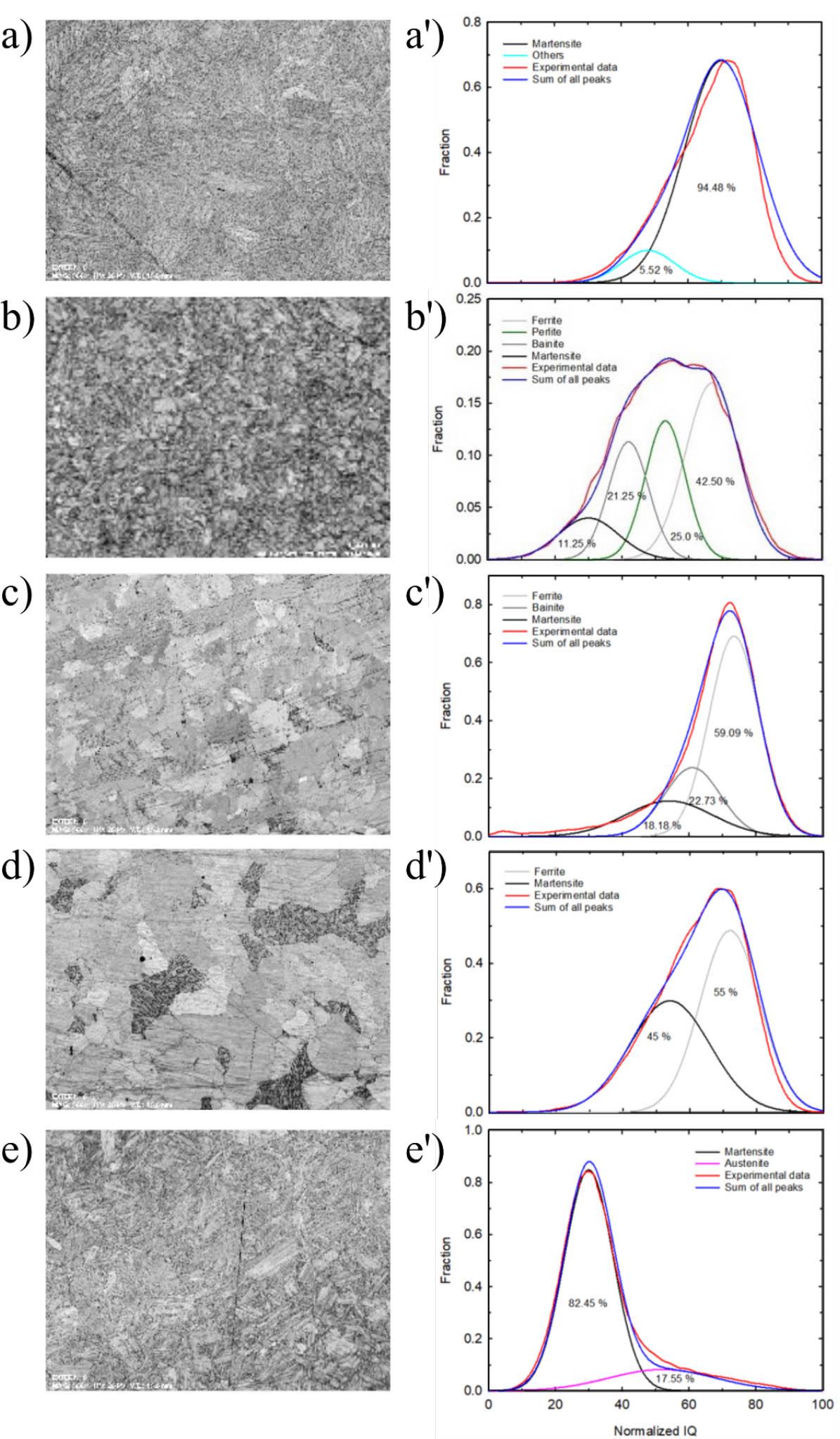

Fig. 4

Fig. 5

Fig. 6

Fig. 7

Chemical composition, % wt_

| C | Mn | P | Si | Cu | Cr | Ni | Mo | V | Nb | Ti |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.02 | 1.621 | 0.0097 | 0.332 | 0.026 | 0.29 | 0.29 | 0.014 | 0.036 | 0.086 | 0.024 |

| C | Mn | P | Si | Cu | Cr | Ni | Mo | V | Nb | Ti |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.02 | 1.621 | 0.0097 | 0.332 | 0.026 | 0.29 | 0.29 | 0.014 | 0.036 | 0.086 | 0.024 |

© 2021 B.C. Acosta-Cinciri, N.M. López-Granados, J.A. Ramos-Banderas, C.A. Hernández-Bocanegra, P. Garnica-González, J.A. López-Corpus, published by Wroclaw University of Science and Technology

This work is licensed under the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 License.