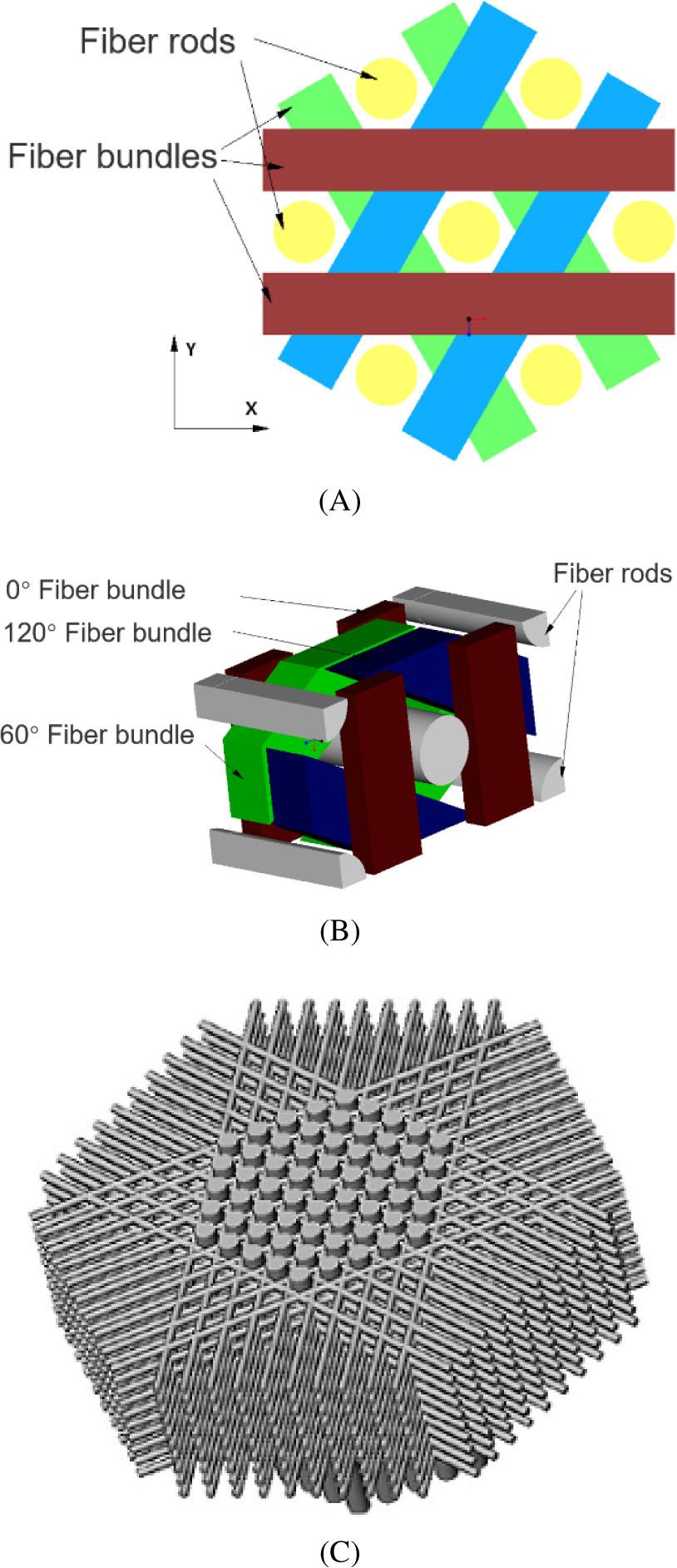

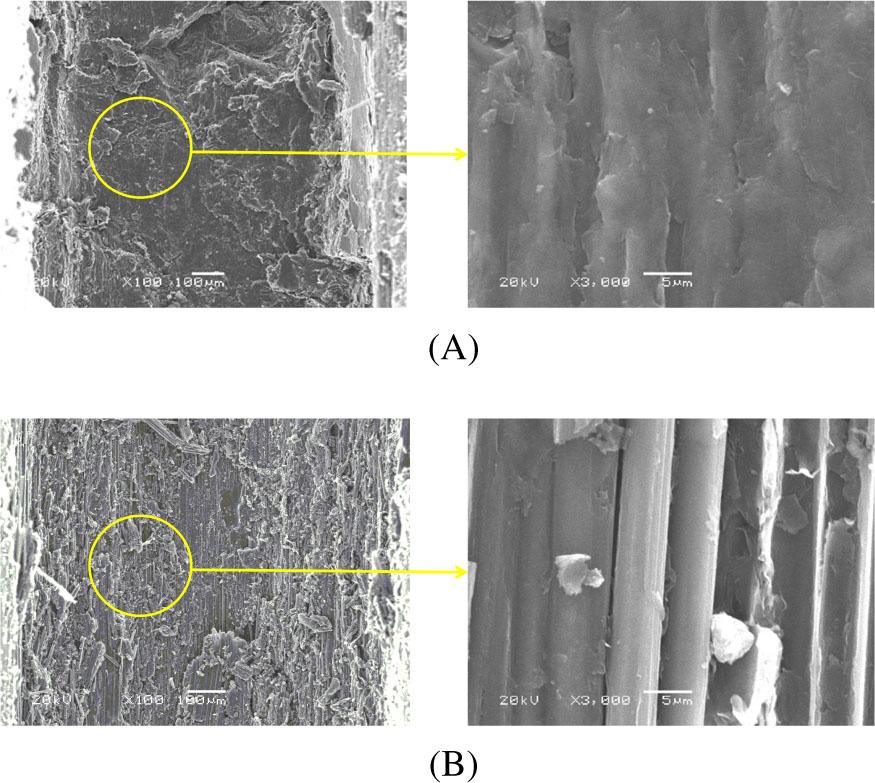

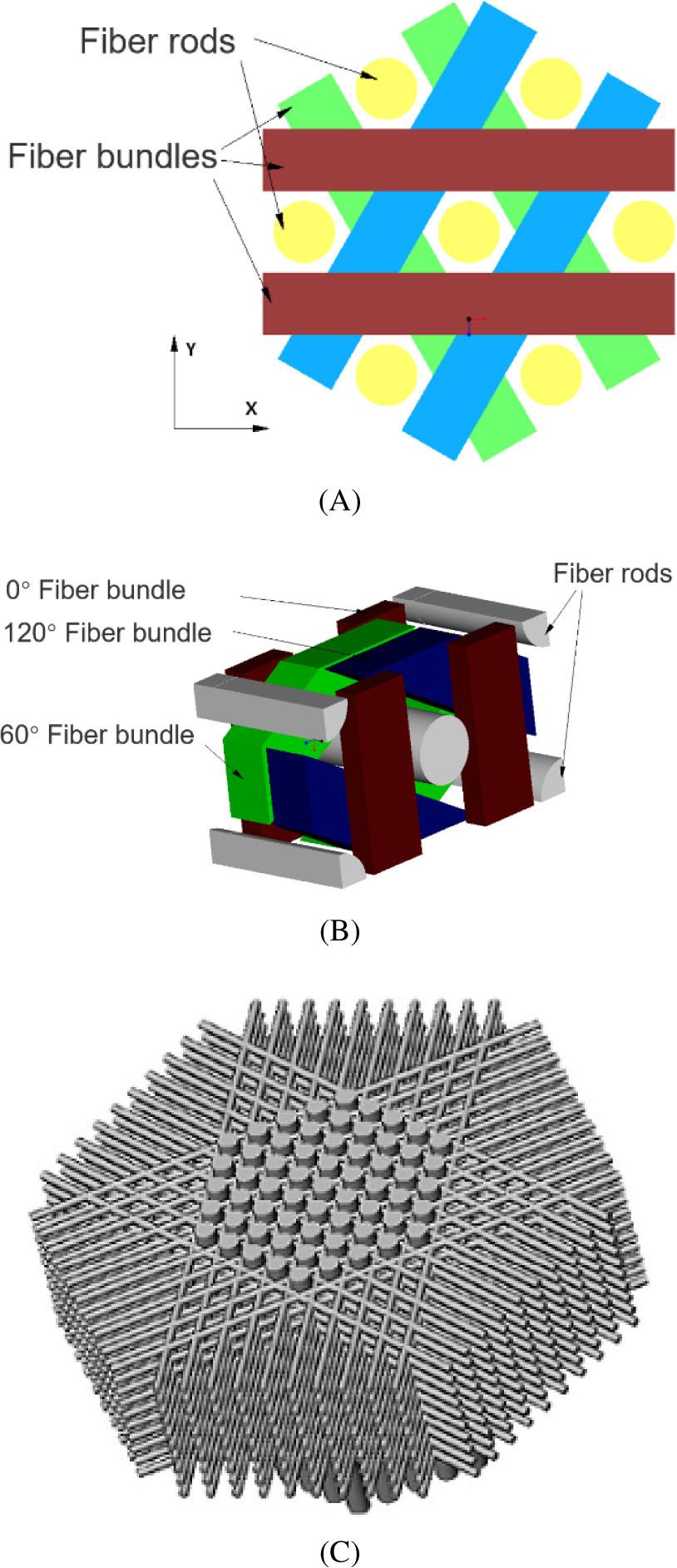

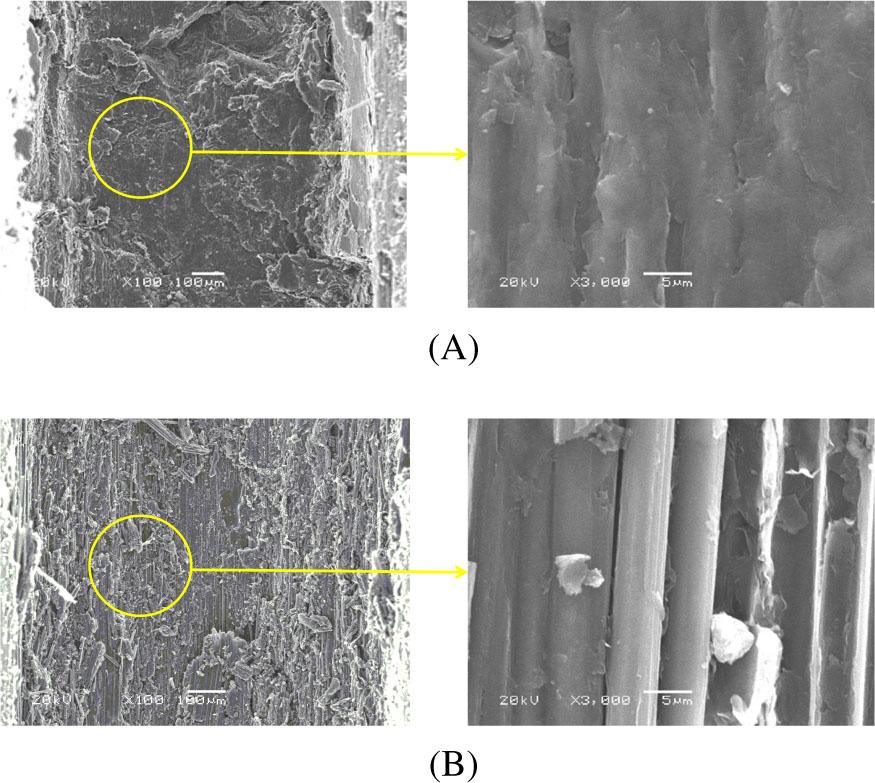

Fig. 1

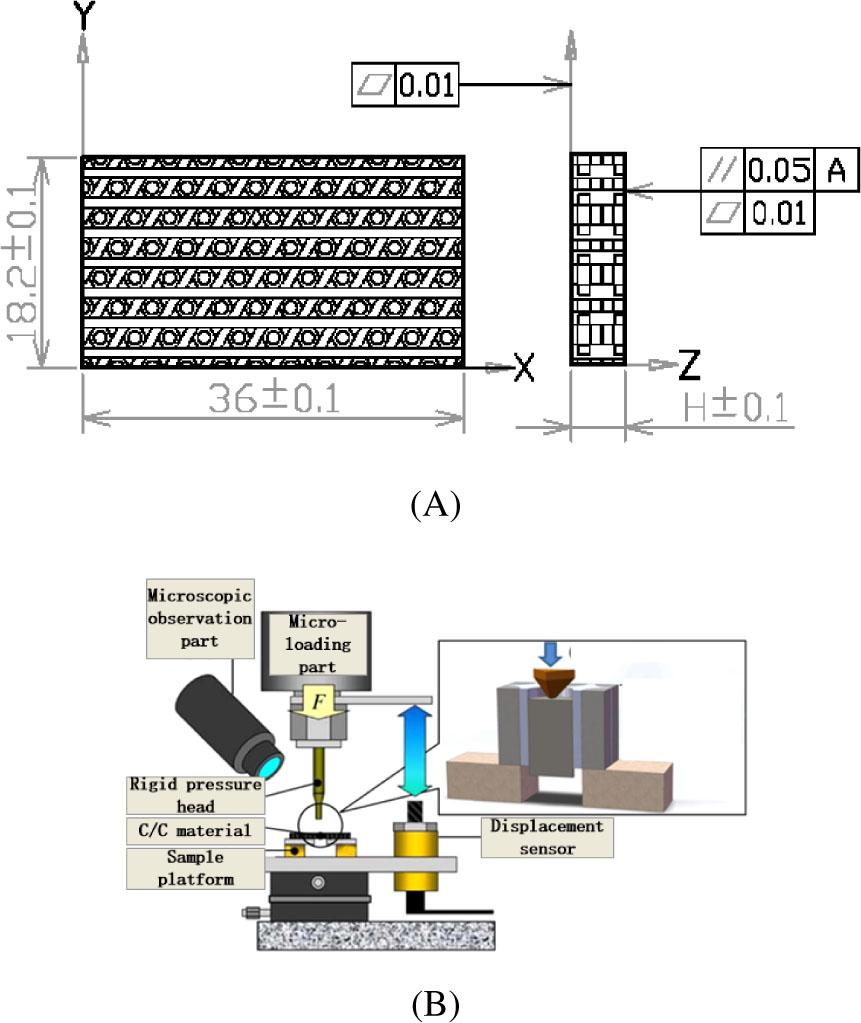

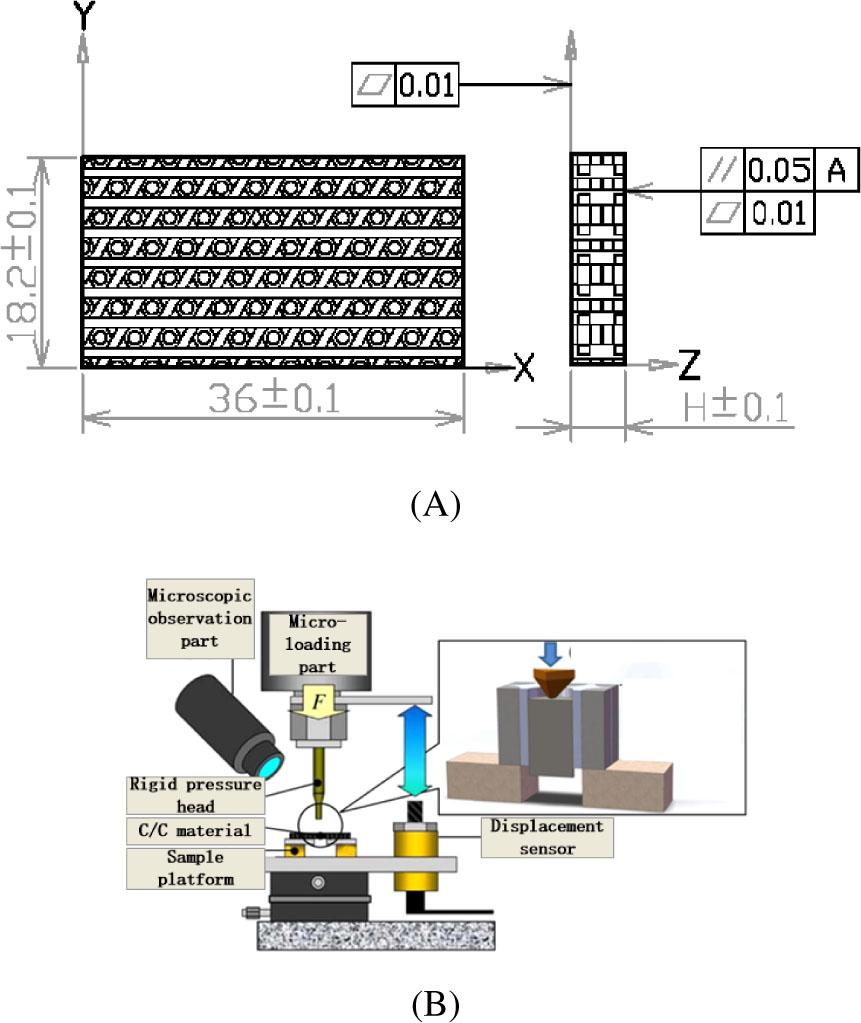

Fig. 2

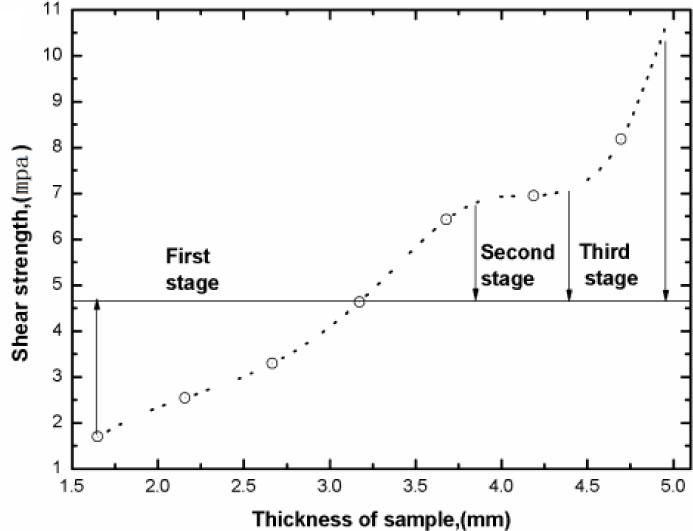

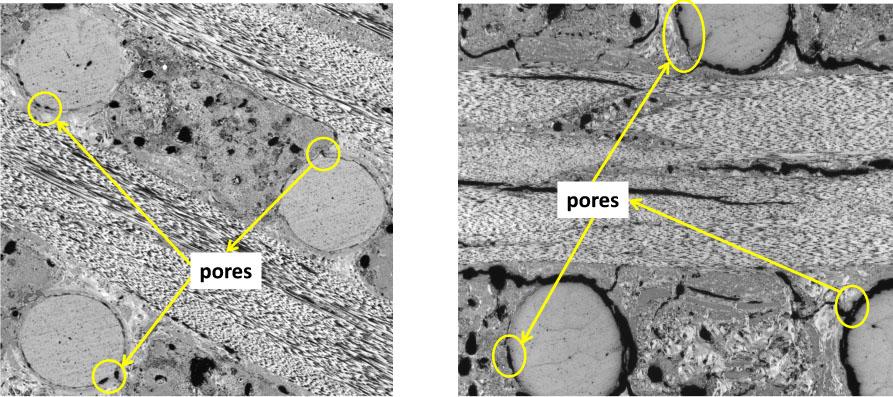

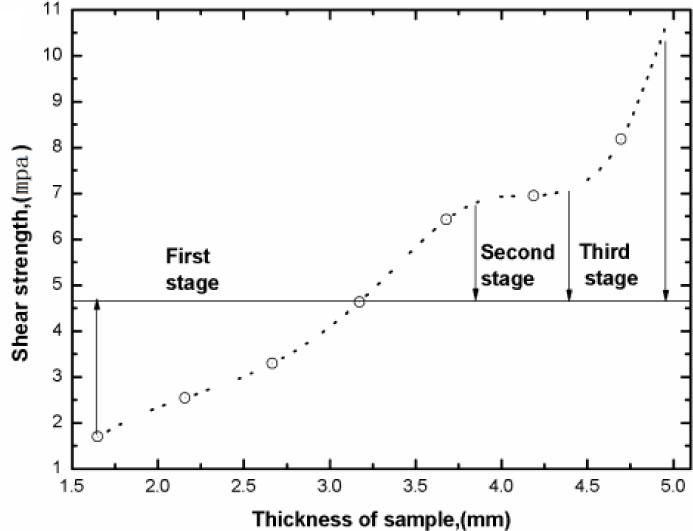

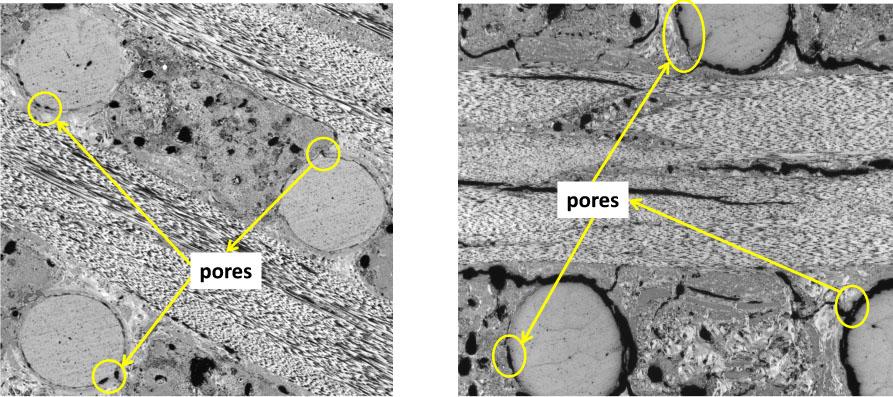

Fig. 3

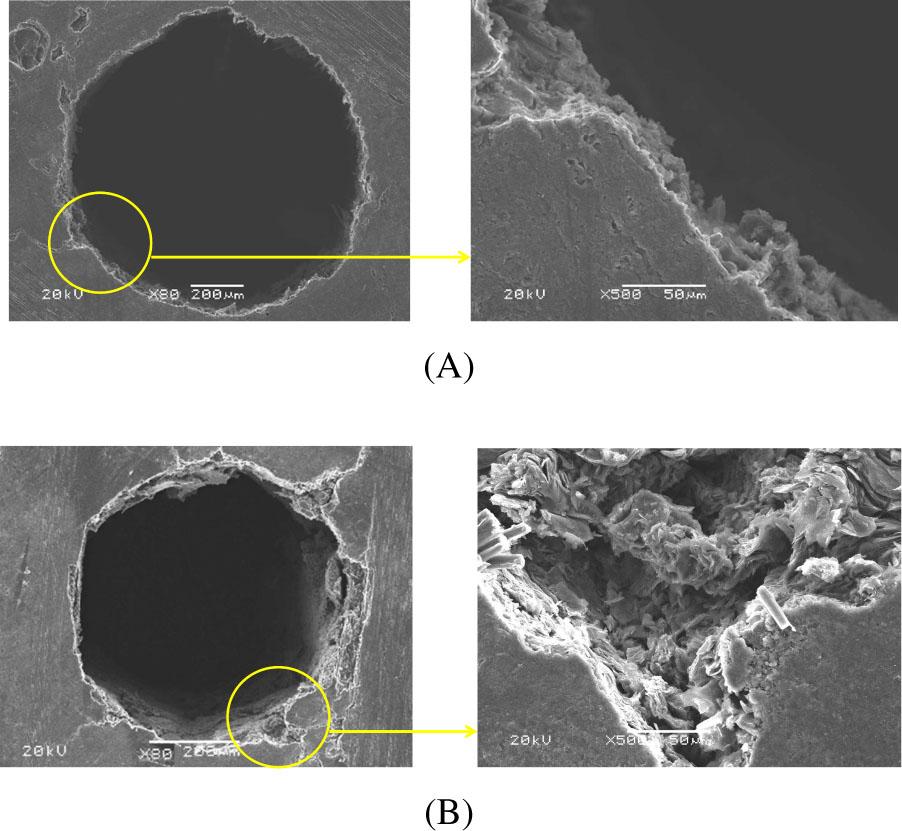

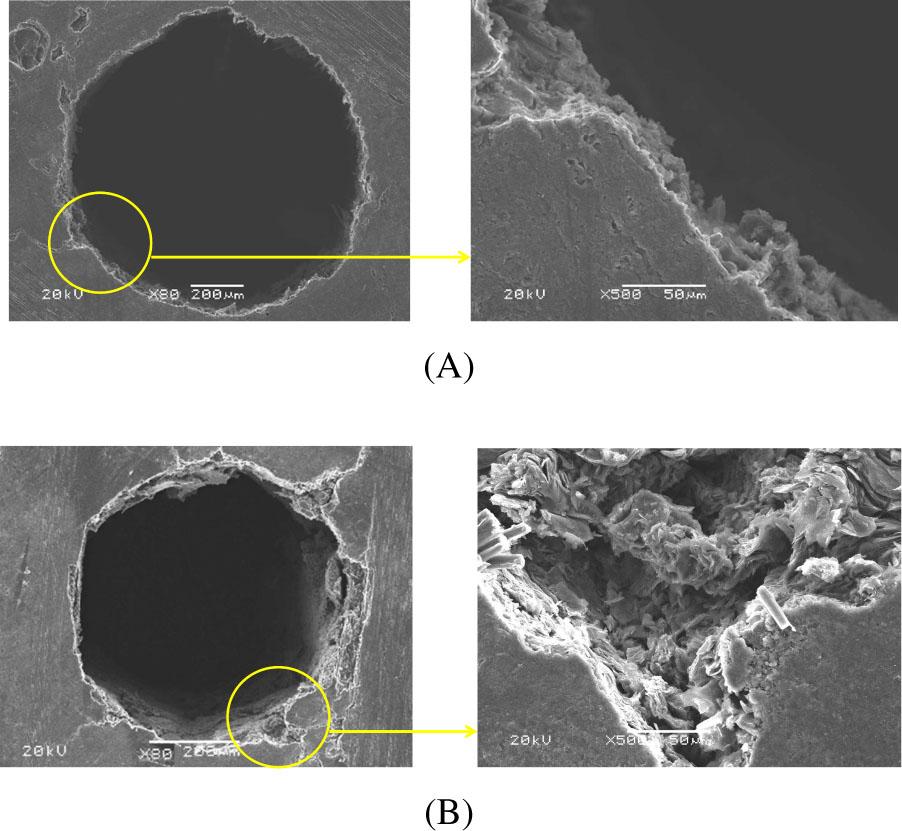

Fig. 4

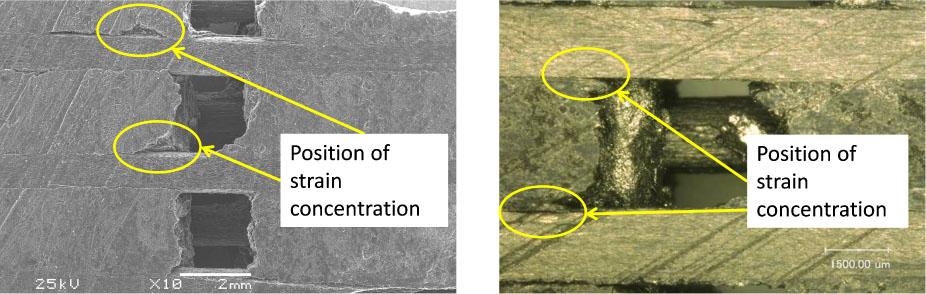

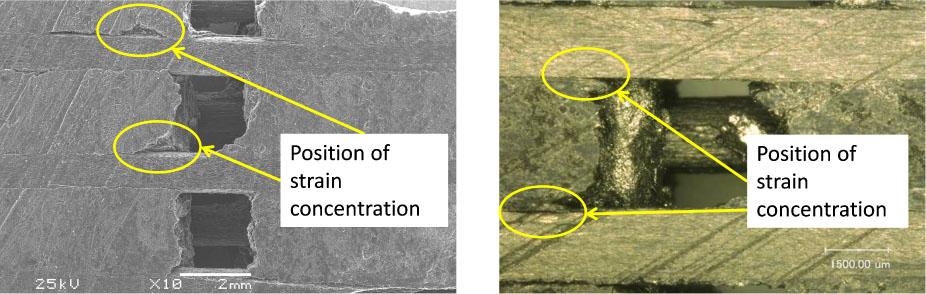

Fig. 5

Fig. 6

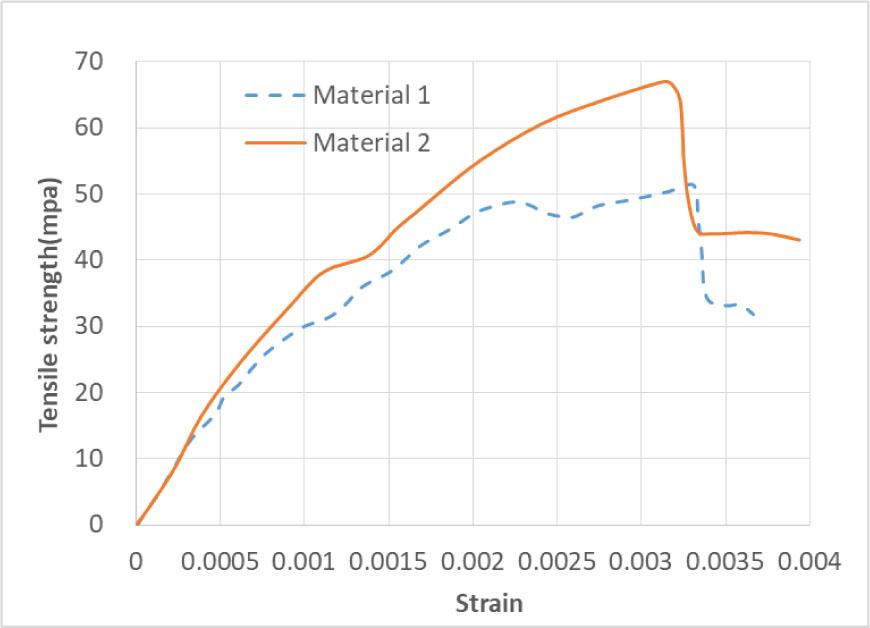

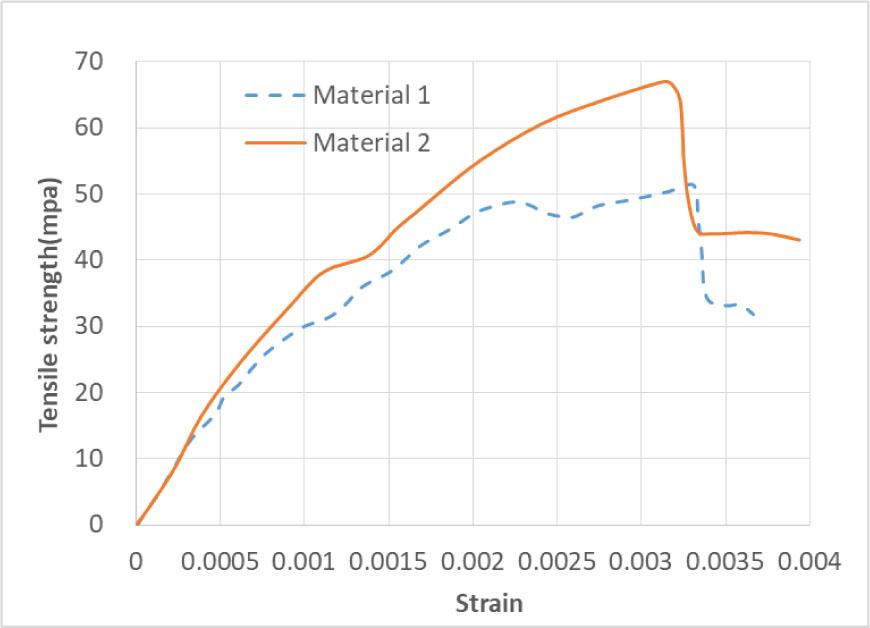

Fig. 7

Fig. 8

Fig. 9

Fig. 10

Fig. 11

Fig. 12

Fig. 13

© 2021 Chunguang Wang, Weiping Tian, Kaining Zhang, published by Wroclaw University of Science and Technology

This work is licensed under the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 License.