Fig. 1

![Results of the 2019 Global Carbon Budget Survey (by country) [3].](https://sciendo-parsed.s3.eu-central-1.amazonaws.com/64725239215d2f6c89dc418d/j_msp-2021-0004_fig_001.jpg?X-Amz-Algorithm=AWS4-HMAC-SHA256&X-Amz-Content-Sha256=UNSIGNED-PAYLOAD&X-Amz-Credential=AKIA6AP2G7AKOUXAVR44%2F20251204%2Feu-central-1%2Fs3%2Faws4_request&X-Amz-Date=20251204T131713Z&X-Amz-Expires=3600&X-Amz-Signature=b083d304d9b369aa9e4ef22f1ddb9a62145711e577b5e81d2b4dea1de70bc7de&X-Amz-SignedHeaders=host&x-amz-checksum-mode=ENABLED&x-id=GetObject)

Fig. 2

![2019 Global Carbon Budget Survey Results (by Industry) [3].](https://sciendo-parsed.s3.eu-central-1.amazonaws.com/64725239215d2f6c89dc418d/j_msp-2021-0004_fig_002.jpg?X-Amz-Algorithm=AWS4-HMAC-SHA256&X-Amz-Content-Sha256=UNSIGNED-PAYLOAD&X-Amz-Credential=AKIA6AP2G7AKOUXAVR44%2F20251204%2Feu-central-1%2Fs3%2Faws4_request&X-Amz-Date=20251204T131713Z&X-Amz-Expires=3600&X-Amz-Signature=6137a61a3baaef2c95e49dd7a96ab4ac5e4cccaf16ec2238e5520dbbc547dc8b&X-Amz-SignedHeaders=host&x-amz-checksum-mode=ENABLED&x-id=GetObject)

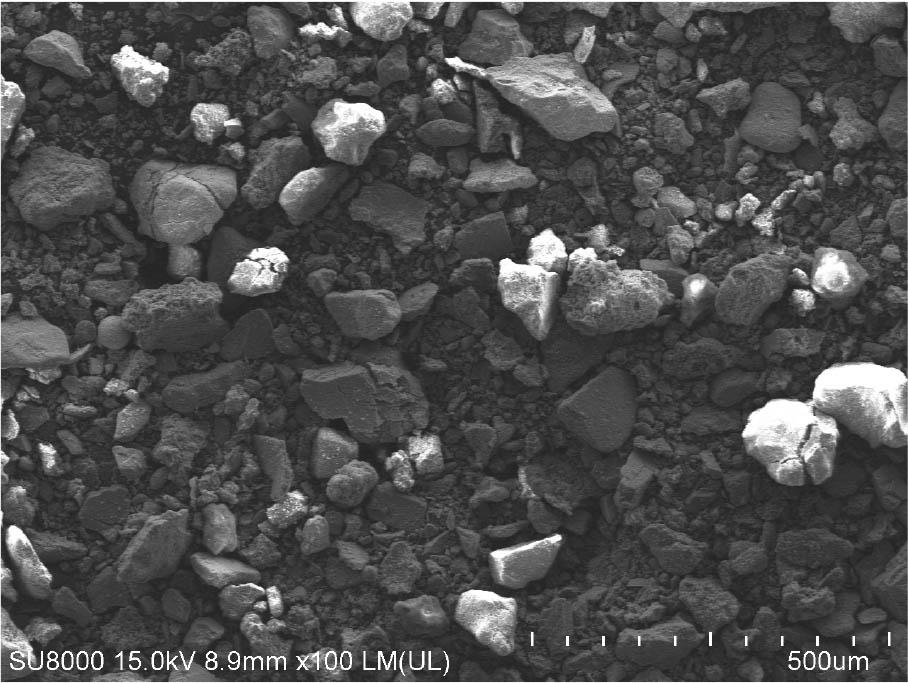

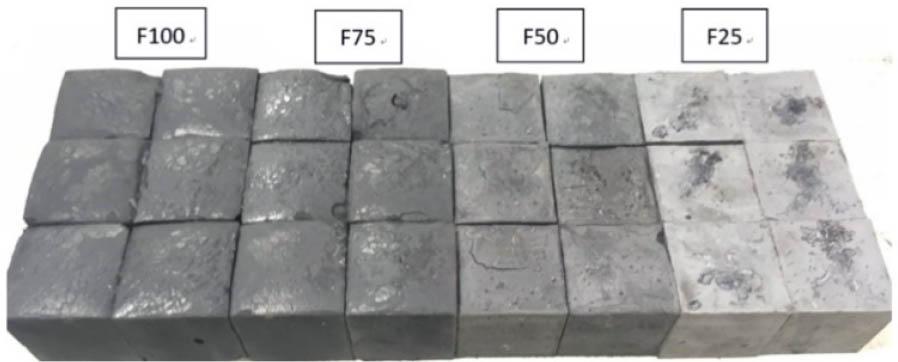

Fig. 3

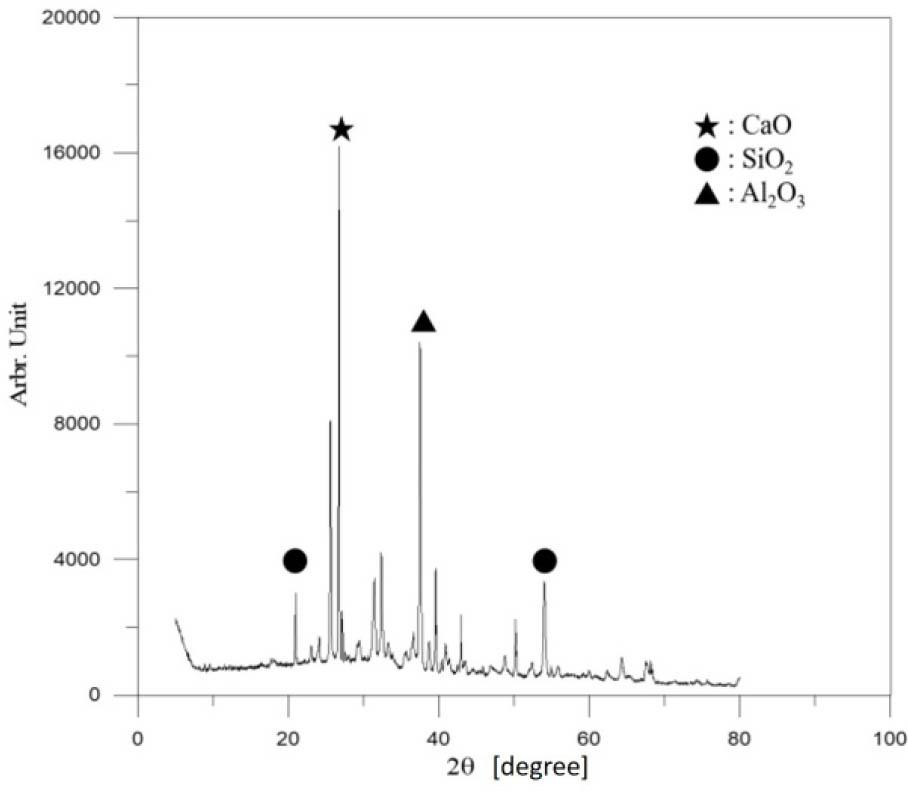

Fig. 4

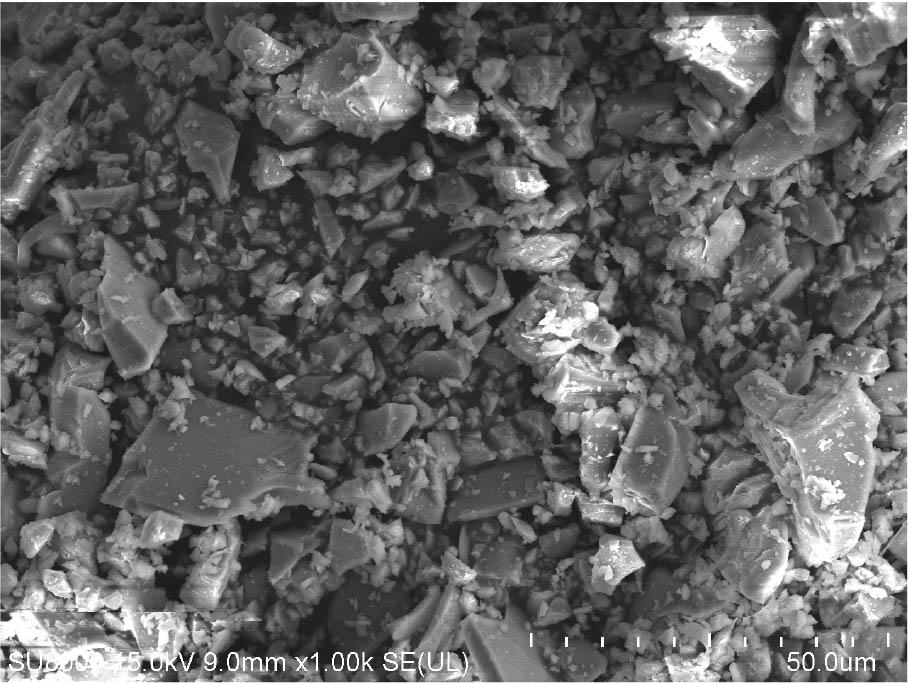

Fig. 5

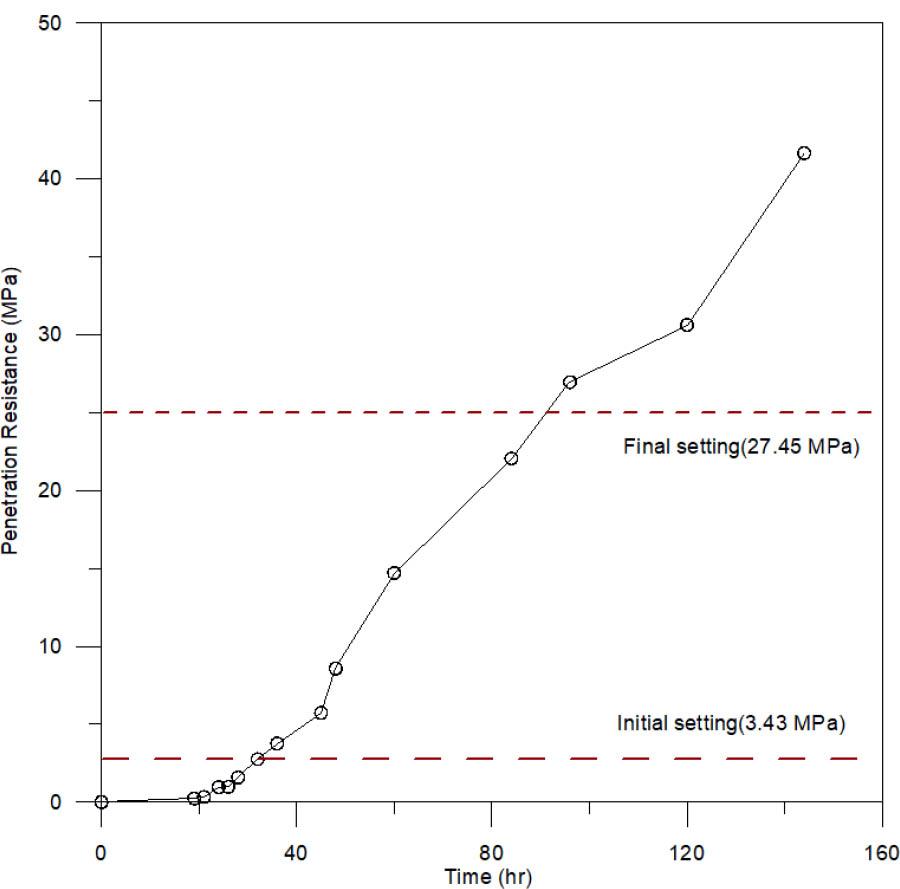

Fig. 6

Fig. 7

Fig. 8

Fig. 9

Fig. 10

Fig. 11

Fig. 12

Fig. 13

Fig. 14

Fig. 15

Fig. 16

ACI 229 recommended dosage for the CLSM_

| Material | Recommended dosage (kg/m3) |

|---|---|

| Cement | 30–120 |

| Class F fly ash (when used instead of fine particles) | 0–1200 |

| Class C fly ash | 0–210 |

| Fine aggregate | 1500–1800 |

| Water | 193–344 |

| Water (when using Class F fly ash) | 590 |

Proportioning design of the CLSM pastes_

| Numbering | CFA (%) | GGBS (%) |

|---|---|---|

| F100 | 100 | 0 |

| F75 | 75 | 25 |

| F50 | 50 | 50 |

| F25 | 25 | 75 |

| F0 | 0 | 100 |

Fresh properties for the mixing materials of the CLSM_

| Material | Advantage | Disadvantage |

|---|---|---|

| CFA | Improve the consistency of the V type | Minimum slump |

| Reduce the possibility of a box-type passage | ||

| Reduce stress resistance | ||

| GGBS | Improve fluidity and slump | Increase compression value |

| Improve stress resistance | ||

| Methylcellulose | Improve consistency | Reduce the possibility of a box-type passage |

| Extend V-type test time | Retard | |

| Superplasticizers | Increase fluidity | Expensive |

| Accelerators | Offset time | Reduce slump |

Compressive strength of the paste specimens at seven days (MPa)_

| Paste specimens Value | F100 | F75 | F50 | F25 | F0 |

|---|---|---|---|---|---|

| 1 | – | 4.71 | 8.14 | 10.00 | – |

| 2 | – | 4.51 | 6.76 | 9.80 | – |

| 3 | – | 4.61 | 7.84 | 9.71 | – |

| Average | – | 4.61 | 7.58 | 9.84 | – |

Fluidities for the strength activity index testing_

| Type | Flowability (cm) | Water (g) |

|---|---|---|

| GGBS | 16.0–21.0 | 230–260 |

| CFA | 11.5–22.4 | 230–270 |

SCC grading table_

| Grade Type | 1 | 2 | 3 |

|---|---|---|---|

| Box test (mm) | Over 300 (R1 disorder) | Over 300 (R2 disorder) | Over 300 (Accessibility) |

| Flowability (mm) | 650~750 | 600~700 | 500~650 |

| V type test (sec) | 10~25 | 7~20 | 7~20 |

Mix design for the activity index test (kg/m3)_

| Specimen No. | Cement | Standard sand | CFA | GGBS | Water |

|---|---|---|---|---|---|

| A-C | 500 | 1375 | 242 | ||

| A-F | 400 | 1375 | 100 | 252 | |

| A-S | 400 | 1375 | 100 | 240 |

Weather observation data_

| Age | Temperature (°C) | Max. temperature (°C) | Min. temperature (°C) | Relative humidity (%) | Precipitation (mm) | Precipitation hours (hr) | Maximum hourly precipitation (mm) | Sunshine hours (hr) | Sunshine rate (%) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 28.4 | 32.8 | 24.4 | 84 | T | 0.3 | T | 8.9 | 65.4 |

| 2 | 28.5 | 33.6 | 25.5 | 83 | 0.7 | 3.1 | 0.5 | 8.7 | 63.9 |

| 3 | 27.8 | 32.5 | 25.0 | 85 | 13.6 | 4.7 | 6.2 | 1.6 | 11.7 |

| 4 | 28.3 | 32.5 | 25.0 | 88 | 0.0 | 0.0 | 0.0 | 6.7 | 49.2 |

| 5 | 25.9 | 28.6 | 23.8 | 93 | 28.6 | 12.8 | 5.5 | 0.0 | 0.0 |

| 6 | 23.4 | 24.7 | 22.6 | 94 | 31.0 | 22.5 | 6.5 | 0.0 | 0.0 |

| 7 | 24.9 | 28.7 | 22.9 | 92 | 6.5 | 8.1 | 2.5 | 0.7 | 5.1 |

| 8 | 24.6 | 27.4 | 23.5 | 94 | 20.9 | 16.0 | 5.6 | 0.0 | 0.0 |

| 9 | 24.9 | 27.5 | 23.2 | 94 | 11.0 | 21.2 | 4.0 | 0.0 | 0.0 |

| 10 | 26.2 | 29.8 | 24.1 | 89 | T | 1.9 | T | 0.1 | 0.7 |

| 11 | 27.3 | 31.2 | 24.2 | 80 | 0.0 | 0.0 | 0.0 | 0.8 | 5.9 |

| 12 | 28.1 | 32.2 | 25.5 | 81 | 0.5 | 2.0 | 0.5 | 0.3 | 2.2 |

| 13 | 28.7 | 33.3 | 24.1 | 79 | 0.0 | 0.0 | 0.0 | 7.4 | 54.3 |

| 14 | 28.7 | 33.6 | 25.5 | 84 | 0.8 | 1.7 | 0.8 | 8.1 | 59.4 |

| 15 | 28.9 | 33.8 | 25.6 | 85 | 0.0 | 0.0 | 0.0 | 8.5 | 62.4 |

| 16 | 29.6 | 34.1 | 26.2 | 82 | 0.0 | 0.0 | 0.0 | 8.6 | 63.1 |

| 17 | 29.7 | 33.2 | 26.3 | 81 | 0.0 | 0.0 | 0.0 | 6.7 | 49.2 |

| 18 | 28.7 | 33.4 | 25.8 | 89 | 26.5 | 3.5 | 26.0 | 4.7 | 34.5 |

| 19 | 29.0 | 33.0 | 25.1 | 87 | T | 1.0 | T | 9.5 | 69.8 |

| 20 | 29.6 | 33.0 | 26.1 | 82 | 0.0 | 0.0 | 0.0 | 10.2 | 74.9 |

| 21 | 29.6 | 33.2 | 27.1 | 83 | 0.0 | 0.0 | 0.0 | 6.9 | 50.7 |

| 22 | 29.3 | 34.5 | 26.1 | 82 | 9.1 | 2.1 | 7.5 | 8.3 | 61.0 |

| 23 | 29.1 | 33.0 | 25.1 | 84 | 0.1 | 0.2 | 0.1 | 11.4 | 83.8 |

| 24 | 29.1 | 33.7 | 26.2 | 83 | 0.4 | 0.8 | 0.3 | 5.6 | 41.2 |

| 25 | 28.9 | 32.6 | 25.9 | 82 | 0.0 | 0.0 | 0.0 | 5.7 | 41.9 |

| 26 | 29.7 | 34.4 | 26.0 | 76 | 0.0 | 0.0 | 0.0 | 8.0 | 58.9 |

| 27 | 29.7 | 33.5 | 26.5 | 80 | 0.0 | 0.0 | 0.0 | 10.3 | 75.8 |

| 28 | 28.4 | 33.3 | 24.7 | 83 | 34.4 | 3.0 | 31.5 | 0.5 | 3.7 |

Chemical compositions of CFA_

| Composition | Value (%) | Composition | Value (%) | ||

|---|---|---|---|---|---|

| Sample I | Sample II | Sample I | Sample II | ||

| Na2O | 0.75 | 0.00 | Fe2O3 | 3.49 | 3.34 |

| MgO | 1.82 | 2.15 | NiO | 0.00 | 0.00 |

| Al2O3 | 19.27 | 12.21 | Co2O3 | 0.00 | 0.05 |

| SiO2 | 29.47 | 26.21 | CuO | 0.00 | 0.04 |

| P2O5 | 0.47 | 0.67 | ZnO | 0.08 | 3.11 |

| SO3 | 7.36 | 10.35 | As2O3 | 0.00 | 0.00 |

| Cl | 0.07 | 0.14 | Br | 0.01 | 0.04 |

| K2O | 1.02 | 0.90 | Rb2O | 0.00 | 0.00 |

| CaO | 35.54 | 40.24 | SrO | 0.05 | 0.04 |

| TiO2 | 0.55 | 0.49 | ZnO2 | 0.00 | 0.00 |

| Cr2O3 | 0.00 | 0.00 | Y2O3 | 0.00 | 0.00 |

| MnO | 0.05 | 0.05 | ZrO2 | 0.02 | 0.03 |

Mix design of CLSM (kg/m3)_

| Mix No. | w/c | Cement | CFA GGBS | Coarse Aggregates | Fine Aggregates | Water | Superplasticizer | Accelerator | Adhesive |

|---|---|---|---|---|---|---|---|---|---|

| T1 | 31.5 | 94.7 155.5 | 1304.0 | 242.5 | 3.2 | 0.060 | |||

| T2 | 47.3 | 142.0 233.3 | 806.8 | 376.4 | 3.2 | 0.060 | |||

| T3 | 34.7 | 104.2 171.1 | 1204.5 | 269.3 | 3.2 | 0.090 | |||

| T4 | 69.3 | 136.9 101.4 | 1204.3 | 269.3 | 3.2 | 0.320 | |||

| T5 | 0.85 | 69.3 | 162.0 76.0 | 400.5 | 1204.2 | 268.9 | 22.1 | 3.2 | 0.410 |

| T6 | 104.0 | 121.5 88.7 | 1204.2 | 267.4 | 5.0 | 0.473 | |||

| T7 | 69.3 | 162.0 76.0 | 1204.2 | 262.0 | 10.0 | 0.473 | |||

| T8 | 69.3 | 162.0 76.0 | 1204.2 | 262.0 | 10.0 | 0.410 | |||

| T9 | 69.3 | 162.0 76.0 | 1204.2 | 268.0 | 4.0 | 0.410 | |||

| T10 | 69.3 | 162.0 76.0 | 1204.2 | 268.4 | 3.6 | 0.410 |

Fresh properties of the CLSM_

| Mix no. | V type test (sec) | Box test | Flowability (cm) | Tube fluidity (cm) |

|---|---|---|---|---|

| T1 | 6 | Pass | 59.5 | 20.0 |

| T2 | Severe bleeding | |||

| T3 | 4 | Severe bleeding | ||

| T4 | 6 | Did not pass | 57.5 | 23.0 |

| T5 | 7 | Pass | 64.0 | 21.5 |

| T6 | 6 | Did not pass | 49.5 | 19.5 |

| T7 | 17 | Did not pass | 38.0 | 15.0 |

| T8 | Rapid hardening | |||

| T9 | 11 | Pass | 46.5 | 18.5 |

| T10 | 7 | Pass | 50.0 | 20.0 |

Designed compressive strength for various backfill materials [35, 36, 37]_

| Items | Backfill material | Compressive strength |

|---|---|---|

| 1 | Specification requirements | 8.3 MPa (1200 psi) |

| 2 | Recommended strength | 2.1 MPa (300 psi) |

| 3 | CLSM long-term compressive strength | 0.3 MPa–2.1 MPa (50 psi–300 psi) |

| 4 | Equivalent to good compaction | 0.35 MPa–0.7 MPa (50 psi–100 psi) |

| 5 | Foundation support | 0.7 MPa–8.3 MPa (100 psi–1200 psi) |

| 6 | Subgrade | 2.8 MPa–8.3 MPa (400 psi–1200 psi) |

| 7 | Can be manually mined | 0.3 MPa (50 psi) |

| 8 | Reliable mechanical digging | 0.7 MPa–1.4 MPa (100 psi–200 psi) |

| 9 | The strength that can be excavated only when using fine sand or fly ash as the granular material | 2.1 MPa (300 psi) |

Optimal mix design of the CLSM using a higher amount of cement replacement_

| Material | Value |

|---|---|

| Water–cement ratio | 0.85 |

| Cement | 69.3 kg/m3 |

| CFA | 162.0 kg/m3 |

| GGBS | 76.0 kg/m3 |

| Coarse aggregate | 400.5 kg/m3 |

| Fine aggregate | 1204.2 kg/m3 |

| water | 268.4 kg/m3 |

| Superplasticizers | 22.5 kg/m3 |

| Adhesives | 0.410 kg/m3 |

| Accelerators | 3.6 kg/m3 |

| Unit weight | 2527 kg/m3 |

Chemical compositions of CFA and GGBS_

| Composition | CFA | GGBS |

|---|---|---|

| Content, wt. (%) | ||

| Silicon dioxide (SiO2) | 29.47 | 33.68 |

| Aluminium oxide (Al2O3) | 19.27 | 14.37 |

| Ferric oxide (Fe2O3) | 3.49 | 0.29 |

| Calcium oxide (CaO) | 35.54 | 40.24 |

| Magnesium oxide (MgO) | 1.82 | 7.83 |

| Sulphur trioxide (SO3) | 7.36 | 0.66 |

| Others | 3.05 | 2.93 |

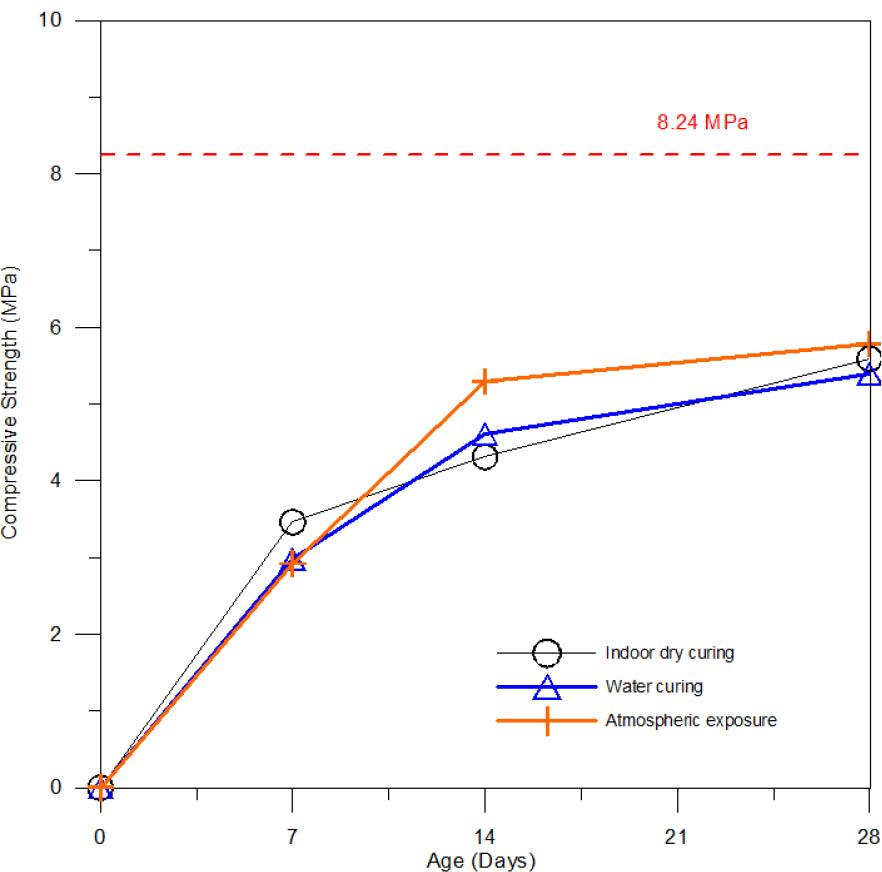

Compressive strength (MPa)_

| Method | 7-day | 14-day | 28-day |

|---|---|---|---|

| Atmospheric exposure (A) | 2.84 | 5.20 | 5.78 |

| Water curing (W) | 2.94 | 4.51 | 5.39 |

| Indoor dry curing (E) | 3.43 | 4.31 | 5.59 |

Pozzolanic strength activity index results_

| Mix no. | Compressive Strength (MPa) | |

|---|---|---|

| 7 days | 28 days | |

| A-C | 32.16 | 44.80 |

| A-F | 31.96 | 41.18 |

| A-S | 31.27 | 50.20 |

| Material | Strength Activity Index | |

| 7 days | 28 days | |

| CFA | 99% | 92% |

| GGBS | 97% | 112% |

Chloride diffusion coefficient from the accelerated chloride migration test (10−12 m2/s)_

| Method | 7-day | 14-day | 28-day |

|---|---|---|---|

| Atmospheric exposure (A) | 2.62 | 2.21 | 0.51 |

| Water curing (W) | 3.02 | 1.43 | 0.14 |

| Indoor dry curing (E) | 3.90 | 1.89 | 1.75 |