Fig. 1.

Fig. 2.

Fig. 3.

Fig. 4.

Fig. 5.

Fig. 6.

Fig. 7.

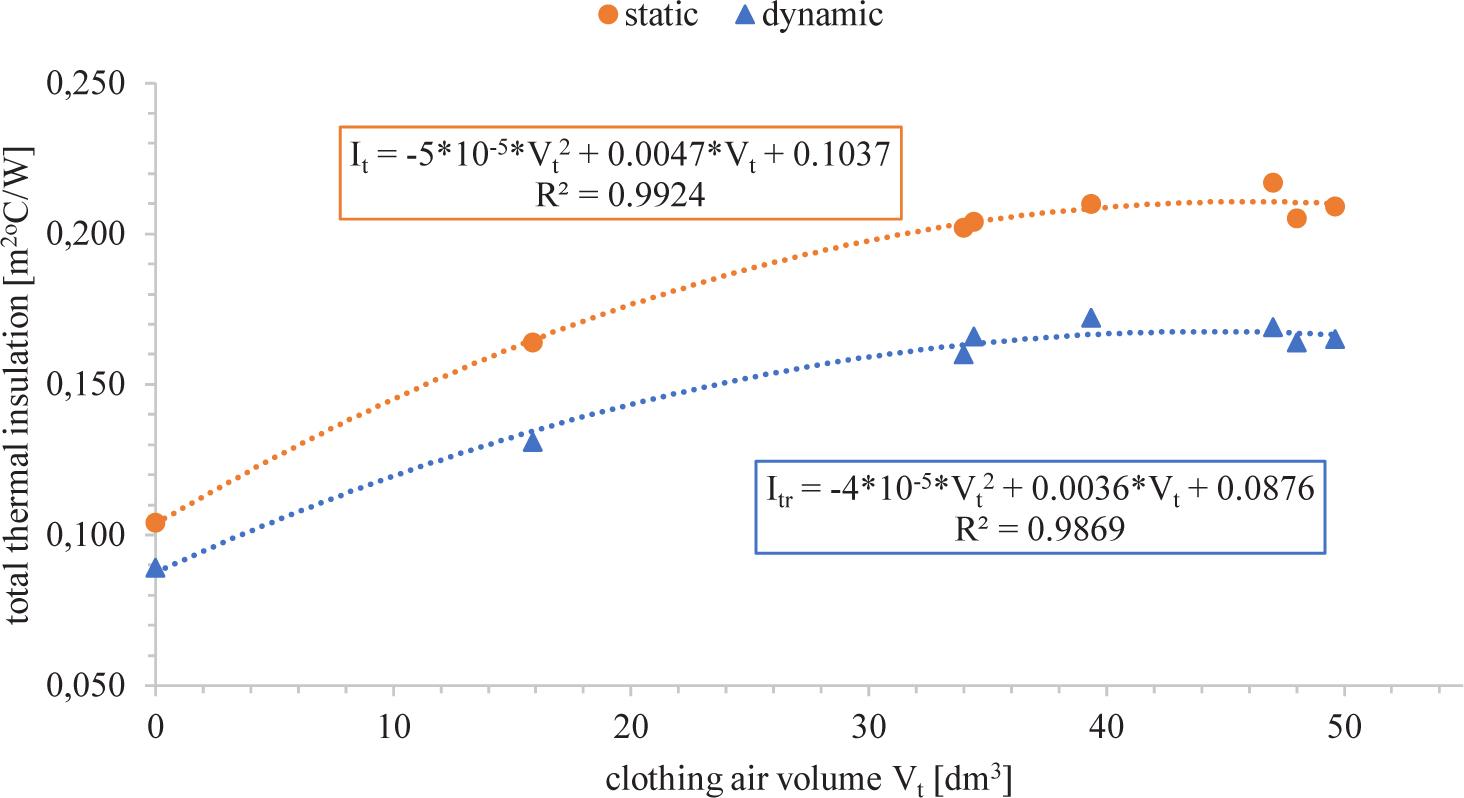

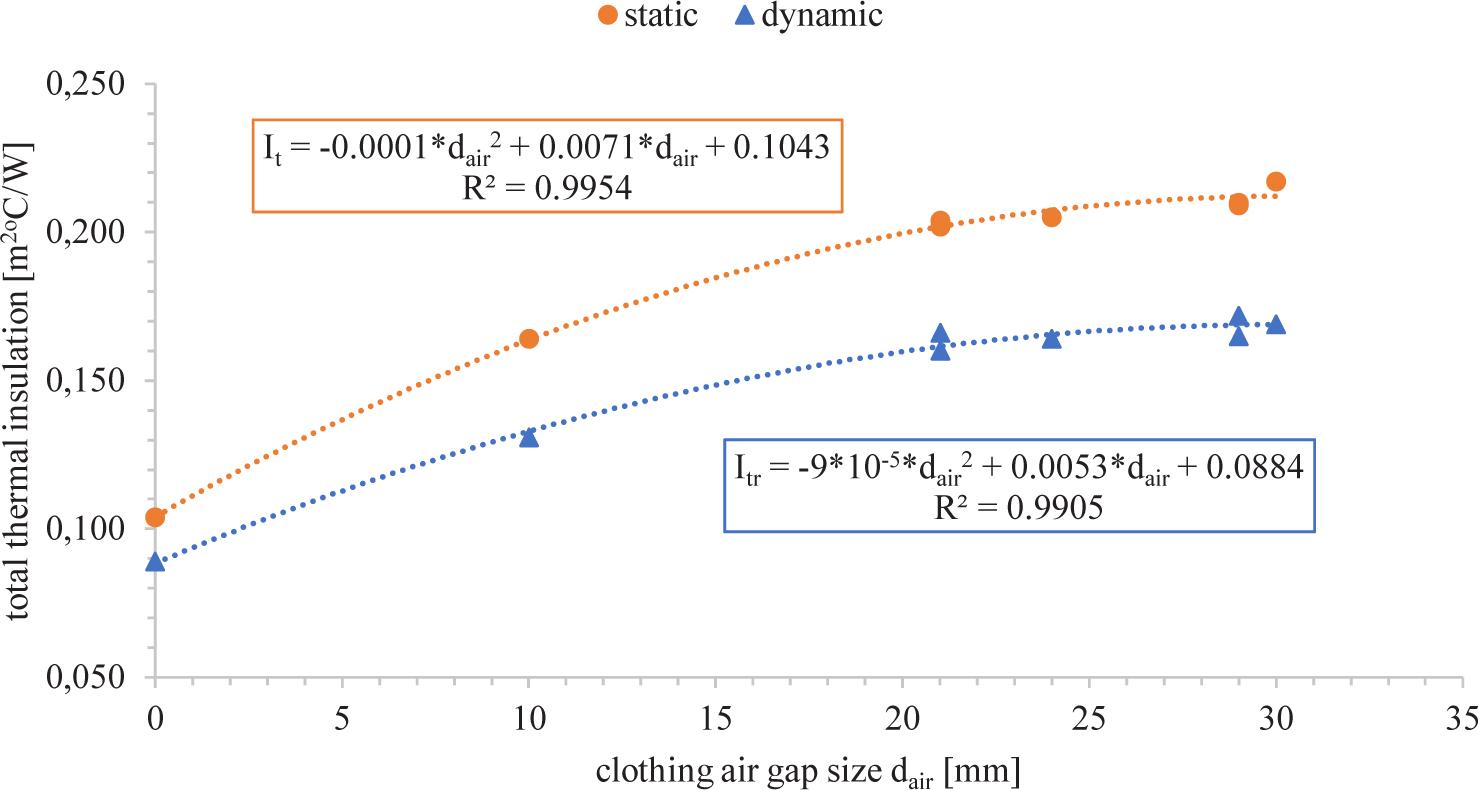

The equations for the relationship between the clothing’s total thermal insulation (in static and dynamic test conditions), total air volume (Vt), and air gap size (dsir)

| Test conditions | Total air volume Vt [dm3] | Average air gap dair [mm] |

|---|---|---|

| static | It = −5*10−5*Vt2 + 0.0047*Vt + 0.104 (2) | It = −0.0001*dair2 + 0.0071*dair + 0.104 (3) |

| dynamic | Itr = −4*10−5*Vt2 + 0.0036*Vt + 0.088 (4) | Itr = −9*10−5*dair2 + 0.0053*dair + 0.088 (5) |

Data obtained from the manufacturer describing the different sizes

| Size | Height [cm] | Circumference | ||

|---|---|---|---|---|

| chest [cm] | waist [cm] | collar [cm] | ||

| 50 | 170-176 | 96-100 | 88-92 | 40-41 |

| 54 | 176-182 | 104-108 | 96-100 | 42-43 |

| 56 | 182-188 | 108-112 | 100-140 | 43-44 |

A detailed description of the tested clothing

| Name | Material composition | Normative requirements | Industrial application | |

|---|---|---|---|---|

| Outerwear clothing | ||||

| Set S1 | jacket and waist-length pants | 79% cotton, 20% polyester, 1% antistatic fiber; Hydro-Tec finish; 260 g/m2 | EN ISO 13688:2013 [21], EN ISO 11611:2015 [22], EN 11612:2015 [23], EN 1149-5:2018 [24], EN 13034:2005 [25], EN ISO 14116:2015 [26], IEC 61482-2:2018 [27] | power industry, chemical industry, welding and hot factors, explosion hazard zone, high visibility |

| Set S2 | acid-proof jacket and acid-proof dungarees | 80% polyester, 20% cotton; 225 g/m2 | EN ISO 13688:2013 [21], EN 13034:2005 [25] | chemical industry |

| Underwear | ||||

| U | long-sleeved t-shirt and underpants | 59% Protex, 39% Cotton, 2% negastat; 205 g/m2 | EN ISO 13688:2013 [21], EN ISO 11612:2015 [22], EN 1149-5:2018 [24] | gas industry, fuel industry, explosion hazard zone |

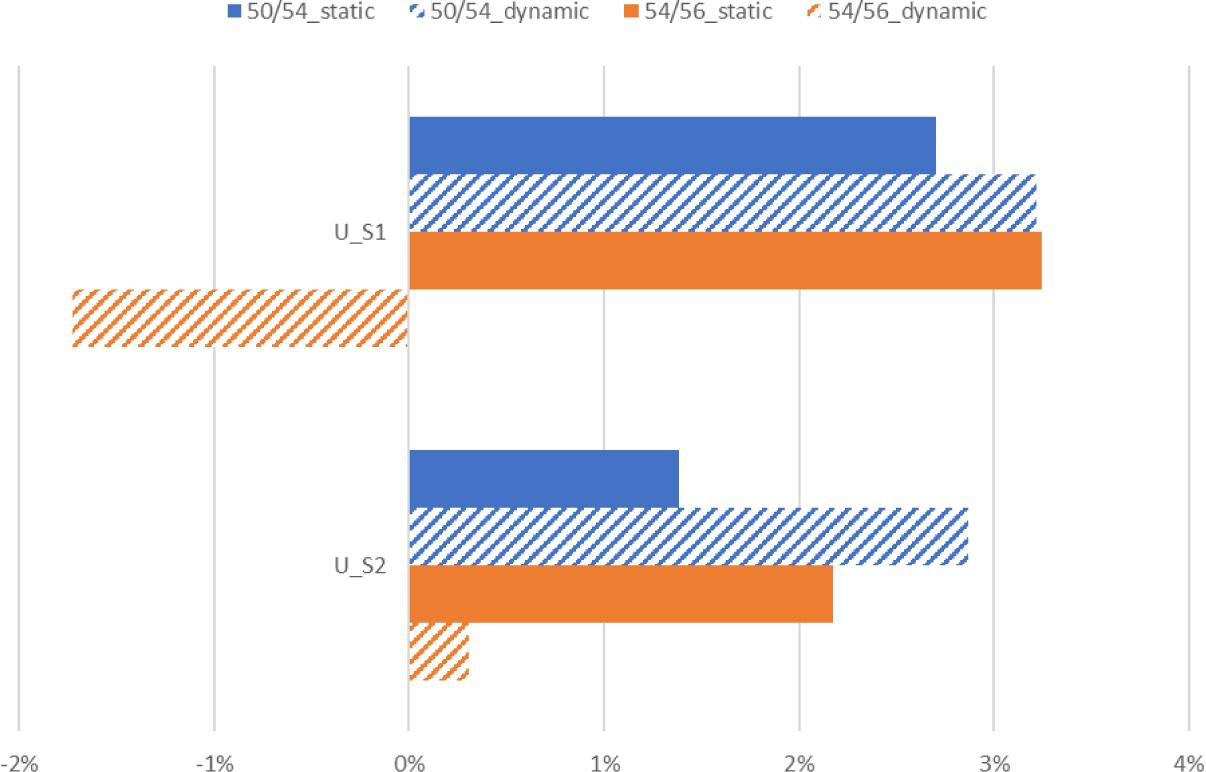

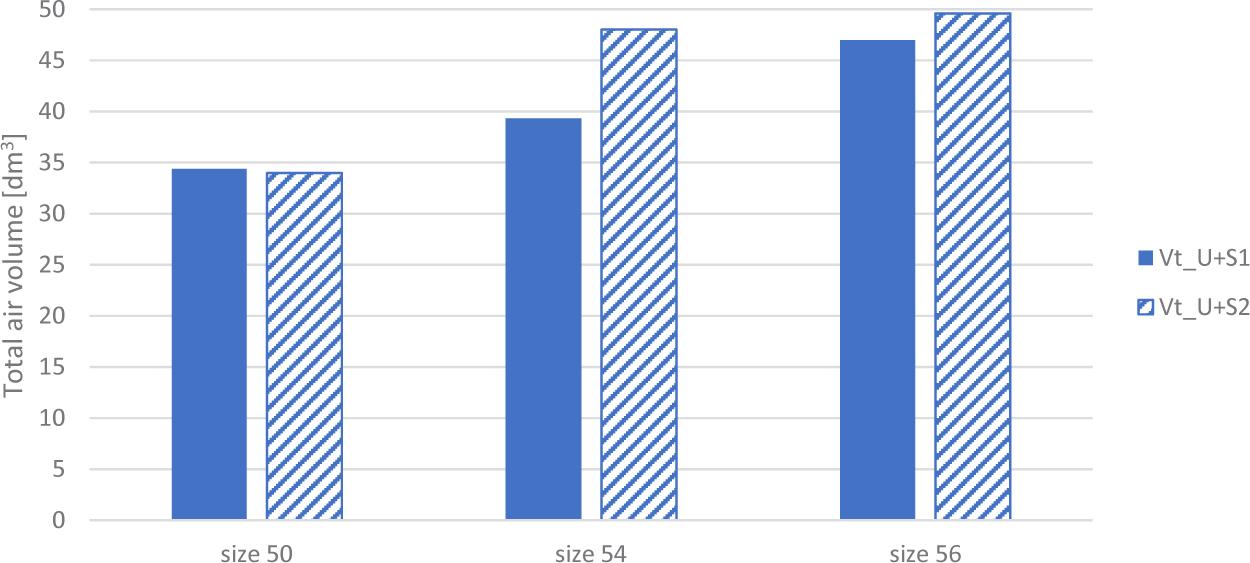

Air volume, air gap size, total thermal Insulation (mean value ± standard deviation) calculated by parallel method for static and dynamic test conditions

| Variants | Size | Vt [dm3] | dair [mm] | Total thermal insulation It [m2oC/W] | Resultant total thermal insulation Itr [m2oC/W] |

|---|---|---|---|---|---|

| U | 54 | 16 | 10 | 0.164±0.001 | 0.131±0.000 |

| U_S1(50) | 50 | 34 | 21 | 0.204±0.001 | 0.166±0.000 |

| U_S1(54) | 54 | 39 | 29 | 0.210±0.001 | 0.172±0.000 |

| U_S1(56) | 56 | 47 | 30 | 0.217±0.000 | 0.169±0.000 |

| U_S2(50) | 50 | 34 | 21 | 0.202±0.000 | 0.160±0.000 |

| U_S2(54) | 54 | 48 | 24 | 0.205±0.002 | 0.164±0.000 |

| U_S2(56) | 56 | 50 | 29 | 0.209±0.000 | 0.165±0.000 |