Due to the rising presence of rubber in the environment, the incorporation of crumb rubber into concrete mixtures has garnered significant research interest. While benefiting the environment, this innovative approach also tries to enhance some of the concrete properties. Numerous studies have explored the influence of rubber additives on concrete properties such as strength, durability, and environmental impact.

Replacing coarse aggregate with crumb rubber in concrete results in a reduction in concrete mechanical properties such as compressive and tensile strength and modulus of elasticity (Deshpande et al., 2014; Girskas & Nagrockienė, 2017; Karunarathna et al., 2021; Fauzan et al., 2023). However, rubberized concrete beams showed reduced displacements compared to reference beams when subjected to similar impact (Pham et al., 2020). Furthermore, rubberized concrete beams experience a lower maximum impact force in a collision and have greater crack resistance compared to the control mixes. Meanwhile, workability does not significantly decrease with the addition of crumb rubber (Fauzan et al., 2023).

In the case of Portland pozzolana cement concrete, Bisht and Ramana (2017) concluded that 4% of fine aggregates might be substituted by weight with crumb rubber to produce a suitable concrete mix for non-structural elements.

In a static and dynamic evaluation, Atahan and Yücel (2012) propose rubberized concrete produced with 20‒40% crumb rubber to substitute natural aggregates in concrete safety barriers that necessitate strength, energy dissipation, and fracture resistance. For substitution percentages greater than 60%, rubberized concrete would be beneficial for concrete impact attenuators where low impact severity is important, and some fracture or fragmentation upon impact is acceptable.

In another study, Walid et al. (2022) replaced fine aggregate with crumb rubber at 0%, 10%, 15%, and 20% by volume and found that compressive strength was acceptable with up to 20% replacement. Rubberized concrete has shown more ductile behavior than reference concrete. The evaluation of the failure modes revealed that crumb rubber can enhance the deformability of the mixture. Moreover, impact resistance under flexural loading increased as the rubber content increased (Abdelmonem et al., 2019).

A study by Mendis et al. (2017) investigating the flexural behavior of reinforced rubberized concrete beams compared to reference concrete showed that reinforced concrete beams using rubberized concrete of similar strength perform similarly under flexural loads.

The incorporation of rubber fibers into natural aggregate concrete showed an enhancement in ductility, compressive strength, tensile strength, and deflection behavior compared to reference concrete (Ismail & Hassan, 2017a, 2017b; Al-Azzawi et al., 2018; Eisa et al., 2020).

Hybrid reinforced rubberized concrete beams outperformed reinforced rubberized concrete beams (Alasmari et al., 2019) in terms of failure patterns, first cracking load, deflection load, and flexural strength, even though reinforced rubberized concrete beams seem to have better ultimate deflection, ductility index, and stress-strain curve.

A synergistic effect was observed between rubber and corrugated round steel fibers (Mohammed & Ali, 2023; Ghoniem & Aboul Nour, 2024), leading to better fresh and hardened concrete properties (workability, density, compressive strength, indirect tensile strength, and flexural strength) when used together. The addition of fiber reinforcement mitigated the negative influence of rubber and vice versa.

The impact of the ratio of crumb rubber and welded wire mesh layers (WWM) on the flexural behavior of reinforced concrete beams was investigated by Ismail et al. (2020) and showed a decrease in compressive strength while increasing the content of crumb rubber, while the addition of WWM improved the beam performance against shear failure. Beams cast with rubberized concrete exhibited a slight reduction in load capacity compared to those without rubber. Furthermore, all beams incorporating crumb rubber exhibited a notable increase in ductility index.

By strengthening the reinforced concrete beams with high-performance rubberized engineered cementitious composite (RECC), AbdelAleem and Hassan (2022) showed an enhancement in flexural strength, ductility cracking behavior, deformability, and bond strength.

In conclusion, based on existing literature, rubberized concrete shows a decrease in compressive and tensile strength, but at the same time, it significantly enhances ductility, energy absorption, and crack resistance. In addition, rubber, in combination with steel or synthetic fibers, can further enhance some of its mechanical properties and durability.

Existing research studies have generally focused on standardized small-scale samples and utilized very low percentages of rubber. Furthermore, rubber incorporation into a concrete mixture reinforced with rebar is yet to be investigated. In this context, our study tries to explore the effect of higher crumb rubber content incorporation on the density, tensile strength, and flexural behavior of steel-reinforced beams. This approach seeks to provide a more comprehensive understanding of the material’s potential for practical applications.

This study aims to contribute to the understanding of using rubberized concrete in structural applications, particularly in the case of reinforced beams, which is an area that is still underexplored despite the extensive research carried out on rubberized concrete behavior. Reinforced beams are structural elements that play a critical role in load-bearing systems; thus, understanding the effect of rubber on their performance is essential for its practical use in construction.

The study aims to analyze the flexural performance of reinforced concrete beams incorporating crumb rubber up to 30% by volume. We provide essential insights into the feasibility of using rubberized concrete in structural applications by evaluating key mechanical properties such as bending capacity, deflection, and failure modes.

Furthermore, with the increasing environmental concerns about waste tire disposal, this research contributes to the development of an eco-friendly construction material. By providing experimental validation and discussing the feasibility of incorporating rubberized concrete in reinforced beams, this study paves the way for future research and practical implementation in sustainable construction projects.

To ensure the quality of our mixture, the material selection process for concrete production was conducted carefully. The cement utilized is CEM II/B-M (S-LL) 42.5R, according to SR EN 197-1 standard (Asociatia de Standardizare din România [ASRO], 2011) type Structo Plus® from HOLCIM (Holcin, 2023). Natural aggregates with rounded edges, sourced from rivers, were selected based on their quality and size distribution and were classified into three groups (0‒4 mm, 4‒8 mm, 8‒16 mm).

Crumb rubber was obtained from a local supplier by cutting end-of-life tires. They underwent a cleaning process aiming to eliminate any foreign elements. Tap water meeting standard quality requirements was used as the mixing water.

In this research, Group 1 is defined as the reference group and has 0% of crumb rubber. Fine and coarse aggregates have been replaced with crumb rubber for Groups 2, 3, and 4 at 10%, 20%, and 30% by volume, respectively.

The concrete used is class C30/37 (Toma et al., 2021), commonly used in standard applications. The water-cement ratio remained constant (W/C = 0.43) for the four mixtures, eliminating the influence of this parameter on the results and isolating the effect of the other variables studied (the addition of crumb rubber).

The mix was prepared according to the proportions in Table 1 using a concrete mixer. Dry natural and crumb rubber aggregates were initially combined and mixed; afterward, dry cement was added, and the mixture was thoroughly mixed for an additional minute. Water and additives were included gradually. The entire mixture was continuously mixed until it was a homogenous mixture.

Mix proportions

| Specification | Group | |||

|---|---|---|---|---|

| 1 (0%) | 2 (10%) | 3 (20%) | 4 (30%) | |

| Cement [kg·m−3] | 489 | |||

| Water [kg·m−3] | 210 | |||

| W/C [-] | 0.43 | |||

| Regular aggregates [kg·m−3] | ||||

| 0‒4 mm | 582 | 523.80 | 465.60 | 407.40 |

| 4‒8 mm | 388 | 310.40 | 232.80 | 155.20 |

| 8‒16 mm | 646.70 | 646.70 | 646.70 | 646.70 |

| Rubber aggregates [kg·m−3] | ||||

| 0‒4 mm | 0 | 10.95 | 21.90 | 32.85 |

| 4‒8 mm | 0 | 14.60 | 29.20 | 43.80 |

| 8‒16 mm | 0 | 0 | 0 | 0 |

| Additives [kg·m−3] | 4.89 | |||

Source: own work.

A formwork oil application was performed on the internal surfaces of all molds before concrete casting. Afterward, the molds were filled, gradually compacted, and vibrated. A trowel was utilized to make a smooth surface. The samples were left to dry until the age of 28 days in standard laboratory conditions.

To evaluate the tensile strength of each mix, cylinders of identical dimensions (diameter 100 mm × height 200 mm) were cast. It was performed according to SR EN 12390-1 standard (ASRO, 2000). A minimum of four cylinders from each group were prepared.

The stripping age was 24 h. All the elements were identified based on their group, number, and casting date.

A total of 16 beams (four from each group) of identical dimensions (length 1,500 mm, height 120 mm, width 90 mm) were cast to evaluate the bending behavior of rubberized concrete beams.

It was made using two high-adhesion steel bars of 10 mm spaced 5 cm apart. Transversal reinforcement was made using 6 mm diameter pins with 10-centimeter spacing. To prevent confusion during the tests, a rectangle was marked on the beam to indicate the area devoid of reinforcements. A three-centimeter concrete cover was maintained. The stripping age was 48 h. All the elements were identified according to their group, number, and casting date.

At 28 days of age, the dimensions of concrete cylinders (diameter and height) were measured using calibrated instruments. The elements were weighed using a calibrated precision scale, and all the data were recorded. The density was calculated using Equation 1, according to the BS EN 12390-7 standard (British Standards Institution [BSI], 2009). Three measurements were conducted on each prepared sample, and the average value was calculated, thereby accounting for measurement errors:

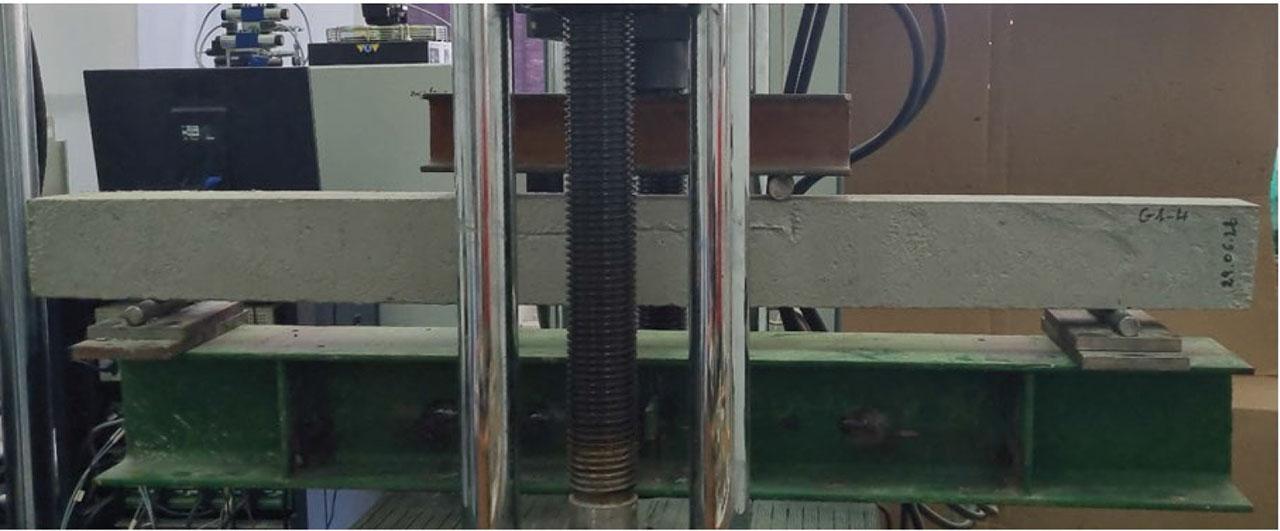

The tensile test (Fig. 1) was carried out in the form of a splitting test on the rubberized concrete cylinders at the age of 28 days using a universal testing machine WAW-600E with a capacity of 600 kN. The procedure was executed according to SR EN 12390-6 (ASRO, 2019b).

Splitting test

Source: own photo.

During the whole test, the loading speed was maintained constant and equal to v = 2 kN·s−1. A load distribution plate was placed on the top surface of the specimen to ensure uniform load distribution. The results (maximum load applied) were obtained using a measurement acquisition system.

The splitting tensile strength fctm [MPa] is then calculated using the following formula:

Four-point flexural tests were conducted on beams at the age of 28 days employing a universal testing machine WAW-600E with a capacity of 600 kN (Fig. 2). The procedure was executed according to SR EN 12390-5 (ASRO, 2019a). The beams were positioned horizontally on two support rollers, and a steel spreader beam was used to distribute the load onto two points.

Test configuration of beams

Source: own photo.

During the whole test, the loading speed was maintained constant and equal to v = 0.1 kN·s−1. The results of the flexural breaking strength and deflection at mid-span were obtained using a measurement acquisition system.

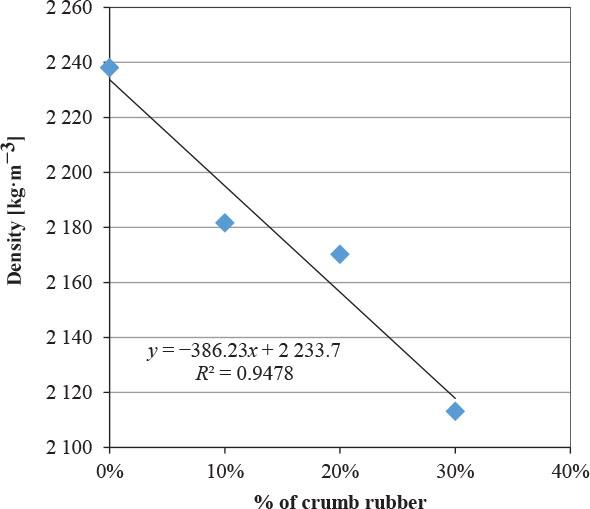

The variation in density across the four groups is presented in Table 2 and Figure 3.

Density curve as a function of crumb rubber content

Source: own work.

Density (ρ) variation

| Specification | Group | |||

|---|---|---|---|---|

| 1 (0%) | 2 (10%) | 3 (20%) | 4 (30%) | |

| ρ [kg·m−3] | 2 238.09 | 2 181.66 | 2 170.22 | 2 113.16 |

| StDev | 6.45 | 10.46 | 6.20 | 5.21 |

| Average + 1StDev | 2 244.54 | 2 192.12 | 2 176.42 | 2 118.37 |

| Average − 1StDev | 2 231.64 | 2 171.19 | 2 164.02 | 2 107.95 |

StDev – the standard deviation.

Source: own work.

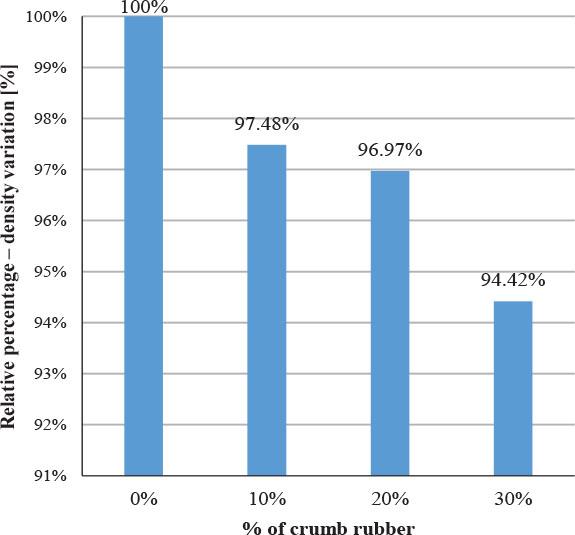

The density results reveal a clear decreasing trend with an increasing percentage of crumb rubber. Group 1 has the highest density at 2,238.09 kg·m−3. For Group 2, with 10% of crumb rubber, the density decreases to 2,181.66 kg·m−3, representing a 2.5% reduction. A further decrease in density was observed in Group 3 at 20% to 2,170.22 kg·m−3, indicating a 3% reduction compared to the reference group. Finally, the lowest density at 2,113.16 kg·m−3 was recorded for Group 4 at 30%, indicating a 5.6% reduction from the reference group (Fig. 4).

Variations in density normalized to the reference group

Source: own work.

The decreasing trend reflects the lower density of crumb rubber in comparison to natural aggregates leading to a progressively lighter concrete as the percentage of crumb rubber increased.

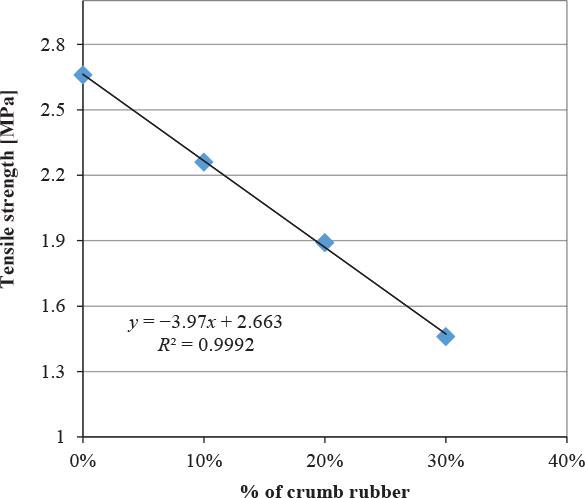

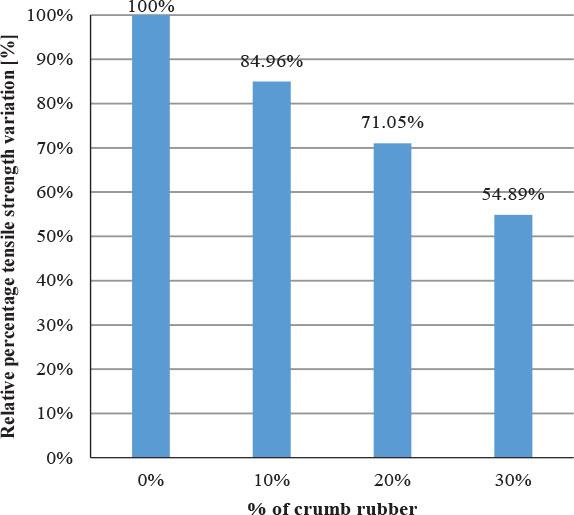

The variation in splitting tensile strength across the four groups is presented in Table 3 and Figure 5.

Tensile strength curve as a function of crumb rubber content

Source: own work.

Splitting tensile strength (fctm) variation

| Specification | Group | |||

|---|---|---|---|---|

| 1 (0%) | 2 (10%) | 3 (20%) | 4 (30%) | |

| fctm [MPa] | 2.66 | 2.26 | 1.89 | 1.46 |

| StDev | 0.15 | 0.25 | 0.08 | 0.11 |

| Average + 1StDev | 2.82 | 2.50 | 1.97 | 1.57 |

| Average − 1StDev | 2.51 | 2.01 | 1.80 | 1.35 |

StDev – the standard deviation.

Source: own work.

The test results show a clear decreasing trend as the percentage of crumb rubber substituting natural fine and coarse aggregates increased. Group 1 (reference concrete) exhibits the maximum value of tensile strength at 2.66 MPa, serving as the reference group. Group 2, with 10% of crumb rubber, shows a decrease in tensile strength to 2.26 MPa, representing a 15% reduction. This reduction was more pronounced for Group 3 at 20% of crumb rubber to 1.89 MPa, indicating a 29% reduction compared to the reference group. The minimum value of 1.46 MPa was recorded for Group 4 at 30% of crumb rubber, making a 45% reduction from the reference group (Fig. 6).

Variations in tensile strength normalized to the reference group

Source: own work.

The tensile strength reduction may be explained by the weak bonding between crumb rubber and the cement paste, which may lead to early crack propagation, as well as the lower density of rubberized concrete, which may lead to a less compact and uniform microstructure and a higher porosity which makes it more prone to crack formation.

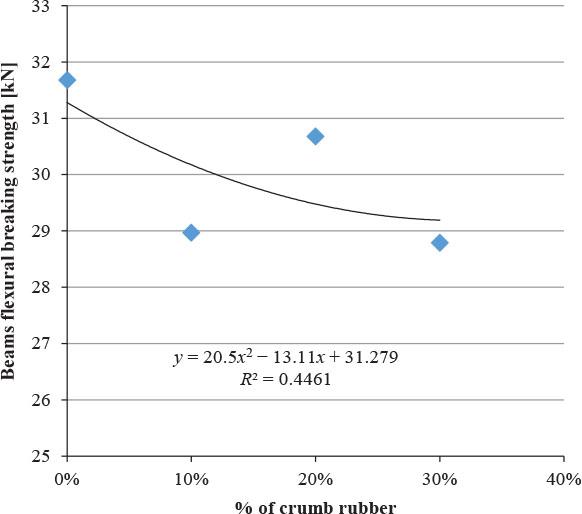

The variation in flexural breaking strength across the four groups is presented in Table 4 and Figure 7.

Flexural breaking strength variation curve as a function of crumb rubber content

Source: own work.

Variation in flexural breaking strength (F)

| Specification | Group | |||

|---|---|---|---|---|

| 1 (0%) | 2 (10%) | 3 (20%) | 4 (30%) | |

| F [kN] | 31.68 | 28.97 | 30.68 | 28.79 |

| StDev | 1.22 | 0.80 | 0.88 | 1.69 |

| Average + 1StDev | 32.90 | 29.77 | 31.56 | 30.48 |

| Average − 1StDev | 30.46 | 28.17 | 29.80 | 27.09 |

StDev – the standard deviation.

Source: own work.

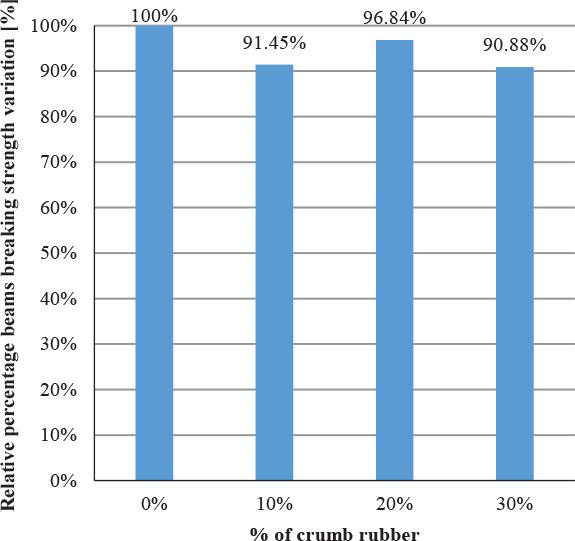

The maximum value of the flexural breaking strength was observed for the reference group at 31.68 kN. For Group 2, with 10% of crumb rubber, a decrease to 28.97 kN was noticed, indicating an 8.6% reduction, which may be explained by the lower stiffness and weaker bonding properties of rubber. Group 3 showed a flexural breaking strength of 30.68 kN, which is slightly lower by only 3% than the reference group; the 20% replacement might be an optimal balance between flexibility and structural integrity. Group 4, with 30% of crumb rubber, showed a further reduction in flexural breaking strength up to 28.79 kN, a 9% drop from the reference group (Fig. 8).

Variations in breaking strength normalized to the reference group

Source: own work.

A decrease in flexural breaking strength may be attributed to the soft nature of crumb rubber, which can reduce the stiffness of concrete. In addition, the weak bonding between crumb rubber and cement and the increased air voids may also contribute to the premature failure of concrete.

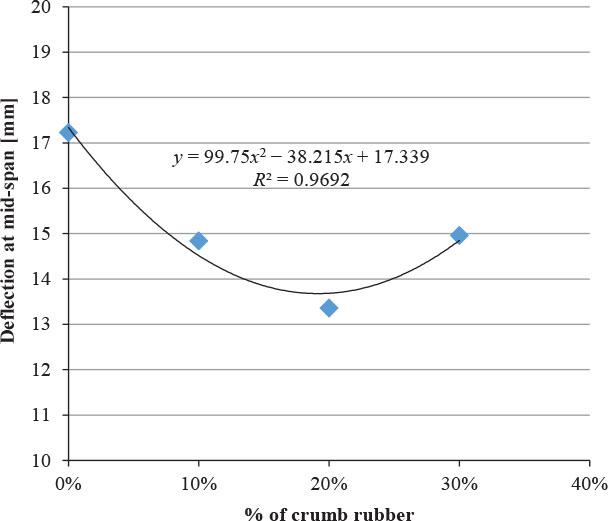

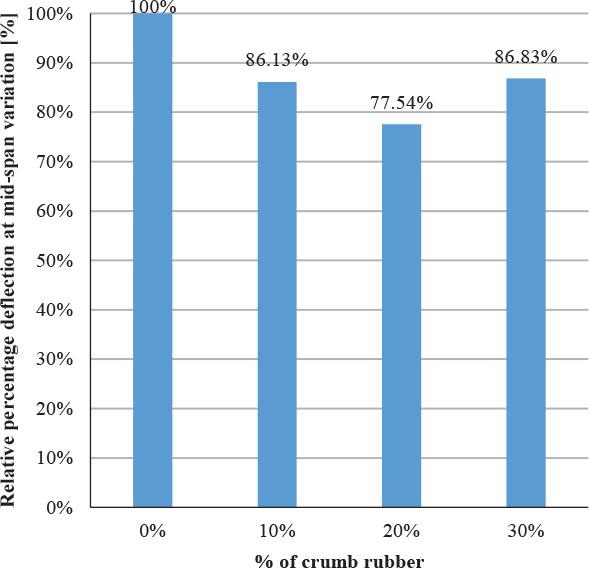

The variation of the deflection at mid-span across the four groups is presented in Table 5 and Figure 9.

The curve of mid-span deflection as a function of crumb rubber content

Source: own work.

Deflection variation at mid-span

| Specification | Group | |||

|---|---|---|---|---|

| 1 (0%) | 2 (10%) | 3 (20%) | 4 (30%) | |

| Deflection [mm] | 17.23 | 14.84 | 13.36 | 14.96 |

| StDev | 3.28 | 1.89 | 0.59 | 1.54 |

| Average + 1StDev | 20.51 | 16.73 | 13.95 | 16.50 |

| Average − 1StDev | 13.95 | 12.95 | 12.76 | 13.42 |

StDev – the standard deviation.

Source: own work.

The peak deflection value of 17.23 mm at the mid-span was observed for the reference group, which serves as the baseline for the comparison. Group 2 showed a drop to 14.84 mm, indicating a 14% reduction in deflection. Group 3, with 20% crumb rubber replacement, shows a more remarkable reduction in deflection up to 13.36 mm, representing a 22.5% decrease from the reference group, which might be explained by an optimal balance in stiffness and flexibility. Group 4 exhibits a deflection of 14.96 mm, which represents a 13% drop from Group 1. The results show that at an optimal rubber content, deflection is reduced by enhancing energy absorption, while above a specific percentage, crumb rubber substitution may start to negatively affect the stiffness of concrete (Fig. 10).

Variations of mid-span deflection normalized to the reference group

Source: own work.

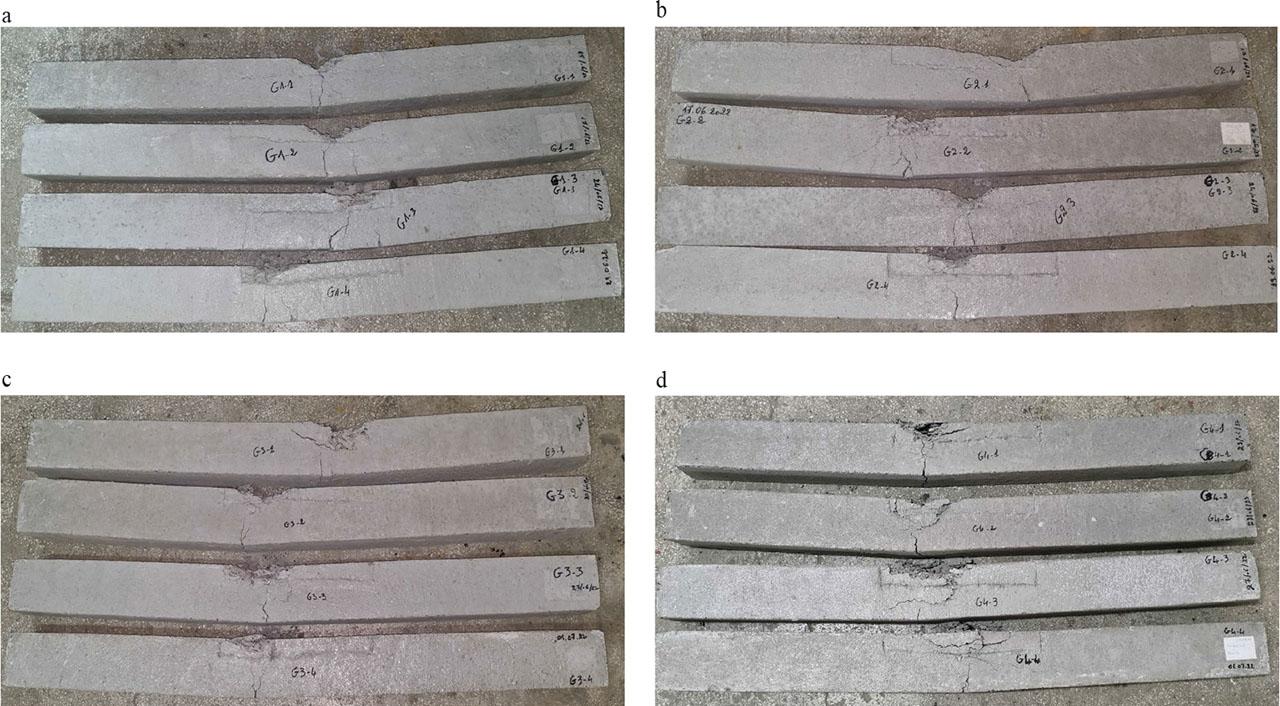

The results of the failure modes across the four groups are presented in Figure 11. The addition of crumb rubber as a replacement for natural aggregates results in distinct variations in the failure mode of beams across the four different groups.

Failure modes of Group 1 (a), Group 2 (b), Group 3 (c) and Group 4 (d)

Source: own work.

For Group 1, a brittle failure mode was observed, which might be explained by the low ductility and high rigidity of reinforced concrete. Group 2 beams tend to show a more ductile failure mode compared to the reference group, which might be attributed to the energy-absorbing properties of rubber. Group 3, with 20% of crumb rubber, shows a further enhancement in ductility as demonstrated by the breaking flexural strength of 30.68 kN and the reduced deflection at mid-span of 13.36 mm. Group 3 beams indicate an optimal balance between flexibility and structural integrity. Finally, for Group 4, at 30% of crumb rubber, beams exhibit a highly ductile failure mode. This behavior might be explained by the flexible nature of crumb rubber, which enhances energy absorption and toughness.

The study investigates the impact of introducing crumb rubber into concrete at varying percentages (10%, 20%, and 30%) and evaluates its effect on concrete properties. The key findings are summarized as follows:

- –

Density tends to decrease slightly as the percentage of crumb rubber increases, which can be beneficial for lightweight construction applications.

- –

Splitting tensile strength was observed to decrease linearly as the percentage of crumb rubber increased, reaching 45%. This can be attributed to the soft nature of rubber compared to natural aggregates, as well as the weak adherence between rubber and cement.

- –

The addition of crumb rubber led to a slight decrease in the flexural breaking strength of the beams. The loss in strength was smaller compared to the reduction in tensile strength, suggesting that the addition of crumb rubber up to 30% of the volume can maintain sufficient structural integrity.

- –

Deflection at mid-span decreases as crumb rubber content increases, which indicates that rubberized concrete beams are less prone to excessive deformation under load, potentially improving their overall serviceability.

- –

Beam failure mode evolves from a brittle failure mode for the reference group to a more ductile failure for rubberized concrete beams with 10%, 20%, and 30% of crumb rubber content. A ductility enhancement was noticed with higher rubber content, which could improve the safety and energy-absorption capacity of structures under dynamic loads as for anti-seismic constructions.

The addition of crumb rubber as a replacement of naturally fine and coarse aggregates at 10%, 20%, and 30% by volume resulted in a significant reduction in splitting tensile strength, while the reduction in flexural breaking strength of the beams was lower. This suggests that rubberized concrete may not be an ideal option for high-load-bearing structural elements but can still be used for some specific applications, such as for non-load-bearing walls and pavement blocks. However, ductility was significantly improved, which could be a desirable characteristic in impact-resistance structures, such as protective barriers. Furthermore, the gradual failure mode makes rubberized concrete a promising material for applications that demand higher deformation capacity, such as shock-absorbing panels.

Based on these findings, it can be noted that rubberized concrete may require careful mix design adjustments to control strength losses. However, its improved ductility, lightweight properties, and improved failure behavior make it a promising material for sustainable and specific construction applications.