Figure 1:

Figure 2:

Figure 3:

Figure 4:

Figure 5:

Figure 6:

Figure 7:

Figure 8:

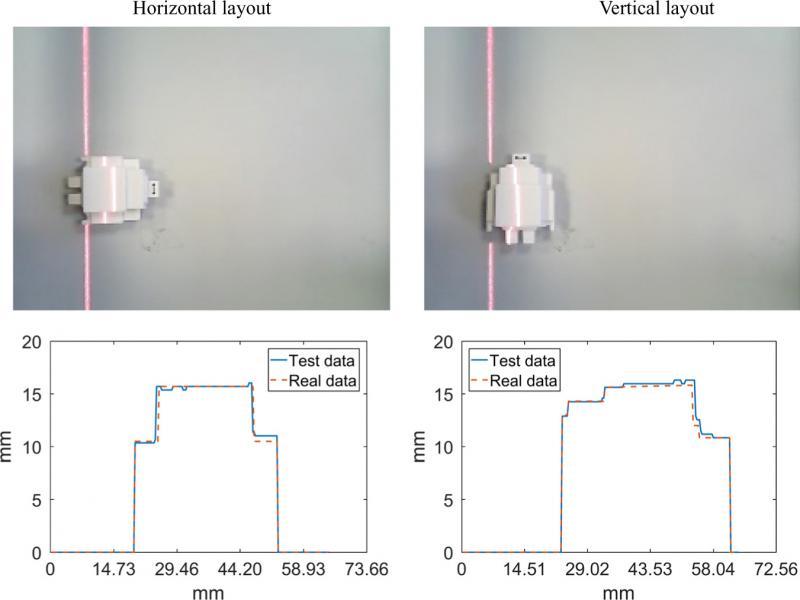

Evaluated cases for complex surface measurement with vertical layout_

| Vertical layout | |||

|---|---|---|---|

| Dist. | Images | 1D Profile H(x) | MSE |

| 19 cm | 0.366 | ||

| 22 cm | 0.209 | ||

| 25 cm | 0.220 | ||

| 28 cm | 0.073 | ||

| 31 cm | 0.161 | ||

| Mean square error (MSE) | 0.206 | ||

Evaluated cases for complex surface measurement with horizontal layout_

| Horizontal layout | |||

|---|---|---|---|

| Dist. | Images | 1D Profile H(x) | MSE |

| 19 cm | 0.427 | ||

| 22 cm | 0.457 | ||

| 25 cm | 0.366 | ||

| 28 cm | 0.375 | ||

| 31 cm | 0.014 | ||

| Mean square error (MSE) | 0.328 | ||

Comparison of 3D surface reconstruction techniques_

| Time of flight | Stereo vision | Optical fiber | Structure light | |

|---|---|---|---|---|

| Working distance | Long | Medium | Short | Short–medium |

| Vision field | Medium | Lenses dependent | Narrow | Medium |

| Cost | High | Medium | Medium | Low |

| Power | Low | Low | Low | Low |

| Accuracy | Medium | Medium | High | Medium |

| Speed | Fast | Fast | Slow | Medium |